On the Electrical Resistivity Measurement Methods and Properties of Conductive 3D-Printing PLA Filaments †

Abstract

1. Introduction

2. Materials and Methods

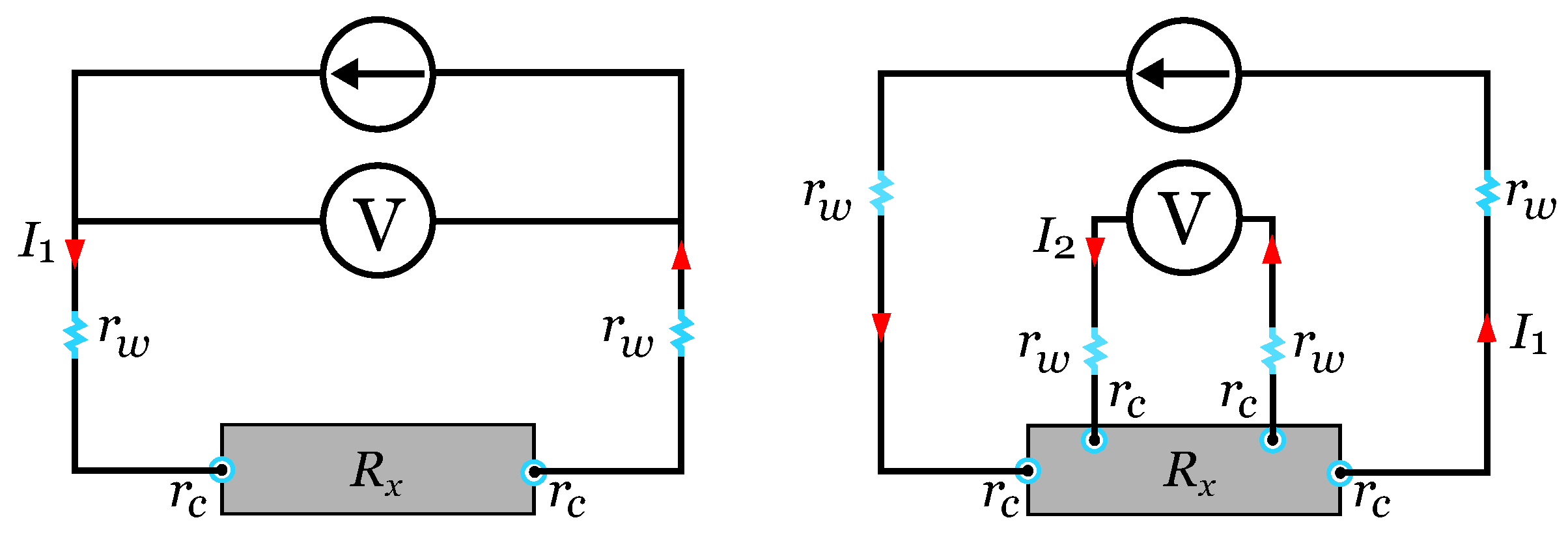

2.1. Electrical Resistivity Measurement Methods and Techniques

2.2. 3D-Printed Self-Sensing Material Specimens

2.3. Instrumentation and Experimental Apparatus

3. Results and Discussion

3.1. Research Rationale and Test Plan

3.2. Electrical Resistivity Measurement Results

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Leigh, S.J.; Bradley, R.J.; Purssell, C.P.; Billson, D.R.; Hutchins, D.A. A simple, low-cost conductive composite material for 3D printing of electronic sensors. PLoS ONE 2012, 7, e49365. [Google Scholar] [CrossRef]

- Jo, A.; Chae, H.; Kim, Y.; Kim, H.; Paek, S.; Soum, V.; Jang, W.; Ryu, S.R.; Kwon, O.S.; Shin, K. Formulation of conductive filament composited of thermoplastic with carbon black for a simple 3D printing electrical device. J. Nanosci. Nanotechnol. 2016, 16, 8415–8418. [Google Scholar] [CrossRef]

- Kwok, S.W.; Goh, K.H.H.; Tan, Z.D.; Tan, S.T.M.; Tjiu, W.W.; Soh, J.Y.; Ng, Z.J.G.; Chan, Y.Z.; Hui, H.K.; Goh, K.E.J. Electrically conductive filament for 3D-printed circuits and sensors. Appl. Mater. Today 2017, 9, 167–175. [Google Scholar] [CrossRef]

- Blyweert, P.; Nicolas, V.; Fierro, V.; Celzard, A. 3D printing of carbon-based materials: A review. Carbon 2021, 183, 449–485. [Google Scholar] [CrossRef]

- Aloqalaa, Z. Electrically conductive fused deposition modeling filaments: Current status and medical applications. Crystals 2022, 12, 1055. [Google Scholar] [CrossRef]

- Froš, D.; Králová, I. Conductive FDM filament: Electrical resistivity assessment and sensor applications. In Proceedings of the 46th International Spring Seminar on Electronics Technology (ISSE), Timisoara, Romania, 10–14 May 2023. [Google Scholar] [CrossRef]

- Massaroni, C.; Vitali, L.; Lo Presti, D.; Silvestri, S.; Schena, E. Fully Additively 3D Manufactured Conductive Deformable Sensors for Pressure Sensing. Adv. Intell. Syst. 2024, 6, 2300901. [Google Scholar] [CrossRef]

- Kumar, S.; Singh, H.; Singh, I.; Bharti, S.; Kumar, D.; Siebert, G.; Koloor, S. A comprehensive review of FDM printing in sensor applications: Advancements and future perspectives. J. Manuf. Process. 2024, 113, 152–170. [Google Scholar] [CrossRef]

- Yang, Y.; Yin, Z.; Zhu, X.; Jamal, H.A.; Lv, X.; Hu, K.; Joshi, M.; Wille, N.; Li, M.; Zhang, B.; et al. A Review of Multimaterial Additively Manufactured Electronics and 4-D Printing/Origami Shape-Memory Devices: Design, Fabrication, and Implementation. Proc. IEEE 2024, 112, 954–999. [Google Scholar] [CrossRef]

- Taya, M.; Kim, W.; Ono, K. Piezoresistivity of a short fiber/elastomer matrix composite. Mech. Mater. 1998, 28, 53–59. [Google Scholar] [CrossRef]

- Avilés, F.; Oliva-Avilés, A.I.; Cen-Puc, M. Piezoresistivity, strain, and damage self-sensing of polymer composites filled with carbon nanostructures. Adv. Eng. Mater. 2018, 20, 1701159. [Google Scholar] [CrossRef]

- Zhang, J.; Yang, B.; Fu, F.; You, F.; Dong, X.; Dai, M. Resistivity and its anisotropy characterization of 3D-printed acrylonitrile butadiene styrene copolymer (ABS)/carbon black (CB) composites. Appl. Sci. 2017, 7, 20. [Google Scholar] [CrossRef]

- Dul, S.; Fambri, L.; Pegoretti, A. Filaments production and fused deposition modelling of ABS/carbon nanotubes composites. Nanomaterials 2018, 8, 49. [Google Scholar] [CrossRef] [PubMed]

- Stankevich, S.; Sevcenko, J.; Bulderberga, O.; Dutovs, A.; Erts, D.; Piskunovs, M.; Ivanovs, V.; Ivanov, V.; Aniskevich, A. Electrical resistivity of 3D-printed polymer elements. Polymers 2023, 15, 2988. [Google Scholar] [CrossRef]

- Chung, D.D.L. A critical review of piezoresistivity and its application in electrical-resistance-based strain sensing. J. Mater. Sci. 2020, 55, 15367–15396. [Google Scholar] [CrossRef]

- Watschke, H.; Hilbig, K.; Vietor, T. Design and characterization of electrically conductive structures additively manufactured by material extrusion. Appl. Sci. 2019, 9, 779. [Google Scholar] [CrossRef]

- Chung, D.D.L. Damage detection using self-sensing concepts. Proc. Inst. Mech. Eng. Part G J. Aerosp. Eng. 2007, 221, 509–520. [Google Scholar] [CrossRef]

- Grossenbacher, A. Four-Terminal Connection Improves Measurement Accuracy; Electro Scientific Industries: Portland, OR, USA, 1983. [Google Scholar]

- Singh, Y. Electrical resistivty measurements: A review. Int. J. Mod. Phys. Conf. Ser. 2013, 22, 745–756. [Google Scholar] [CrossRef]

- Crapnell, R.D.; Kalinke, C.; Silva, L.R.G.; Stefano, J.S.; Williams, R.J.; Abarza Munoz, R.A.; Bonacin, J.A.; Janegitz, B.C.; Banks, C.E. Additive manufacturing electrochemistry: An overview of producing bespoke conductive additive manufacturing filaments. Mater. Today 2023, 71, 73–90. [Google Scholar] [CrossRef]

- Hampel, B.; Monshausen, S.; Schilling, M. Properties and applications of electrically conductive thermoplastics for additive manufacturing of sensors. TM–Tech. Mess. 2017, 84, 593–599. [Google Scholar] [CrossRef]

- Nowka, M.; Ruge, K.; Schulze, L.; Hilbig, K.; Vietor, T. Characterization of the anisotropic electrical properties of additively manufactured structures made from electrically conductive composites by material extrusion. Polymers 2024, 16, 2891. [Google Scholar] [CrossRef]

- ProtoPasta. Electrically Conductive Composite PLA. 2022. Available online: https://www.proto-pasta.com/products/conductive-pla#product_details (accessed on 18 September 2023).

- ASTM D638-14; Standard Test Method for Tensile Properties of Plastics. ASTM: West Conshohocken, PA, USA, 2014. [CrossRef]

- Keysight Technologies. Impedance Measurement Handbook: A Guide to Measurement Technology and Techniques, 6th ed.; Keysight Technologies: Santa Rosa, CA, USA, 2020. [Google Scholar]

- Arh, M.; Slavič, J.; Boltežar, M. Experimental identification of the dynamic piezoresistivity of fused-filament-fabricated structures. Addit. Manuf. 2020, 36, 101493. [Google Scholar] [CrossRef]

| /mm | /mm | /mm | /mm2 | |

|---|---|---|---|---|

| Silver paint and silver paste | 20.0 | 5.85 | 3.77 | 22.05 |

| Crocodile clips | 20.2 | 6.10 | 3.92 | 23.91 |

| Inlaid during printing | 26.2 | 6.10 | 3.92 | 23.91 |

| Four-Probe (Multimeter) | Two-Probe (Multimeter) | Four-Probe 1 (NI DAQ System) | ||||

|---|---|---|---|---|---|---|

| Electrical Connection Variant | cm | cm | cm | |||

| (a) Silver paint & silver paste | 148.20 | 16.38 | 151.93 | 16.79 | 150.47 | 16.59 |

| (b) Crocodile clips | 140.11 | 16.58 | 447.43 | 52.92 | 142.73 | 16.89 |

| (c) Inlaid during printing | 169.70 | 15.36 | 729.00 | 62.37 | 171.70 | 15.55 |

| Four-Probe (NI DAQ System) | ||||||||

|---|---|---|---|---|---|---|---|---|

| 5.40 mA | 10.03 mA | 15.04 mA | 19.97 mA | |||||

| Electrical Connection Variant | cm | cm | cm | cm | ||||

| (a) Silver paint and silver paste | 148.15 | 16.34 | 148.11 | 16.33 | 152.88 | 16.86 | 152.75 | 16.84 |

| (b) Crocodile clips | 140.56 | 16.63 | 140.37 | 16.61 | 144.24 | 17.07 | 145.74 | 17.24 |

| (c) Inlaid during printing | 169.59 | 15.35 | 169.41 | 15.34 | 173.49 | 15.71 | 174.29 | 15.78 |

| Electrical Connection Variant | |

|---|---|

| (a) Silver paint and silver paste | 3.73 |

| (b) Crocodile clips | 304.6 |

| (c) Inlaid during printing | 559.3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vasques, C.M.A.; Ferreira, J.P.R.; Figueiredo, F.A.V.; Abrantes, J.C.C. On the Electrical Resistivity Measurement Methods and Properties of Conductive 3D-Printing PLA Filaments. Eng. Proc. 2025, 87, 26. https://doi.org/10.3390/engproc2025087026

Vasques CMA, Ferreira JPR, Figueiredo FAV, Abrantes JCC. On the Electrical Resistivity Measurement Methods and Properties of Conductive 3D-Printing PLA Filaments. Engineering Proceedings. 2025; 87(1):26. https://doi.org/10.3390/engproc2025087026

Chicago/Turabian StyleVasques, César M. A., João P. R. Ferreira, Fernando A. V. Figueiredo, and João C. C. Abrantes. 2025. "On the Electrical Resistivity Measurement Methods and Properties of Conductive 3D-Printing PLA Filaments" Engineering Proceedings 87, no. 1: 26. https://doi.org/10.3390/engproc2025087026

APA StyleVasques, C. M. A., Ferreira, J. P. R., Figueiredo, F. A. V., & Abrantes, J. C. C. (2025). On the Electrical Resistivity Measurement Methods and Properties of Conductive 3D-Printing PLA Filaments. Engineering Proceedings, 87(1), 26. https://doi.org/10.3390/engproc2025087026