Abstract

The formulation of eco-friendly coatings with protective properties against corrosion and/or mechanical degradation requires the selection of appropriate bio-based binders and functional additives. Although the concentration of additives remains limited, the replacement of fossil-based additives with bio-based additives may deliver an important contribution to improving the carbon footprint of a coating, in parallel with their influences on coating performance, lifetime, and processing. However, the role of bio-based additives in life-cycle analysis (LCA) is often neglected and minorly considered in current literature. Reasons for this include the complexity of the full system, together with a lack of data, methodological inconveniences, and appropriate design of realistic scenarios. Within this work, an approach of simplified LCA is followed by ab initio cradle-to-gate analysis of coating formulations focusing on the replacement of specific fossil additives (e.g., carbon black, silicates, and calcium carbonate) with bio-based additives (e.g., biochar, bio-based wax, recovered calcium carbonate, and nanocellulose). The different environmental impact parameters (human health, eco-toxicity, resource scarcity, and carbon footprint) for bio-based additives and coating formulations are calculated from eco-cost analysis (Idemat 2024 v2.2 database), indicating a 15 to 30% gain in carbon footprint for coatings with bio-based additives. In a particular case study for improving coating performance by substituting cellulosic additives into nanocellulose from different sources, the reduction in environmental impact parameters is positively associated with their high performance at low concentration. The need for intermediate processing of bio-based additives is a main parameter contributing to their environmental impact, but environmental benefits are abundantly compensated by their carbon storage credit and performance improvement.

1. Introduction

In the quest for sustainable development, the coatings and paints industry has faced mounting pressure to minimize its environmental footprint [1]. The traditional protective coatings relying on petrochemical sources contribute significantly to environmental pollution and resource depletion. This calls for a shift towards integration of components from native or residual biomass with promising reduction in ecological impact [2]. While most emphasis in the coating industry has recently been put on the shift towards bio-based binders [3], the bio-based additives play a crucial role in enhancing the functional properties of bio-based coatings and may influence their ecological impact. As the selection of functional bio-based additives is not merely a matter of replacing petrochemical components [4], a comprehensive understanding of their life cycle impacts is required to ensure true environmental benefits.

The life-cycle analysis (LCA) offers a robust framework for evaluating the environmental implications of fossil-based versus bio-based coatings [5]. In the first estimate, a holistic view needs to be obtained by considering the entire life cycle from raw material extraction and processing, through the formulation of the coating, and its use phase towards ultimate disposal. Therefore, a high-throughput screening method should allow for the rapid assessment of numerous additives, providing insights into their potential environmental impacts at an early stage in the design phase [6]. A proactive approach at low levels of TRL (technological readiness level) would not only accelerate the development of green coatings but also align with the principles of green chemistry and engineering [7]. The ab initio cradle-to-grave LCA would enable the identification of critical hotspots, facilitating informed decisions in the early selection of eco-friendly additives; e.g., the analysis may reveal that certain bio-based additives, while renewable, have high energy demands during production, prompting a re-evaluation of manufacturing processes [8]. It integrates data from various stages of the additive’s life cycle, ensuring that the chosen substances genuinely contribute to the sustainability goals of bio-based coatings [9]. Furthermore, the adoption of ab initio LCA can drive innovation by highlighting opportunities for improvements across the supply chain. The continuous feedback loop promotes the development of additives that are not only environmentally friendly but also economically feasible, thereby ensuring their adoption in mainstream coatings production. However, it has been clearly recognized in the recent literature that data on additives are poorly available and the role of additives is seldomly included in LCA databases for plastic production processes, while additive impacts are little reported [10]. A review on LCA of bio-based versus traditional functional fillers also confirmed that the role of additives in polymer products or coatings is poorly documented with scattered information [11].

As the implementation of ab initio life-cycle analysis in the selection of eco-friendly additives for bio-based coatings represents a significant step towards sustainable industrial practices, this study demonstrates how a simplified LCA tool assists in the formulation of environmentally friendly coatings and helps to identify benign additives and coating compositions at low TRL levels (e.g., in the design phase of the coating). Given the lack of quantitative data on the environmental impact of additives in coatings, this study aims to provide an illustrative calculation method for some model coating formulations as a guideline for the development of novel bio-based coatings. The novelty of this work relies on the integration of LCA data as guidance for the formulation of novel bio-based coatings. As industry continues to evolve, integration of simplified analytical methods will be crucial in fostering innovation and promoting environmentally responsible coatings.

2. Experimental Details

2.1. Methodology and Scope

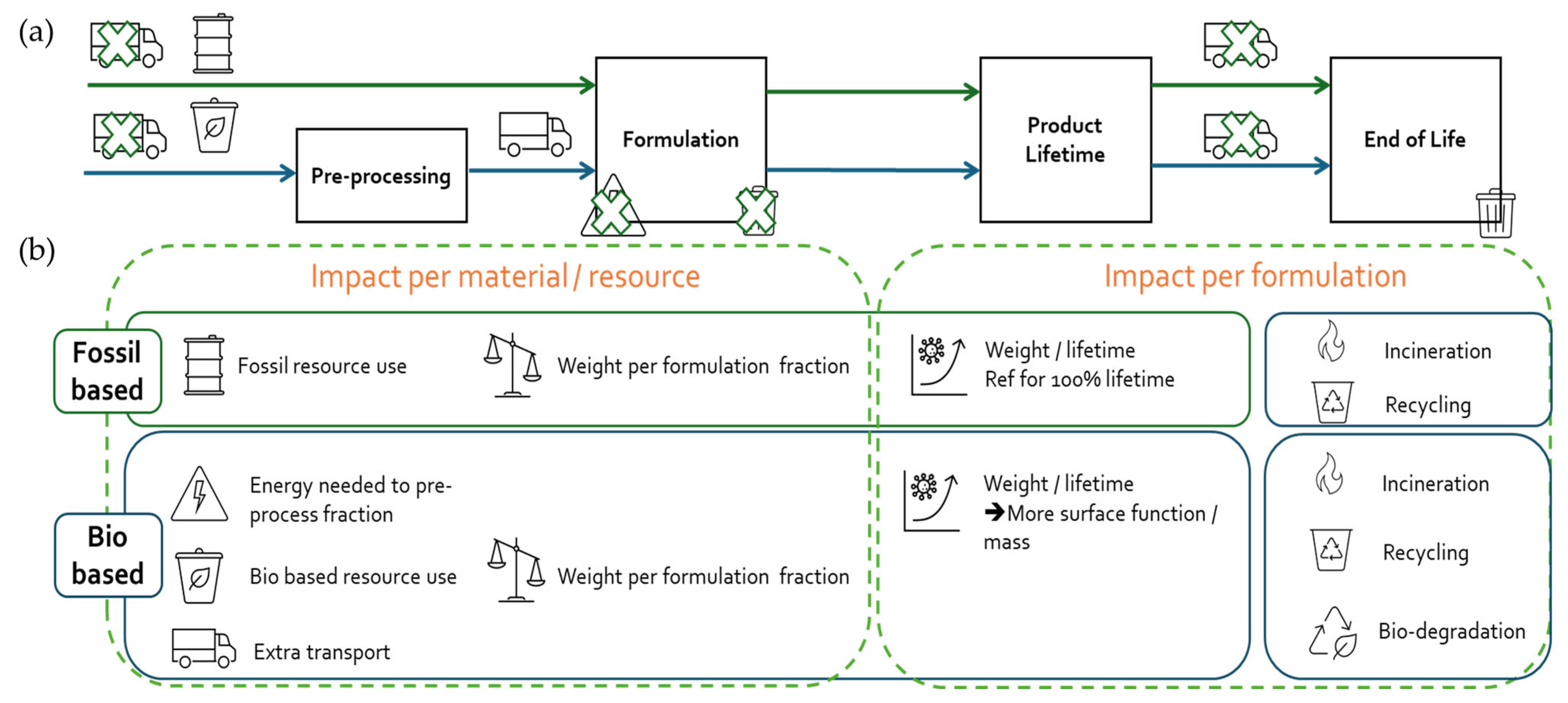

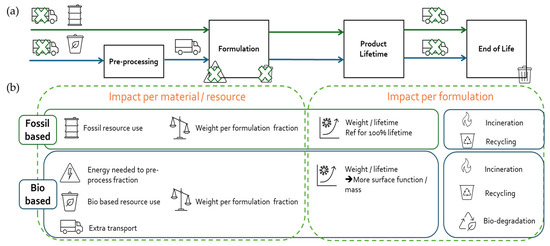

A simplified LCA is performed to estimate the consequences on environmental parameters in a scenario for comparative analysis of given coating compositions with fossil-based versus bio-based additives. Within a cradle-to-grave approach (Figure 1a), the processing chains for coating formulations with bio-based and fossil-based additives are shown with an indication of the most influential processing steps. As the processes to formulate a coating with bio-based and fossil-based additives are similar, their effects on differences in environmental impact between fossil-based and bio-based coatings are inferior in a first comparative analysis. In the first approach, it can also be assumed that the environmental effects for different end-of-life scenarios (recycling and/or biodegradation) will be neutral or an order of magnitude lower compared to resource selection for bio-based versus fossil-based coatings. Therefore, the main contributions to the environmental impact of bio-based coatings in this study are focused on (i) the need for pre-processing biomass into a functional additive form and (ii) an eventual positive impact due to enhanced performance or product lifetime.

Figure 1.

Indicative approach for simplified LCA highlighting the main effects on environmental impact for bio-based versus fossil-based additives in coatings, with (a) comparative processing chain between fossil-based and bio-based coating formulations focusing on main contributions of pre-processing and product lifetime and (b) different impacts and selection of functional units.

As a unit of measure (Figure 1b), data are referred to 1 kg of a given coating composition with impacts of the additives depending on their concentration (weight per formulation fraction), together with their resulting performance credit (weight/lifetime).

2.2. Data Collection

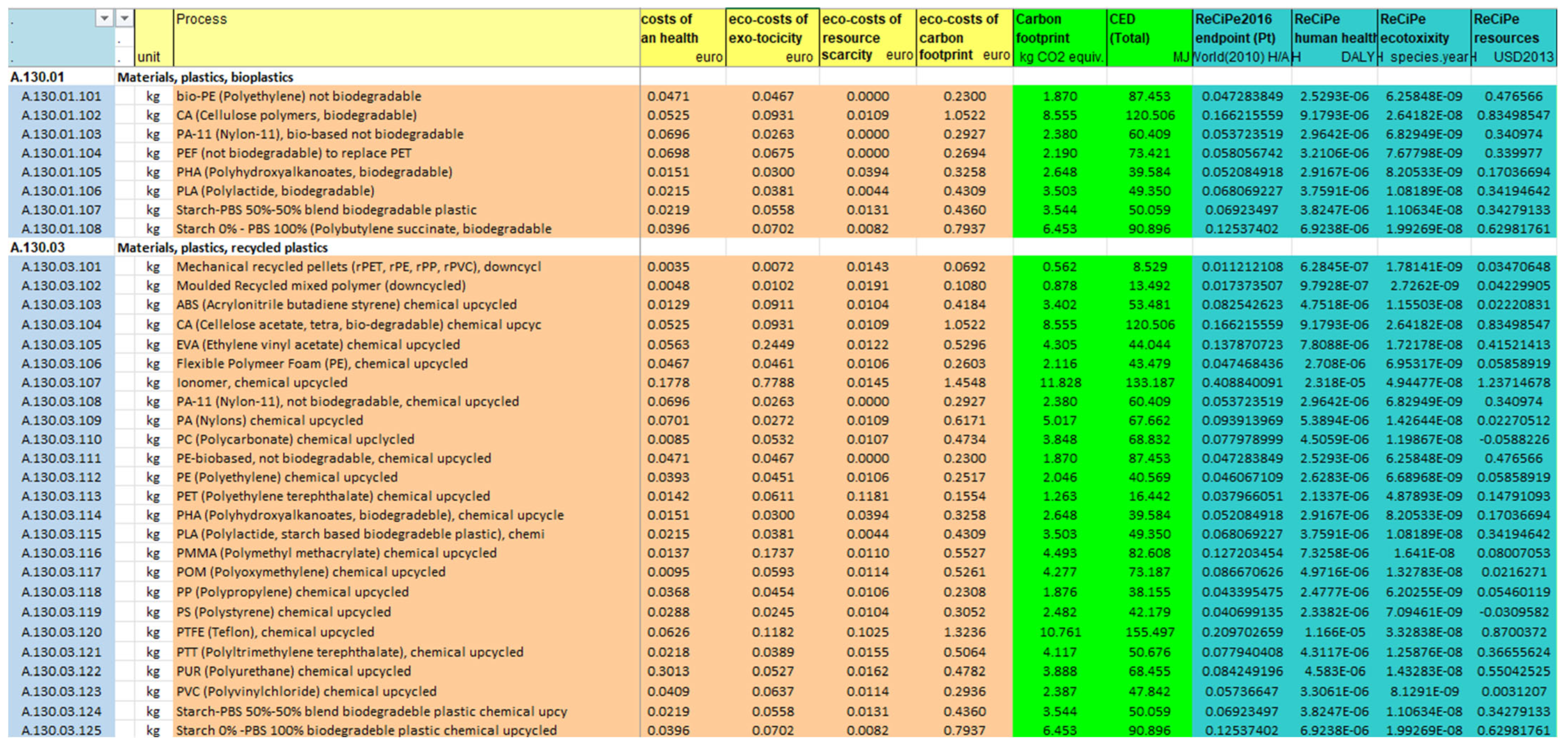

Data for environmental parameters according to the eco-cost method (including carbon footprint [kg CO2 eq], total eco-cost [EUR], and specific eco-costs [EUR] related to human health, eco-toxicity, resource scarcity, and carbon) are retrieved from the Idemat database (v2.2, 2024). Preference for the database was based on transparent calculations, availability of up-to-date values, and a science-based approach. A single database version was used in order to enable this benchmarking study, for which an example of retrieved information is shown in Figure 2. Environmental impact data for different categories of basic additives can be either found directly in the database, or proximate data for processed biomass are expressed in terms of energy input [MJ] needed for processing the biomass into suitable additive form, selecting the impact based on the environmental parameters of average European electricity (EU-27). Based on previous reports [12], the calculation results according to the eco-cost method provide some lower impact as compared to Ecoinvent results, as the latter often include older (or extrapolated) datasets and lag behind on data for electricity. In contrast with Idemat, Ecoinvent also includes infrastructure and does not have a cut-off point. Therefore, differences of approximately 2% are to be expected, where Ecoinvent is more on the safe side (‘precautionary principle’) by implementing worst-case scenarios. Moreover, Idemat is frequently used as a materials selection tool for a comparative analysis, including a dataset of more than 1000 materials, services, production processes, and end-of-life scenarios. It is based on data from the Swiss Ecoinvent database and CES EduPack, plus additional LCIs made by Delft University of Technology [13].

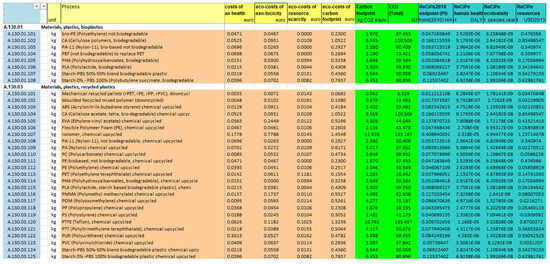

Figure 2.

Illustrative data for various materials as retrieved from the Idemat database (v2.2, 2024).

3. Results and Discussion

3.1. Data Collection (Inventory) for Bio-Based Binders

Knowing that a clear coating composition is based on 70 to 80% polymer binder, the environmental impact of fossil versus bio-based binders is illustrated first. The selection of suitable polymer binders for the coatings was based on two experimental cases, i.e., (i) the formulation of a protective thermoset coating based on epoxy and (ii) the formulation of a thermoset powder coating based on polyester (PET). The traditional fossil-based epoxy coatings contain a DGEBA (bisphenol A diglycidyl ether) resin with hexamethylene diamine hardener mixed in a 1:1 weight ratio, while a commercial 100% bio-based epoxy resin is produced from epoxidized fatty acids in combination with a bio-based acid as a crosslinker. Both epoxy coatings can be applied under the same processing steps and crosslinked under environmental conditions (no thermal curing). The thermoset powder coatings consider a potential replacement of virgin PET with recycled PET (rPET) content, resulting in similar processing conditions and properties.

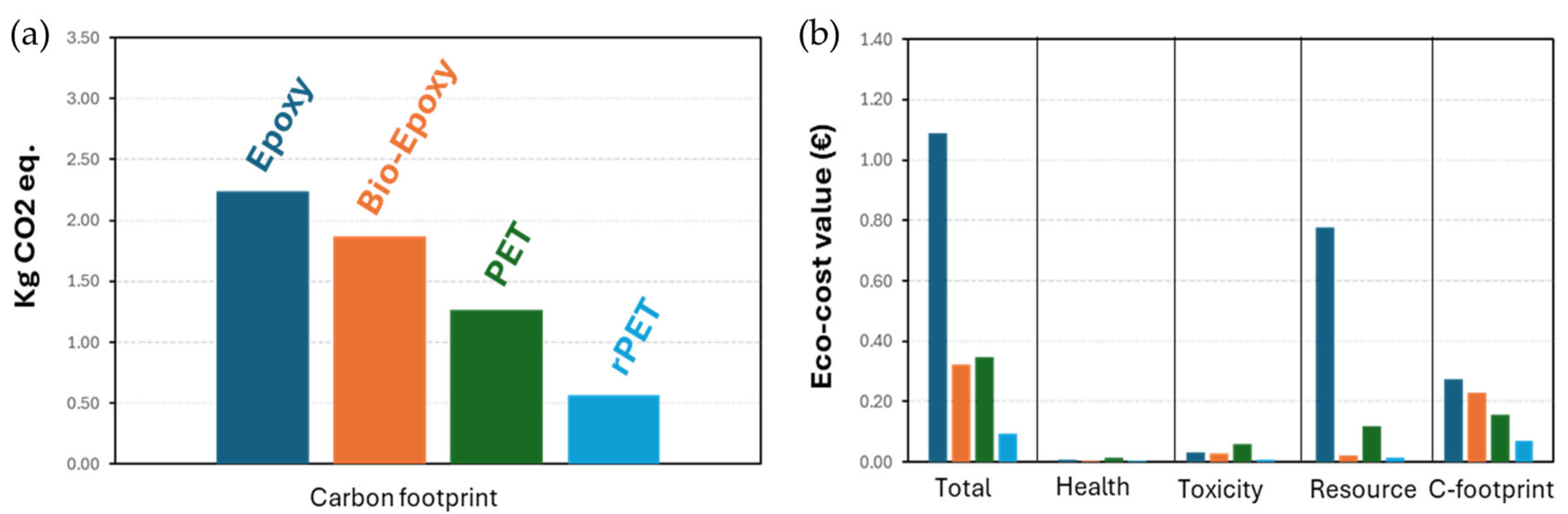

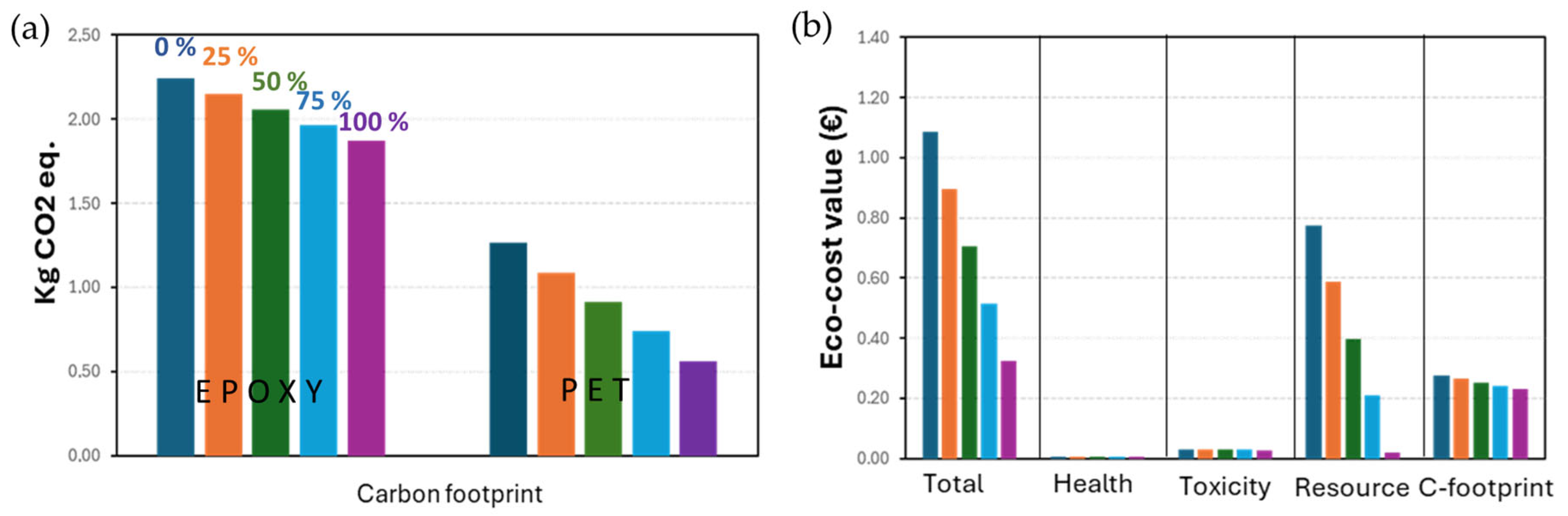

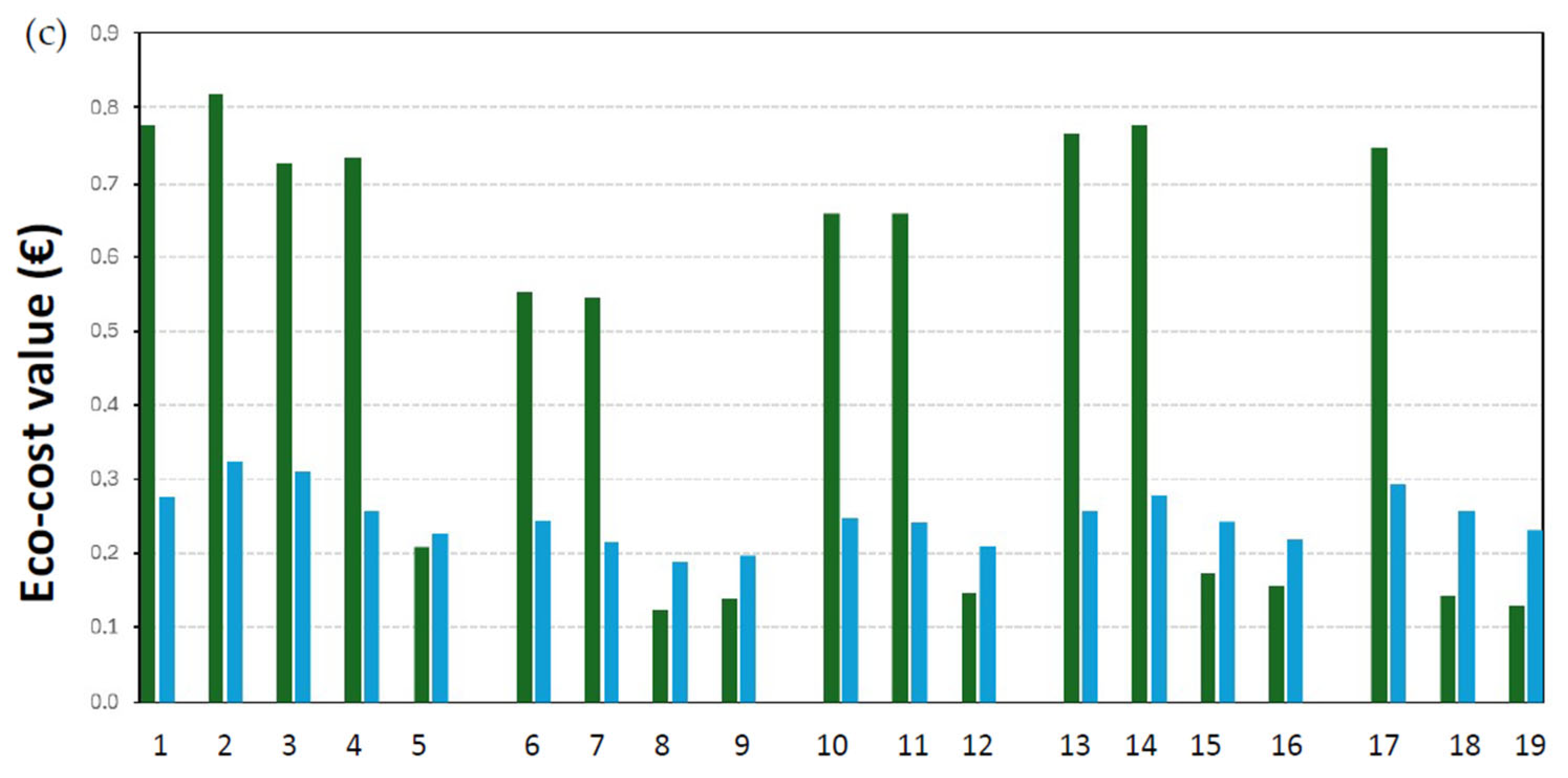

The carbon footprint and different environmental impact parameters (Figure 3) for fossil-based versus bio-based or recycled coating binders are compared, with a reduced carbon footprint for bio-epoxy compared to epoxy (17%) and a reduced carbon footprint for rPET compared to PET (55%) (Figure 3a). By further detailing the different impact categories, the highest reduction in environmental impact is related to resource depletion, followed by a reduction in toxicity (Figure 3b). The changes in health issues after transition from bio-based versus fossil-based binders are inferior, as they are likely based on similar chemistries. While it is known that a performant powder coating formulation may only function with rPET content up to 25%, according to present state-of-the-art [14], the progressive replacement of fossil-based coatings with 100% bio-based coatings should consider different concentration ratios of bio-based versus fossil-based binders, resulting in a linear decrease of carbon footprint (Figure 4a) and environmental impact parameters (Figure 4b).

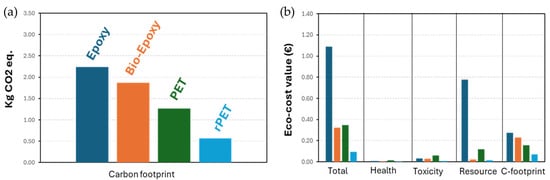

Figure 3.

Inventory of environmental impact parameters for epoxy versus bio-epoxy and PET versus rPET binders used in coating formulations: (a) CO2 carbon footprint and (b) eco-cost values for different environmental impact categories (colors indicate different binders as indicated in (a)).

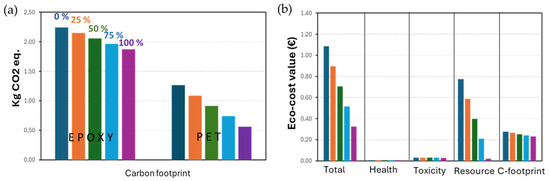

Figure 4.

Variation in environmental impact parameters for gradual substitution of fossil-based epoxy (DGEBA + amine) into bio-based epoxy (vegetable oil + bio-based acid) or PET into rPET: (a) CO2 carbon footprint for epoxy and PET and (b) eco-cost values for different environmental impact categories for epoxy (colors indicate different wt.% of bio-based binders as indicated in (a)).

3.2. Data Collection (Inventory) of Bio-Based Additives

The different types of fossil-based and bio-based additives were selected based on their expected functionality extending the coating performance. Similar functionalities between fossil-based and bio-based additives can be obtained, e.g., mechanical reinforcement, lubrication, wear reduction, color, or hydrophobicity, among others (anti-corrosion and flame retardance). A number of additives were selected according to industrial availability and known performance based on literature [15,16,17,18,19,20,21,22,23]. A comparative list of appropriate drop-in bio-based additives with several functionalities as used in this study is listed in Table 1.

Table 1.

Selection of fossil-based versus bio-based additives for different coating functionalities.

The inventory of environmental parameters for commodity additives is accessible through the explored database, while it needs to be calculated for additives obtained from processed biomass. The latter is based on the environmental parameters of average energy input needed for the biomass conversion (Table 2). The equivalent energy input for respective conversion processes (per kg biomass) is estimated from best practices (private discussions and preliminary testing with industrial partners) and literature data [24,25,26], representing large differences in the range of energy consumption depending on the conversion processes and used primary biomass. Among the basic conversions towards dry powders, energy demand includes drying of the biomass and losses in mechanical energy during grinding owing to the important (visco-)elastic losses, especially within the cork material. The basic thermal operations for pyrolysis include heating towards an appropriate temperature of 600 to 800 °C in combination with post-processing requirements. The high energy input for fibrillation of biomass into nanocellulose is in line with the breakdown of physical bonds within the wood or cellulose structure and therefore highly depends on the original biomass source (e.g., virgin wood versus recovered cellulose fibers from the paper industry). The processing of virgin wood also includes the removal of lignin, while the recovered cellulose fibers are already pre-processed during earlier conversion.

Table 2.

Energy requirements for basic operations in biomass processing.

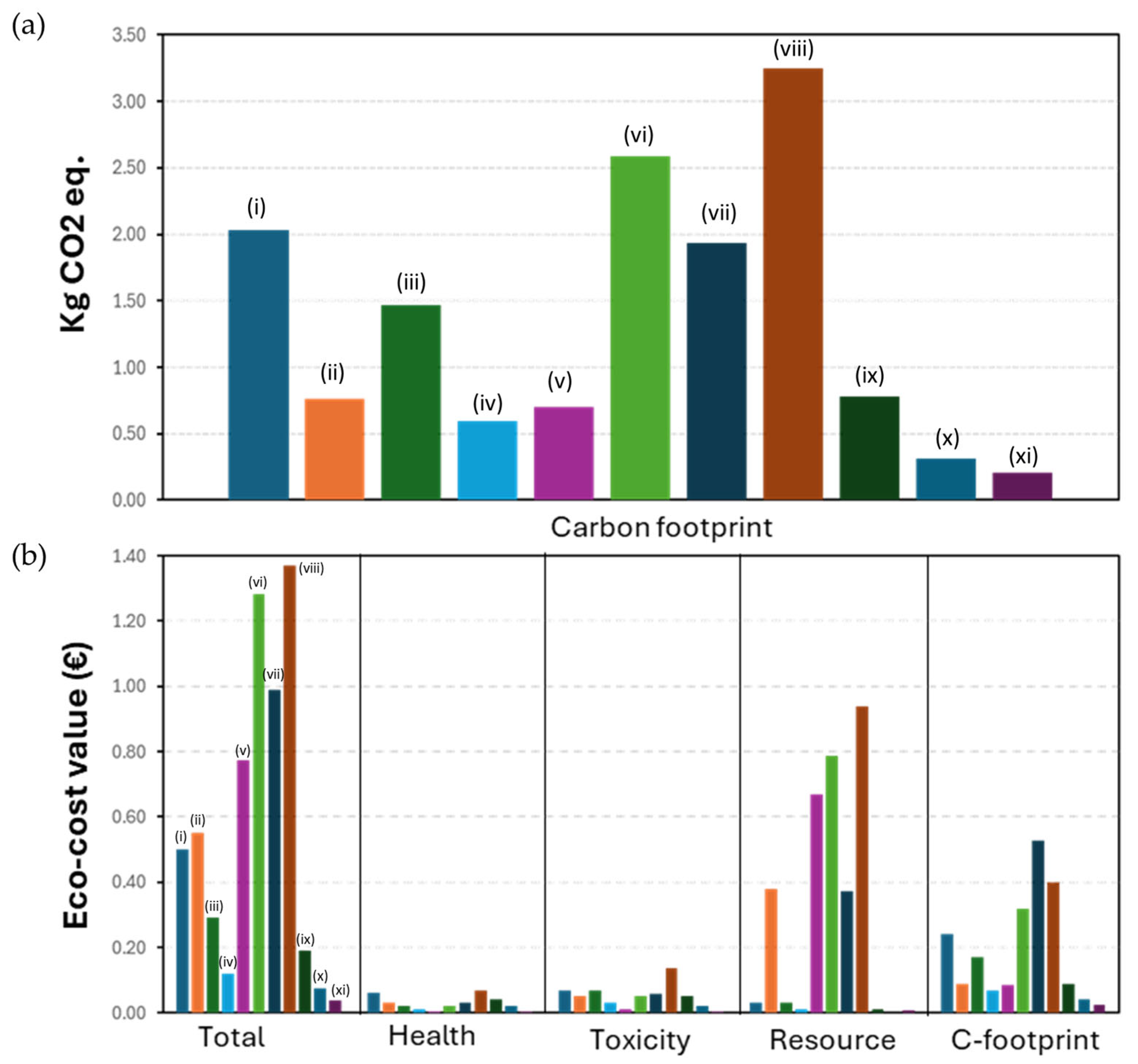

Based on the inventory data of base materials and environmental parameters of electricity (EU-27), the calculated environmental parameters for producing the selected functional additives from fossil sources or processed biomass (see Table 1) are summarized in Figure 5, including carbon footprint and eco-cost values for different impact categories.

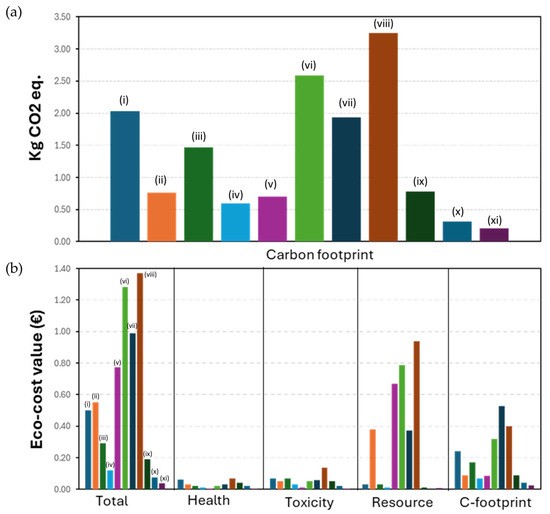

Figure 5.

Inventory of environmental impact parameters for selected fossil-based (F) and bio-based (B) functional additives: (a) CO2 carbon footprint and (b) eco-cost values for different environmental impact categories for (i) silicate (F), (ii) rice husk biochar (B), (iii) calcium carbonate (virgin, F), (iv) calcium carbonate (renewable, B), (v) cellulose (wood pulp, B), (vi) nanocellulose (cellulose fibers, B), (vii) nanocellulose (from wood pulp, B), (viii) carbon black (F), (ix) polyethylene wax (F), (x) biowax (general, B), and (xi) cork granulate (B). The same color code applies for all samples.

Although the need for processing biomass into appropriate additives requires additional energy, the values for the carbon footprint of fossil additives such as silicate, calcium carbonate, and carbon black remain higher as compared to the bio-based alternatives of rice husk biochar, renewable calcium carbonate, biowax, cellulose pulp, or cork (Figure 5a). Alternatively, the carbon footprint of bio-based additives that require intense processing, such as, e.g., nanocellulose from cellulose fibers or wood pulp, may become significantly higher. The same trends are reflected in the total eco-cost values and eco-cost values for the different impact categories (Figure 5b). The bio-based wax, rice husk, and renewable calcium carbonate additives have clear environmental benefits with lower impact parameters in health, toxicity, and resource depletion. However, the environmental impact parameters for bio-based additives with a strong need for processing, such as, e.g., nanocellulose, highly depend on the source and energy input for fibrillation. Overall, the most significant environmental impact factor is related to resource scarcity, with sometimes relatively high values for bio-based additives (e.g., rice husk, cellulose, and nanocellulose) in relation to high water consumption during processing.

3.3. Calculations for Bio-Based Coating Compositions

After presenting the separate roles of binders (see Section 3.1) and additives (see Section 3.2), the environmental impact of some final coating formulations is illustrated below. For a selection of basic coating formulations (i.e., binder + additive) with different portions of bio-based versus fossil-based epoxy resin and bio-based versus fossil-based additives, the trends in environmental impact categories are indicatively calculated. The proposed coating formulations as below are typically used as protective coatings (e.g., flooring, wood, and furniture) and designed for enhanced mechanical properties and lifetime.

The selected coating formulations, as summarized in Table 3, are examples based on experimental experience of functional coatings (performance details of the coatings are not given in this paper but are based on extensive testing): (i) in series 01, a one-by-one substitution of fossil-based into bio-based additives is considered; (ii) in series 02, the functionality and performance are optimized by adapting additive concentrations. The coating formulations with 10 wt.-% biochar were selected as optimized for best mechanical performance [27]; the 30 wt.-% CaCO3 [28], 20 wt.-% cork granulate [29], and 15 wt.-% biowax [30] were selected as formulations with maximized filler content; and the 0.75 wt.-% nanocellulose (dry content) proved best mechanical performance and lifetime after testing the concentration ranges between 0.1 and 1.5 wt.-% [31]. Besides the variations in composition, the effect of a supplementary factor with 10% performance credit (product lifetime improvement) can be included for most performant coatings (e.g., samples 16, 19) [31].

Table 3.

Selected formulations of fossil-based and bio-based coatings (additives in wt.-%).

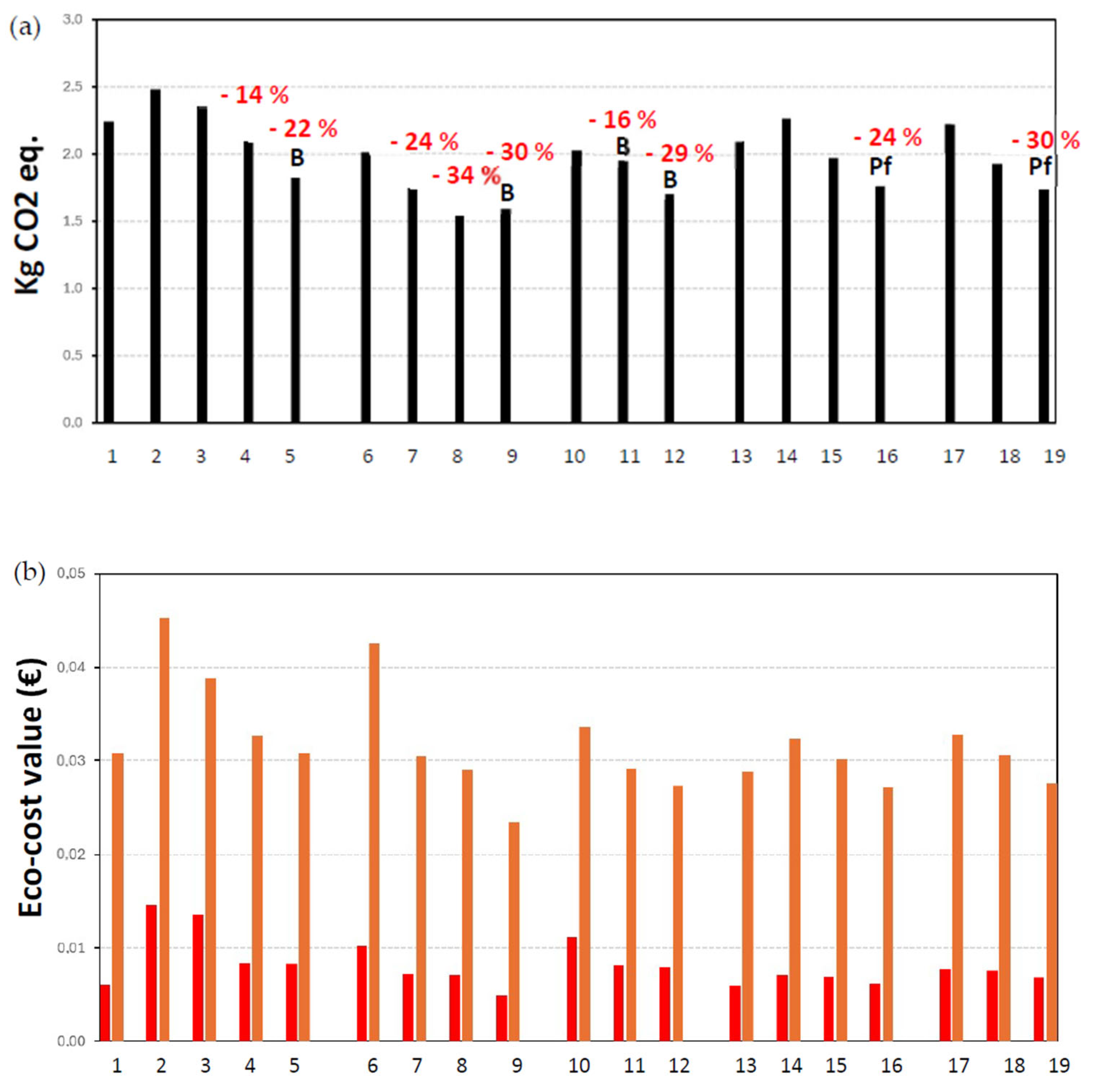

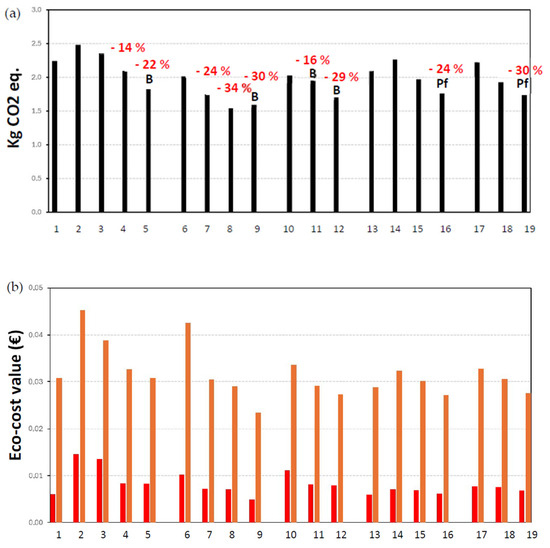

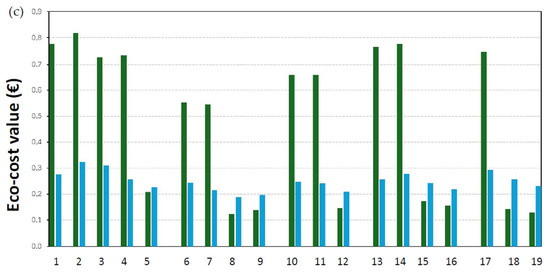

For selected coating formulations as in Table 3, the values for carbon footprint (Figure 6a) together with eco-cost values related to different environmental impact parameters (Figure 6b,c) are calculated based on the inventory data from previous paragraphs. The gain (percentage) in carbon footprint for coatings with either bio-based binders or bio-based additives is expressed relative to a neat fossil-based epoxy coating with fossil additives. The comparative analysis of environmental impact between different coating formulations indicates main influencing parameters and estimated environmental benefits.

Figure 6.

Calculated environmental impact parameters for different coating formulations (samples 1 to 19 as detailed in Table 3): (a) CO2 carbon footprint; (b) eco-cost values for different environmental impact categories: human health (red bar) and eco-toxicity (orange bar); and (c) eco-cost values for different environmental impact categories: resource scarcity (green bar) and carbon footprint (blue bar). Bio-based coatings are indicated as ‘B’ and performance credit as ‘Pf’.

The effects on carbon footprint (Figure 6a) by adding 10 wt.-% biochar as a substituent for the same concentration of carbon black or silicates are shown by comparing samples 1 to 5. The introduction of rice-husk biochar provides a gain in carbon footprint of 14% (substituting carbon black) or 10% (substituting silicates) when applied in a fossil-based epoxy matrix, while a further reduction in carbon footprint of 22% is obtained by replacing the fossil-based epoxy with a bio-based epoxy binder. The effects on carbon footprint while substituting 30 wt.-% virgin CaCO3 into 30 wt.-% renewable CaCO3 are seen by comparing samples 6 to 8, indicating a significant gain of 24% (with a fossil-based epoxy) or 34% (with a bio-epoxy binder), which are comparable to the introduction of cork additives that also require extensive mechanical pre-processing by grinding and sieving. The substitution of 15 wt.-% PE wax into 15 wt.-% biowax is illustrated by comparing samples 10 to 12, providing a reduction in carbon footprint of 16% (with fossil-based epoxy) to 29% (with bio-epoxy). Alternatively, while introducing the 0.75 wt.-% nanocellulose additives replacing the 10 wt.-% cellulose fibers, an increase in environmental impact parameters might occur when a fossil-based epoxy coating remains used (samples 13 and 14), and a slight decrease in environmental impact parameters occurs when also the fossil-based epoxy is replaced by a bio-based epoxy (samples 14 and 15). Based on the estimated improvement in properties and performance credit of coatings with small concentrations of 0.75 wt.-% nanocellulose [31], a more significant reduction in environmental impact can be expected within the range of 24% (sample 16) to 30% (sample 19). In parallel with the above trends on carbon footprint, the benefits in eco-cost for the different environmental impact categories are along the same lines (Figure 6b,c), with the lower eco-cost related to resource scarcity as the dominating environmental impact category, whereas the eco-costs related to health and eco-toxicity are systematically lower for the bio-based formulations.

Although additives are added in minor concentrations, it can generally be concluded that the bio-based additives may significantly reduce the carbon footprint compared to fossil-based additives, in the range of 15 to 20% (indicative) in combination with a fossil-based binder or in the range of 20 to 30% (indicative) in combination with a bio-based binder, where the selection of compositions with appropriate additive concentrations apparently compensates for the additional energy requirements in biomass processing.

4. Conclusions

After introducing bio-based binders and additives in selected coating formulations, the potential effects on carbon footprint and environmental impact parameters were demonstrated based on ab initio data collection for the different components. Depending on the data collection as illustrated, the presented approach is applicable at the low-TRL coating development stage. With assigned energy requirements for the conversion of biomass into functional additives and for selected coating formulations with concentrations of functional additives based on experimental experience, a reduction in carbon footprint in the range of 15 to 30% can potentially be obtained. However, the compositions and operational conditions with enhanced functional performance of bio-based coatings should be selected, which results in a significant performance credit.

Author Contributions

Conceptualization, P.S. and T.V.; methodology, T.V.; software, T.V.; validation, P.S.; formal analysis, P.S.; resources, P.C.; data curation, P.S.; writing—original draft preparation, P.S.; writing—review and editing, P.C. and T.V.; funding acquisition, P.C. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Flanders Innovation and Entrepreneurship (VLAIO), grant number HBC.2023.0479 (AddBio).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The dataset is available upon request from the authors.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Stichnothe, H.; Morgan, A.; Gujba, H.; Azapagic, A. Estimating the carbon footprint of paints: Some important considerations. Surf. Coat. Internat. 2011, 94, 108–114. [Google Scholar]

- Juhl, M.; Hauschild, M.Z.; Dam-Johansen, K. An eco-strategy for development of more sustainable coatings. Prog. Org. Coat. 2024, 197, 108781. [Google Scholar] [CrossRef]

- Hayeri, T. Bio-based oligomers: Progress, applications, and future perspectives. Sus. Chem. Eng. 2024, 5, 471–480. [Google Scholar]

- Marturano, V.; Marotta, A.; Salazar, S.A.; Ambrogi, V.; Cerruti, P. Recent advances in bio-based functional additives for polymers. Prog. Mater. Sci. 2023, 139, 101186. [Google Scholar] [CrossRef]

- Bishop, G.; Styles, D.; Lens, P.N.L. Environmental performance comparison of bioplastics and petrochemical plastics: A review of life cycle assessment (LCA) methodological decisions. Res. Cons. Recycl. 2021, 168, 105451. [Google Scholar] [CrossRef]

- Meisel, K.; Röver, L.; Majer, S.; Herklotz, B.; Thrän, D. A comparison of functional fillers: Greenhouse gas emissions and air pollutants from lignin-based filler, carbon black and silica. Sustainability 2022, 14, 5393. [Google Scholar] [CrossRef]

- Suarez, L.; Castellano, J.; Diaz, S.; Tcharkhtchi, A.; Ortega, Z. Are natural-based composites sustainable? Polymers 2021, 13, 2326. [Google Scholar] [CrossRef]

- Haylock, R.; Rosentrater, K.A. Cradle-to-grave life cycle assessment and techno-economic analysis of polylactic acid composites with traditional and biobased fillers. J. Polym. Environ. 2018, 26, 1484–1503. [Google Scholar] [CrossRef]

- Hahladakis, J.N.; Velis, C.A.; Weber, R.; Iacovidou, E.; Purnell, P. An overview of chemical additives present in plastics: Migration, release, fate and environmental impact during their use, disposal and recycling. J. Hazard. Mater. 2018, 344, 179–199. [Google Scholar] [CrossRef]

- Logan, H.; De Meester, S.; Damgaard, T.F.A. Additive inclusion in plastic life cycle assessments, part II: Review of additive inventory data trends and availability. J. Ind. Ecol. 2024, 28, 1554–1566. [Google Scholar] [CrossRef]

- Civancik-Uslu, D.; Ferrer, L.; Puig, R.; Fullana-i-Palmer, P. Are functional fillers improving environmental behaviour of plastics? A review on LCA studies. Sci. Total Envion. 2018, 626, 927–940. [Google Scholar] [CrossRef] [PubMed]

- Balcioglu, G.; Fitzgerald, A.M.; Rodes, F.A.M.; Allen, S.R. Data quality and uncertainty assessment of life cycle inventory data for composites. Comp. B Eng. 2025, 292, 112021. [Google Scholar] [CrossRef]

- Martinez-Rocamara, A.; Solis-Guzman, J.; Marrero, M. LCA databases focused on construction materials: A review. Renew. Sustain. Energy Rev. 2016, 58, 565–573. [Google Scholar] [CrossRef]

- Silva, E.; Fedel, M.; Deflorian, F.; Cotting, F.; Lins, V. Properties of post-consumer polyethylene terephthalate coating mechanically deposited on mild steels. Coatings 2019, 9, 28. [Google Scholar] [CrossRef]

- Richard, S.; Rajadurai, J.S.; Manikandan, V. Effects of particle loading and particle size on tribological properties of biochar particulate reinforced polymer composites. J. Tribol. 2017, 139, 012202. [Google Scholar] [CrossRef]

- Azadi, M.; Bahrololoom, M.E.; Heidari, F. Enhancing the mechanical properties of an epoxy coating with rice husk ash, a green product. J. Coat. Technol. Res. 2011, 8, 117–123. [Google Scholar] [CrossRef]

- Jimoh, O.A.; Ariffin, K.S.; Hussin, H.B.; Temitope, A.E. Synthesis of precipitated calcium carbonate: A review. Carbonates Evaporites 2018, 33, 331–346. [Google Scholar] [CrossRef]

- Hayeemasae, N.; Worlee, A.; Masa, A. Influence of calcium carbonate content on properties of natural rubber and acrylic blends for coating applications. J. Appl. Sci. Eng. 2025, 28, 411–419. [Google Scholar]

- Attharangsan, S.; Ismail, H.; Bakar, M.A.; Ismail, J. Carbon black (CB)/rice husk powder (RHP) hybrid filler-filled natural rubber composites: Effect of CB/RHP ratio on property of the composites. Polym. Plast. Technol. Eng. 2012, 51, 655–662. [Google Scholar] [CrossRef]

- Calovi, M.; Rossi, M. Impact of high concentrations of cellulose fibers on the morphology, durability and protective properties of wood paint. Coatings 2023, 13, 721. [Google Scholar] [CrossRef]

- Liang, G.; Qi, Y.; Gong, R.; Hu, Y.; Yao, F.; Liu, Y.; Liu, B.; Zhao, Y.; Dai, Y.; Dong, X.; et al. Nanocellulose-reinforced polyurethane as flexible coating for cork floor. Prog. Org. Coat. 2023, 178, 107480. [Google Scholar] [CrossRef]

- Nasri, N.S.; Ahmed, M.; Naemah, M.N.; Mohammed, J.; Hamza, U.D.; Zain, H.M. Hydrophobicity characterization of bio-wax derived from taro leaf for surface coating applications. Adv. Mater. Res. 2014, 1043, 184–188. [Google Scholar] [CrossRef]

- Martins, C.I.; Gil, V. Processing–structure–properties of cork polymer composites. Front. Mater. 2020, 7, 297. [Google Scholar] [CrossRef]

- Longo, A.; Nobre, C.; Sen, A.; Panizio, R.; Brito, P.; Goncalves, M. Torrefaction upgrading of heterogenous wastes containing cork and chlorinated polymers. Environments 2022, 9, 99. [Google Scholar] [CrossRef]

- Kargupta, W.; Seifert, R.; Martinez, M.; Olson, J.; Tanner, J.; Batchelor, W. Sustainable production process of mechanically prepared nanocellulose from hardwood and softwood: A comparative investigation of refining energy consumption at laboratory and pilot scale. Ind. Crops Prod. 2021, 171, 113868. [Google Scholar] [CrossRef]

- Jewiarz, M.; Wrobel, M.; Mudryk, K.; Szufa, S. Impact of the drying temperature and grinding technique on biomass grindability. Energies 2020, 13, 3392. [Google Scholar] [CrossRef]

- Hidalgo, P.; Salgado, L.; Ibacache, N.; Hunter, R. Influence of biochar and bio-oil loading on the properties of epoxy resin composites. Polymers 2023, 15, 1895. [Google Scholar] [CrossRef]

- Rudawska, A.; Frigione, M. Aging effects of aqueous environment on mechanical properties of calcium carbonate-modified epoxy resin. Polymers 2020, 12, 2541. [Google Scholar] [CrossRef]

- Baumgartner, G.L. Cork Composition Containing Epoxy. Resin. Patent US2904524A, 15 September 1959. [Google Scholar]

- Grötzinger, J.; Von der Brüggen, U.; Viertel, J.; Kasemi, E. Epoxy Resin Composition for Coating. Purposes. Patent US20200354604A1, 12 November 2020. [Google Scholar]

- Samyn, P.; Cosemans, P. Nanocellulose grades with different morphologies and surface modification as additives for waterborne epoxy coatings. Polymers 2024, 16, 1095. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).