Development of a Heat Transfer Model for a Free Double Piston and Identification of Thermal Management Challenges †

Abstract

1. Introduction

2. Methodology

- ⮚

- Bypass Heat Transfer Coefficient: A range of 50 to 300 W/m2K is employed to optimize convective cooling performance. This range is based on theoretical calculations for air flowing over cylindrical geometries at high velocities.

- ⮚

- Material Selection: The properties of the cylinder and surrounding regions are evaluated to determine their influence on thermal behavior.

- ⮚

- Heat Dissipation Analysis: The study also focuses on analyzing and quantifying the amount of heat dissipated from the system, providing insights into overall thermal management.

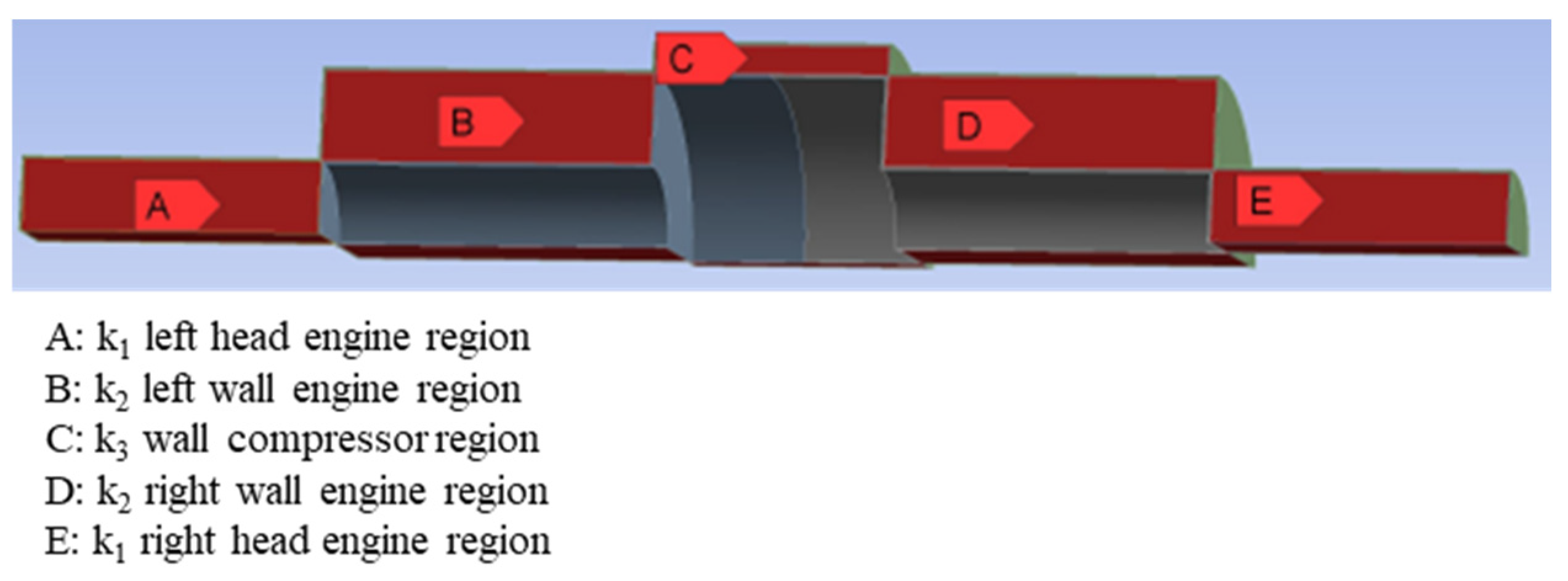

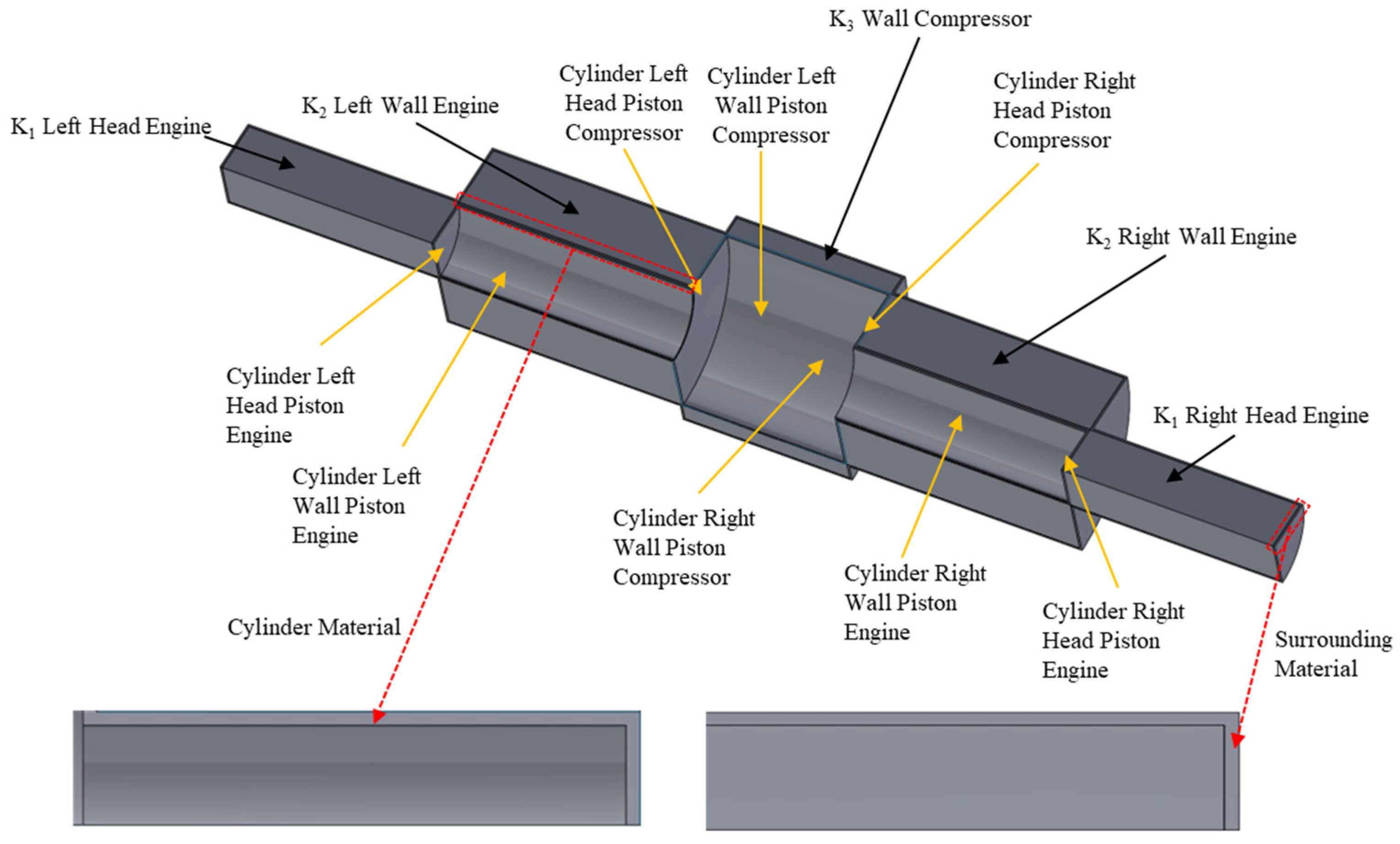

2.1. Computational Domain Setup

2.1.1. Geometry

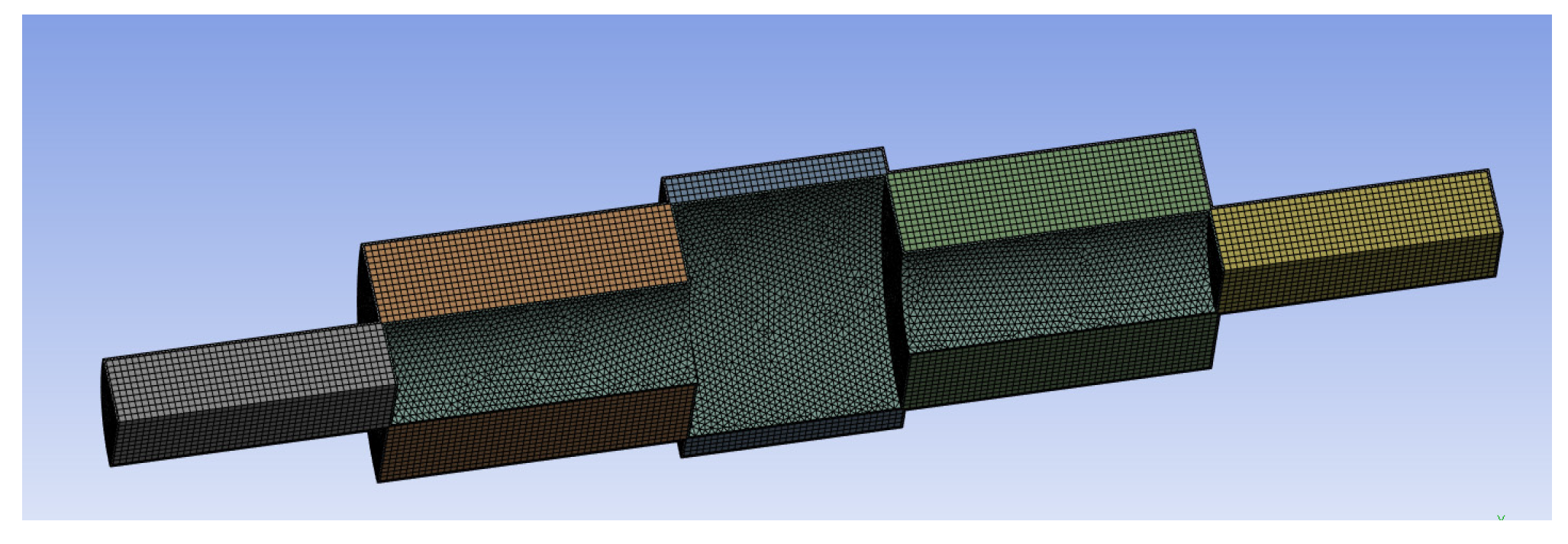

2.1.2. Mesh Generation

2.1.3. Boundary Conditions

2.1.4. Computational Setup

2.2. Strategy for Using Bypass Air for Cooling

- ⮚

- Enhancement of Convective Cooling via Bypass Transfer Coefficient

- ⮚

- Analysis and Quantification of Heat Dissipation

- ⮚

- Evaluation of Cylinder and Surrounding Materials

2.2.1. Enhancement of Convective Cooling via Bypass Transfer Coefficient

2.2.2. Analysis and Quantification of Heat Dissipation

- ✓

- represents the bypass heat transfer coefficient, ranging from 50 to 300 W/m2K, as shown in Table 3;

- ✓

- is the wall temperature of each piston cylinder block;

- ✓

- represents the temperature of the bypass air.

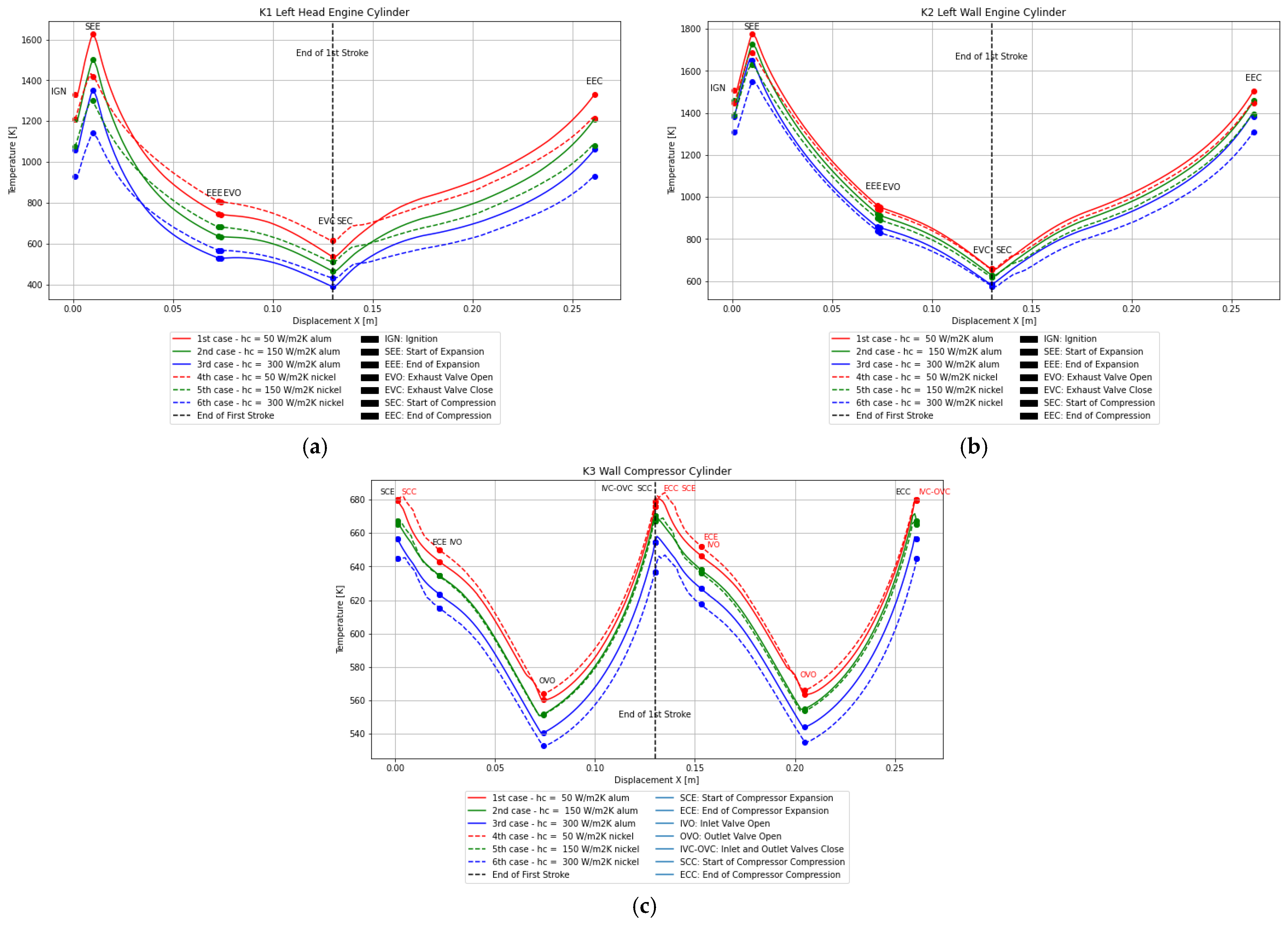

| 1st Case | 2nd Case | 3rd Case | 4th Case | 5th Case | 6th Case | |

|---|---|---|---|---|---|---|

| Cylinder Material | Aluminum alloy | Aluminum alloy | Aluminum alloy | Nickel alloy | Nickel alloy | Nickel alloy |

| Surrounding Material | Aluminum alloy | Aluminum alloy | Aluminum alloy | Aluminum alloy | Aluminum alloy | Aluminum alloy |

| Bypass Hc | 50 W/m2K | 150 W/m2K | 300 W/m2K | 50 W/m2K | 150 W/m2K | 300 W/m2K |

- ⮚

- The heat flux, , is calculated for each block in the surrounding region to determine the amount of heat being removed from the engine components by the bypass air.

- ⮚

- The temperature difference between the wall temperature () and the bypass air temperature () is a key parameter in calculating the rate of heat dissipation.

- ⮚

- After calculating the heat flux for each surface block, the heat dissipation per unit volume (W/m3) is computed for the corresponding blocks. This step provides a detailed quantification of the heat removed relative to each block’s volume.

- ⮚

- The calculated heat dissipation is integrated into the overall computational domain using a User-Defined Function (UDF).

- ⮚

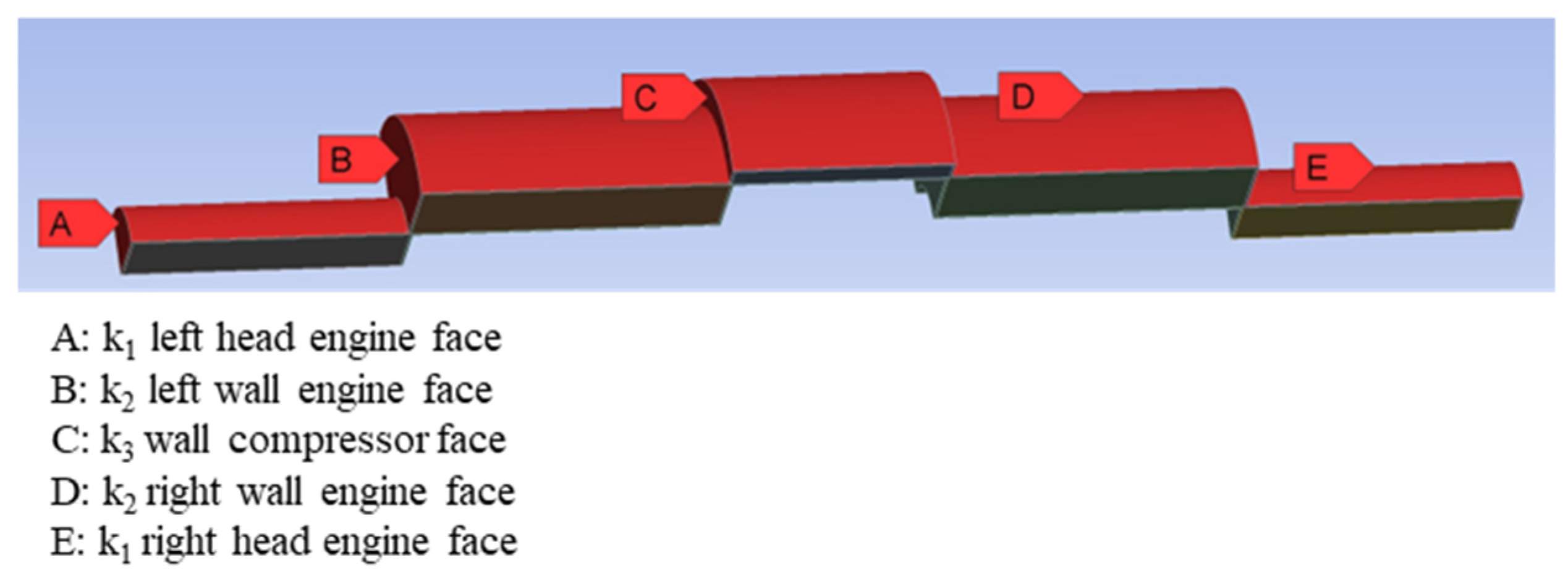

- The temperature distribution results across the faces depicted in Figure 4 are evaluated, as presented in Section 3.2.

2.2.3. Evaluation of Cylinder and Surrounding Materials

3. Results and Discussion

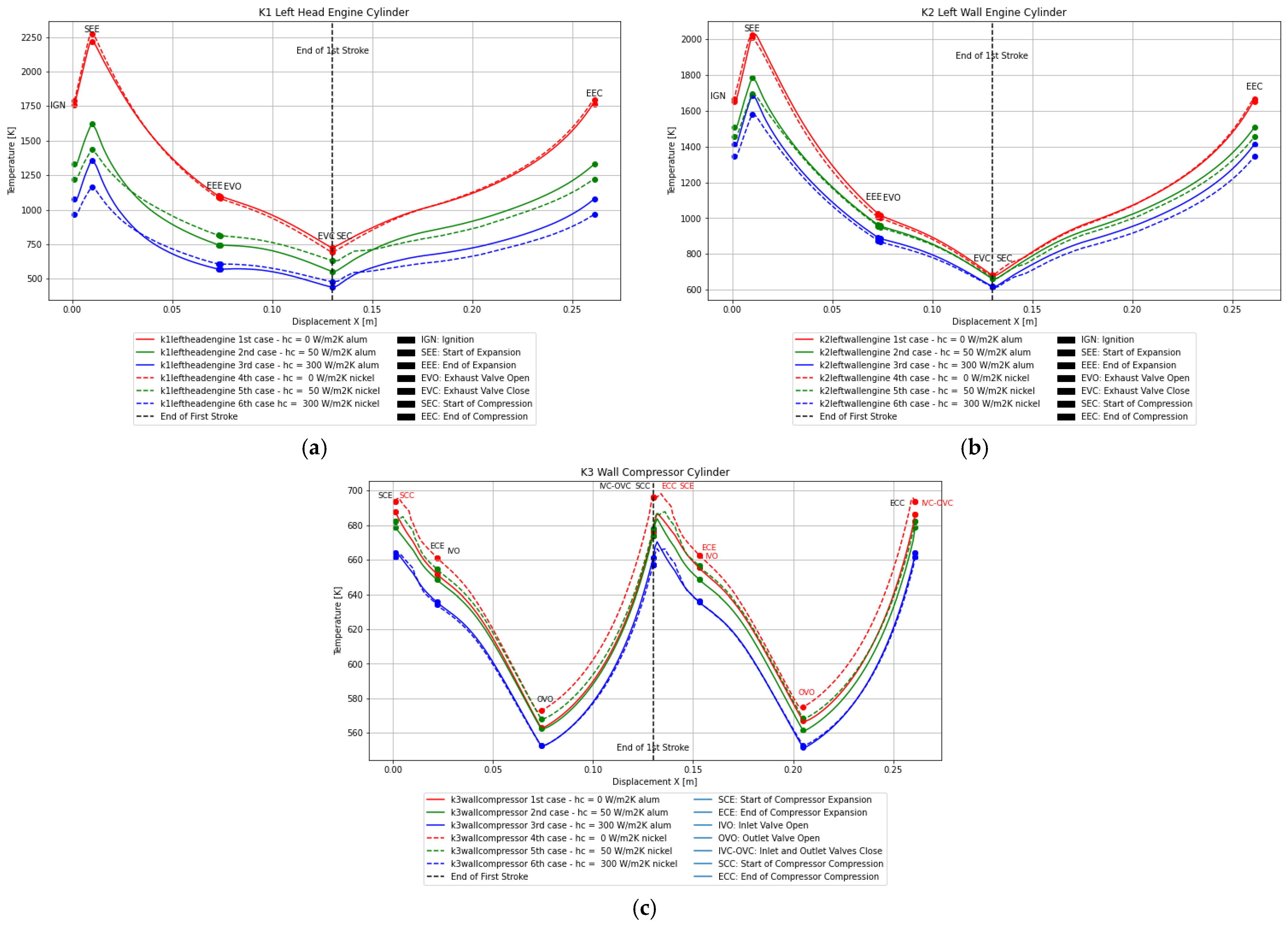

3.1. Results of Enhancement of Convective Cooling via Bypass Heat Transfer Coefficient

3.2. Results of the Analysis and Quantification of Heat Dissipation

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Jensen, L. Revision of the EU Emissions Trading System: Aviation; European Parliament: Strasbourg, France, 2022. [Google Scholar]

- Epstein, A.H. Aeropropulsion for Commercial Aviation in the Twenty-First Century and Research Directions Needed. AIAA J. 2014, 52, 901–911. [Google Scholar] [CrossRef]

- Zima, S. Ungewöhnliche Motoren, 1st ed.; Vogel Communications Group GmbH & Co. KG: Würzburg, Germany, 2004. [Google Scholar]

- Klingels, H. Wärmekraftmaschine mit Freikolbenverdichter. DE Patent 10 2012 206 123 A1, 17 October 2013. [Google Scholar]

- Achten, P.; van den Oever, J.; Potma, J.; Vael, G. Horsepower with Brains: The Design of the CHIRON Free Piston Engine; SAE Technical Paper 2000-01-2545; Society of Automotive Engineers (SAE): Warrendale, PA, USA, 2000. [Google Scholar] [CrossRef]

- Khaimovich, M. Hydraulic Control of Machine Tools, 1st ed.; Oxford Pergamon Press: Oxford, UK, 1965. [Google Scholar]

- Jafari, S.; Nikolaidis, T. Thermal Management Systems for Civil Aircraft Engines: Review, Challenges and Exploring the Future. Appl. Sci. 2018, 8, 2044. [Google Scholar] [CrossRef]

- MTU Engines. Blazing New Trails: MTU Aero Engines Showcases Innovative Evolutionary and Revolutionary Technologies for Commercial Aircraft at the 2019 Paris Air Show. Available online: www.mtu.de/fileadmin/EN/7_News_Media/1_Press/1_Latest_Press_Realeases/2019/Composite_Cycle.en.jpg (accessed on 12 August 2024).

- Fotis, K.C.; Vlahostergios, Z.; Misirlis, D.; Yakinthos, K. Heat transfer model development for the Free Double Piston engine concept, In Proceedings of the Technical Conference for Power and Propulsion Sector (GPPS Chania24), Chania, Greece, 4–6 September 2024. [CrossRef]

- Kaiser, S.; Schmitz, O.; Klingels, H. Aero Engine Concepts Beyond 2030: Part 2—The Free-Piston Composite Cycle Engine. ASME J. Eng. Gas Turbines Power 2021, 143, 021002. [Google Scholar] [CrossRef]

- ANSYS, Inc. ANSYS Fluent 12.0 User’s Guide; ANSYS, Inc.: Canonsburg, PA, USA, 2009. [Google Scholar]

| Parameter | Value/Description |

|---|---|

| Piston Wall Flux | UDF (defined from 2-stroke FDP model) |

| Element Size | 2 × 10−3 m |

| Number of Elements | 1.34 million |

| 1st Case | 2nd Case | 3rd Case | 4th Case | 5th Case | 6th Case | |

|---|---|---|---|---|---|---|

| Cylinder Material | Aluminum alloy | Aluminum alloy | Aluminum alloy | Nickel alloy | Nickel alloy | Nickel alloy |

| Surrounding Material | Aluminum alloy | Aluminum alloy | Aluminum alloy | Aluminum alloy | Aluminum alloy | Aluminum alloy |

| Bypass Hc | 0 W/m2K | 50 W/m2K | 300 W/m2K | 0 W/m2K | 50 W/m2K | 300 W/m2K |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fotis, K.; Vlahostergios, Z.; Misirlis, D.; Yakinthos, K. Development of a Heat Transfer Model for a Free Double Piston and Identification of Thermal Management Challenges. Eng. Proc. 2025, 90, 45. https://doi.org/10.3390/engproc2025090045

Fotis K, Vlahostergios Z, Misirlis D, Yakinthos K. Development of a Heat Transfer Model for a Free Double Piston and Identification of Thermal Management Challenges. Engineering Proceedings. 2025; 90(1):45. https://doi.org/10.3390/engproc2025090045

Chicago/Turabian StyleFotis, Konstantinos, Zinon Vlahostergios, Dimitrios Misirlis, and Kyros Yakinthos. 2025. "Development of a Heat Transfer Model for a Free Double Piston and Identification of Thermal Management Challenges" Engineering Proceedings 90, no. 1: 45. https://doi.org/10.3390/engproc2025090045

APA StyleFotis, K., Vlahostergios, Z., Misirlis, D., & Yakinthos, K. (2025). Development of a Heat Transfer Model for a Free Double Piston and Identification of Thermal Management Challenges. Engineering Proceedings, 90(1), 45. https://doi.org/10.3390/engproc2025090045