Fuzzy Logic-Based Sprinkler Controller for a Precision Irrigation System: A Case Study of Semi-Arid Regions in India †

Abstract

1. Introduction

- calculate an accurate crop water demand

- successfully use advanced and low-cost technology to maximize the yields

- precise irrigation control to make appropriate management decisions

- Conventional irrigation control systems predominantly operate through a wired framework, employing serial bus and field bus technology, rendering system installation and maintenance uncomplicated [15].

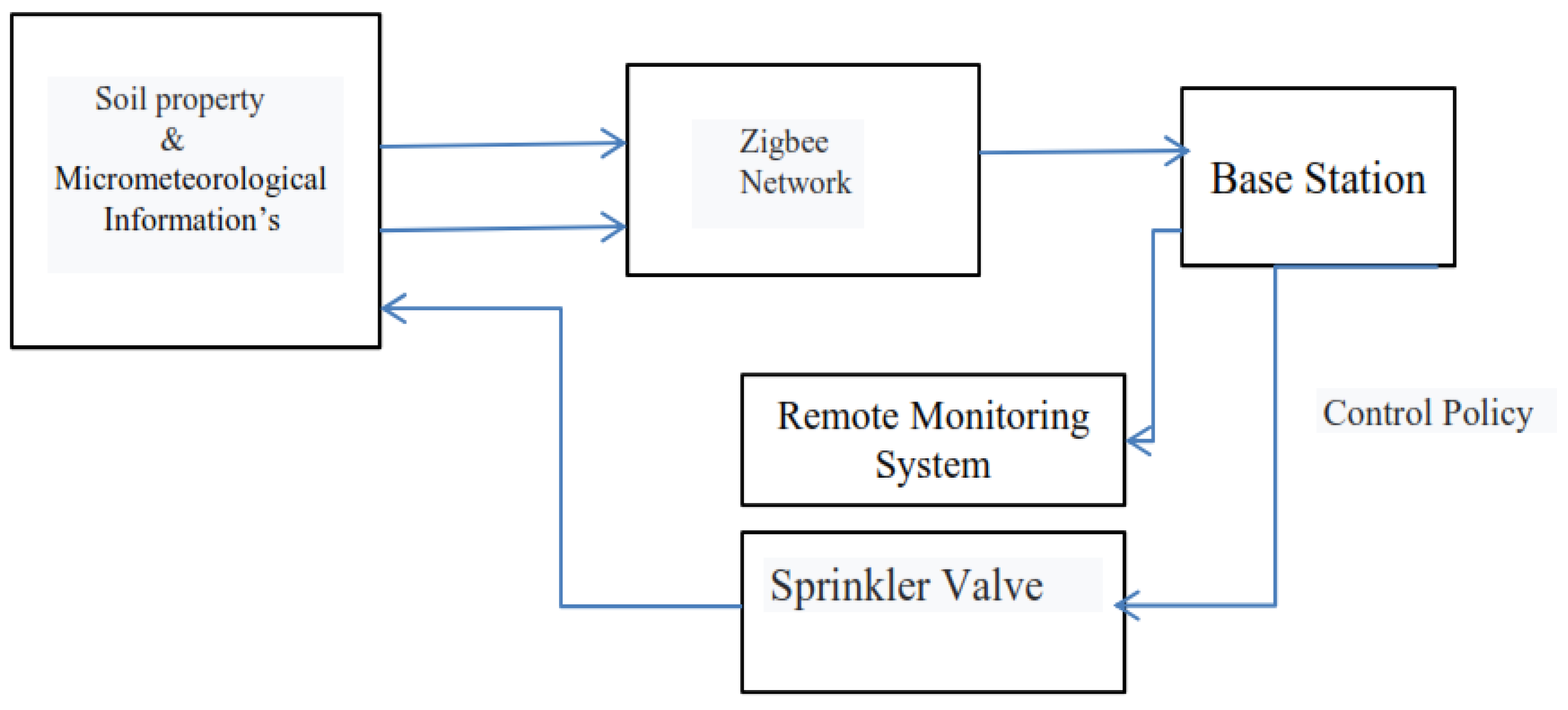

- Precise irrigation, a sophisticated system, is intricately influenced by multi-sensor information derived from soil, crops, and the environment. Presently, a deficiency exists in terms of suitable control strategies. Freshly, significant strides have been made for wireless sensor networks and fuzzy control technology in precision irrigation system research. This development lays a robust foundation for innovative ideas and promising applications in precision-based irrigation. Notably, wireless transmission utilizing ZigBee technology in sensor networks exhibits characteristics such as low power consumption, cost-effectiveness, expansive network range and capacity, simplicity, and flexibility in the network structure. Its emphasis on low-speed transmission renders it particularly well suited for precision irrigation applications, garnering interest from scholars both domestically and internationally in areas that fall under semi-arid regions [16].

2. Proposed Model

2.1. Overall System Design

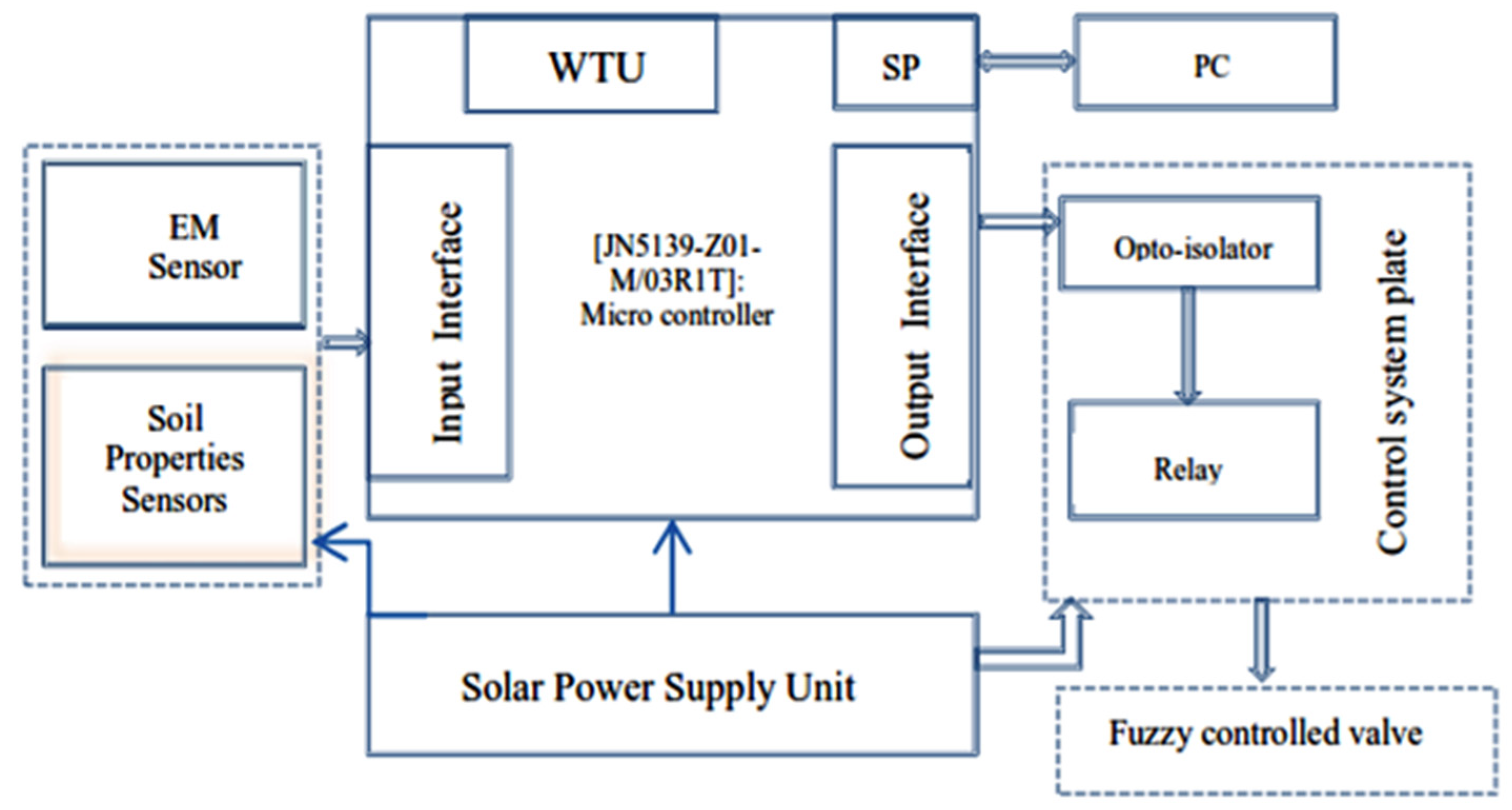

2.2. Wireless Sensor Network Node Design

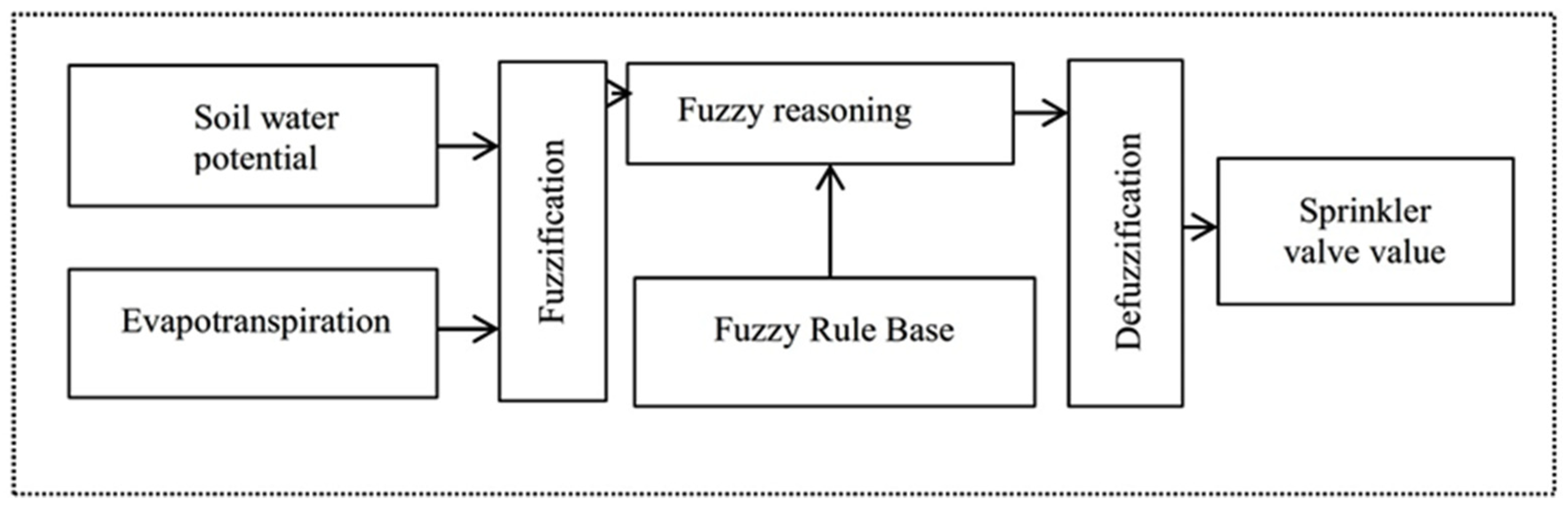

3. Fuzzy Controller Design

3.1. Obtaining Input Quantities

3.2. Fuzzy Control Strategy

- (1)

- Fuzzification: Convert the precise value of the input variable into an appropriate domain of discourse fuzzy language variable valuthat is, determine the variation range of each input and output quantity and its domain of iscourse on fuzzy linguistic variables. For example, the farmland evapotranspiration cg/h, he change range is [0, +1], and its domain of discussion is selected X = {0, 0.23, 0.46, 0.69, 0.92}. Figure 6, shows the overall structure of fuzzy controller.

- (2)

- Fuzzy inference: Based on the knowledge base and through a certain inference engine system, the process of obtaining fuzzy output value from input value. For the inference rules, summarize based on experience andhave the rules expressed in an “ifthen” statement. According to experience, when the soil water potential is lower than the lower limit, the soil is water-deficient. At this time, regardless of the level of farmland evapotranspiration, crops require a large amount of irrigation. It is a fuzzy inference rule: “if WP is VL, then WT is VH”. The fuzzy inference rule base is in Table 1. In practical applications, it is also necessary that the rules are adjusted according to different situations and the optimal irrigation plan is gradually formed.

- (3)

- De-fuzzy: Multiply the results obtained by fuzzy inference by the scaling factor. Obtain the precise output value of the control quantity required by the system. This system adopts the quality method used to de-fuzzify and obtain the opening time of the sprinkler’s irrigation head control valve. The fuzzy controller is design using the LabVIEW 2021 SP1 software toolkit.

4. System Application and Verification

5. Conclusions and Discussion

- We propose to combine the ZigBee wireless sensor network with fuzzy control. We designed a method suitable for precision irrigation, and a corresponding system was adopted. By collecting and analyzing the soil water potential and farmland evapotranspiration in crop planting areas, we accurately obtained the crop water requirements and realized automatic positioning and real-time and appropriate irrigation. The system is economical and practical, especially suitable for small- and medium-sized irrigation areas and pass-tested for drip irrigation in Panwari Block, Mahoba District, Uttar Pradesh. Preliminary trials on farms have shown that the system has reliable communication and high control accuracy and is in good running condition.

- We propose the corresponding wireless sensor network node design method and verify it proves the feasibility of the ZigBee wireless sensor network for remote irrigation control.

- We designed an information collection method for accurately determining crop water requirements. This case established a model based on the Priestley and Taylor formula and fuzzy number multi-sensor data fusion method, which comprehensively considers soil water potential, ambient temperature, humidity, solar radiation, and wind speed related to farmland evapotranspiration. The influence of other factors improved the accuracy of decision-making.

- The wireless sensor network designed in this article adopted a star network topology structure, requiring each node to receive data so that the node transmit power was consistent with the high energy consumption, and the new network topology and networking will be further studied in the future.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Umam, F.; Dafid, A.; Cahyani, A.D. Implementation of Fuzzy Logic Control Method on Chilli Cultivation Technology Based Smart Drip Irrigation System. J. Ilm. Tek. Elektro Komput. Inform. 2023, 9, 132–141. [Google Scholar]

- Ibrahim, M.F.; Elbar, O.H.; Farag, R.; Hikal, M.; El-Kelish, A.; El-Yazied, A.A.; Alkahtani, J.; El-Gawad, H.G. Melatonin counteracts drought induced oxidative damage and stimulates growth, productivity and fruit quality properties of tomato plants. Plants 2020, 9, 1276. [Google Scholar] [CrossRef] [PubMed]

- Tayyab, N.; Naz, R.; Yasmin, H.; Nosheen, A.; Keyani, R.; Sajjad, M.; Hassan, M.N.; Roberts, T.H. Combined seed and foliar pre-treatments with exogenous methyl jasmonate and salicylic acid mitigate drought-induced stress in maize. PLoS ONE 2020, 15, e0232269. [Google Scholar] [CrossRef] [PubMed]

- Devi, M.J.; Reddy, V.R.; Timlin, D. Drought-Induced Responses in Maize under Different Vapor Pressure Deficit Conditions. Plants 2022, 11, 2771. [Google Scholar] [CrossRef]

- Selim, M.M. Introduction to the integrated nutrient management strategies and their contribution to yield and soil properties. Int. J. Agron. 2020, 2020, 2821678. [Google Scholar]

- Owolabi, T.A.; Mohandes, S.R.; Zayed, T. Investigating the impact of sewer overflow on the environment: A comprehensive literature review paper. J. Environ. Manag. 2022, 301, 113810. [Google Scholar]

- Abioye, E.A.; Abidin, M.S.Z.; Mahmud, M.S.A.; Buyamin, S.; Ishak, M.H.I.; Rahman, M.K.I.A.; Otuoze, A.O.; Onotu, P. A review on monitoring and advanced control strategies for precision irrigation. Comput. Electron. Agric. 2020, 173, 105441. [Google Scholar] [CrossRef]

- Bellvert, J.; Mata, M.; Vallverdú, X.; Paris, C.; Marsal, J. Optimizing precision irrigation of a vineyard to improve water use efficiency and profitability by using a decision-oriented vine water consumption model. Precis. Agric. 2021, 22, 319–341. [Google Scholar] [CrossRef]

- Prasad, R.; Tiwari, R.; Srivastava, A.K. IoT-Based Fuzzy Logic Controller for Smart Soil Health Monitoring: A Case Study of Semi-Arid Region of India. In Proceedings of the 10th International Electronic Conference on Sensors and Applications (ECSA-10), Online, 15–30 November 2023; Volume 15. [Google Scholar]

- Prasad, R.; Shukla, P.K. Weather Forecasting using Machine Learning for Smart Farming. In Future Farming: Advancing Agriculture with Artificial Intelligence; Bentham Science: Sharjah, United Arab Emirates, 2023; Volume 1, pp. 97–113. [Google Scholar]

- Jamroen, C.; Komkum, P.; Fongkerd, C.; Krongpha, W. An intelligent irrigation scheduling system using low-cost wireless sensor network toward sustainable and precision agriculture. IEEE Access 2020, 8, 172756–172769. [Google Scholar]

- Khriji, S.; El Houssaini, D.; Kammoun, I.; Kanoun, O. Precision irrigation: An IoT-enabled wireless sensor network for smart irrigation systems. In Women in Precision Agriculture: Technological Breakthroughs, Challenges and Aspirations for a Prosperous and Sustainable Future; Springer: Cham, Switzerland, 2021; pp. 107–129. [Google Scholar]

- Sanjeevi, P.; Prasanna, S.; Kumar, B.S.; Gunasekaran, G.; Alagiri, I.; Anand, R.V. Precision agriculture and farming using Internet of Things based on wireless sensor network. Trans. Emerg. Telecommun. Technol. 2020, 31, e3978. [Google Scholar]

- Lloret, J.; Sendra, S.; Garcia, L.; Jimenez, J.M. A wireless sensor network deployment for soil moisture monitoring in precision agriculture. Sensors 2021, 21, 7243. [Google Scholar] [CrossRef]

- Santra, P. Performance evaluation of solar PV pumping system for providing irrigation through micro-irrigation techniques using surface water resources in hot arid region of India. Agric. Water Manag. 2021, 245, 106554. [Google Scholar]

- Routis, G.; Roussaki, I. Low Power IoT Electronics in Precision Irrigation. Smart Agric. Technol. 2023, 5, 100310. [Google Scholar]

- Wang, Z. Greenhouse data acquisition system based on ZigBee wireless sensor network to promote the development of agricultural economy. Environ. Technol. Innov. 2021, 24, 101689. [Google Scholar]

- Prasad, R.; Shukla, P.K. A Review on the Hybridization of Fuzzy Systems and Machine Learning Techniques. In Computer Vision and Robotics; Algorithms for Intelligent Systems; Bansal, J.C., Engelbrecht, A., Shukla, P.K., Eds.; Springer: Singapore, 2022. [Google Scholar] [CrossRef]

- Anitha, N.; Priya, R.D.; Baskar, C.; Jaikaran, D. Design of prescriptive model using nano-enabled sensors for water treatment and precise drip irrigation. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1055, 012068. [Google Scholar]

- Xie, J.; Chen, Y.; Gao, P.; Sun, D.; Xue, X.; Yin, D.; Han, Y.; Wang, W. Smart fuzzy irrigation system for litchi orchards. Comput. Electron. Agric. 2022, 201, 107287. [Google Scholar]

- Elsherbiny, O.; Zhou, L.; Feng, L.; Qiu, Z. Integration of visible and thermal imagery with an artificial neural network approach for robust forecasting of canopy water content in rice. Remote Sens. 2021, 13, 1785. [Google Scholar] [CrossRef]

- Ramya, C.M.; Shanmugaraj, M.; Prabakaran, R. Study on ZigBee technology. In Proceedings of the 2011 3rd International Conference on Electronics Computer Technology, Kanyakumari, India, 8–10 April 2011; Volume 6. [Google Scholar]

- Somani, N.A.; Patel, Y. Zigbee: A low power wireless technology for industrial applications. Int. J. Control Theory Comput. Model. (IJCTCM) 2012, 2, 27–33. [Google Scholar]

- Jeffrey, T.; Kring, J. LabVIEW for Everyone: Graphical Programming Made Easy and Fun; Prentice Hall: Hoboken, NJ, USA, 2006. [Google Scholar]

- Visan, D.A.; Lita, I.; Jurian, M.; Cioc, I.B. Wireless measurement system based on ZigBee transmission technology. In Proceedings of the 33rd International Spring Seminar on Electronics Technology, ISSE 2010, Warsaw, Poland, 12–16 May 2010. [Google Scholar]

- Zhang, Q.; Yang, X.-L.; Zhou, Y.-M.; Wang, L.-R.; Guo, X.-S. A wireless solution for greenhouse monitoring and control system based on ZigBee technology. J. Zhejiang Univ. Sci. A 2007, 8, 1584–1587. [Google Scholar]

- Stewart, R.B.; Rouse, W.R. Substantiation of the Priestley and Taylor parameter α = 1.26 for potential evaporation in high latitudes. J. Appl. Meteorol. Climatol. 1977, 16, 649–650. [Google Scholar]

- Flint, A.L.; Childs, S.W. Use of the Priestley-Taylor evaporation equation for soil water limited conditions in a small forest clearcut. Agric. For. Meteorol. 1991, 56, 247–260. [Google Scholar]

- Zadeh, L.A. Is there a need for fuzzy logic? Inf. Sci. 2008, 178, 2751–2779. [Google Scholar]

- Prasad, R.; Shukla, P.K. Indeterminacy Handling of Adaptive Neuro-fuzzy Inference System Using Neutrosophic Set Theory: A Case Study for the Classification of Diabetes Mellitus. Int. J. Intell. Syst. Appl. (IJISA) 2023, 15, 1–15. [Google Scholar] [CrossRef]

- Prasad, R.; Shukla, P.K. Interpretable Fuzzy System for Early Detection Autism Spectrum Disorder. Int. J. Intell. Syst. Appl. (IJISA) 2023, 15, 26–36. [Google Scholar] [CrossRef]

- Prasad, R.; Shukla, P.K. Identification of Ischemic Stroke Origin Using Machine Learning Techniques. In Advances in Data-driven Computing and Intelligent Systems; Lecture Notes in Networks and Systems; Das, S., Saha, S., Coello Coello, C.A., Bansal, J.C., Eds.; Springer: Singapore, 2023; Volume 653. [Google Scholar] [CrossRef]

- Prasad, R.; Shukla, P.K. Interpretable Fuzzy System for Malicious Domain Classification Using Projection Neural Network. Int. J. Wirel. Microw. Technol. (IJWMT) 2023, 13, 1–14. [Google Scholar] [CrossRef]

| Evapotranspiration | Soil Water Potential (WP) Title 3 | ||||

|---|---|---|---|---|---|

| VL | L | M | H | VH | |

| VL | VH | H | M | L | VL |

| L | VH | H | M | L | VL |

| M | VH | H | M | L | VL |

| H | VH | H | M | L | VL |

| VH | VH | VH | H | M | L |

| # | Temp | Humidity | Atom-Presser | Wind Speed | Valve Open in % |

|---|---|---|---|---|---|

| 1 | 37.26 | 9 | 985 | 4.62 | 60 |

| 2 | 31.87 | 13 | 987 | 1.23 | 50 |

| 3 | 29.95 | 15 | 988 | 2.05 | 45 |

| 4 | 27.91 | 19 | 987 | 1.68 | 40 |

| 5 | 26.28 | 22 | 988 | 0.65 | 46 |

| 6 | 32.7 | 16 | 990 | 0.17 | 47 |

| 7 | 39.18 | 10 | 990 | 1.22 | 46 |

| 8 | 40.28 | 8 | 986 | 4.87 | 73 |

| 9 | 39.06 | 9 | 984 | 3.73 | 70 |

| 10 | 33.5 | 13 | 986 | 1.12 | 72 |

| 11 | 43.27 | 14 | 986 | 1.68 | 65 |

| 12 | 42.43 | 16 | 984 | 3.48 | 52 |

| 13 | 43.34 | 17 | 985 | 2.67 | 54 |

| 14 | 43.23 | 12 | 987 | 2.34 | 67 |

| 15 | 44.65 | 8 | 987 | 3.51 | 69 |

| 16 | 41.65 | 7 | 983 | 5.11 | 73 |

| 17 | 43.13 | 7 | 982 | 4.14 | 75 |

| 18 | 42.03 | 11 | 983 | 2.38 | 62 |

| 19 | 41.71 | 14 | 984 | 2.47 | 58 |

| 20 | 43.95 | 18 | 983 | 2.72 | 63 |

| 21 | 34.99 | 21 | 983 | 2.09 | 56 |

| 22 | 35.12 | 14 | 986 | 2.29 | 51 |

| 23 | 35.59 | 9 | 985 | 5.44 | 48 |

| 24 | 34.96 | 7 | 982 | 5.26 | 57 |

| 25 | 36.29 | 8 | 980 | 4.06 | 68 |

| 26 | 35.41 | 11 | 982 | 2.3 | 62 |

| 27 | 33.51 | 13 | 983 | 2.99 | 61 |

| 28 | 31.46 | 14 | 982 | 2.42 | 53 |

| 29 | 32.08 | 16 | 983 | 1.87 | 58 |

| 30 | 35.83 | 56 | 985 | 2.25 | 45 |

| 31 | 32.07 | 68 | 985 | 4.53 | 43 |

| 32 | 33.37 | 58 | 982 | 4.72 | 30 |

| 33 | 31.69 | 70 | 980 | 4.55 | 45 |

| 34 | 35.66 | 78 | 983 | 1.69 | 35 |

| 35 | 33.37 | 93 | 984 | 2.4 | 24 |

| 36 | 31.74 | 96 | 983 | 0.91 | 20 |

| 37 | 31.54 | 98 | 984 | 1.42 | 17 |

| 38 | 33.99 | 94 | 986 | 1.47 | 19 |

| 39 | 34.41 | 97 | 985 | 3.19 | 18 |

| 40 | 33.56 | 93 | 982 | 4.66 | 20 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Prasad, R.; Srivastava, A.K.; Tiwari, R. Fuzzy Logic-Based Sprinkler Controller for a Precision Irrigation System: A Case Study of Semi-Arid Regions in India. Eng. Proc. 2024, 82, 103. https://doi.org/10.3390/ecsa-11-20504

Prasad R, Srivastava AK, Tiwari R. Fuzzy Logic-Based Sprinkler Controller for a Precision Irrigation System: A Case Study of Semi-Arid Regions in India. Engineering Proceedings. 2024; 82(1):103. https://doi.org/10.3390/ecsa-11-20504

Chicago/Turabian StylePrasad, Rajan, Adesh Kumar Srivastava, and Rajinder Tiwari. 2024. "Fuzzy Logic-Based Sprinkler Controller for a Precision Irrigation System: A Case Study of Semi-Arid Regions in India" Engineering Proceedings 82, no. 1: 103. https://doi.org/10.3390/ecsa-11-20504

APA StylePrasad, R., Srivastava, A. K., & Tiwari, R. (2024). Fuzzy Logic-Based Sprinkler Controller for a Precision Irrigation System: A Case Study of Semi-Arid Regions in India. Engineering Proceedings, 82(1), 103. https://doi.org/10.3390/ecsa-11-20504