1. Introduction

The integration of sustainability into business models (BMs) has become a key focus across industries, particularly regarding the treatment of products at the end of their life cycle [

1]. For instance, the aviation and wind energy sectors face significant challenges in managing end-of-life (EoL) components related to aircraft and wind turbine blades (WTBs), respectively. The aviation industry presents concerning forecasts; for example, it is known that by 2032, around 10,000 aircraft will be retired [

1]. This massive wave of decommissioning will not only require dismantling and recycling but will also generate substantial societal and environmental impacts that demand urgent and innovative solutions. Similarly, although the wind energy industry represents one of the best technologies for generating clean and renewable energy with zero greenhouse gas emissions, it faces a major challenge in disposing WTBs at the end of their life cycle [

2]. A comprehensive life cycle analysis of WTBs reveals that their manufacturing process is energy-intensive and involves various environmentally hazardous chemical compounds [

2,

3]. Thus, addressing the dismantling of WTBs is essential, given their large quantity and mass and their composition of mixed chemical compounds. This issue is driving companies to seek sustainable solutions and applications for the EoL of WTBs, including environmental, economic, and social analyses, with specific commercial guidelines.

The EoL stage represents a pivotal opportunity for the aviation and wind energy sectors to transition toward circular economy practices. These practices aim to minimize waste, optimize resource use, and reduce environmental harm by fostering reuse, repair, and repurposing strategies. Addressing EoL challenges is not only essential for mitigating the negative impacts associated with decommissioning but also for unlocking economic opportunities and advancing sustainability goals.

In this context, some studies have addressed these challenges, focusing on circular economy strategies to circulate aircraft components and WTBs efficiently and economically at the end of their life cycle. In the aviation industry, notable works include Johst et al.’s [

4], which proposed a strategic approach to return out-of-service aviation composite parts to the material cycle through a systematic 6R strategy (reuse, repair, refurbish, remanufacture, repurpose, and recycling), identifying eco-circular subsystems for aviation composite components. Likewise, Keivanpoura et al. [

1] focused on the EoL aircraft treatment, considering lean management, sustainable development, and global business environment, providing an integrated optimization network to support decision-making at both strategic and managerial levels. Regarding the wind energy sector, remarkable works include Johst et al.’s. [

5], which explored the reuse of WTBs as a promising approach from both procedural and technological perspectives, conducting a life cycle assessment (LCA) to evaluate three reuse scenarios based on environmental aspects. Gennitsaris et al. [

6] evaluated the sustainability performance of wind turbine dismantling options and suggested policies to improve the sustainability of the EoL phase by jointly applying LCA methodologies and data envelopment analysis (DEA). Hasheminezhad et al. [

7] presented a comprehensive review of sustainable solutions for reusing WTB waste materials in civil engineering applications, where reuse is considered a sustainable EoL option for managing wind turbine shredder waste from both economic and environmental perspectives.

Although the proposed solutions represent valuable advances in the EoL treatment of components in both the aviation and wind energy sectors, an SBG is still lacking. Such guidance or roadmap should integrate all stakeholders and ensure not only technical and economic viability but also environmental responsibility, thereby supporting a sustainable business model (SBM). SBMs are typically seen as a way to generate revenue while reducing the overall environmental impact of a business or service for a wide range of stakeholders with a long-term perspective [

8,

9,

10,

11]. Despite their aim to pivot businesses toward greater sustainability and stakeholder integration, a key challenge of SBMs lies in their practical implementation. Here, SBG plays a critical role, enabling SBMs to establish themselves in the market and ensuring successful applicability.

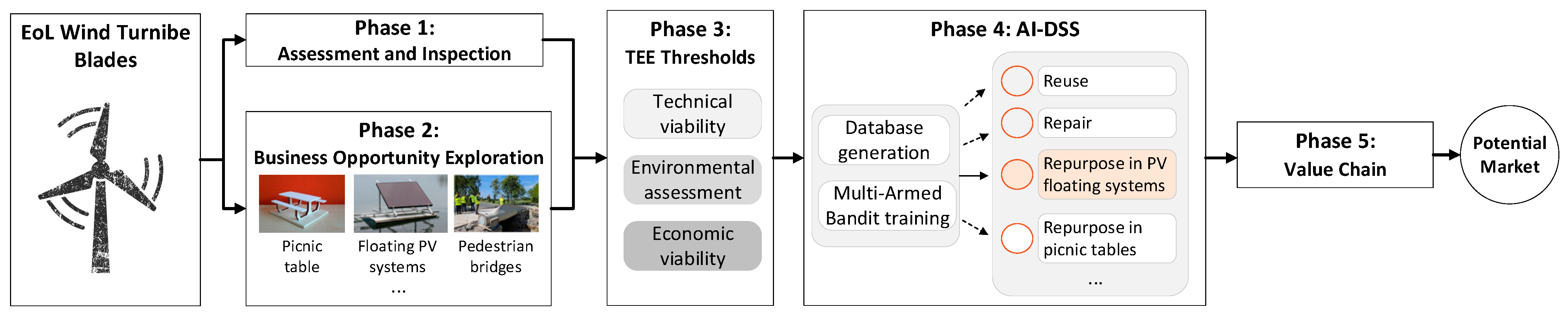

Thus, this paper proposes developing a SBG framework focused on the EoL management of aircraft parts and WTB components. The backbone of the proposed SBG comprises five phases: (1) assessment and inspection; (2) business opportunities exploration; (3) technical, economical, and environmental (TEE) thresholds; (4) an artificial intelligence (AI) decision support system (DSS); and (5) value chain analysis. In addition, this business roadmap not only offers strategic guidance on managing EoL applications in the aviation and wind energy sectors but also illustrates how the SBG could be applied in a real use case involving photovoltaic (PV) floating systems as an EoL application of reused EoL WTB segments.

2. Sustainable Business Guide (SBG)

This SBG provides a comprehensive overview of the essential phases and processes that guide companies in transforming innovative ideas into successful business opportunities. The framework proposed in this paper provides a structured approach to managing EoL components in the aviation and wind energy sectors.

Figure 1 illustrates the overall framework of the SBG, designed specifically for the aerospace and wind energy sectors. This methodology is structured into five phases, integrating technical, economic, and environmental dimensions, ensuring a robust and sustainable pathway. Each phase is described in detail below.

2.1. Assessment and Inspection

This phase aims to assess the condition of aircraft components and WTB parts at the end of their life. Due to various adverse factors—such as exposure to harsh environmental conditions [

12], aerodynamic and hydrodynamic forces, and prolonged use—these elements can suffer different types of damage that impact their structural integrity and performance. Therefore, non-destructive testing (NDT), including ultrasonic testing [

13] and infrared thermography inspection [

14], is proposed for defect identification. Additionally, the Laser-Induced Breakdown Spectroscopy (LIBS) technique is recommended for evaluating the EoL matrix compounds.

Figure 2 shows an example of NDT defect identification for WTB and a hinge as an aircraft component. As shown, this inspection identifies the presence, location, and size of a defect in the WTB. In contrast, for the hinge, the inspection identifies only the location and size of screw tracks, which do not represent defects. Additionally, the LIBS technique applied to these components reveals resins (polymers and hardeners) and fibers (glass or carbon) as notable findings, highlighting key elements such as C, H, O, and N.

2.2. Business Opportunities Exploration

This phase refers to the potential business opportunities in EoL aircraft and WTB components. These opportunities are based on the circular economy and follow three fundamental BMs: reuse, repair, and repurposing. The first model focuses on maximizing the value of parts and components in good condition, allowing their reuse and re-entry into the market, which significantly increases their life cycle and optimizes resources. The second model involves extending the useful life of components through repair, which not only optimizes resources and reduces production costs, but also minimizes waste and the environmental impact associated with the manufacture of new components. Finally, the repurposing model extends the useful life of components by modifying their original function for new uses and applications, transforming what would otherwise be waste into a valuable resource. Therefore, these BMs not only make a significant contribution in economic and environmental terms but also promote an innovative and responsible approach to resource management.

In the aviation industry, the reuse-based business model is commonly applied to parts used as spares, especially for older aircraft or those whose models are no longer manufactured [

15]. Similarly, the repair model is a fundamental practice in this industry, as it plays an integral role in reverse supply chain activities [

16]. Additionally, the repurpose model is gaining prominence, with innovative examples such as transforming retired aircraft shells into architectural designs for offices, restaurants, glamping pods, and more [

17].

On the other hand, in the wind energy industry, reuse and repair models are widely implemented. For example, damaged WTBs are often repaired, or in some cases, older WTBs are reused in less demanding environments [

18]. As for the repurpose model, it has gained significant relevance in recent years, with various proposals, such as the construction of pedestrian bridges, structural beams [

19], housing prototypes [

20], picnic tables [

21], and photovoltaic floating systems [

22].

2.3. Technical, Economic, and Environmental (TEE) Thresholds

In this phase, the technical, economic, and environmental feasibility of the considered EoL applications is determined. The technical feasibility is based on analyzing standards, Eurocodes, laws, and governmental restrictions, which, together with the inspection data obtained from aircraft parts and WTBs, will establish the technical thresholds for the BM to be exploited. Additionally, various types of data will be recorded, such as the manufacturer, model of the aircraft parts and EoL WTBs, capacity, rotor diameter, tower height, location, and dismantling details (e.g., date and storage conditions).

Subsequently, the economic feasibility is assessed by determining the monetary impacts arising from the inspection phase (Phase 1) and each manufacturing process of the EoL business opportunities (Phase 2). The economic impacts should be calculated by considering the Life Cycle Cost (LCC) [

23]. Specifically, investment costs, operating costs (labor, maintenance, materials, energy), environmental costs, and residual costs should be considered.

Finally, the environmental feasibility will be assessed through a Life Cycle Assessment (LCA) following standards 14040 and 14044 [

24]. Similarly to the scope of the economic analysis, the LCA should be conducted for both the inspection phase (Phase 1) and each manufacturing process of the EoL business opportunities (Phase 2). The LCA results may focus on measuring impacts on human health, ecosystems, and resources.

2.4. Artificial Intelligence Decision Support System (AI—DSS)

After obtaining the results for the technical, economic, and environmental thresholds, the next step is to standardize the information for each business model related to reuse, repair, and repurpose. This process helps build a robust database, allowing a learning model to identify the most optimal business model, thereby providing strong support for more effective and informed decision-making.

The advantage of using learning models to support decision-making lies in their ability to analyze large amounts of data and evaluate multiple variables (technical, economic, and environmental) simultaneously, which enables the identification of more sustainable and profitable decisions.

In this context, it is proposed to use the AI model known as the Multi-Armed Bandit (MAB), which is considered a simplified form of reinforcement learning. The MAB model fits the problem addressed by the SBG, as it aims to select the best action (business opportunity) from several alternatives based on a reward associated with each action (TEE feasibility), balancing the dilemma between exploration and exploitation [

25]. Exploration involves trying different actions to gather information on the rewards, while exploitation focuses on selecting the action that currently offers the highest reward [

25]. The name of this algorithm is derived from the slot machines in a casino, where the player aims to obtain the highest reward by pulling different arms [

26]. The MAB model consists of an agent making decisions over multiple rounds, known as the horizon. In each round, the agent selects an arm (action) and receives a reward, drawn from the probability distribution of the respective arm, independently of previous actions [

26].

Figure 3 shows the MAB flowchart adapted to the SBG problem.

2.5. Value Chain

To determine the competitive advantage and market integration of circular strategies such as reuse, repair, and repurposing of aircraft parts or WTB, this paper proposes an adaptation of Porter’s Five Forces Model. In 1979, Michael Porter asked why certain industries are more profitable than others. Answering this question involves analyzing an industry’s structure by considering the power of buyers and suppliers, the rivalry among existing competitors, and the threats posed by substitutes and new entrants [

27].

The methodology adopted to apply Porter’s Five Forces in this study follows guidelines for identifying the relevant industry and its boundaries, assessing influential factors for each force, determining the overall industry structure, and understanding its dynamics.

To evaluate the market integration of business opportunities in the aerospace and wind energy sectors, this SBG proposes interviewing at least four experts with extensive experience in the respective fields. These experts should represent roles such as sales representatives, business development and parts procurement professionals, as well as managers from major European companies such as Boeing and Siemens Gamesa Renewable Energy. Since circular strategies also consider possible repurposing activities primarily targeting the light manufacturing industry, metal and plastic products, structural components, and carpentry metal products, interviews should also focus on these sectors. Interviewees should be selected based on their expertise. Procurement representatives will assess buyer power, while sales representatives will discuss buyer power and competitor rivalry.

Finally, based on the analysis results, solid market entry strategies for the identified business opportunities should be developed.

3. SBG Usage Example Focusing on PV Floating Systems

The SBG usage example focuses on the wind energy industry, where reuse, repair, and repurposing business models, along with various EoL applications for WTB components, are considered. In particular, the case of PV floating systems is highlighted as an example of a repurposing business model. The schematic of this example of use is presented in

Figure 4.

As shown in

Figure 4, Phase 1 involves the assessment and inspection of the WTBs according to the specific guidelines outlined in

Section 2.1. During this phase, data on defects (location and size) and main components (C, H, O, and N) determined by the LIBS technique are collected.

Simultaneously, Phase 2 explores reuse, repair, and repurposing business opportunities related to EoL applications of WTBs. Several applications have been identified in different contexts, such as the construction of pedestrian bridges, urban architectural elements, structural beams, picnic tables, and PV floating systems. The specific example of the PV floating system involves an innovative application that transforms a segment of a WTB Enercon E40 into a float for this system.

Once the information from the inspection of WTBs and the various business models related to EoL applications has been gathered, the analysis of the technical, economic, and environmental thresholds must be performed (Phase 3). On the one hand, technical feasibility, based on norms, standards, and Eurecodes, along with the information from Phase 1 and Phase 2, establishes the technical thresholds for the BM to be exploited. On the other hand, economic feasibility assesses the economic impacts arising from both Phase 1 and Phase 2 (for each EoL business opportunity). Given the environmentally friendly nature of this SBG, the economic feasibility calculation should focus on LCC for both the inspection and EoL applications. In the case of the PV floating system, the three main components in its manufacture are the floating body, the support structure, and the PV module. Therefore, its main cost advantage over a conventional panel lies in the lower manufacturing cost of the floating body, which is approximately 21% cheaper. Finally, environmental feasibility is based on determining the pollutant emissions from the inspection (Phase 1) and the manufacturing processes of the EoL business opportunities (Phase 2). The environmental analysis must comply with the LCA standards specified in

Section 2.3, as these contain essential inventories to determine overall energy efficiency. The environmental analysis of the PV floating system is predicted to be favorable in terms of waste reduction, as the use of retired WTBs promotes the reuse of composite materials, significantly decreasing landfill waste and the impact of EoL. Additionally, manufacturing PV floating systems with EoL WTBs could reduce carbon emissions compared to using new materials. From an energy efficiency perspective, the production phase and the reuse of these materials influence the net energy consumed and the long-term sustainability of the system.

Following the analysis of the TEE Thresholds (Phase 3), the AI-DSS is executed. First, the information obtained from Phase 3 must be standardized and consolidated to create a compact and structured database for each identified business opportunity (e.g., reuse, repair, repurpose in pedestrian bridges, structural beams, PV floating systems, etc.). This database will be used by the MAB model to identify the most promising business opportunity, as outlined in the flowchart in

Figure 4.

Finally, in Phase 5, the business opportunity identified by the AI-DSS is evaluated within the value chain context using Porter’s Five Forces model. For instance, if the AI-DSS identifies PV floating systems as the most promising business opportunity, the competitive rivalry can be considered moderate to high, as these systems are part of innovative applications in the growing renewable energy sector. Since large-scale production is still under development, the bargaining power of buyers is moderate and depends on the perceived value of sustainable solutions. Conversely, suppliers may have significant power due to the limited availability of specialized materials and the need for corrosion-resistant components. Barriers to market entry are high due to technological and regulatory requirements, including certifications and safety testing. The primary competition comes from other renewable energy sources, such as ground-based solar panels and alternative EoL WTB applications. Economic data are essential, as they can indicate lower costs and higher efficiency compared to conventional panels. In summary, the viability of EoL WTB applications in PV floating systems relies on managing strategic alliances, reducing entry costs, and adapting to the evolving competitive landscape.

4. Conclusions and Future Implications

The proposed SBG integrating technical, economic, and environmental assessments, and, with its five strategic phases, has proven to be an effective framework for analyzing, supporting, and making crucial decisions regarding the reuse, repair, and repurposing of aircraft and WTB parts. The use of the SBG through a real case of floating PV platforms demonstrated their practicality for enhancing sustainability in the wind energy sector and confirmed their potential as a promising solution that combines renewable energy with a circular economy.

The incorporation of an AI model for decision-making in a sustainable business roadmap enables the optimization of business model selection by effectively balancing technical, economic, and environmental dimensions. Standardized data systems and improved information management will contribute to a more robust database, enhancing the AI-DSS’s accuracy, efficiency, and scalability.

The Porter’s Five Forces analysis, supplemented by human judgment, identifies real barriers to market entry and facilitates the development of an appropriate entry strategy. To enhance the flexibility and comprehensiveness of the SGB, it is recommended to expand its scope to include aircraft dismantling and WTB operations as an initial phase, given that these involve complex processes requiring technical expertise, resource consumption, and effective logistical planning.

This work establishes a strong foundation for advancing end-of-life component management strategies in the aerospace and wind energy sectors. Future efforts should aim to delve deeper into the practical challenges involved in technical, economic, and environmental assessments, with particular emphasis on the complexities of composite materials. Such advancements would enhance the practical implementation of the SBG, facilitating an effective transition to sustainable practices in these critical sectors.

Author Contributions

Conceptualization, L.A.R.-O. and E.A.T.S.; methodology, L.A.R.-O., E.A.T.S., A.A., C.C. and R.M.S.; validation, L.A.R.-O., D.C.B. and P.J.; formal analysis, L.A.R.-O. and E.A.T.S.; investigation, L.A.R.-O. and E.A.T.S.; resources, L.A.R.-O.; data curation, L.A.R.-O. and E.A.T.S.; writing—original draft preparation, L.A.R.-O., P.J. and E.A.T.S.; writing—review and editing, L.A.R.-O., E.A.T.S. and S.M.-L.; supervision, R.B.; project administration, A.A., P.J. and R.B.; funding acquisition, L.A.R.-O. All authors have read and agreed to the published version of the manuscript.

Funding

This work has been developed within the EURECOMP project under the great agreement 101058089, funded by the European Union’s Horizon 2021 program. Views and opinions expressed are however those of the author(s) only and not necessarily reflect those of the European Union or HADEA. Neither the European Union nor HADEA can be held responsible for them.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

No new data were created in this study. Data sharing is not applicable.

Acknowledgments

The authors would like to thank all the members of the Singular, Strategic, Safety, and Sustainable Initiative (S4I) unit, the Smart Systems and Smart Manufacturing (S3M) unit of the AIMEN Technology Center, as well as the Institute for Development-Oriented Mechanical Engineering and the Faculty of Engineering at Leipzig University of Applied Sciences for their comments and fruitful discussions.

Conflicts of Interest

The authors declare no conflicts of interest.

Abbreviations

| AI | Artificial Intelligence |

| BM | Business Model |

| DSS | Decision Support System |

| EoL | End of Life |

| LCA | Life Cycle Assessment |

| LCC | Life Cycle Cost |

| LIBS | Laser-Induced Breakdown Spectroscopy |

| MAB | Multi-Armed Bandit |

| NDT | Non-Destructive Testing |

| PV | Photovoltaic |

| SBG | Sustainable Business Guide |

| TEE | Technical, Economic, and Environmental |

| WTB | Wind Turbine Blade |

References

- Keivanpour, S.; Kadi, D.A.; Mascle, C. End-of-life aircraft treatment in the context of sustainable development, lean management, and global business. Int. J. Sustain. Transp. 2017, 11, 357–380. [Google Scholar] [CrossRef]

- Land-Based Wind Market Report: 2023 Edition. Available online: https://escholarship.org/uc/item/51c9d2vt (accessed on 14 November 2024).

- Song, Y.S.; Youn, J.R.; Gutowski, T.G. Life cycle energy analysis of fiber-reinforced composites. Compos. Part. A Appl. Sci. Manuf. 2009, 40, 1257–1265. [Google Scholar] [CrossRef]

- Johst, P.; Kucher, M.; Schulz, P.; Knorr, A.; Kupfer, R. Identification of circular eco-subsystems for end-of-life aviation composite components based on a systematized R6-strategy. J. Phys. Conf. Ser. 2023, 2526, 012055. [Google Scholar] [CrossRef]

- Johst, P.; Kucher, M.; Bühl, M.; Schulz, P.; Kupfer, R.; Schilling, L.; Santos, R.M.; Carneiro, C.; Voigt, P.; Modler, N. Identification and Environmental Assessments for Different Scenarios of Repurposed Decommissioned Wind Turbine Blades. Mater. Circ. Econ. 2023, 5, 13. [Google Scholar] [CrossRef]

- Gennitsaris, S.; Sofianopoulou, S. Wind turbine end-of-life options based on the UN Sustainable Development Goals (SDGs). Green. Technol. Sustain. 2024, 2, 100108. [Google Scholar] [CrossRef]

- Hasheminezhad, A.; Nazari, Z.; Yang, B.; Ceylan, H.; Kim, S. A comprehensive review of sustainable solutions for reusing wind turbine blade waste materials. J. Environ. Manage 2024, 366, 121735. [Google Scholar] [CrossRef] [PubMed]

- Schlüter, L.; Kørnøv, L.; Mortensen, L.; Løkke, S.; Storrs, K.; Lyhne, I.; Nors, B. Sustainable business model innovation: Design guidelines for integrating systems thinking principles in tools for early-stage sustainability assessment. J. Clean. Prod. 2023, 387, 135776. [Google Scholar] [CrossRef]

- Schaltegger, S.; Hansen, E.G.; Lüdeke-Freund, F. Business Models for Sustainability: Origins, Present Research, and Future Avenues. Organ. Environ. 2015, 29, 3–10. [Google Scholar] [CrossRef]

- Kaplan, S. The Business Model Innovation Factory: How to Stay Relevant When the World is Changing; John Wiley & Sons: Hoboken, NJ, USA, 2012. [Google Scholar] [CrossRef]

- Lüdeke-Freund, F.; Carroux, S.; Joyce, A.; Massa, L.; Breuer, H. The sustainable business model pattern taxonomy—45 patterns to support sustainability-oriented business model innovation. Sustain. Prod. Consum. 2018, 15, 145–162. [Google Scholar] [CrossRef]

- Kucher, M.; Johst, P.; Lizaranzu, M.; Lahuerta, F.; Böhm, R. A Micromechanical Modeling Approach for the Estimation of the Weathering-Induced Degradation of Wind Turbine Blades. Mater. Circ. Econ. 2023, 5, 17. [Google Scholar] [CrossRef]

- Taheri, H.; Hassen, A.A. Nondestructive ultrasonic inspection of composite materials: A comparative advantage of phased array ultrasonic. Appl. Sci. 2019, 9, 1628. [Google Scholar] [CrossRef]

- Civera, M.; Surace, C. Non-destructive techniques for the condition and structural health monitoring of wind turbines: A literature review of the last 20 years. Sensors 2022, 22, 1627. [Google Scholar] [CrossRef] [PubMed]

- Sabaghi, M.; Cai, Y.; Mascle, C.; Baptiste, P. Towards a Sustainable Disassembly/Dismantling in Aerospace Industry. Procedia CIRP. In Proceedings of the 13th Global Conference on Sustainable Manufacturing—Decoupling Growth from Resource Use, Ho Chi Minh City/Binh Duong, Vietnam, 16–18 September 2015. [Google Scholar] [CrossRef]

- Keivanpour, S.; Kadi, D.A. An integrated approach to analysis and modeling of End of Life phase of the complex products. IFAC-PapersOnLine 2016, 49, 1892–1897. [Google Scholar] [CrossRef]

- Air Charter Service. Available online: https://www.aircharterserviceusa.com/about-us/news-features/blog/ingenious-ways-to-repurpose-old-aircraft (accessed on 18 November 2024).

- Beauson, J.; Laurent, A.; Rudolph, D.P.; Jensen, J.P. The complex end-of-life of wind turbine blades: A review of the European context. Renew. Sustain. Energy Rev. 2022, 155, 111847. [Google Scholar] [CrossRef]

- Zhang, Z.; McDonald, A.; Alshannaq, A.; Gentry, T.R.; Bank, L.C.; Leahy, P.; Nagle, A.; Ruane, K.; Huynh, A. BladeBridg: Design and construction of a pedestrian bridge using decommissioned wind turbine blades. In Structures and Architecture. A Viable Urban Perspective? 1st ed.; CRC Press: London, UK, 2022; pp. 1195–1202. [Google Scholar]

- Bank, L.C.; Arias, F.R.; Yazdanbakhsh, A.; Gentry, T.R.; Al-Haddad, T.; Chen, J.F.; Morrow, R. Concepts for reusing composite materials from decommissioned wind turbine blades in affordable housing. Recycling 2018, 3, 3. [Google Scholar] [CrossRef]

- Joustra, J.; Flipsen, B.; Balkenende, R. Structural reuse of wind turbine blades through segmentation. Composites Part C Open Access 2021, 5, 100137. [Google Scholar] [CrossRef]

- Johst, P.; Seibert, D.; Zschiebsch, W.; Kucher, M.; Carneiro, C.; Araújo, A.; Santos, R.M.; Rodriguez-Ortiz, L.A.; Tapia, E.A.; Böhm, R. Eco-efficient manufacturing: Transforming end-of-life wind turbine blade components into floats for PV-floating systems. In Proceedings of the MATEC Web Conference 21st International Conference on Manufacturing Research (ICMR2024), Glasgow, UK, 28–30 August 2024. [Google Scholar] [CrossRef]

- Rebitzer, G.; Hunkeler, D. Life cycle costing in LCM: Ambitions, opportunities, and limitations. Int. J. Life Cycle Assess. 2003, 8, 253–256. [Google Scholar] [CrossRef]

- ISO 14040; Environmental Management—Life Cycle Assessment—Principles and Framework. International Organization for Standardization: Geneva, Switzerland, 2006.

- Bouneffouf, D.; Rish, I. A survey on practical applications of multi-armed and contextual bandits. arXiv 2019, arXiv:1904.10040. [Google Scholar] [CrossRef]

- Fei, B. Comparative analysis and applications of classic multi-armed bandit algorithms and their variants. Appl. Comput. Eng. 2024, 68, 17–30. [Google Scholar] [CrossRef]

- Porter, M.E. How Competitive Forces Shape Strategy. Harv. Bus. Rev. 1979, 57, 137–145. [Google Scholar]

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).