Analysis of Gearbox Losses for High-Performance Electric Motorcycle Applications †

Abstract

1. Introduction

2. Materials and Methods

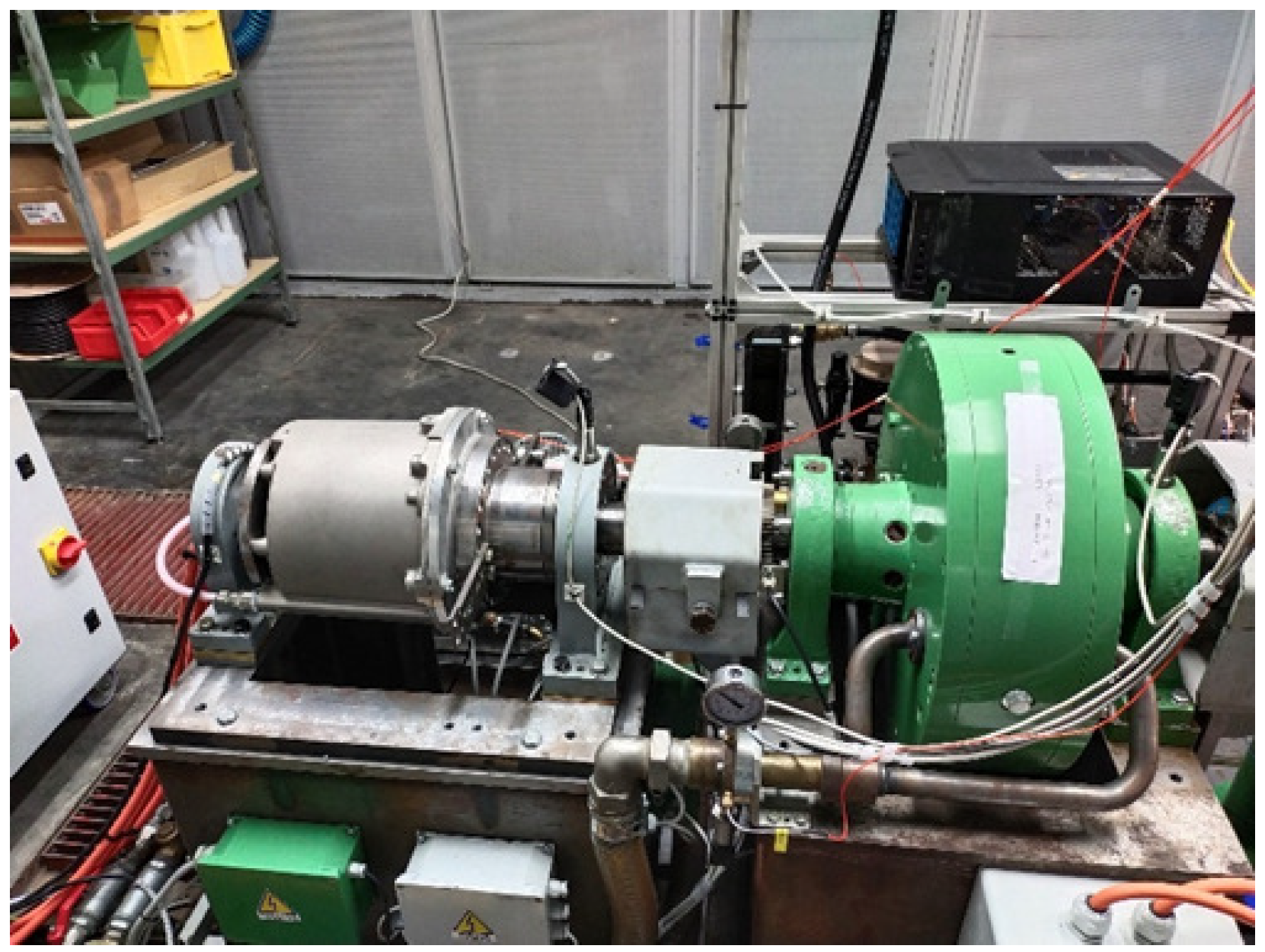

2.1. Test Bench and Setup

2.2. No-Load Losses

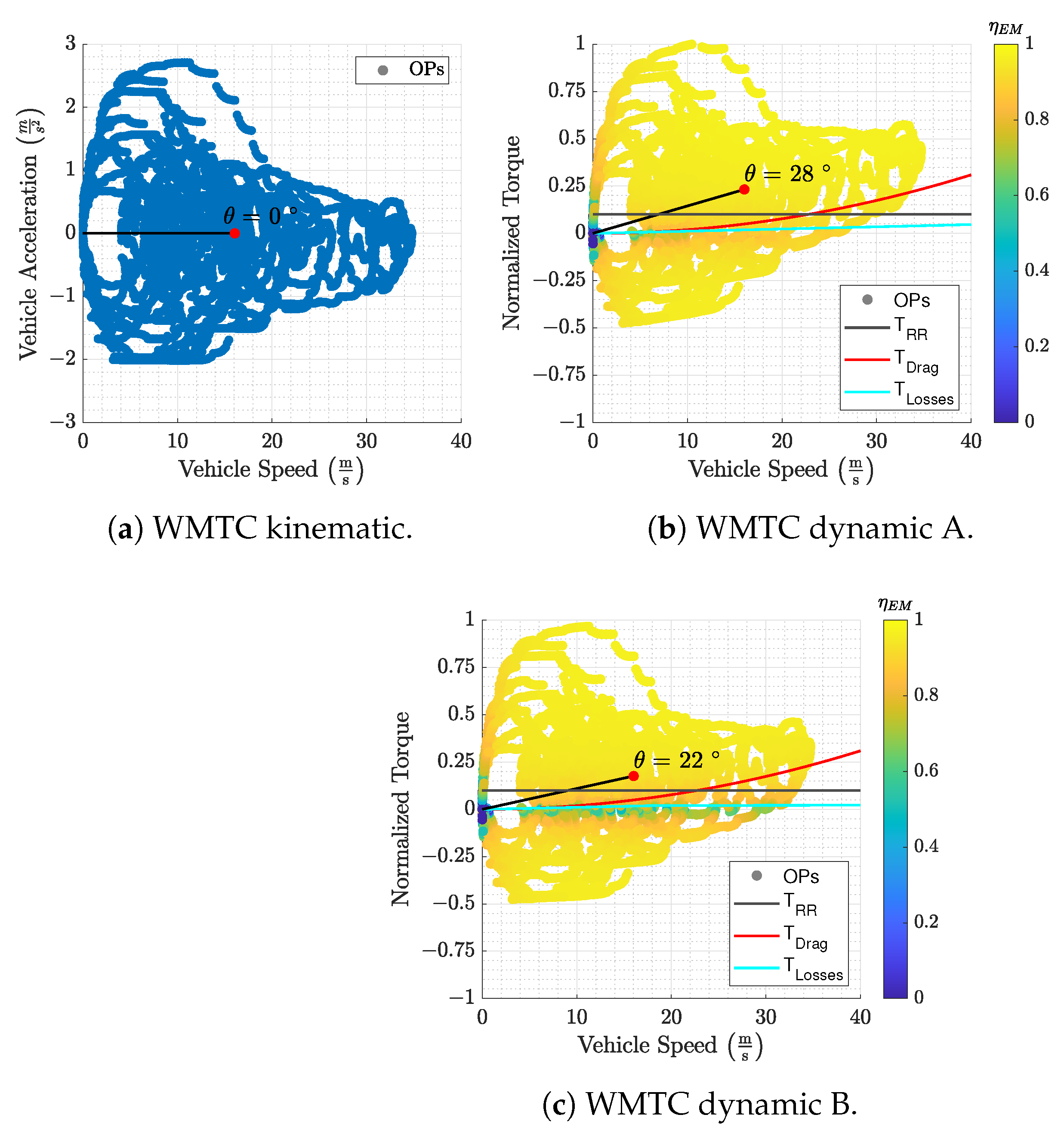

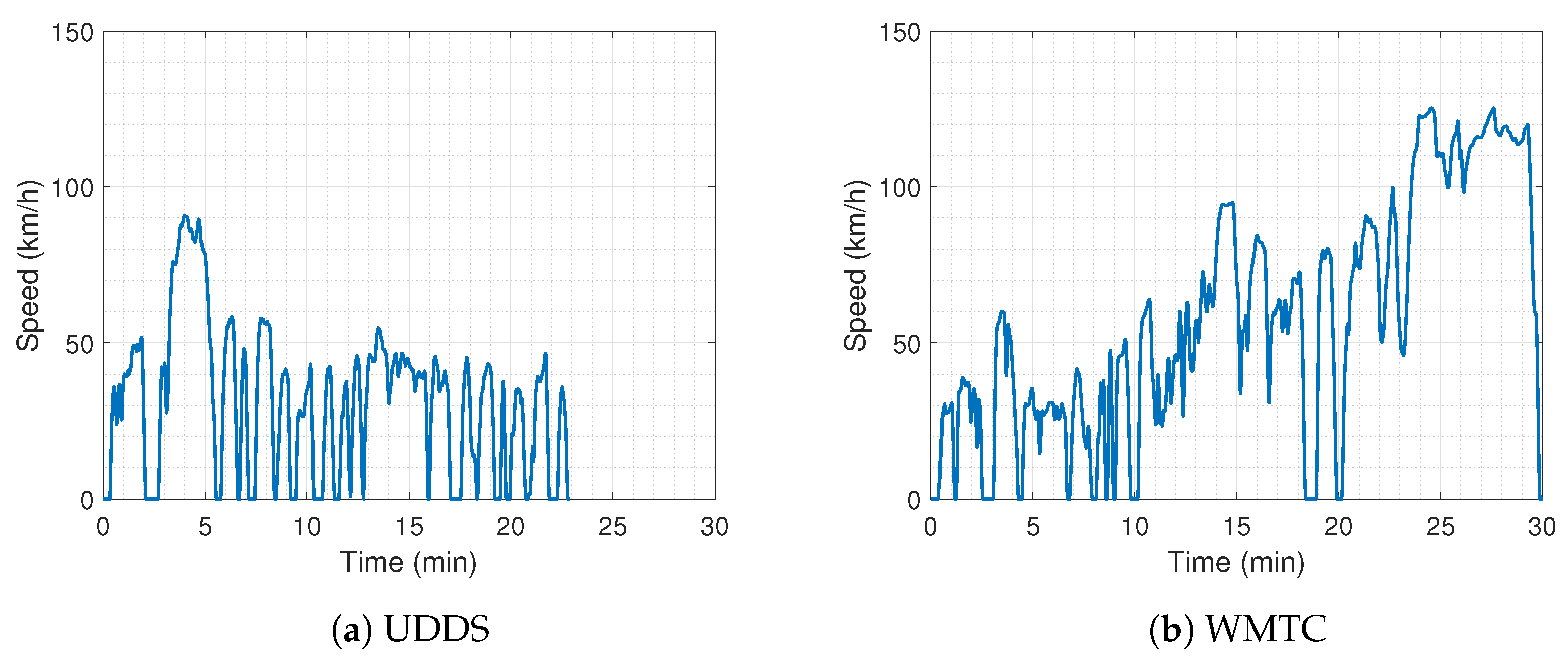

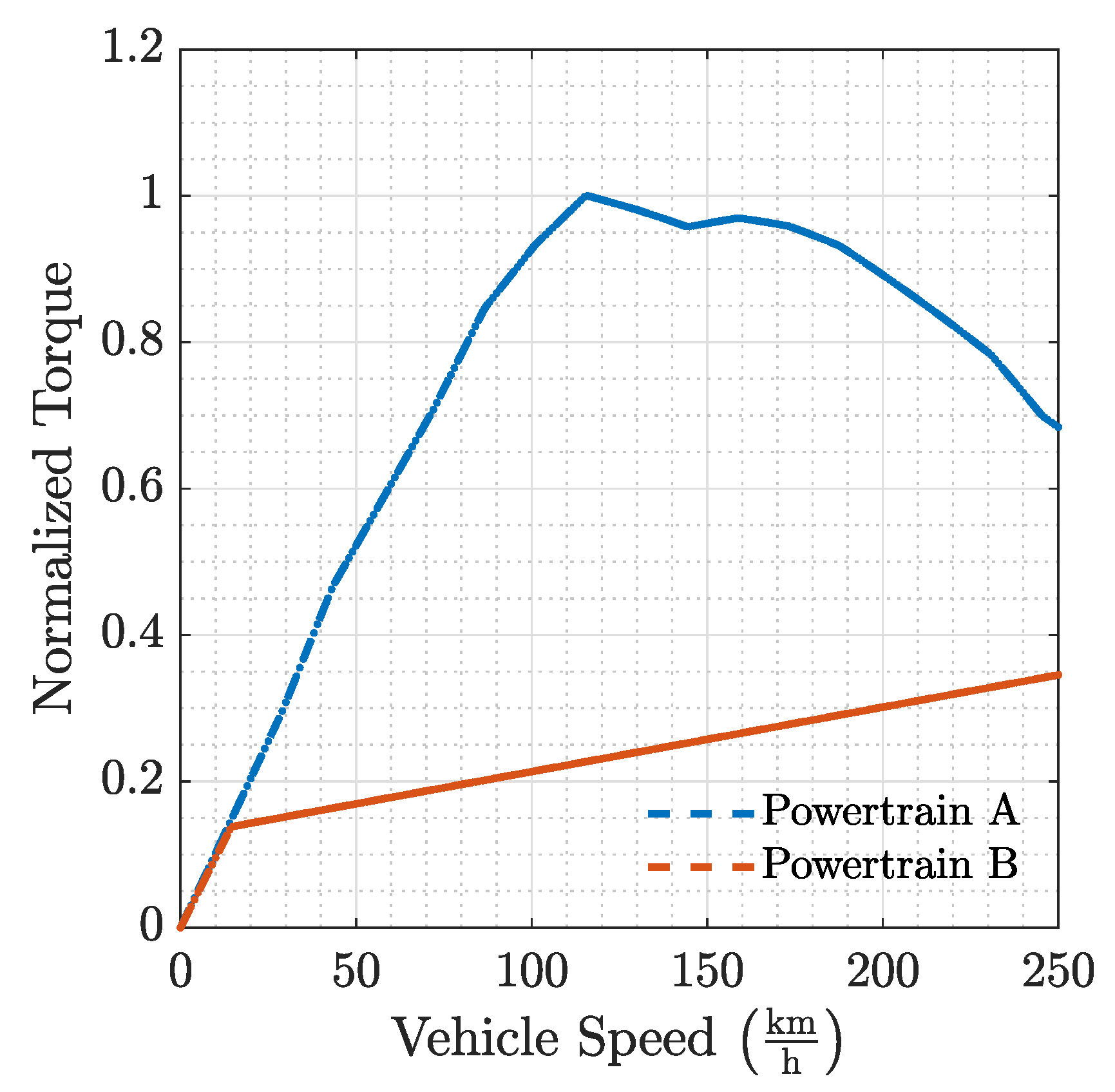

2.3. Vehicle Model and Speed Profiles

3. Results

3.1. Free-Driving Losses

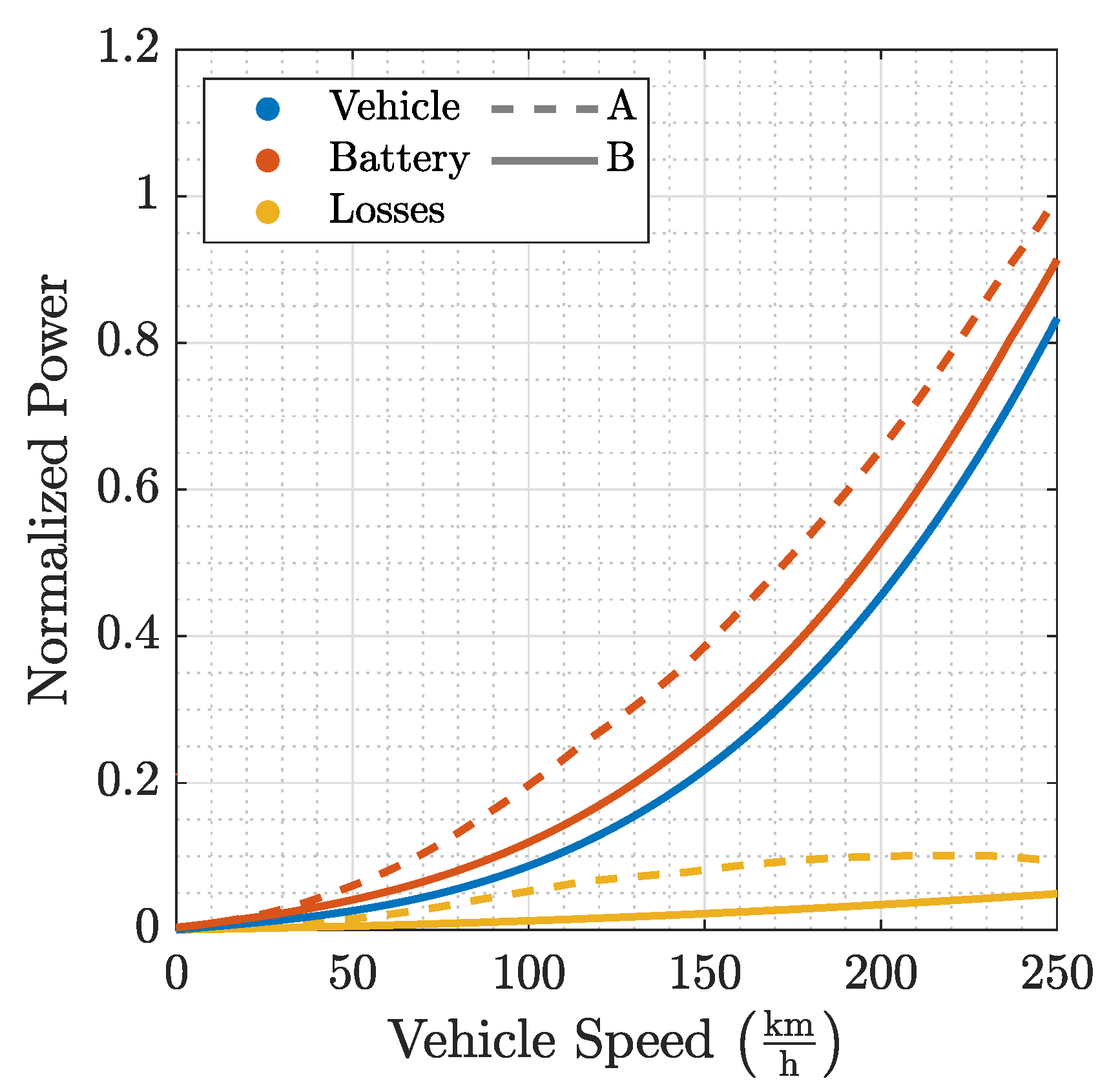

3.2. Energy Consumption

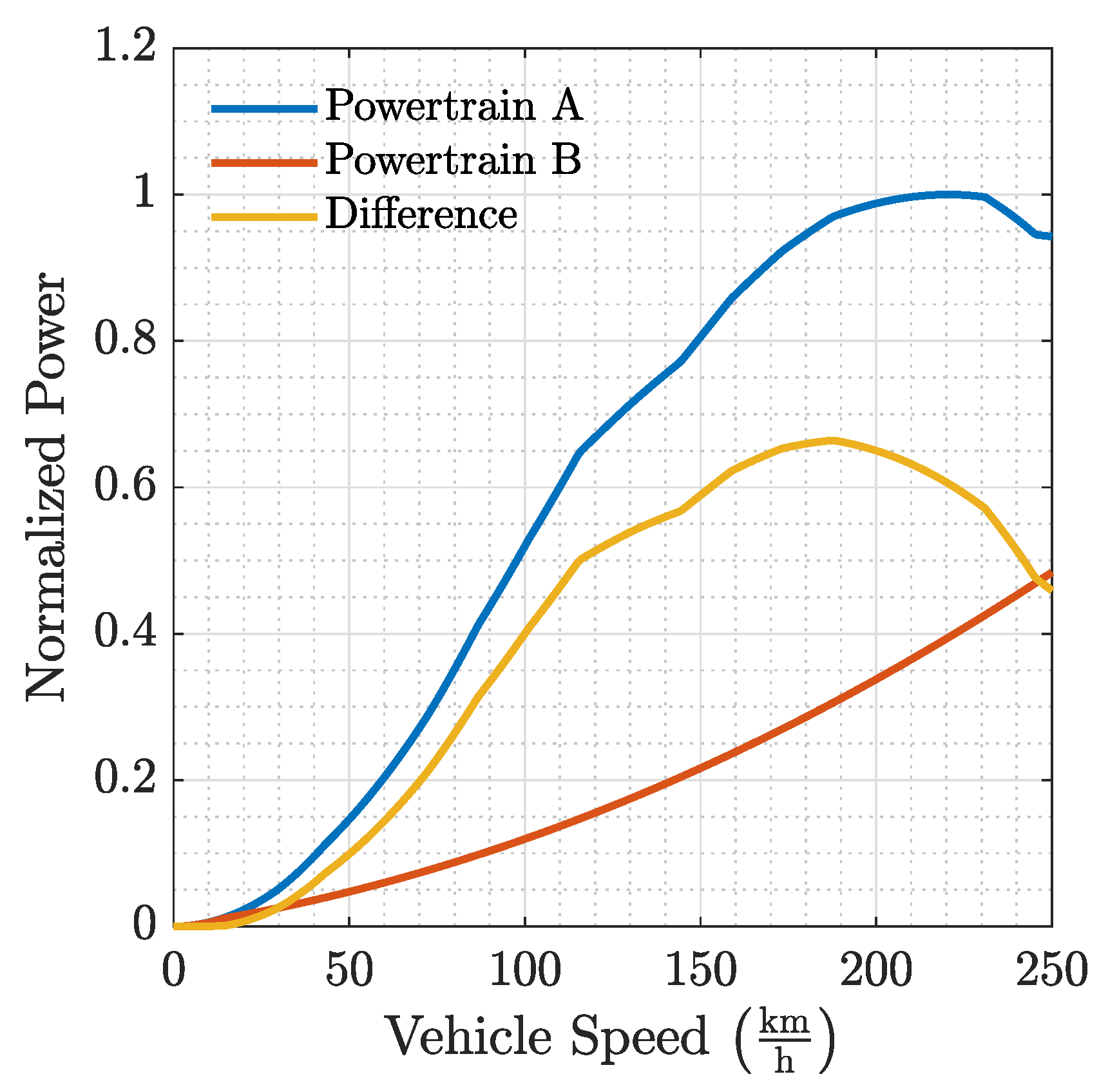

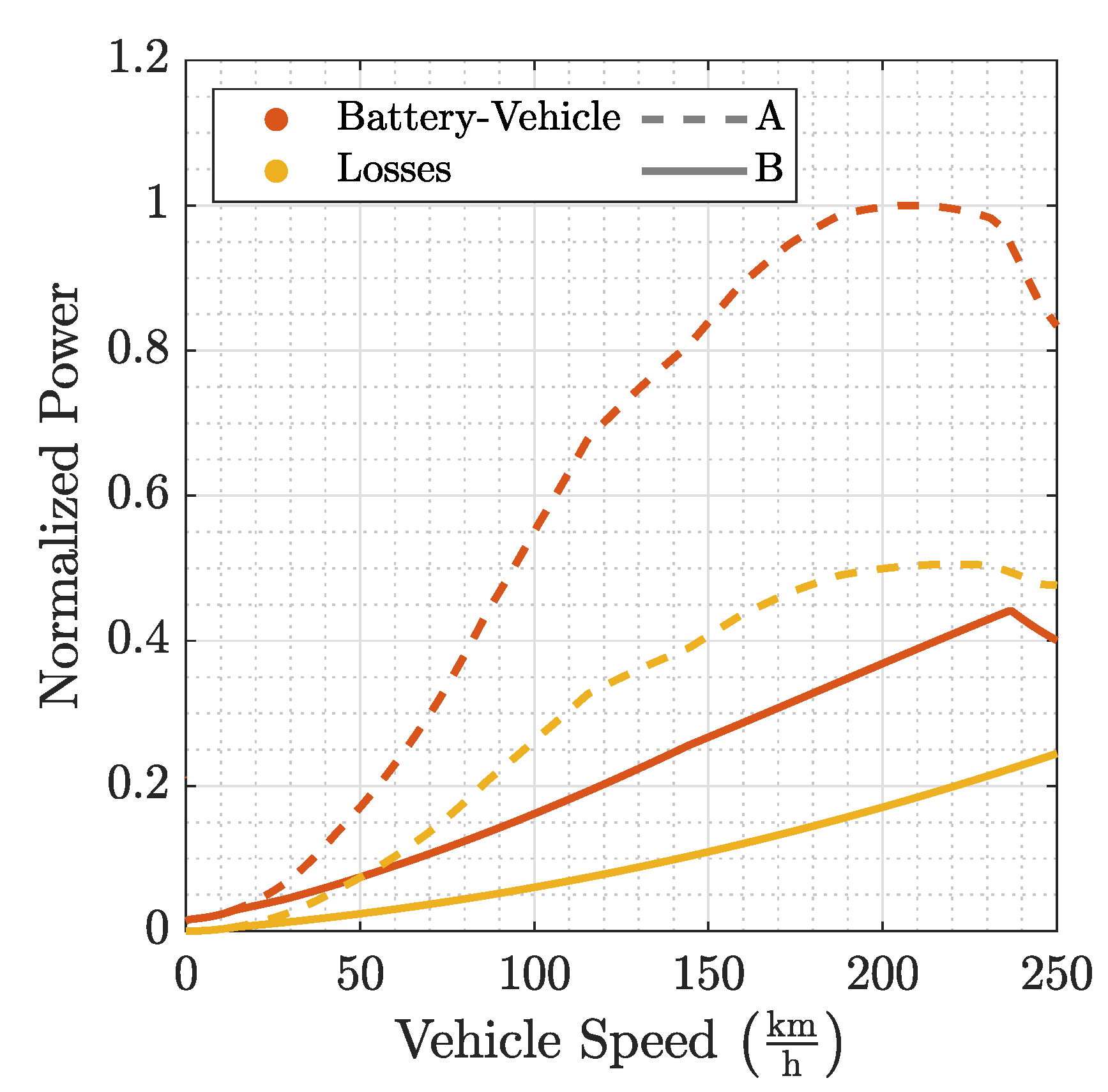

3.3. Power Ratios

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

References

- IEA. Global EV Outlook: Moving Towards Increased Affordability; IEA: Paris, France, 2024. [Google Scholar]

- Gao, Y.; Chen, L.; Ehsani, M. Investigation of the Effectiveness of Regenerative Braking for EV and HEV. SAE Trans. 1999, 108, 3184–3190. [Google Scholar]

- Nam, K. AC Motor Control and Electric Vehicle Applications, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2018. [Google Scholar]

- Pyrhonen, J.; Jokinen, T.; Hrabovcova, V. Design of Rotating Electrical Machines; Wiley: Hoboken, NJ, USA, 2009. [Google Scholar]

- SAE. Riding Range Test Procedure for On-Highway Electric Motorcycles, SAE Standard J2982 202210; SAE International: Warrendale, PA, USA, 2022. [Google Scholar] [CrossRef]

- Roshandel, E.; Mahmoudi, A.; Kahourzade, S.; Yazdani, A.; Shafiullah, G. Losses in Efficiency Maps of Electric Vehicles: An Overview. Energies 2021, 14, 7805. [Google Scholar] [CrossRef]

- ISO/TR 14179-2:2001; Gears—Thermal Capacity Part 2: Thermal Load-Carrying Capacity; Technical Report. International Organization for Standardization: Geneva, Switzerland, 2001.

- Gilson, A.; Sindjui, R.; Chareyron, B.; Milosavljevic, M. No-Load Loss Separation of High-Speed Electric Motors for Electrically-Assisted Turbochargers. In Proceedings of the 2020 International Conference on Electrical Machines (ICEM), Gothenburg, Sweden, 23–26 August 2020; Volume 1, pp. 2439–2444. [Google Scholar] [CrossRef]

- Bourhis, G.; Sindjui, R.; Gilson, A.; Zito, G. Experimental Separation of No-Load Losses of an Electric Motor with Direct Oil Cooling. In Proceedings of the 2022 International Conference on Electrical Machines (ICEM), Valencia, Spain, 5–8 September 2022; pp. 1341–1347. [Google Scholar] [CrossRef]

- Cossalter, V. Motorcycle Dynamics, 2nd ed.; Lulu.com: Morrisville, NC, USA, 2006. [Google Scholar]

- Fernandes, C.M.; Marques, P.M.; Martins, R.C.; Seabra, J.H. Gearbox power loss. Part I: Losses in rolling bearings. Tribol. Int. 2015, 88, 298–308. [Google Scholar] [CrossRef]

- Fernandes, C.M.; Marques, P.M.; Martins, R.C.; Seabra, J.H. Gearbox power loss. Part II: Friction losses in gears. Tribol. Int. 2015, 88, 309–316. [Google Scholar] [CrossRef]

| Driving Cycle | Model | |||||

|---|---|---|---|---|---|---|

| UDSS | A | 39.17 | 92.79 | 4.28 | 88.51 | 21.09 |

| B | 39.17 | 66.96 | 4.29 | 62.66 | 7.04 | |

| WMTC | A | 56.76 | 125.40 | 2.70 | 122.70 | 31.9 |

| B | 56.76 | 81.54 | 2.80 | 78.76 | 8.30 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Niccolai, A.; Berzi, L.; Baldanzini, N. Analysis of Gearbox Losses for High-Performance Electric Motorcycle Applications. Eng. Proc. 2025, 85, 34. https://doi.org/10.3390/engproc2025085034

Niccolai A, Berzi L, Baldanzini N. Analysis of Gearbox Losses for High-Performance Electric Motorcycle Applications. Engineering Proceedings. 2025; 85(1):34. https://doi.org/10.3390/engproc2025085034

Chicago/Turabian StyleNiccolai, Adelmo, Lorenzo Berzi, and Niccolò Baldanzini. 2025. "Analysis of Gearbox Losses for High-Performance Electric Motorcycle Applications" Engineering Proceedings 85, no. 1: 34. https://doi.org/10.3390/engproc2025085034

APA StyleNiccolai, A., Berzi, L., & Baldanzini, N. (2025). Analysis of Gearbox Losses for High-Performance Electric Motorcycle Applications. Engineering Proceedings, 85(1), 34. https://doi.org/10.3390/engproc2025085034