Novel Modeling Methodology for Thermal Evaluation of an Electrically Assisted High-Speed Turbomachine †

Abstract

1. Introduction

1.1. Broader Context of Climate Change

1.2. Background of a Charged Fuel-Cell System

1.3. Electric Machine Topologies for Electric Turbo-Compressors

1.4. Forced-Air Cooling Concept

1.5. Thermal Evaluation Scheme

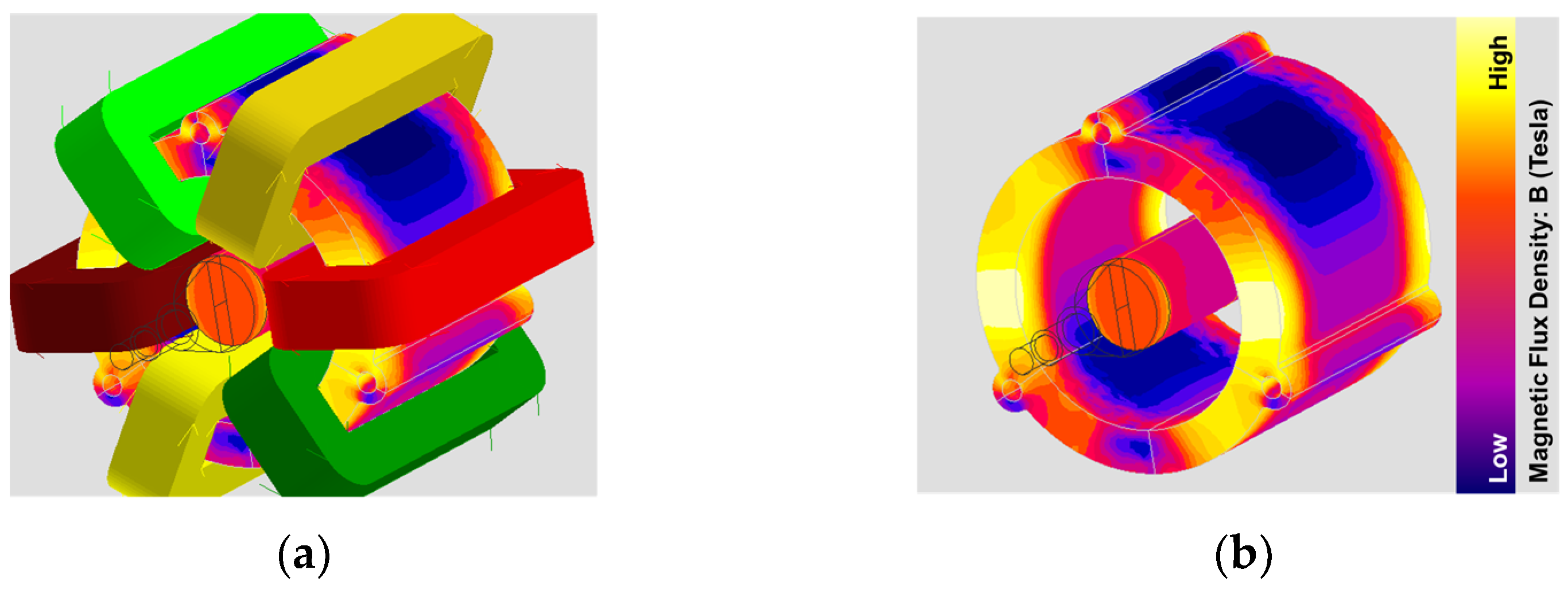

2. Electromagnetic Simulation

3. Computational Fluid Dynamics Analysis

3.1. Mesh Independence Study

3.2. Near-Wall Modeling Methodology and Numerical Heat Transfer Calculation

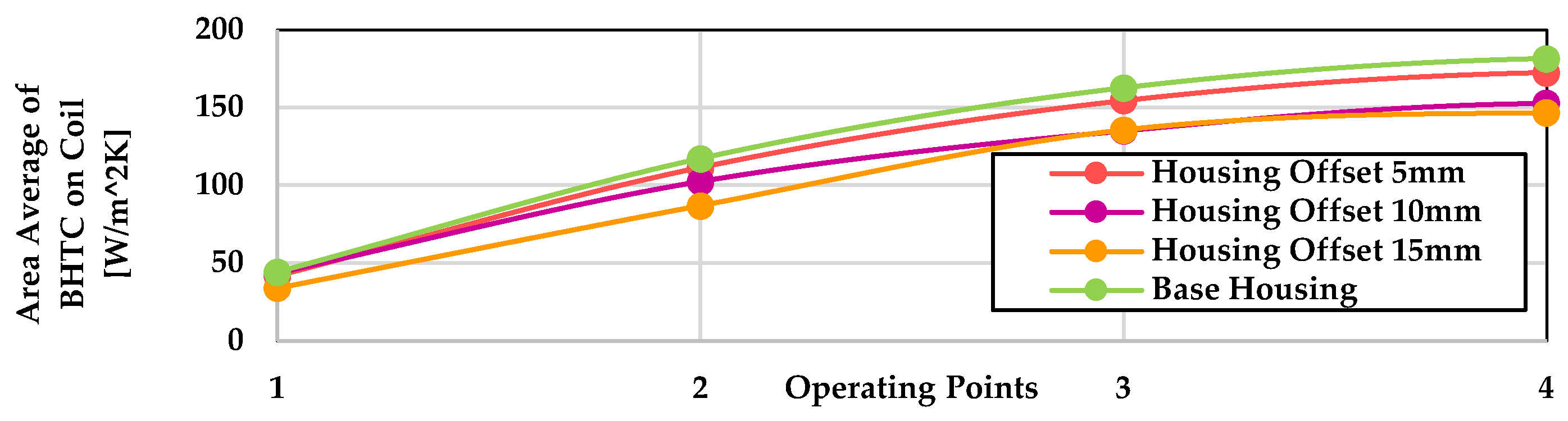

3.3. Cooling Capacity Case Study

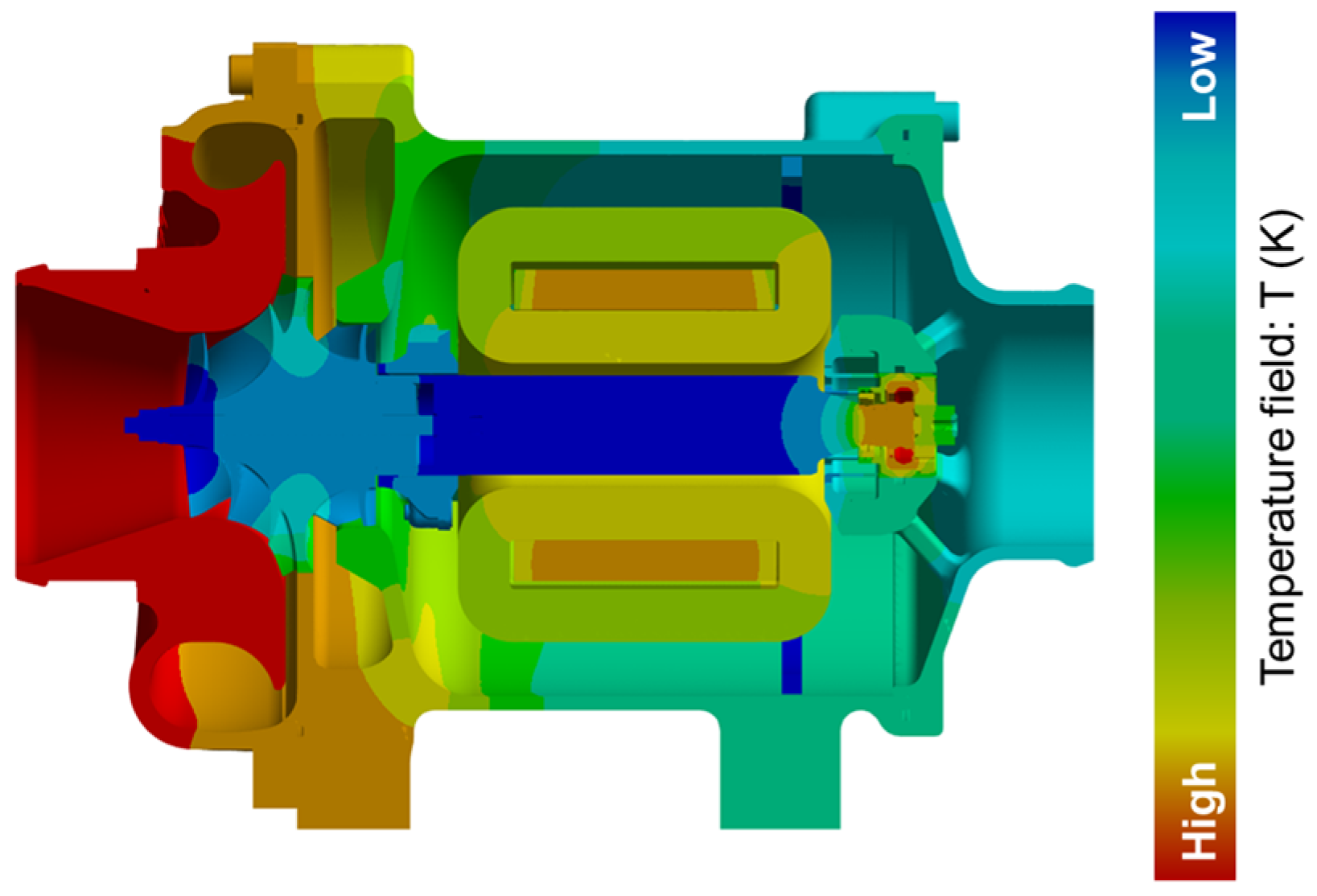

4. Solid Thermal Model

4.1. Model Setup

4.2. Thermal Model Results

5. Conclusions

5.1. Electromagnetic Model

5.2. Computational Fluid Dynamics Model

5.3. Thermal Model

5.4. Virtual Proof of Concept

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- ICCT. The International Council on Clean Transportation. Available online: https://theicct.org/transport-could-burn-up-the-eus-entire-carbon-budget/ (accessed on 23 April 2023).

- United Nations Climate Change. Available online: https://unfccc.int/process-and-meetings/the-paris-agreement (accessed on 12 April 2023).

- European Commission. Available online: https://energy.ec.europa.eu/topics/energy-systems-integration/hydrogen/key-actions-eu-hydrogen-strategy_en (accessed on 12 April 2023).

- IRENA. Available online: https://www.irena.org/Energy-Transition/Outlook (accessed on 23 April 2022).

- Yan, Q.; Toghiani, H.; Causey, H. Steady state and dynamic performance of proton exchange membrane fuel cells (PEMFCs) under various operating conditions and load changes. J. Power Sources 2006, 161, 492–502. [Google Scholar] [CrossRef]

- Schmelcher, M.; Häßy, J. Hydrogen fuel cells for aviation? A potential analysis comparing different thrust categories. In Proceedings of the ISABE 2022, Ottawa, ON, Canada, 25–30 September 2022. [Google Scholar]

- Clean Hydrogen Partnership. Hydrogen-Powered Aviation—European Commission. Available online: https://european-union.europa.eu/index_el (accessed on 11 April 2023).

- Filsinger, D.; Kuwata, G.; Ikeya, N. Tailored Centrifugal Turbomachinery for Electric Fuel Cell Turbocharger. Int. J. Rotating Mach. 2021, 2021, 3972387. [Google Scholar] [CrossRef]

- Garrett Advancing Motion. Available online: https://www.garrettmotion.com/emission-reduction/garrett-e-turbo/ (accessed on 4 May 2023).

- Spinner, G.; Dahinten, F.; Dauscher, S.; Münz, S. Electrified boosting systems in today’s and future automotive applications. In Proceedings of the 2018 Thirteenth International Conference on Ecological Vehicles and Renewable Energies (EVER), Monte Carlo, Monaco, 10–12 April 2018; pp. 1–5. [Google Scholar] [CrossRef]

- Blunier, B.; Miraui, A. Proton Exchange Membrane Fuel Cell air Management in Automotive Applications. J. Electrochem. Energy Convers. Storage 2010, 7, 041007. [Google Scholar] [CrossRef]

- Rathke, P.; Di Modica, D.V.; Fink, S.K.; Filsinger, D.; Burgmair, R.; von Unwerth, T. Model Based Investigation on Drive Train Performance of a Heavy-Duty Fuel Cell Truck Focusing on the Fuel Cell Air Delivery System. In Proceedings of the FC3 Fuel Cell Conference, Chemnitz, Germany, 12–13 November 2024. [Google Scholar]

- Hayashi, K.; Kaneda, S.; Ikeya, N.; Daito, Y.; Kitamura, K. Development of Electric Turbocharger for Fuel Cell Systems to Contribute to the Realization of Carbon Neutrality. IHI Eng. Rev. 2023, 56. Available online: https://www.ihi.co.jp/en/technology/techinfo/contents_no/1199411_13586.html (accessed on 13 March 2025).

- Gilson, A.; Dubas, F.; Depernet, D.; Espanet, C. Comparison of high-speed PM machine topologies for electrically-assisted turbocharger applications. In Proceedings of the 2016 19th International Conference on Electrical Machines and Systems (ICEMS), Chiba, Japan, 13–16 November 2016; pp. 1–5. [Google Scholar]

- Xu, F. Investigation of High-Speed Permanent Magnet Motors with Toroidal Windings. Ph.D. Thesis, University of Sheffield, Sheffield, UK, 2022. [Google Scholar]

- Tavernier, S.; Espanet, C.; Andrieux, G. Modeling and Optimal Design of a Very High Speed Motor Slotless Technology with Toroidal Winding for Serial Production. In Proceedings of the 2021 IEEE Energy Conversion Congress and Exposition (ECCE), Vancouver, BC, Canada, 10–14 October 2021. [Google Scholar]

- Borisavljevic, A.; Jumayev, S.; Lomonova, E. Toroidally-wound permanent magnet machines in high-speed applications. In Proceedings of the 2014 International Conference on Electrical Machines (ICEM), Berlin, Germany, 2–5 September 2014. [Google Scholar]

- Suzuki, M.; Sakai, K. Reduction of torque ripple for PM motor with toroidal winding. In Proceedings of the 2016 19th International Conference on Electrical Machines and Systems (ICEMS), Chiba, Japan, 13–16 November 2016. [Google Scholar]

- Karamavruc, A. Obtaining bulk flow based heat transfer coefficients for thermal evaluation of turbochargers. In Proceedings of the IMechE Conference, London, UK, 17–18 May 2016; BorgWarner Global Core Science-Structural Mechanics: Arden, NC, USA, 2016. [Google Scholar]

- Adrian, M.; Marian, L.; Mariusz, K. Influence of an end-winding size on proximity losses in a high-speed PM synchronous motor. In Proceedings of the 2015 Selected Problems of Electrical Engineering and Electronics (WZEE), Kielce, Poland, 17–19 September 2015. [Google Scholar]

- Harley, P.; Spence, S.; Filsinger, D.; Dietrich, M.; Early, J. Experimental and numerical benchmarking of an improved meanline modeling method for automotive turbocharger centrifugal compressors. In Proceedings of the ASME Turbo Expo 2015, Montreal, QC, Canada, 15–19 June 2015. [Google Scholar]

- Tsilingiris, P. Thermophysical and transport properties of humid air at temperature range between 0 and 100 °C. Energy Convers. Manag. 2007, 49, 1098–1110. [Google Scholar] [CrossRef]

- Celik, I.B.; Ghia, U.; Roache, P.J.; Freitas, C.J. Procedure for Estimation and Reporting of Uncertainty. ASME J. Fluids Eng. 1993, 115, 194–195. [Google Scholar] [CrossRef]

- Slater, J.W. Examining Spatial (Grid) Convergence; NASA: Washington, DC, USA, 2021.

- Kader, B.A. Temperature and concentration profiles in fully turbulent boundary layers. Int. J. Heat Mass Transf. 1981, 24, 1541–1544. [Google Scholar] [CrossRef]

- Alexandrovic, U.V.; Reinhold, K.; Jovan, M. Experimental Investigation and Modeling of Contact Heat Transfer. Doctoral Dissertation, RWTH Aachen University, Aechen, Germany, 2018. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Arvithis, G.S.; Iosifidis, G.; DeSantis, R.; Rode, M.; Burgmair, R.; Kalfas, A.I. Novel Modeling Methodology for Thermal Evaluation of an Electrically Assisted High-Speed Turbomachine. Eng. Proc. 2025, 90, 48. https://doi.org/10.3390/engproc2025090048

Arvithis GS, Iosifidis G, DeSantis R, Rode M, Burgmair R, Kalfas AI. Novel Modeling Methodology for Thermal Evaluation of an Electrically Assisted High-Speed Turbomachine. Engineering Proceedings. 2025; 90(1):48. https://doi.org/10.3390/engproc2025090048

Chicago/Turabian StyleArvithis, Georgios S., Georgios Iosifidis, Roberto DeSantis, Martin Rode, Raphael Burgmair, and Anestis I. Kalfas. 2025. "Novel Modeling Methodology for Thermal Evaluation of an Electrically Assisted High-Speed Turbomachine" Engineering Proceedings 90, no. 1: 48. https://doi.org/10.3390/engproc2025090048

APA StyleArvithis, G. S., Iosifidis, G., DeSantis, R., Rode, M., Burgmair, R., & Kalfas, A. I. (2025). Novel Modeling Methodology for Thermal Evaluation of an Electrically Assisted High-Speed Turbomachine. Engineering Proceedings, 90(1), 48. https://doi.org/10.3390/engproc2025090048