Abstract

The increasing interest in metamaterials stems from the ability to expand the design space for material properties by tailoring the material architecture. Spinodal decomposition-inspired topologies are an emerging class of minimal surface-based metamaterials with promising properties. The diffusion process of the binary mixture is modeled using the Cahn–Hilliard equation, which is typically approached with a statistical method (superimposition of Gaussian random fields) that is well founded only for its initial stages. In this work, a fast and efficient computational method based on the finite difference method is employed to simulate the entire 2D dynamic evolution. Next, the solution field is converted into a CAD model forming the metamaterial. The elastic properties are assessed using a computational homogenization in which both homogeneous displacement and periodic boundary conditions have been applied for comparison. Finally, results from experimental testing confirm the accuracy of the FE homogenization procedure developed here.

1. Introduction

Over the past two decades, the research and development of metamaterials have been fostered by advancements in additive manufacturing [1]. The mechanical properties of these materials, different from traditional materials, are mostly determined by their geometry rather than their chemical composition or thermomechanical treatments [2,3,4]. This convenient feature allows us to design materials with unique properties such as negative Poisson’s ratio, vanishing shear modulus, and negative thermal expansion, making them appropriate for a broad range of applications [5,6,7].

Mechanical metamaterials are commonly classified into beam-based, plate-based, and minimal surface-based structures, each offering distinct advantages [8]. The latter has been emerging as a promising alternative to the first two options since they suffer from stress concentrations at the junctions of their structural elements, leading to decreased strength and structural premature failure [9,10,11]. Shell-based topologies, due to their bicontinuous and smoothly curved architecture, do not experience this issue [12,13,14]. Furthermore, these thin structures also when undergo biaxial bending keep a beneficial stretching-dominant behavior [15], which brings advantages to the overall stiffness of the structure. Despite their undeniable advantages, the performance of shell metamaterials heavily depends on their symmetry and periodicity, making them significantly sensitive to imperfections [16,17], for instance, the surface roughness attributable to the 3D printing process.

Spinodal metamaterials are non-periodic, leading to a mitigation of the issues related to manufacturing inaccuracies and an enlargement of the design space to achieve anisotropic mechanical properties [18,19,20,21,22]. Moreover, these structures have demonstrated superior stiffness-to-density scaling compared to traditional truss and plate-based configurations, resulting in a desirable stretching-dominated behavior [22]. The primary challenge in generating a spinodal metamaterial is solving the equation modeling the spinodal transformation, namely the Cahn–Hilliard equation [23,24], which is deemed computationally challenging by many researchers [20,21]. Consequently, it is generally approached with a statistical approach employing Gaussian random fields (GRF) [25], which lead to an exact result only in the first instants of the simulation. Another common approach is the finite difference method (FDM) [22,26], which is adopted in this work in an efficient and fast way. The key innovation of our approach lies in utilizing a convolution-based method to compute the double Laplacian operator, which significantly reduces computational costs.

Finally, the elastic properties of the designed metamaterials are obtained through numerical homogenization, imposing both homogeneous displacement and periodic boundary conditions for comparison. These results are then validated through experimental testing.

2. Methodology

In this section, the methodology employed in this study is outlined. First, the mathematical modeling to solve the Cahn–Hilliard equation is briefly delineated (Section 2.1). Next, the computational homogenization procedure using FEM is described (Section 2.2), and to conclude, the experimental testing setup is illustrated (Section 2.3).

2.1. Mathematical Modeling: Cahn–Hilliard Equation

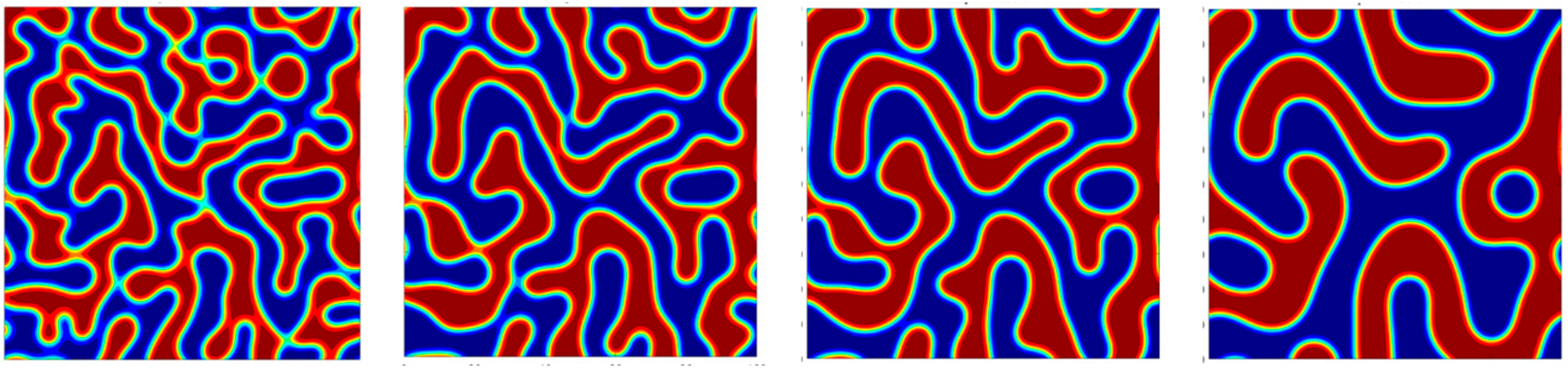

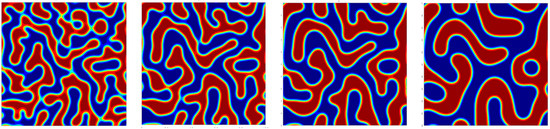

The spinodal decomposition is a diffusional process involving the separation of a homogeneous mixture into two coexisting phases (Figure 1) while maintaining their initial volume fractions (50–50%).

Figure 1.

Example of spinodal decomposition evolution from t = 50 s to t = 400 s.

The mathematical model underlying this phenomenon is the Cahn–Hilliard equation [23,24,27,28], which is generally regarded as computationally demanding due to its nonlinearity. In this paragraph, the model and the numerical algorithm used to approach it are briefly summarized for context, with full details provided in [29].

Typically, the equations governing the above-mentioned phenomenon are the following:

where is the chemical potential, is the interphasic thickness interface, is a dimensionless energy parameter, is the dimensionless concentration, and D is the diffusion (mobility) coefficient. In this form, the model involves three parameters, i.e., , , and D.

As for the boundary conditions, the same concentration has been imposed on the opposite faces of the cubic domain, i.e., periodic boundary conditions have been applied. These conditions are essential for assembling the obtained unit cell with others of the same type later in order to construct the metamaterial structure. Additionally, as the initial condition, an equal random distribution of the two phases (i.e., same volume fraction) has been considered.

Aiming at reducing the number of parameters, making the design and the subsequent optimization more straightforward, in our approach, Equation (1) has been made dimensionless and, consequently, the number of parameters has been reduced to only two. Equation (1) can be reviewed as follows:

where , , and are the dimensionless time, space, and chemical potential, respectively, whilst and are the newly introduced dimensionless independent parameters.

Equation (2) must be solved with a numerical approach, specifically the finite difference method (FDM). In [20,21], an approximated method based on Gaussian random fields is commonly employed to address the complexity of Equation (2), though it tends to lose accuracy over time. To provide an overview of our method [29], here are the key points: the time derivative is handled with an explicit forward Euler scheme, while the Laplacian operator is computed using a 9-point stencil [30].

2.2. Computational Homogenization

Mechanical properties of the designed metamaterial have been evaluated through computational homogenization, where they are obtained as the averaged properties within the representative volume element (RVE). This method involves the formulation of a localization problem to establish a relationship between the stress or strain at the macroscopic (homogeneous material) and the microscopic scale (heterogeneous material) [31]. The accuracy of the results obtained through this approach largely depends on the proper definition of the boundary conditions applied to the RVE. Commonly, three types of boundary conditions can be imposed: homogeneous displacement boundary conditions (DBCs), homogeneous traction boundary conditions (TBCs), and periodic boundary conditions (PBCs) [32,33]. Below, they are briefly summarized, highlighting their advantages and disadvantages to guide the selection of the most appropriate boundary conditions when dealing with complex RVE topologies.

The first type of boundary condition involves the imposition of a uniform displacement on the boundary of the RVE, representing a strain-controlled approach. In the literature, it is well known that these boundary conditions tend to overestimate the actual material properties [32,33,34] and lead to a non-equilibrated solution. These findings have been verified by comparing the FE homogenization results using DBCs with those published in [35,36], which have been assumed as a benchmark.

The second type is prescribed by enforcing a uniform traction over the RVE boundaries. Typically, these boundary conditions underestimate the material’s effective properties and culminate in an equilibrated solution but not compatible. In the current study, this case has been excluded due to the unacceptable mismatch with the benchmark results.

The former strategy addresses the issues mentioned above providing both an equilibrated and compatible solution to the localization problem of the RVE. Periodic boundary conditions require that opposite boundaries of the RVE exhibit the same deformation profile. While these conditions are regarded as the most accurate to assess the effective material properties, they are more complex to apply in a FE model compared to other methods. In fact, imposing the same displacement field on the corresponding boundaries of the RVE implies that each node on one side has its counterpart on the opposite one. In the case here proposed, the mesh conformity is completely ensured by the periodicity of the concentration imposed in Equation (2): by imposing a periodic concentration, since the metamaterial structure is derived from the solution field, the structure itself will also be periodic. In cases where the mesh is not perfectly periodic, several approaches are suggested in the literature, including polynomial interpolation [37] and the master–slave technique [38].

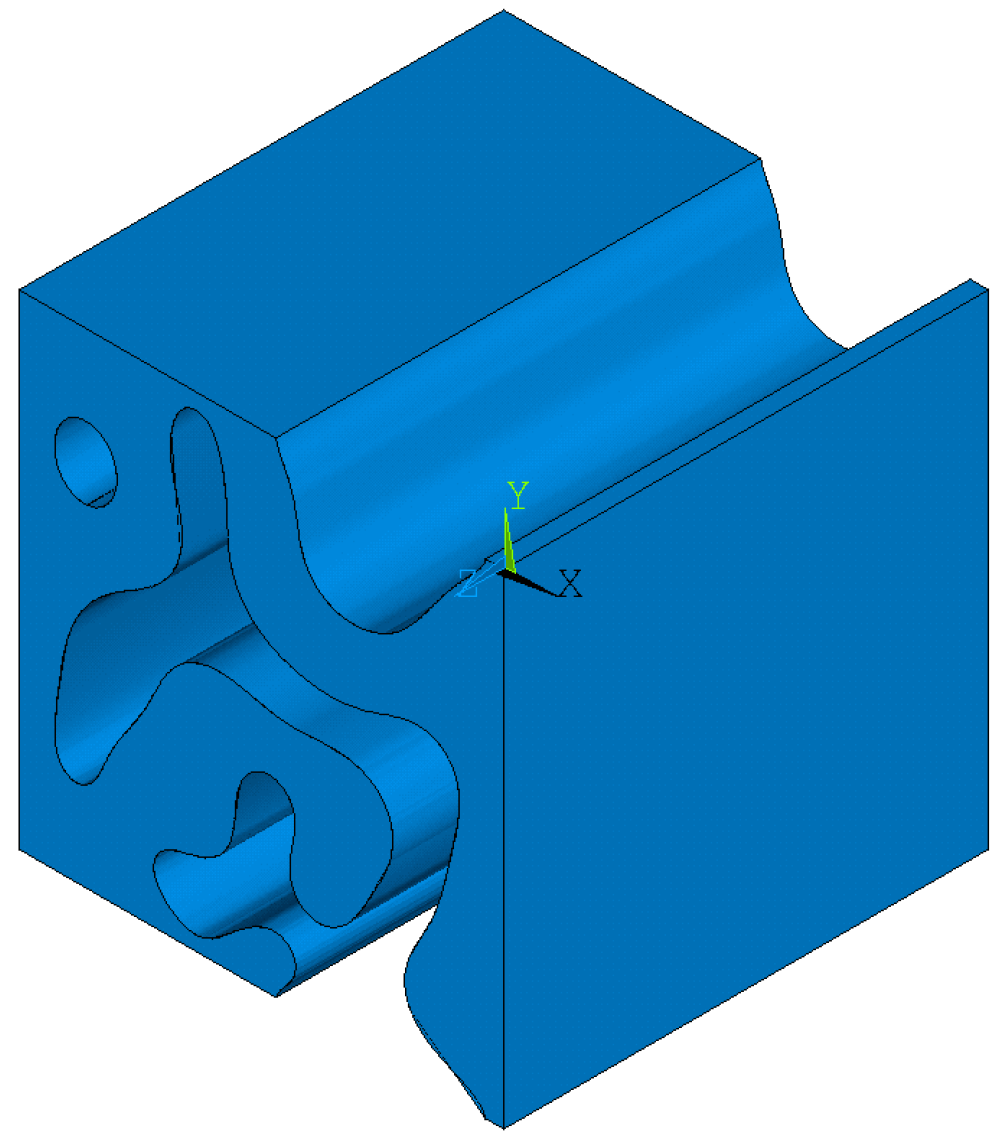

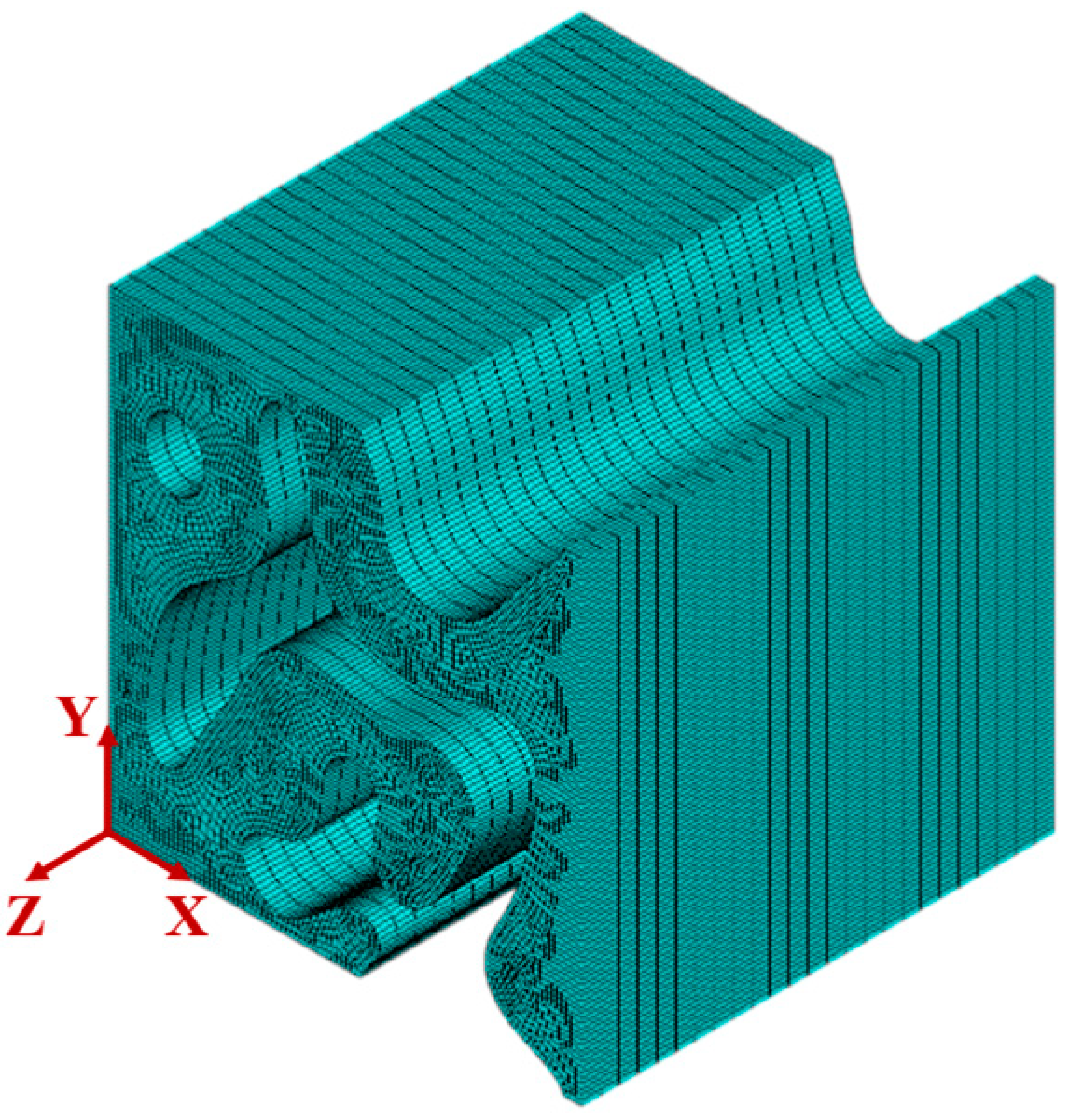

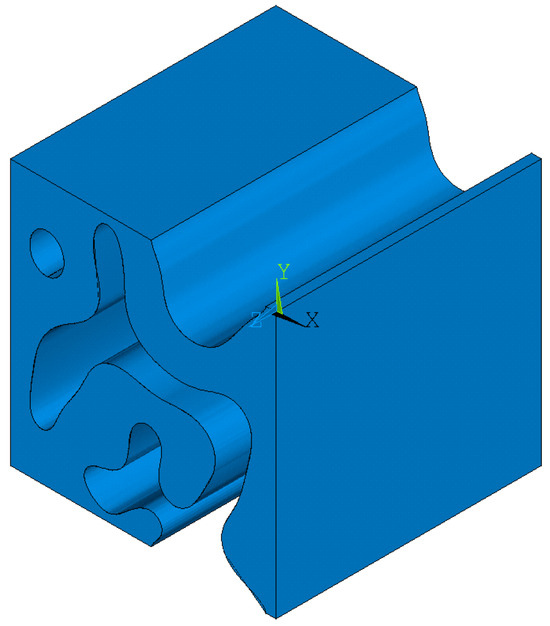

To validate the homogenization algorithm, out of all the possible samples generated by varying and , the structure corresponding to = 1.45 and = 650 has been selected as RVE (Figure 2). This sample has been obtained by extruding along the Z direction the area derived from the solution field. As stated above, homogenized mechanical properties have been calculated by imposing DBCs and PBCs on the boundary of the cell. To enforce the PBCs multi-point constraints have been used on the homologous sides of the structure. The results from these methods have been compared with experimental testing to determine which provides more accurate outcomes.

Figure 2.

RVE resulting from α = 1.45 and β = 650.

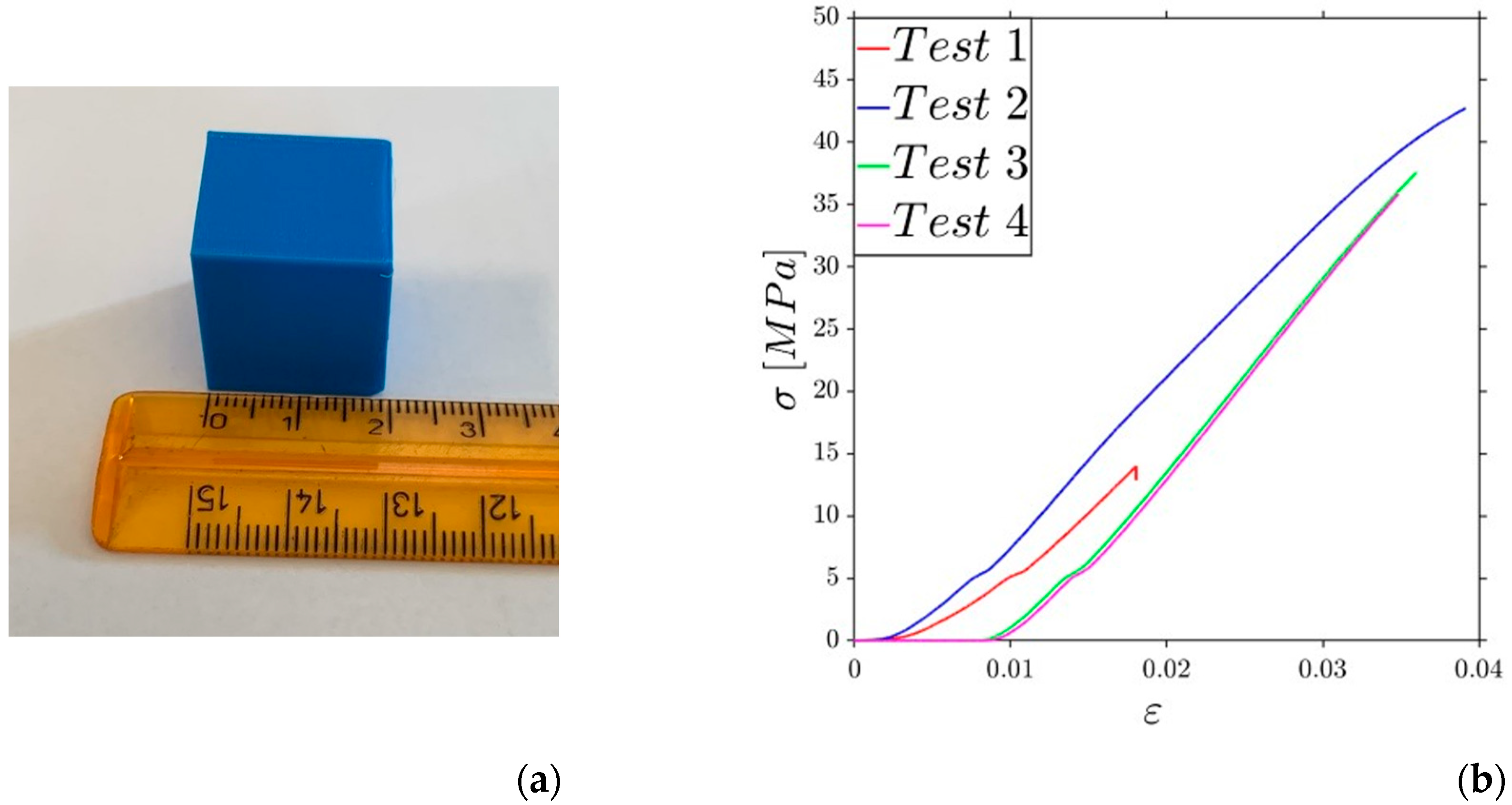

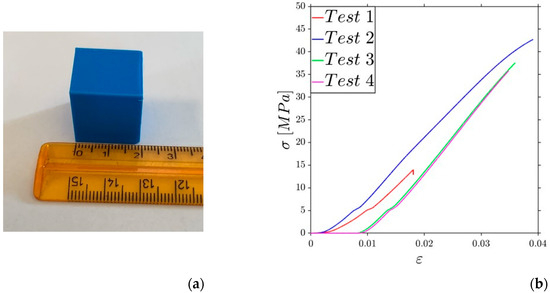

2.3. Experimental Testing

In order to assess the accuracy of the results arising from the FE simulations, static flat compression tests have been conducted in a compression machine equipped with a pair of compression plates. Prior to examining the mechanical response of the metamaterial sample, the printing material (PLA) has been characterized. For this purpose, a compression test has been performed on a cube with a volume of 8 cm3 (Figure 3a). According to the stress–strain curve resulting from this testing (Figure 3b), Young’s modulus of PLA is equal to 1.57 GPa.

Figure 3.

PLA characterization: (a) cubic sample; (b) experimental stress–strain curve of PLA.

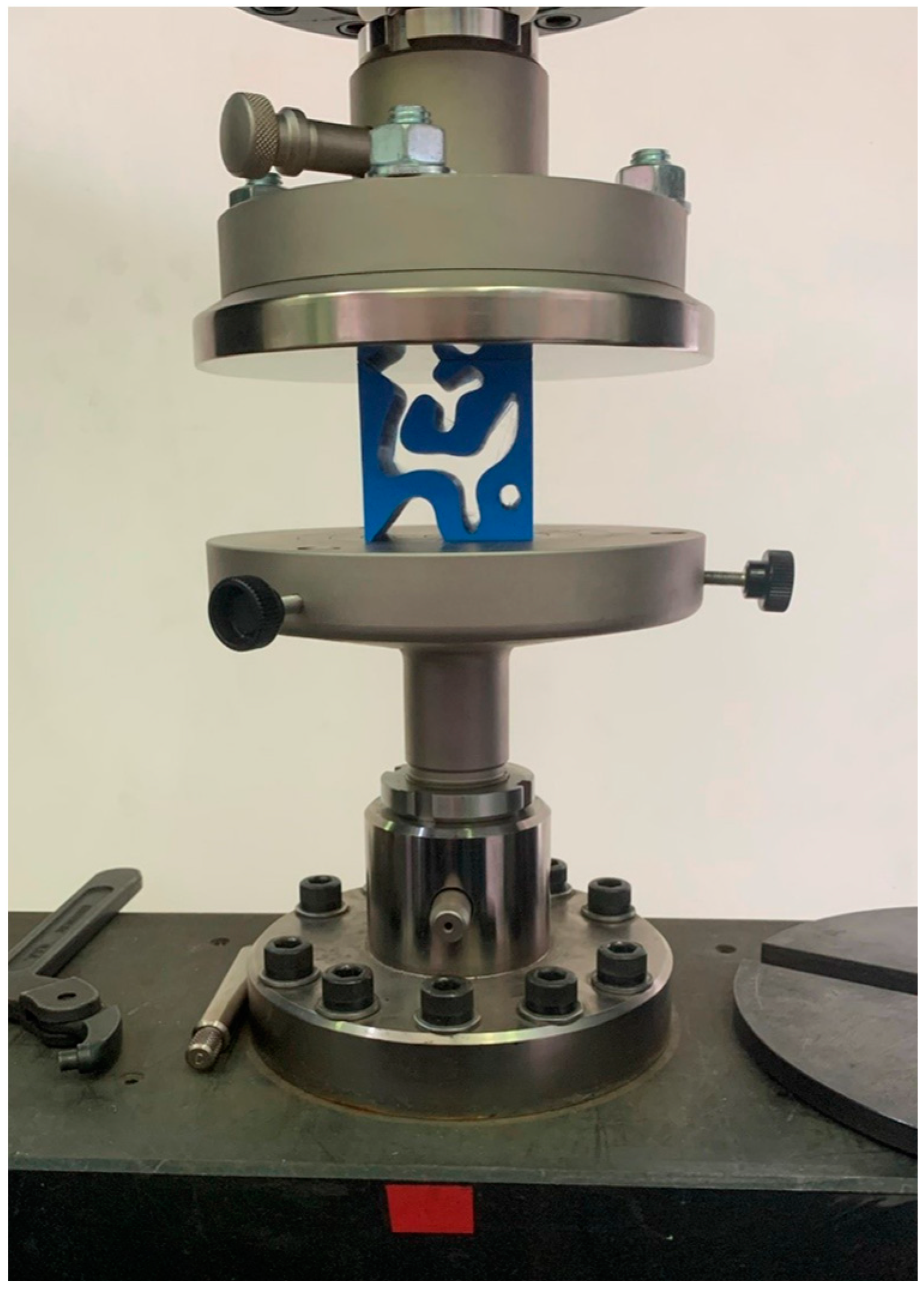

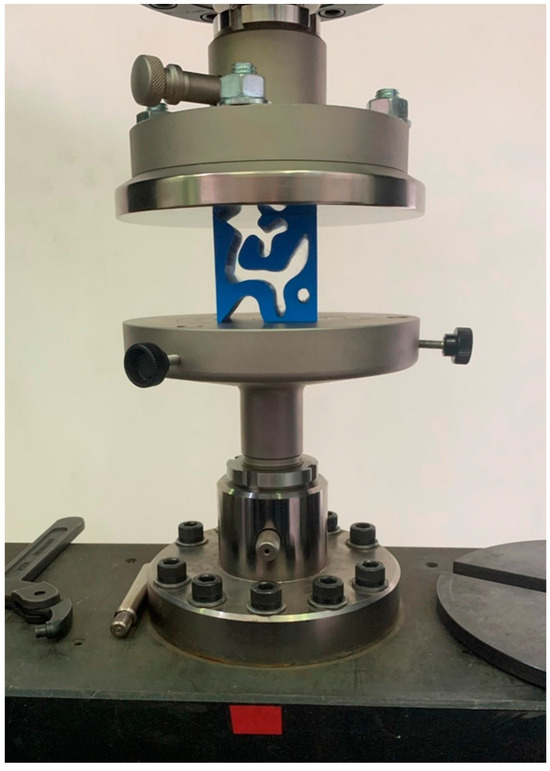

The experimental setup described above has been used to analyze the mechanical behavior of the metamaterial in Figure 2 by performing a compression test in all three spatial directions (Figure 4) to calculate the Young moduli of the metamaterial sample.

Figure 4.

Experimental setup for metamaterial characterization.

3. Results and Discussion

In this section, the results are summarized and discussed to offer insights into which method for applying boundary conditions on the RVE boundary is most accurate when dealing with complex geometries. Finally, the validation of the homogenization algorithm through experimentation is shown.

3.1. FE Homogenization Results

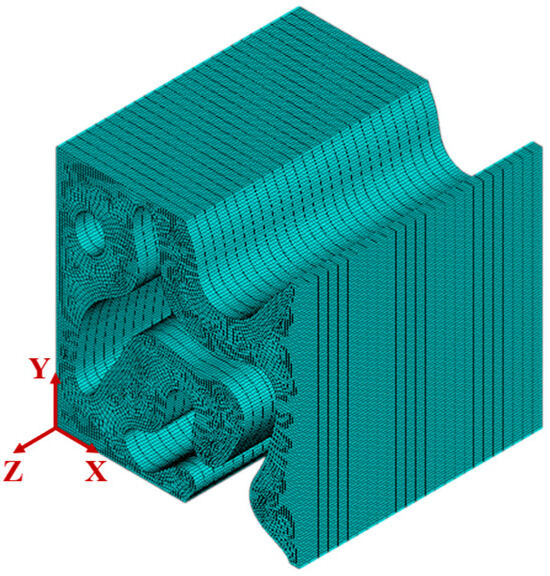

The solid model shown in Figure 2 has been created using FE software (Ansys Mechanical APDL 23.1). The mesh, consisting of solid elements with eight nodes, is shown in Figure 5. In the FE analyses, the material has been assumed to be linear and isotropic with a Young modulus E of 1.57 GPa (derived from PLA characterization) and a Poisson ratio equal to 0.3.

Figure 5.

FE mesh of the RVE resulting from α = 1.45 and β = 650.

As for the boundary conditions, six independent load cases have been considered both under DBCs and PBCs to completely determine the stiffness matrix of this material and to derive its mechanical properties.

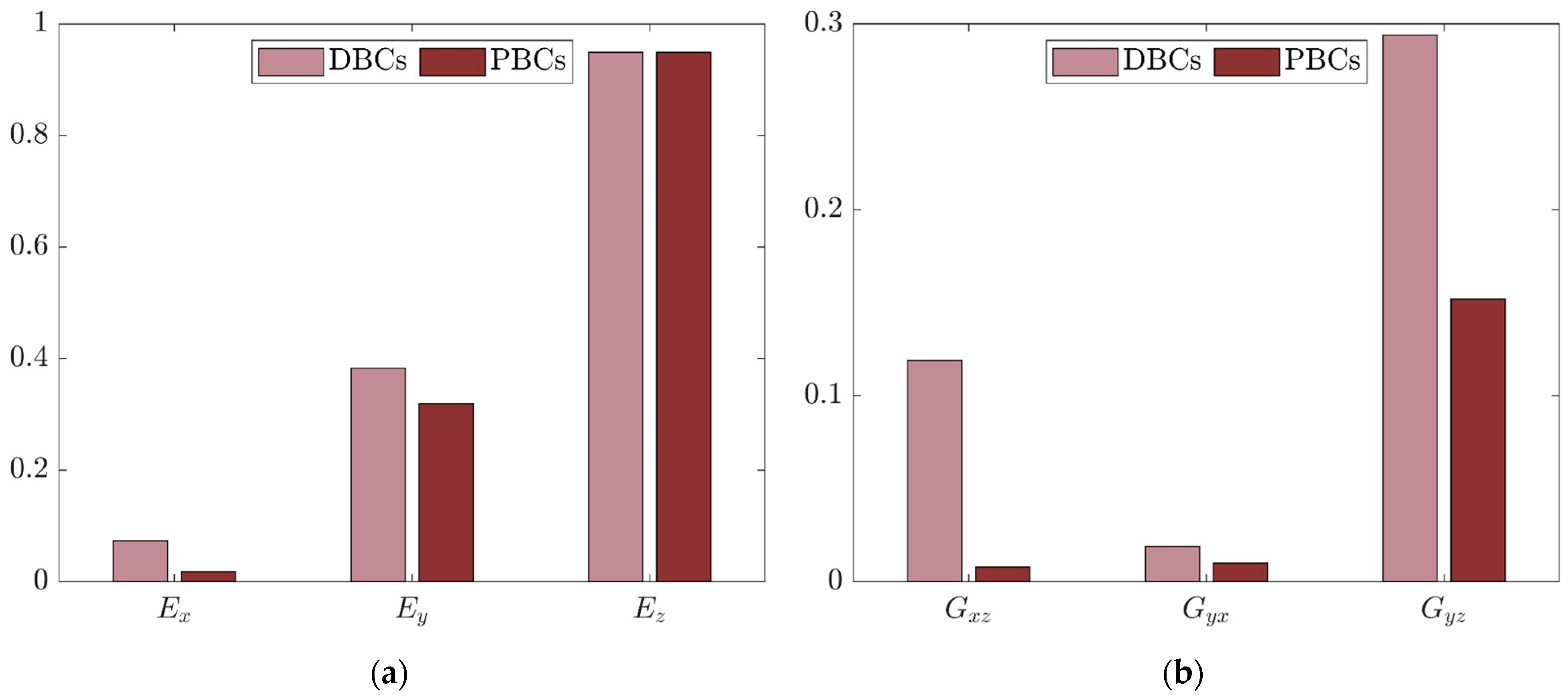

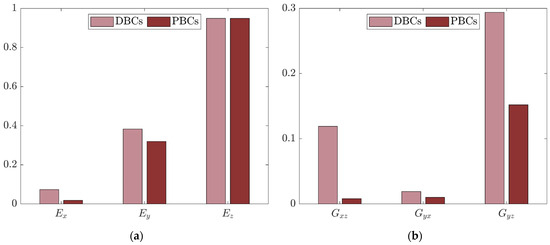

Table 1 summarizes the Young moduli (EX, EY, and EZ) and bulk moduli resulting from the FE analyses above. The material properties calculated using DBCs are higher than those calculated by PBCs. In this case, both the Young and bulk moduli are overestimated. Notably, the two methods yield the same value for Young’s modulus only along the extrusion direction. This is intricately linked to the fact that the derived spinodal architecture has a complex topology, and 3D printing technology cannot guarantee a material with homogeneous behavior, as in the FE model. The print direction with parallel oblique lines, as well as the thermal effects during printing, also influence the result. Nevertheless, the goal of this work is to develop a reliable methodology for assessing the mechanical properties of metamaterials derived from the solution field of Equation (2), with the intention of extending it to the more complex three-dimensional case. Indeed, the two-dimensional case is easier to manage when identifying troubles in both the equation-solving algorithm and the homogenization procedure.

Table 1.

Mechanical properties (in GPa) resulting from the FE homogenization applying DBCs and PBCs.

For the sake of clarity, in Figure 6, bar plots are shown, visually proving this trend.

Figure 6.

Charts of FE homogenization results applying DBCs and PBCs: (a) Young’s moduli [GPa]; (b) shear moduli [GPa].

3.2. Experimental Validation

By comparing the results summarized in Table 1 with the experimental data, it is evident that periodic boundary conditions (PBCs) yield more accurate results, which aligns well with the existing literature.

Table 2 lists the Young moduli obtained from compressive tests and FE homogenization using PBCs. Along the extrusion direction, the discrepancy between these results is minimal. In contrast, along the other two directions, the discrepancy is greater but still reasonable, considering that the tests have been conducted without LVDTs, which may improve the accuracy.

Table 2.

Comparison of Young’s moduli (in GPa) resulting from compression tests and FE homogenization applying PBCs.

4. Conclusions

This work focuses on deriving a metamaterial based on the solution field of the bidimensional Cahn–Hilliard equation, which models the spinodal decomposition process. It is important to emphasize that the evolution of this phenomenon is of particular interest. However, in our work, the interest in the chemical phenomenon itself is limited to the extent that its solution is useful for modeling a metamaterial. The approach here used, based on the finite difference method, can completely simulate this transformation as opposed to the statistical method based on Gaussian random fields, which is commonly used in the literature.

The process of creating the metamaterial involves converting the solution field into a CAD model; to this end, a dedicated MATLAB (R2023b) code was developed. Subsequently, computational homogenization was performed by imposing both homogeneous displacement and periodic boundary conditions. This dual approach was essential to understand which method yields the most accurate results when dealing with complex topologies such as those proposed in this paper. The homogenization procedure was validated through experimental testing, which proved that periodic boundary conditions provide more reliable results.

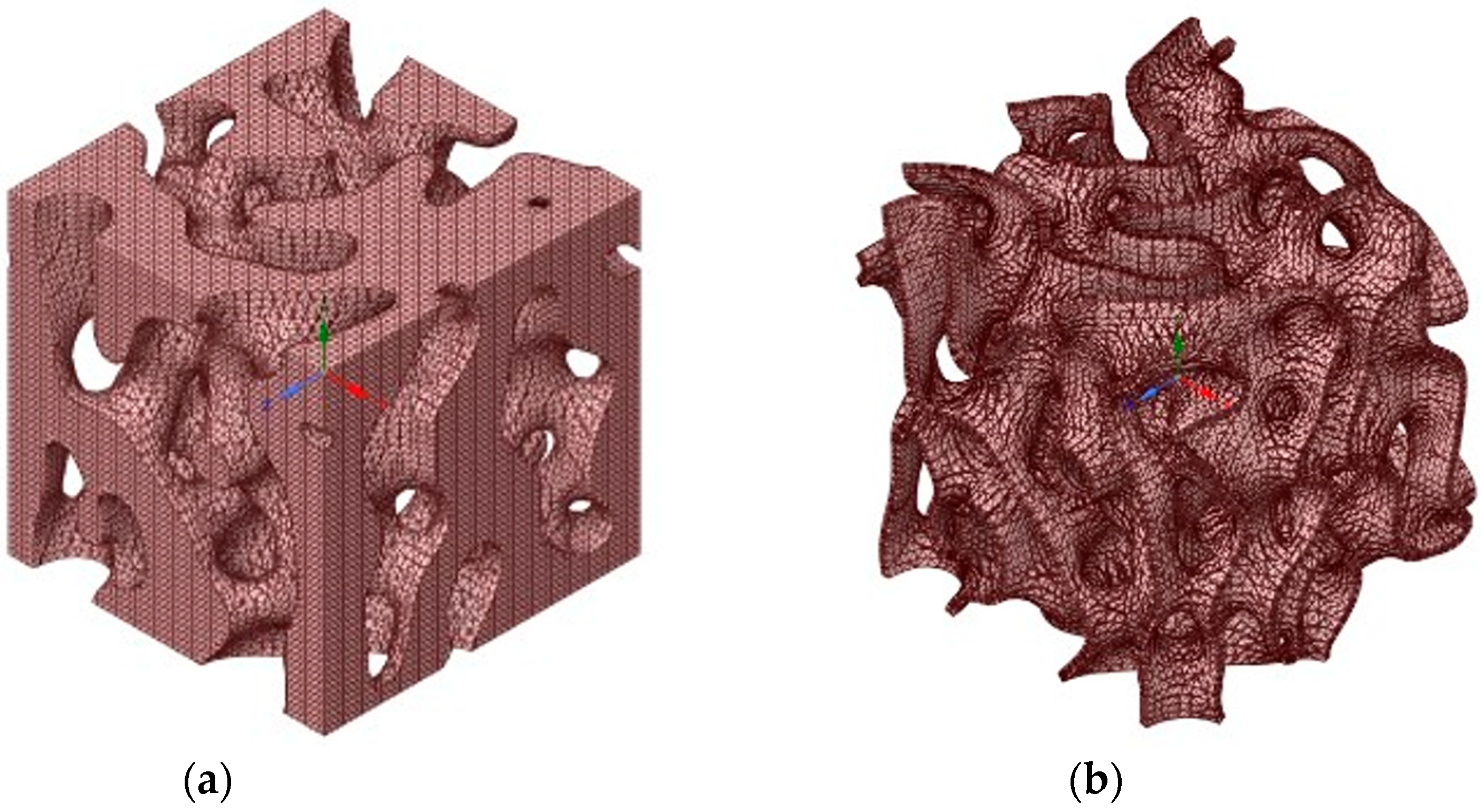

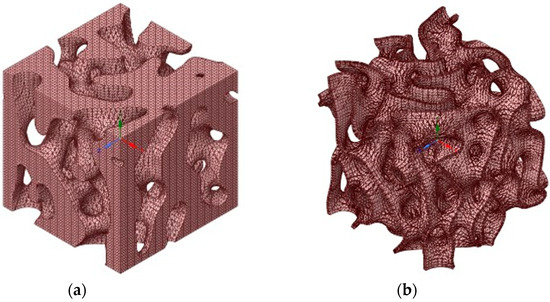

For future developments, the design of this metamaterial can be guided solely by the two dimensionless parameters introduced in this study. This allows the mechanical properties to be analyzed entirely through these parameters, enabling an inverse design and homogenization of the metamaterial. Future work will involve extending the design and analysis of a metamaterial derived from the 3D solution (Figure 7).

Figure 7.

Metamaterial derived from the 3D solution: (a) solid topology; (b) shell topology.

Author Contributions

Conceptualization, B.M., C.I. and V.G.B.; methodology, B.M., C.I. and V.G.B.; software, B.M., C.I. and V.G.B.; validation, B.M., C.I. and V.G.B.; formal analysis, B.M.; investigation, B.M. and C.I.; resources, F.V.; data curation, B.M.; writing—original draft preparation, B.M. and C.I.; writing—review and editing, B.M., C.I., V.G.B. and F.V.; visualization, B.M.; supervision, F.V.; project administration, F.V. All authors have read and agreed to the published version of the manuscript.

Funding

European Union—NextGenerationEU, Project ECS 0000024 Rome Technopole.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data are contained within the article.

Acknowledgments

This study was supported by the Project ECS 0000024 Rome Technopole—CUP B83C22002820006, NRP Mission 4 Component 2 Investment 1.5, Funded by the European Union—NextGenerationEU.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Askari, M.; Hutchins, D.A.; Thomas, P.J.; Astolfi, L.; Watson, R.L.; Abdi, M.; Ricci, M.; Laureti, S.; Nie, L.; Freear, S.; et al. Additive Manufacturing of Metamaterials: A Review. Addit. Manuf. 2020, 36, 101562. [Google Scholar] [CrossRef]

- Zadpoor, A.A. Mechanical Meta-Materials. Mater. Horiz. 2016, 3, 371–381. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, X. Metamaterials: A New Frontier of Science and Technology. Chem. Soc. Rev. 2011, 40, 2494. [Google Scholar] [CrossRef]

- Bauer, J.; Meza, L.R.; Schaedler, T.A.; Schwaiger, R.; Zheng, X.; Valdevit, L. Nanolattices: An Emerging Class of Mechanical Metamaterials. Adv. Mater. 2017, 29, 1701850. [Google Scholar] [CrossRef] [PubMed]

- Valipour, A.; Kargozarfard, M.H.; Rakhshi, M.; Yaghootian, A.; Sedighi, H.M. Metamaterials and Their Applications: An Overview. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2022, 236, 2171–2210. [Google Scholar] [CrossRef]

- Jiao, P.; Mueller, J.; Raney, J.R.; Zheng, X.; Alavi, A.H. Mechanical Metamaterials and Beyond. Nat. Commun. 2023, 14, 6004. [Google Scholar] [CrossRef]

- Al Rifaie, M.; Abdulhadi, H.; Mian, A. Advances in Mechanical Metamaterials for Vibration Isolation: A Review. Adv. Mech. Eng. 2022, 14, 168781322210828. [Google Scholar] [CrossRef]

- Lu, C.; Hsieh, M.; Huang, Z.; Zhang, C.; Lin, Y.; Shen, Q.; Chen, F.; Zhang, L. Architectural Design and Additive Manufacturing of Mechanical Metamaterials: A Review. Engineering 2022, 17, 44–63. [Google Scholar] [CrossRef]

- Latture, R.M.; Rodriguez, R.X.; Holmes, L.R.; Zok, F.W. Effects of Nodal Fillets and External Boundaries on Compressive Response of an Octet Truss. Acta Mater. 2018, 149, 78–87. [Google Scholar] [CrossRef]

- Mateos, A.J.; Huang, W.; Zhang, Y.; Greer, J.R. Discrete-Continuum Duality of Architected Materials: Failure, Flaws, and Fracture. Adv. Funct. Mater. 2019, 29, 1806772. [Google Scholar] [CrossRef]

- Iandiorio, C.; Mattei, G.; Marotta, E.; Costanza, G.; Tata, M.E.; Salvini, P. The Beneficial Effect of a TPMS-Based Fillet Shape on the Mechanical Strength of Metal Cubic Lattice Structures. Materials 2024, 17, 1553. [Google Scholar] [CrossRef]

- Al-Ketan, O.; Rezgui, R.; Rowshan, R.; Du, H.; Fang, N.X.; Abu Al-Rub, R.K. Microarchitected Stretching-Dominated Mechanical Metamaterials with Minimal Surface Topologies. Adv. Eng. Mater. 2018, 20, 1800029. [Google Scholar] [CrossRef]

- Han, S.C.; Lee, J.W.; Kang, K. A New Type of Low Density Material: Shellular. Adv. Mater. 2015, 27, 5506–5511. [Google Scholar] [CrossRef] [PubMed]

- Bonatti, C.; Mohr, D. Smooth-Shell Metamaterials of Cubic Symmetry: Anisotropic Elasticity, Yield Strength and Specific Energy Absorption. Acta Mater. 2019, 164, 301–321. [Google Scholar] [CrossRef]

- Pini, V.; Ruz, J.J.; Kosaka, P.M.; Malvar, O.; Calleja, M.; Tamayo, J. How Two-Dimensional Bending Can Extraordinarily Stiffen Thin Sheets. Sci. Rep. 2016, 6, 29627. [Google Scholar] [CrossRef]

- Liu, L.; Kamm, P.; García-Moreno, F.; Banhart, J.; Pasini, D. Elastic and Failure Response of Imperfect Three-Dimensional Metallic Lattices: The Role of Geometric Defects Induced by Selective Laser Melting. J. Mech. Phys. Solids 2017, 107, 160–184. [Google Scholar] [CrossRef]

- Symons, D.D.; Fleck, N.A. The Imperfection Sensitivity of Isotropic Two-Dimensional Elastic Lattices. J. Appl. Mech. 2008, 75, 051011. [Google Scholar] [CrossRef]

- Vidyasagar, A.; Krödel, S.; Kochmann, D.M. Microstructural Patterns with Tunable Mechanical Anisotropy Obtained by Simulating Anisotropic Spinodal Decomposition. Proc. R. Soc. A 2018, 474, 20180535. [Google Scholar] [CrossRef]

- Portela, C.M.; Vidyasagar, A.; Krödel, S.; Weissenbach, T.; Yee, D.W.; Greer, J.R.; Kochmann, D.M. Extreme Mechanical Resilience of Self-Assembled Nanolabyrinthine Materials. Proc. Natl. Acad. Sci. USA 2020, 117, 5686–5693. [Google Scholar] [CrossRef]

- Zheng, L.; Kumar, S.; Kochmann, D.M. Data-Driven Topology Optimization of Spinodoid Metamaterials with Seamlessly Tunable Anisotropy. Comput. Methods Appl. Mech. Eng. 2021, 383, 113894. [Google Scholar] [CrossRef]

- Kumar, S.; Tan, S.; Zheng, L.; Kochmann, D.M. Inverse-Designed Spinodoid Metamaterials. Npj Comput. Mater. 2020, 6, 73. [Google Scholar] [CrossRef]

- Hsieh, M.-T.; Endo, B.; Zhang, Y.; Bauer, J.; Valdevit, L. The Mechanical Response of Cellular Materials with Spinodal Topologies. J. Mech. Phys. Solids 2019, 125, 401–419. [Google Scholar] [CrossRef]

- Cahn, J.W.; Hilliard, J.E. Free Energy of a Nonuniform System. I. Interfacial Free Energy. J. Chem. Phys. 1958, 28, 258–267. [Google Scholar] [CrossRef]

- Cahn, J.W. Free Energy of a Nonuniform System. II. Thermodynamic Basis. J. Chem. Phys. 1959, 30, 1121–1124. [Google Scholar] [CrossRef]

- Cahn, J.W. Phase Separation by Spinodal Decomposition in Isotropic Systems. J. Chem. Phys. 1965, 42, 93–99. [Google Scholar] [CrossRef]

- Sun, X.-Y.; Xu, G.-K.; Li, X.; Feng, X.-Q.; Gao, H. Mechanical Properties and Scaling Laws of Nanoporous Gold. J. Appl. Phys. 2013, 113, 023505. [Google Scholar] [CrossRef]

- Cahn, J.W. On Spinodal Decomposition in Cubic Crystals. Acta Metall. 1962, 10, 179–183. [Google Scholar] [CrossRef]

- Cahn, J.W. On Spinodal Decomposition. Acta Metall. 1961, 9, 795–801. [Google Scholar] [CrossRef]

- Mandolesi, B.; Iandiorio, C.; Belardi, V.G.; Vivio, F. Spinodal decomposition-inspired metamaterial: Tailored homogenized elastic properties via the dimensionless Cahn-Hilliard equation. Eur. J. Mech.-A/Solids 2025, 112, 105615. [Google Scholar]

- Lynch, R.E. Fundamental Solutions of 9-Point Discrete Laplacians. Appl. Numer. Math. 1992, 10, 325–334. [Google Scholar]

- Hill, R. Elastic Properties of Reinforced Solids: Some Theoretical Principles. J. Mech. Phys. Solids 1963, 11, 357–372. [Google Scholar] [CrossRef]

- Okereke, M.; Keates, S. Finite Element Applications; Springer Tracts in Mechanical Engineering; Springer International Publishing: Cham, Switzerland, 2018; ISBN 978-3-319-67124-6. [Google Scholar]

- Denisiewicz, A.; Kuczma, M.; Kula, K.; Socha, T. Influence of Boundary Conditions on Numerical Homogenization of High Performance Concrete. Materials 2021, 14, 1009. [Google Scholar] [CrossRef]

- Xia, Z.; Zhang, Y.; Ellyin, F. A Unified Periodical Boundary Conditions for Representative Volume Elements of Composites and Applications. Int. J. Solids Struct. 2003, 40, 1907–1921. [Google Scholar] [CrossRef]

- Belardi, V.G.; Trupiano, S.; Fanelli, P.; Vivio, F. Overall Elastic Characterization of Equivalent FE Models for Aluminum Foams through Computational Homogenization Approach and Genetic Algorithm Optimization. Eur. J. Mech.-A/Solids 2024, 103, 105189. [Google Scholar] [CrossRef]

- Belardi, V.G.; Fanelli, P.; Trupiano, S.; Vivio, F. Multiscale Analysis and Mechanical Characterization of Open-Cell Foams by Simplified FE Modeling. Eur. J. Mech.-A/Solids 2021, 89, 104291. [Google Scholar] [CrossRef]

- Nguyen, V.-D.; Béchet, E.; Geuzaine, C.; Noels, L. Imposing Periodic Boundary Condition on Arbitrary Meshes by Polynomial Interpolation. Comput. Mater. Sci. 2012, 55, 390–406. [Google Scholar] [CrossRef]

- Schneider, K.; Klusemann, B.; Bargmann, S. Fully Periodic RVEs for Technological Relevant Composites: Not Worth the Effort! J. Mech. Mater. Struct. 2017, 12, 471–484. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).