Comparative Review of Rotary Friction Welding Between Aluminium and Copper Alloys for Enhanced Joint Strength †

Abstract

1. Introduction

- A.

- Background and Significance

- B.

- Scope of the Review

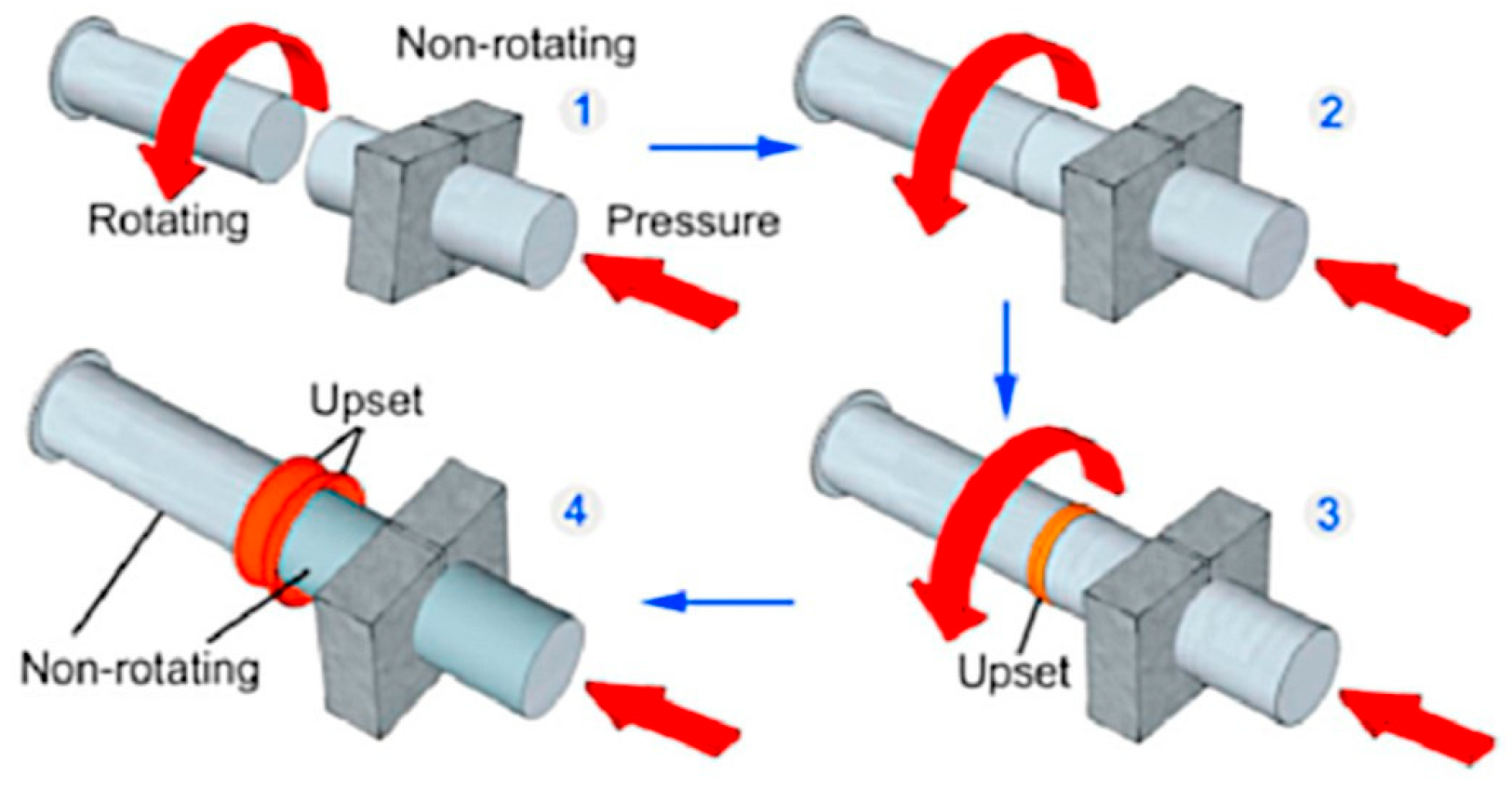

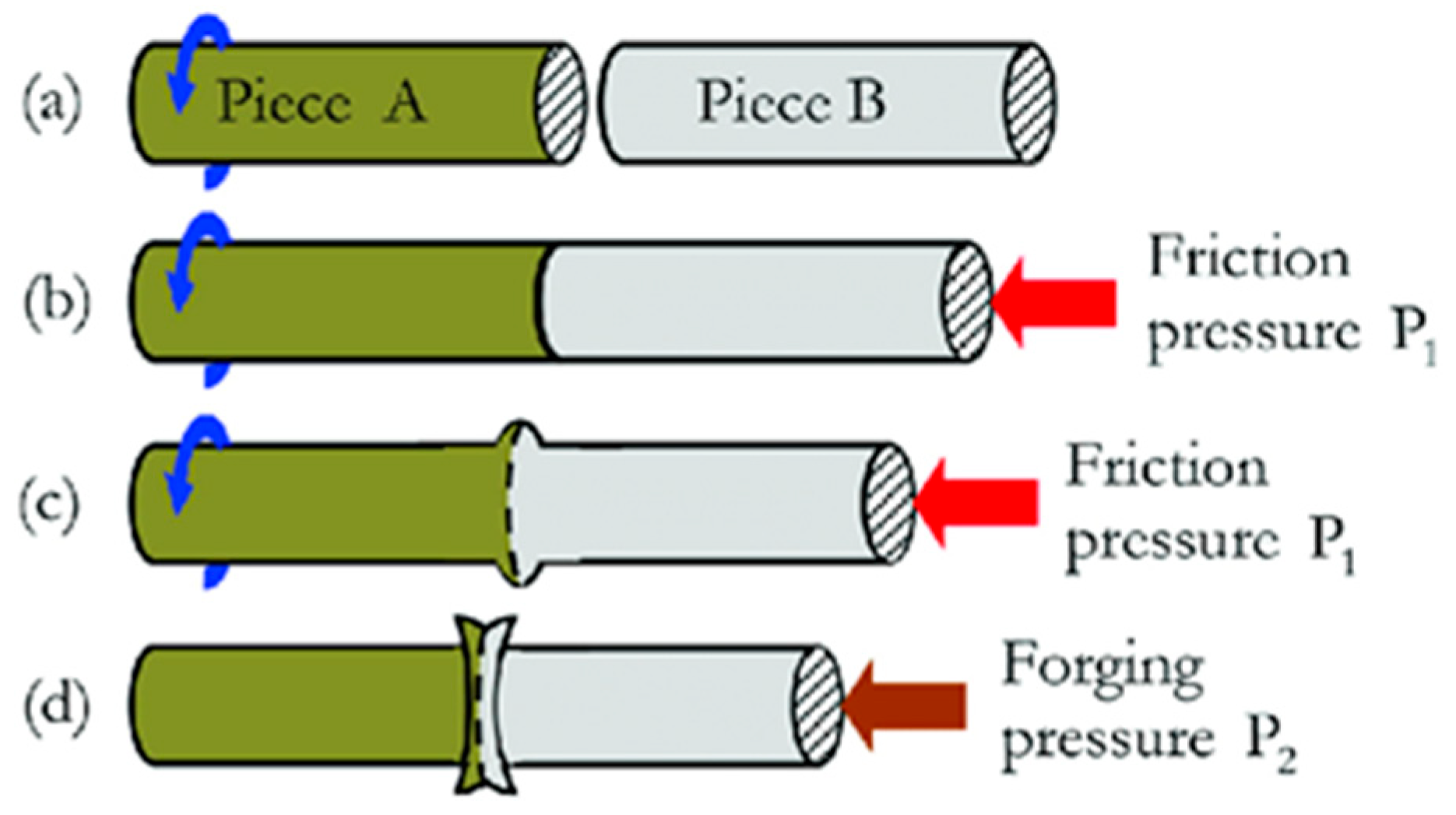

2. Fundamentals of Rotary Friction Welding

3. Material Characteristics

Properties of Aluminium and Its Alloys

4. Results and Discussion

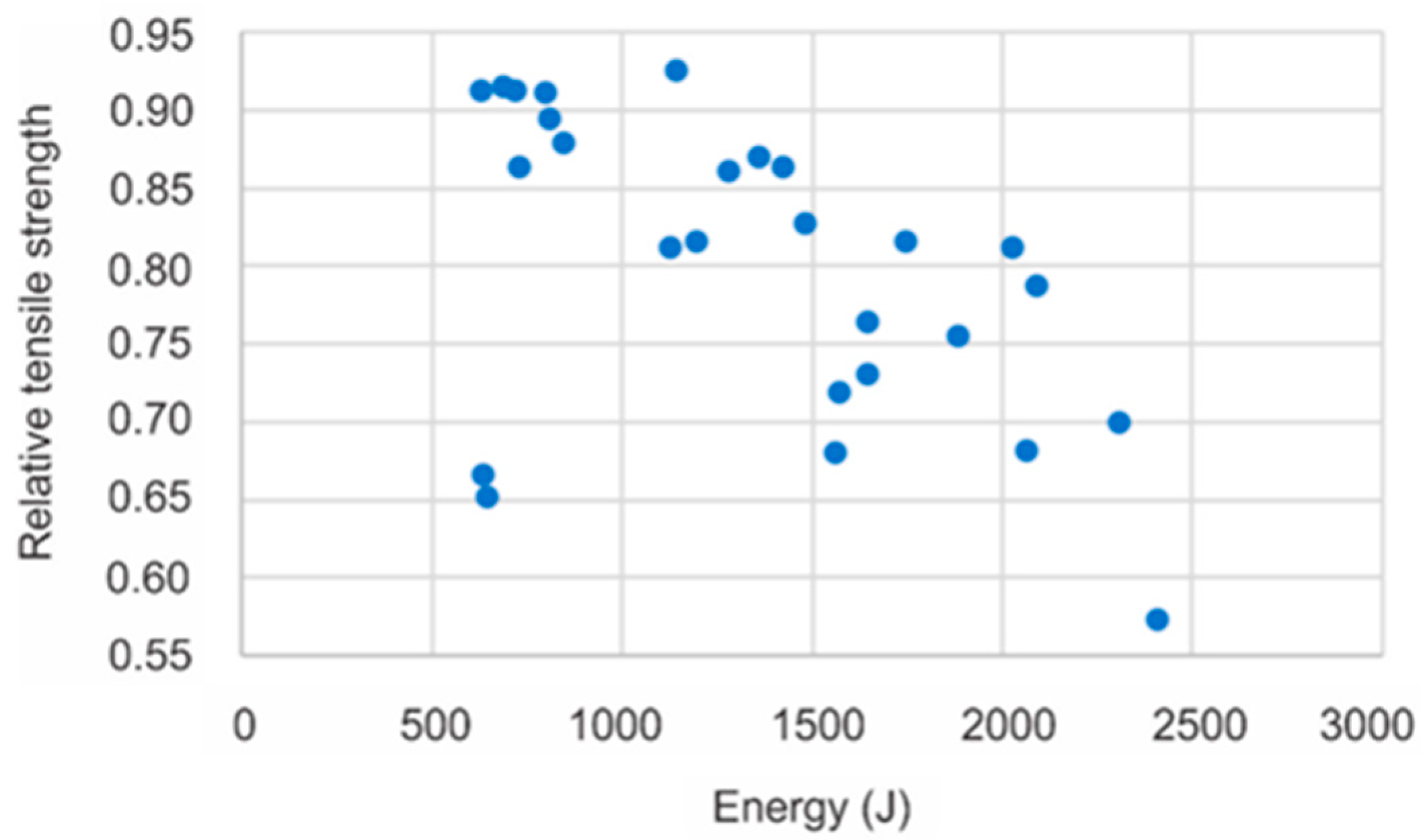

4.1. Analysis of Process Parameters and Their Optimization for Al-Cu RFW

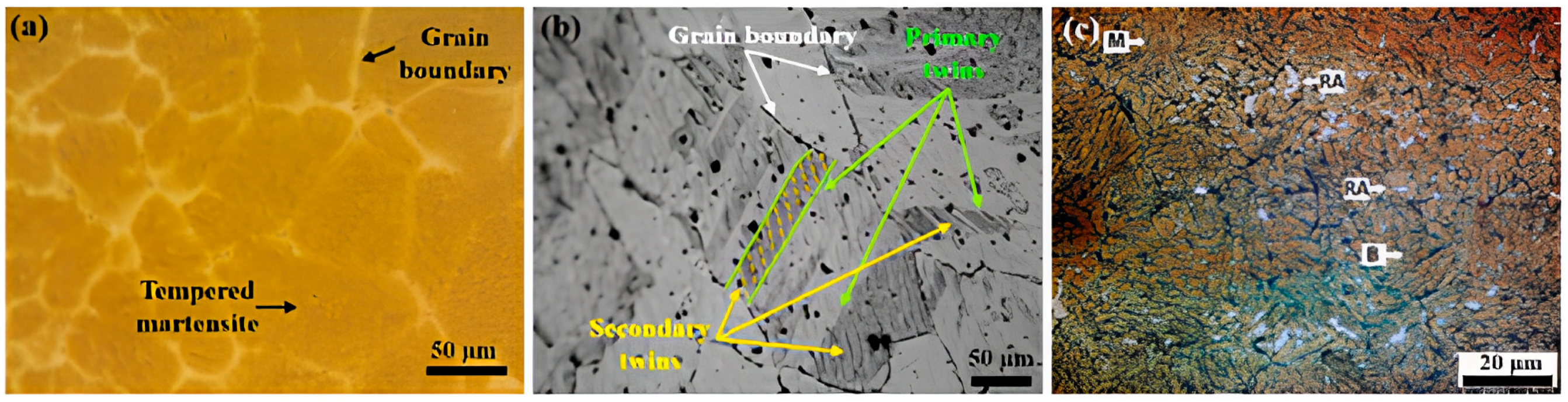

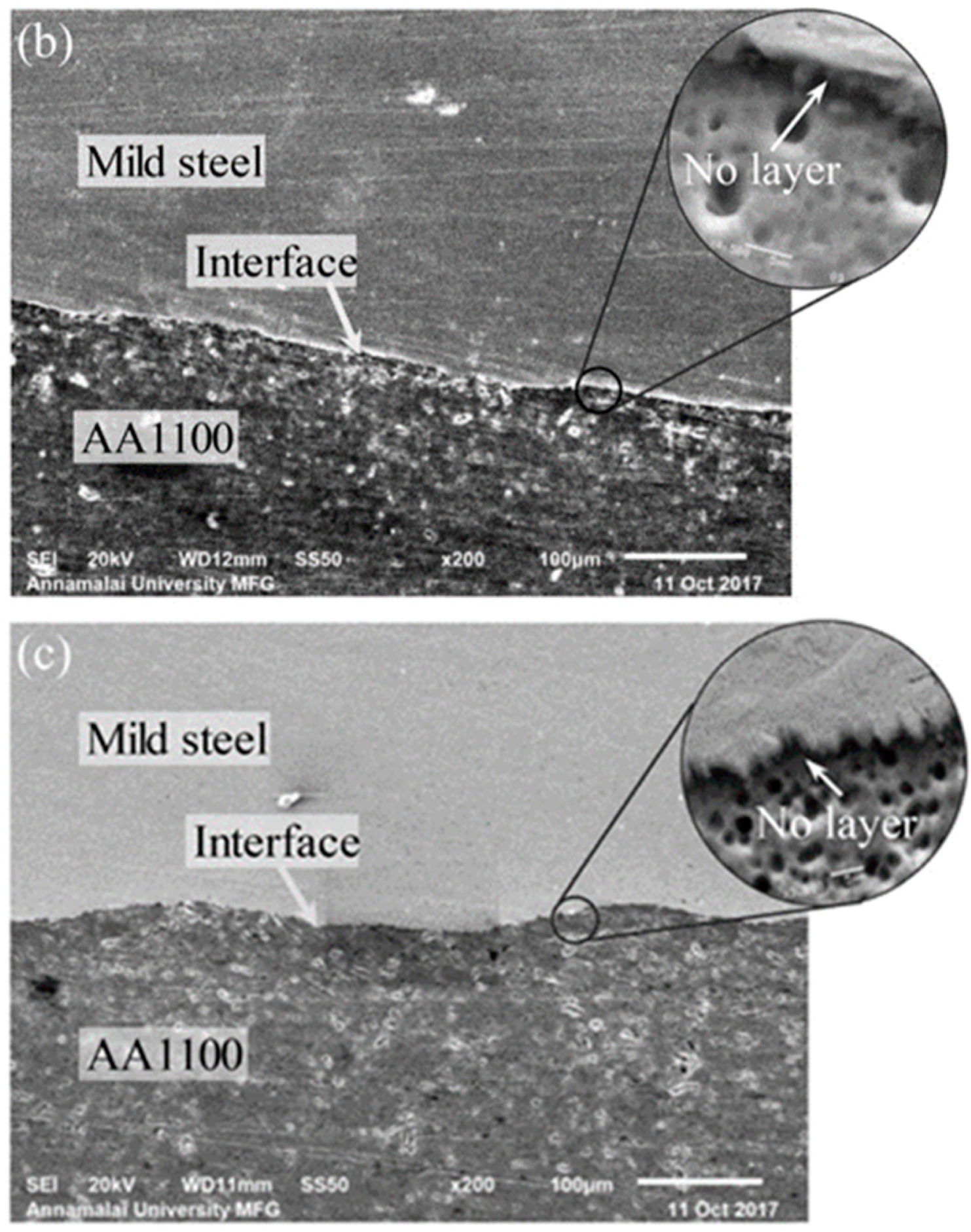

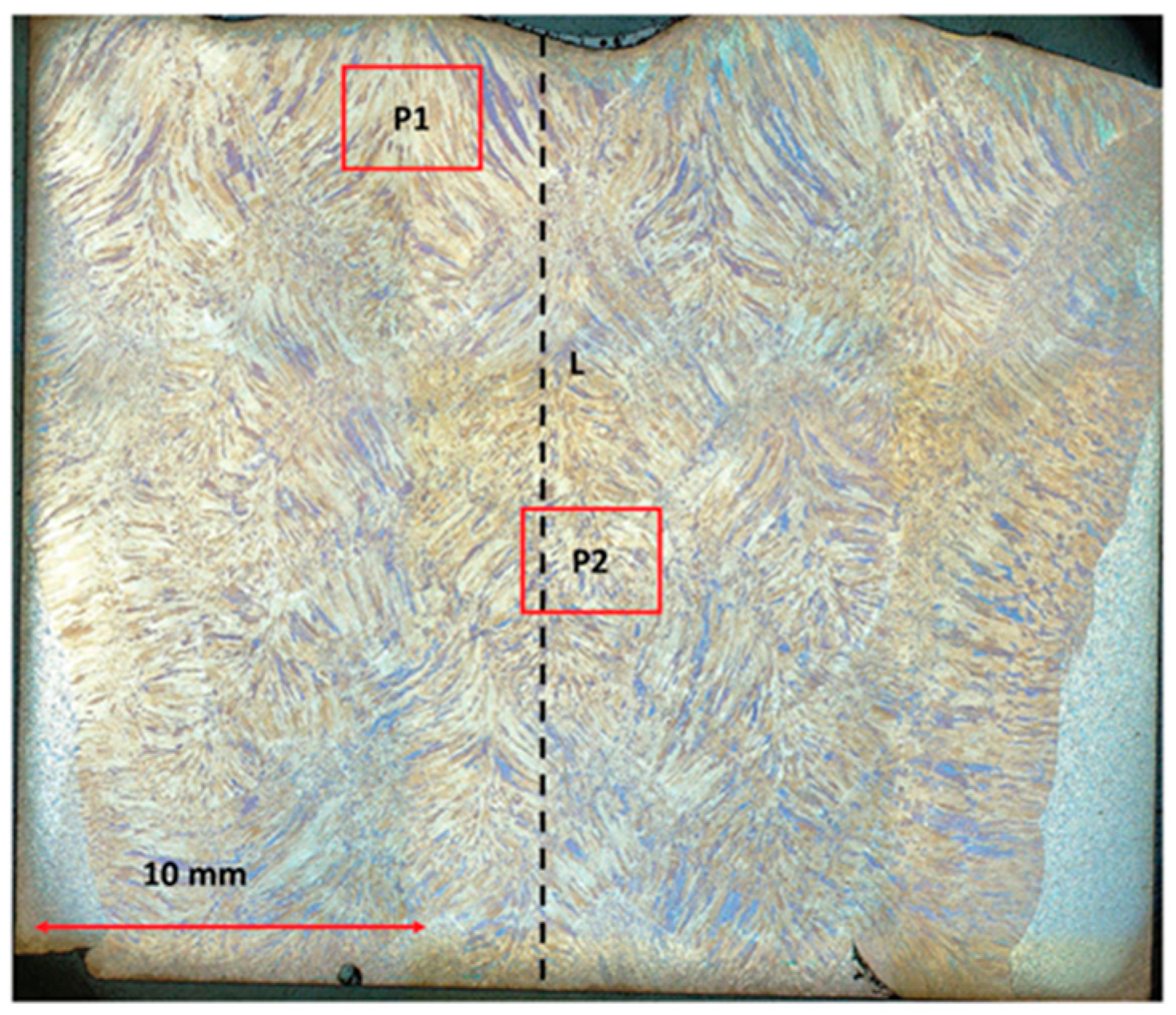

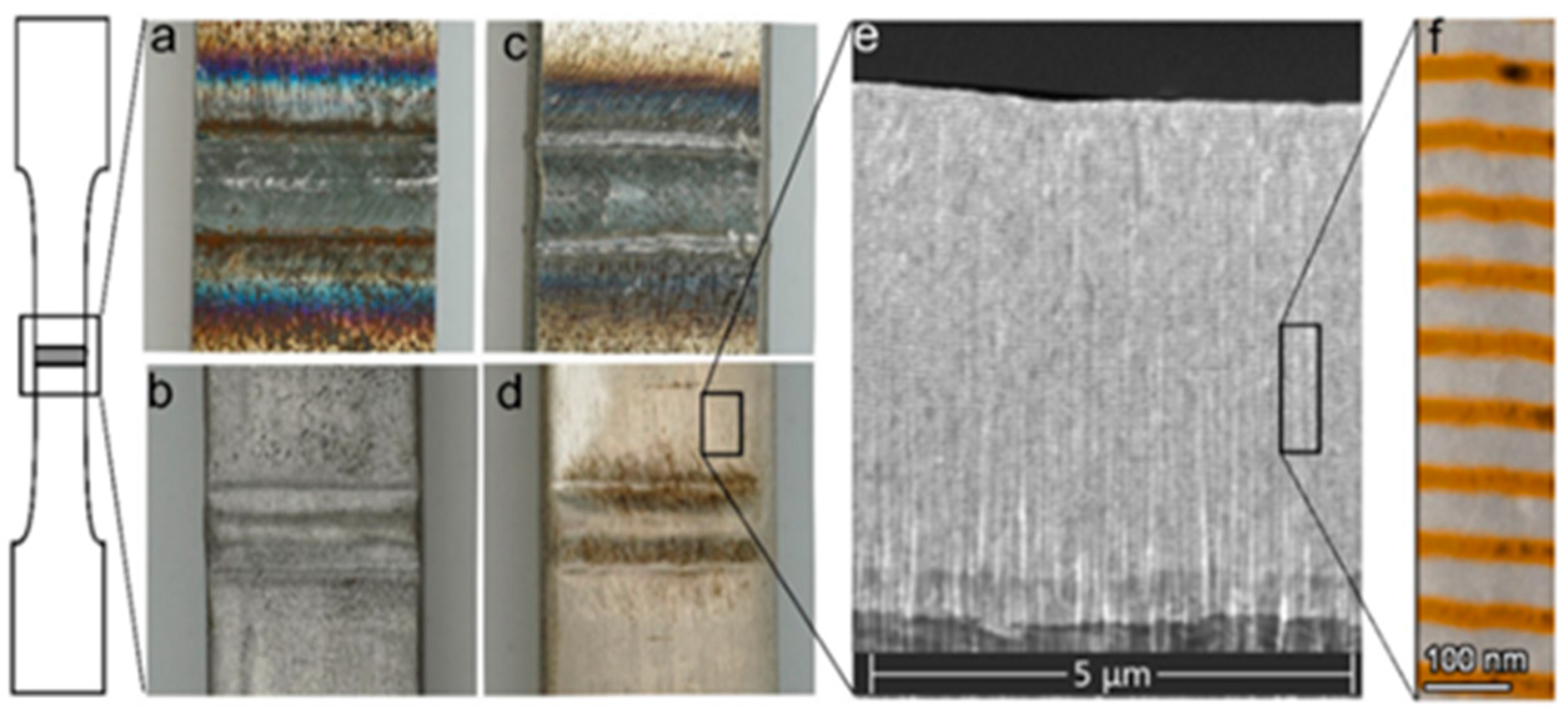

4.2. Evaluation of Microstructural Characteristics and Their Influence on Joint Properties

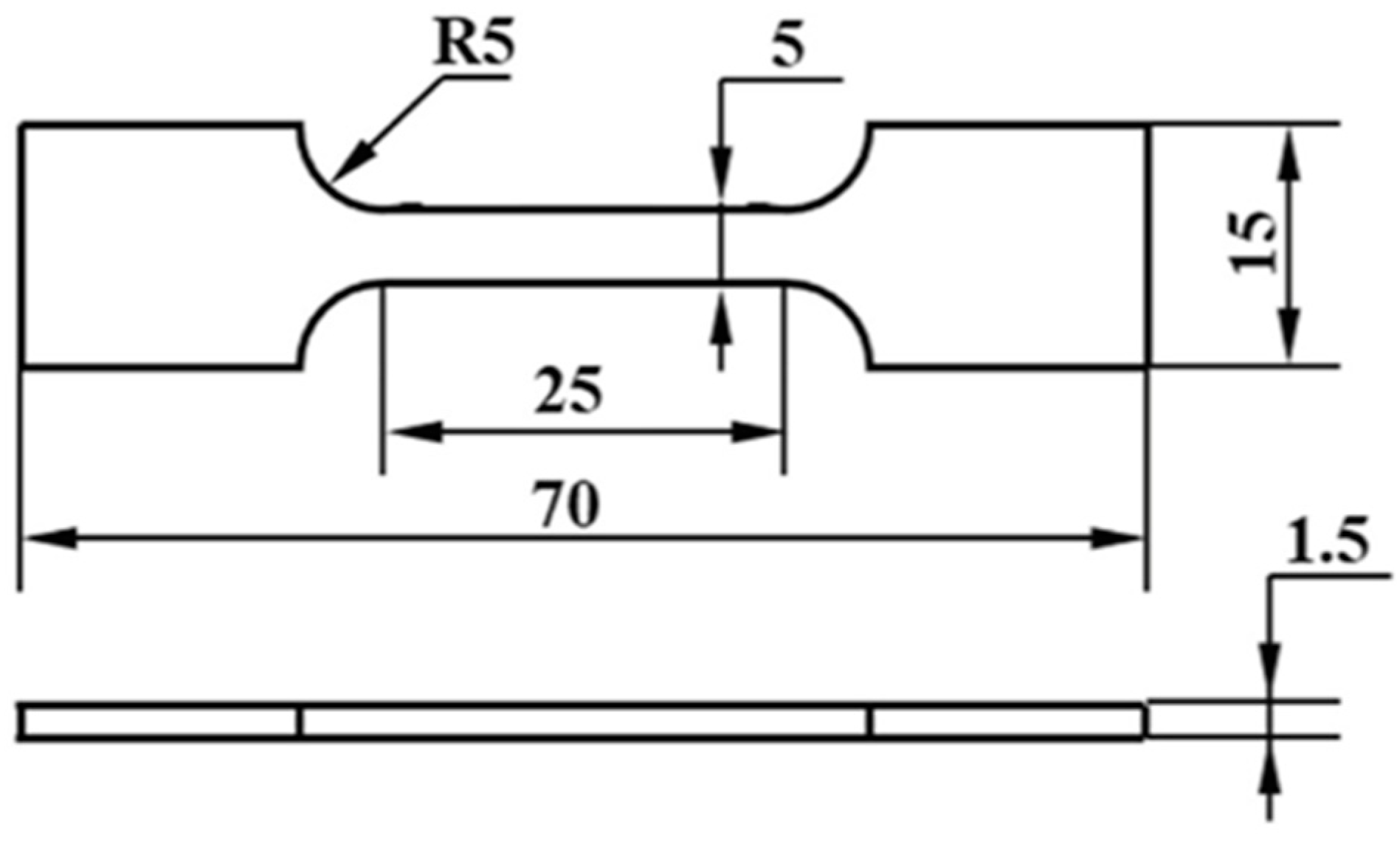

4.3. Assessment of Mechanical Properties, Including Tensile Strength, Hardness, and Fatigue Resistance

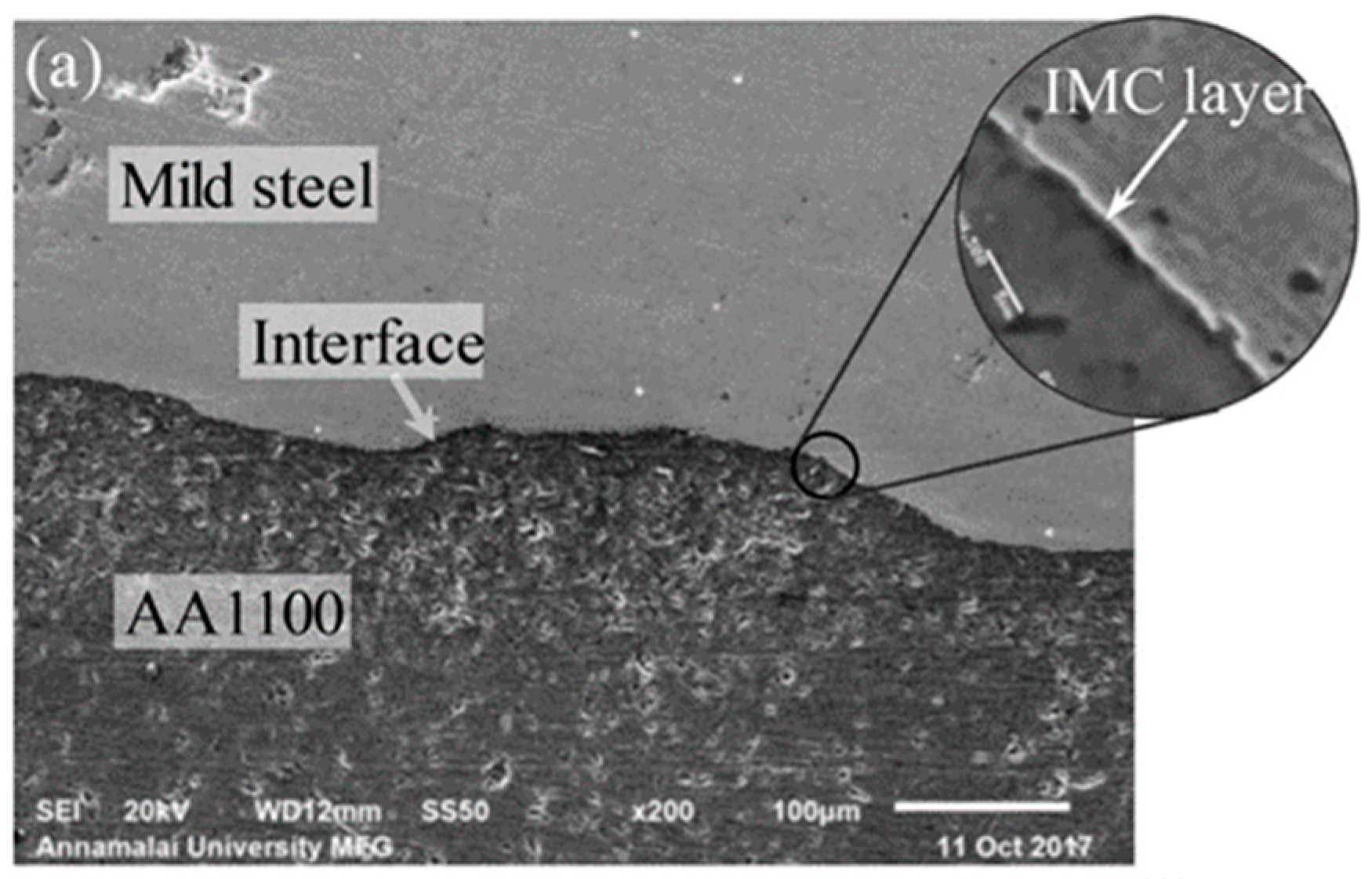

4.4. Testing of Intermetallic Compound Formation and Its Effects on Joint Strength

4.5. Investigation of Post-Weld Treatments to Improve Joint Strength

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Chapke, Y.; Kamble, D.N. View of Effect of friction-welding parameters on the tensile strength of AA6063 with dissimilar joints. Frat. Integrità Strutt. 2022, 16, 573–584. [Google Scholar] [CrossRef]

- Taysom, B.S.; Society, A.W.; Sorensen, C.D.; Nelson, T.W. Strength in Rotary Friction Welding of Five Dissimilar Nickel-Based Superalloys. Weld. J. 2021, 100, 302–308. [Google Scholar] [CrossRef]

- Manikandan, P.; Prabhu, T.A.; Manwatkar, S.K.; Rao, G.S.; Murty, S.V.S.N.; Sivakumar, D.; Pant, B.; Mohan, M. Tensile and Fracture Properties of Aluminium Alloy AA2219-T87 Friction Stir Weld Joints for Aerospace Applications. Met. Mater. Trans. A. 2021, 52, 3759–3776. [Google Scholar] [CrossRef]

- Winiczenko, R.; Skibicki, A.; Skoczylas, P. The Experimental and FEM Studies of Friction Welding Process of Tungsten Heavy Alloy with Aluminium Alloy. Appl. Sci. 2024, 14, 2038. [Google Scholar] [CrossRef]

- Yaduwanshi, D.K.; Rao, C.R.M.; Naidu, S.C.V.R.M.; Sakharwade, S.G.; Sharma, S.; Khalkar, V.; Baskar, S.; Kaliyaperumal, G. Thermal evaluation of aluminum welding: A comparative study of friction stir welding (FSW), plasma-fsw, and tungsten inert gas (TIG)-FSW techniques. Int. J. Interact. Des. Manuf. (IJIDeM) 2024, 18, 5501–5513. [Google Scholar] [CrossRef]

- Manjunath, B.N.; Jayaprakash, P.; Mishra, A.; Karthik, H.S.; Arulkirubakaran, D.; Kiran, D.V.; Venkaiah, N. Joining dissimilar metals using cold metal transfer process: A review. Weld. World 2024, 68, 579–591. [Google Scholar] [CrossRef]

- Selvaraj, S.; Srirangarajalu, N.; Kengachalam, N.; Pranaybabu, K. Investigation of Mechanical Properties on Underwater Friction Stir Welded AA7075 with Pure Copper Dissimilar Joints. Trans. Indian Inst. Met. 2024, 77, 1181–1194. [Google Scholar] [CrossRef]

- Salih, O.S.; Ou, H.; Sun, W. Heat generation, plastic deformation and residual stresses in friction stir welding of aluminium alloy. Int. J. Mech. Sci. 2023, 238, 107827. [Google Scholar] [CrossRef]

- Derbiszewski, B.; Obraniak, A.; Rylski, A.; Siczek, K.; Wozniak, M. Studies on the Quality of Joints and Phenomena Therein for Welded Automotive Components Made of Aluminum Alloy—A Review. Coatings 2024, 14, 601. [Google Scholar] [CrossRef]

- Ramesh, A.P.; Subramaniyan, M.; Eswaran, P. Review on Friction Welding of Similar/Dissimilar Metals. J. Phys. Conf. Ser. 2019, 1362, 012032. [Google Scholar] [CrossRef]

- Nugroho, A.W.; Rahman, K.A.; Rahman, M.B.N. The Effect of Rotational Tool Speed on Dissimilar Joint Aluminum-Copper Plate Friction Stir Welded Joint. Semesta Tek. 2023, 26, 128–136. [Google Scholar] [CrossRef]

- Reyes, A.E.S.; Rodriguez, G.L.; Parra, J.R.G.; Lemus, V.H.M. Microstructural Characterization and Corrosion Behavior of Similar and Dissimilar Welded Advanced High-Strength Steels (AHSS) by Rotary Friction Welding. Materials 2024, 17, 918. [Google Scholar] [CrossRef]

- Atamashkin, A.; Priymak, E.; Tulibaev, E.; Syomka, Y.; Trushov, V. Influence of force parameters of rotary friction welding on the microstructure and mechanical properties of welded joints of high-strength drill pipes. Int. J. Interact. Des. Manuf. 2024. preprint (Version 1) available at Research Square. [Google Scholar] [CrossRef]

- Fakhri, M.; Al-Mukhtar, A.; Mahmood, I. Mechanical behavior and failure mechanism of resistance spot welded Aluminum and Copper joint used in the lightweight structures. Diagnostyka 2024, 25, 2024207. [Google Scholar] [CrossRef]

- Mao, Y.; Ke, L.; Chen, Y.; Liu, F.; Xing, L. Inhomogeneity of microstructure and mechanical properties in the nugget of friction stir welded thick 7075 aluminum alloy joints. J. Mater. Sci. Technol. 2018, 34, 228–236. [Google Scholar] [CrossRef]

- Kah, P.; Shrestha, M.; Martikainen, J. Trends in Joining Dissimilar Metals by Welding. Appl. Mech. Mater. 2013, 440, 269–276. [Google Scholar] [CrossRef]

- Mandal, A.; Barma, J.D.; Majumdar, G. Effect of Tool Pin Geometries on Weld Quality of Al/Cu Dissimilar Friction Stir Welding. J. Inst. Eng. (India) Ser. D 2024, 105, 211–225. [Google Scholar] [CrossRef]

- Ghari, H.; Taherizadeh, A.; Sadeghian, B.; Cavaliere, P. Metallurgical characteristics of aluminum-steel joints manufactured by rotary friction welding: A review and statistical analysis. J. Mater. Res. Technol. 2024, 30, 2520–2550. [Google Scholar] [CrossRef]

- Tan, C.; Jiang, Z.; Li, L.; Chen, Y.; Chen, X. Microstructural evolution and mechanical properties of dissimilar Al–Cu joints produced by friction stir welding. Mater. Des. 2013, 51, 466–473. [Google Scholar] [CrossRef]

- Shehabeldeen, T.A.; El-Shafai, N.M.; El-Mehasseb, I.M.; Yin, Y.; Ji, X.; Shen, X.; Zhou, J. Improvement of microstructure and mechanical properties of dissimilar friction stir welded aluminum/titanium joints via aluminum oxide nanopowder. Vacuum 2021, 188, 110216. [Google Scholar] [CrossRef]

- Chapke, Y.; Kamble, D.; Shaikh, S.M.S. Friction welding of Aluminium Alloy 6063 with copper. E3S Web Conf. 2020, 170, 02004. [Google Scholar] [CrossRef]

- Busarac, N.; Adamovic, D.; Grujovic, N.; Zivic, F. Lightweight Materials for Automobiles. IOP Conf. Ser. Mater. Sci. Eng. 2022, 1271, 012010. [Google Scholar] [CrossRef]

- Taub, A.I.; Luo, A.A. Advanced lightweight materials and manufacturing processes for automotive applications. MRS Bull. 2015, 40, 1045–1054. [Google Scholar] [CrossRef]

- Zhang, W.; Xu, J. Advanced lightweight materials for Automobiles: A review. Mater. Des. 2022, 221, 110994. [Google Scholar] [CrossRef]

- Gao, P.; Zhang, Y.; Mehta, K.P. Metallurgical and Mechanical Properties of Al–Cu Joint by Friction Stir Spot Welding and Modified Friction Stir Clinching. Met. Mater. Int. 2021, 27, 3085–3094. [Google Scholar] [CrossRef]

- Wahid, M.A.; Siddiquee, A.N.; Khan, Z.A.; Asjad, M. Friction Stir Welds of Al Alloy-Cu: An Investigation on Effect of Plunge Depth. Arch. Mech. Eng. 2016, 63, 619–634. [Google Scholar] [CrossRef]

- Yu, F.; Zhao, Y.; Lin, Z.; Miao, Y.; Zhao, F.; Xie, Y. Prediction of Mechanical Properties and Optimization of Friction Stir Welded 2195 Aluminum Alloy Based on BP Neural Network. Metals 2023, 13, 267. [Google Scholar] [CrossRef]

- Colmenero, A.N.; Orozco, M.S.; Macías, E.J.; Fernández, J.B.; Muro, J.C.S.-D.; Fals, H.C.; Roca, A.S. Optimization of friction stir spot welding process parameters for Al-Cu dissimilar joints using the energy of the vibration signals. Int. J. Adv. Manuf. Technol. 2019, 100, 2795–2802. [Google Scholar] [CrossRef]

- Li, P.; Pan, L.; Hao, X.; Li, S.; Dong, H. Effect of post-weld heat treatment on inhomogeneity of aluminum/copper rotary friction welded joint. Mater. Res. Express 2018, 5, 096504. [Google Scholar] [CrossRef]

- Kumar, J.P.; Raj, A.; Arul, K.; Mohanavel, V. A literature review on friction stir welding of dissimilar materials. Mater. Today Proc. 2021, 47, 286–291. [Google Scholar] [CrossRef]

- Zhou, N.; Gan, C.; Song, D.; Qi, W.; Attallah, M.M. Influence of Forging Pressure on Microstructural and Mechanical Properties Development in Linear Friction Welded Al-Cu Dissimilar Joint. Soldag. Inspecao 2019, 24, e2401. [Google Scholar] [CrossRef]

- Kumar, N. A Review on the Friction Stir Welding Processes Used for Joining the Various Dissimilar Materials from the a Review on the Friction Stir Welding Processes Used for Joining the Various Dissimilar Materials from the Year 2017 to the Year 2023. 2023. Available online: www.tijer.org (accessed on 5 February 2024).

- Sahin, M. Joining of aluminium and copper materials with friction welding. Int. J. Adv. Manuf. Technol. 2010, 49, 527–534. [Google Scholar] [CrossRef]

- Ciemiorek, M.; Morawiński, Ł.; Jasiński, C.; Orłowska, M.; Chmielewski, T.; Olejnik, L.; Lewandowska, M. Characterization of ultrafine-grained copper joints acquired by rotary friction welding. Arch. Civ. Mech. Eng. 2022, 22, 9. [Google Scholar] [CrossRef]

- Ojetoye, A.; Akangbe, S.; Olorunda, O. Friction Welding Processes: A Review. FUOYE J. Eng. Technol. 2024, 9, 103–110. [Google Scholar] [CrossRef]

- Lakache, H.E.; May, A.; Badji, R.; Poirot, N.; Yssaad, S.N.E.R. Effect of copper interlayer in dissimilar TA6V/AU4G rotary friction weld joints. Weld. World 2024, 68, 1869–1879. [Google Scholar] [CrossRef]

- Karetnikov, D.V.; Tokarev, A.S.; Yakhin, A.V.; Fairushin, A.M. Assessment of the possibility of using RFW for the production of composite joints from steel X10CRNITI18-10. J. Phys. Conf. Ser. 2022, 2373, 072018. [Google Scholar] [CrossRef]

- Vuyolwethu Mjali, K.; Andrew Mkoko, Z. Manufacturing Letters Varying Rotational Speeds and Their Effect on the Mechanical Properties of Friction Stir Welded 6082-T651 Aluminium Alloy Plates-NC-ND License Peer-Review Under Responsibility of the Scientific Committee of the NAMRI/SME. 2023. Available online: www.sciencedirect.com (accessed on 1 March 2024).

- Jiang, F.; Wang, W.; Zhang, X.; Gong, W. Microstructure and Mechanical Properties of Friction Stir Lap Welding Joint of Al/CU Dissimilar Metals. Metals 2023, 13, 1969. [Google Scholar] [CrossRef]

- Taborda, D.; Leal, R.M.; Morgado, T.; Leitão, C.; Galvão, I. Copper/Stainless Steel Friction Stir Spot Welds—Feasibility and Microstructural Analysis. Mater. Proc. 2022, 8, 128. [Google Scholar] [CrossRef]

- Kurabayashi, K.; Tokita, S.; Sato, Y.S. Effect of Ni Addition on the Interfacial Strength of Al/Cu Dissimilar Welds Produced by Friction Stir Lap Welding. Metals 2022, 12, 453. [Google Scholar] [CrossRef]

- Boucherit, A.; Abdi, S.; Aissani, M.; Mehdi, B.; Abib, K.; Badji, R. Weldability, microstructure, and residual stress in Al/Cu and Cu/Al friction stir spot weld joints with Zn interlayer. Int. J. Adv. Manuf. Technol. 2020, 111, 1553–1569. [Google Scholar] [CrossRef]

- Maniscalco, J.; Elmustafa, A.A.; Bhukya, S.; Wu, Z. Numerical Simulation of the Donor-Assisted Stir Material for Friction Stir Welding of Aluminum Alloys and Carbon Steel. Metals 2023, 13, 164. [Google Scholar] [CrossRef]

- Malik, V.R.; Bajakke, P.A.; Jambagi, S.C.; Nagarjuna, C.; Deshpande, A.S. Investigating Mechanical and Corrosion Behavior of Plain and Reinforced AA1050 Sheets Fabricated by Friction Stir Processing. JOM 2020, 72, 3582–3593. [Google Scholar] [CrossRef]

- Mehdi, H.; Kumar, V.; Kumar, A. Effect of Silicon content on the Mechanical Properties of Aluminum Alloy. Int. Res. J. Eng. Technol. 2015, 2, 1326–1330. Available online: https://www.researchgate.net/publication/282704257 (accessed on 13 January 2024).

- Stąpór, S.; Górny, M.; Kawalec, M.; Gracz, B. Effect of variable manganese content on microstructure of al-cu alloys. Arch. Met. Mater. 2020, 65, 1377–1383. [Google Scholar] [CrossRef]

- Micah, B.; Akor, T. Physical and Mechanical Characterization Of Aluminum Bronze (Cu-10%Al) Alloy Doped with Fe. J. Sci. Technol. Educ. 2021, 9, 450–458. [Google Scholar]

- Kumar Chaurasiya, A. Effect of Aluminum/Copper as a Metal Filler in Non-Asbestos Organic (NAO) Brake Composites Materials for Medium Duty Application. 2023. Available online: https://www.researchgate.net/publication/372315432 (accessed on 21 February 2024).

- Kang, J.-W.; Zhang, S.; Thi, T.-A.B.; Hong, S.-T.; Lee, S.; Han, H.N. Friction-Assisted Dissimilar Solid State Lap Joining of Aluminum and Copper Pipes. Int. J. Precis. Eng. Manuf. 2023, 24, 199–208. [Google Scholar] [CrossRef]

- Kundu, S.; Mondal, S.C. Electro-thermal and mechanical property analysis of powder metallurgy processed, multi-stage ball milled aluminium-copper-multi walled carbon nanotube composite. Eng. Res. Express 2024, 6, 025574. [Google Scholar] [CrossRef]

- Ooi, S. A new index to estimate the corrosion resistance of aluminium-containing steel. Mater. Corros. 2024, 75, 902–913. [Google Scholar] [CrossRef]

- Zhu, H.; Li, J. Advancements in corrosion protection for aerospace aluminum alloys through surface treatment. Int. J. Electrochem. Sci. 2024, 19, 100487. [Google Scholar] [CrossRef]

- Yong, Y. Research on Properties and Applications of New Lightweight Aluminum Alloy Materials. Highlights Sci. Eng. Technol. 2024, 84, 99–107. [Google Scholar] [CrossRef]

- Sasikala, P.; Madhusudhan, R. Enhancing Friction Stir Welding Efficiency through Rotational Speed Adjustment: A Microstructural and Mechanical Analysis of Al-Cu Alloy. Eng. Res. Express 2024, 6, 015053. [Google Scholar] [CrossRef]

- Isaeva, A.; Priymak, E.; Atamashkin, A.; Kirilenko, A. Optimization of rotary friction welding parameters for dissimilar joints of exploration drill pipes. Int. J. Adv. Manuf. Technol. 2023, 126, 5325–5337. [Google Scholar] [CrossRef]

- Pang, Q.; Zhao, M.; Zhang, Z. The Effect of High-Temperature Deformation on the Mechanical Properties and Corrosion Resistance of the 2024 Aluminum Alloy Joint after Friction Stir Welding. Materials 2024, 17, 2969. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.; Guo, F.; Wang, T.; Duan, S.; Zou, Y. Study on corrosion resistance of HAZ and TMAZ in friction stir welding joint of 7075 aluminum alloy by thermal simulation. Mater. Res. Express 2023, 10, 016505. [Google Scholar] [CrossRef]

- Hamdy, K.; Pozdniakov, A.V.; Aly, W.Y.; Amer, S.M. Investigation of the Abrasion Resistance of Aluminum Copper Magnesium Alloy. J. Egypt. Soc. Tribol. 2022, 19, 19–27. [Google Scholar] [CrossRef]

- Naresh Kumar, M.; Dewangan, R.; Rao, K.R. Thermal Analysis of Friction Stir Welded Joints of Aluminum and Copper Alloys. 2024. Available online: https://www.researchgate.net/publication/381322835 (accessed on 23 March 2024).

- Kumar, N.; Dewangan, R. The Friction Stir Welding of Aluminium and Copper. Metszet J. 2024, 9, 126–136. [Google Scholar]

- Collini, L. Copper Alloys—Early Applications and Current Performance—Enhancing Processes; IntechOpen: Rijeka, Croatia, 2012. [Google Scholar] [CrossRef]

- Kumar, A.Y.; Wang, J.; Bai, Y.; Huxtable, S.T.; Williams, C.B. Impacts of process-induced porosity on material properties of copper made by binder jetting additive manufacturing. Mater. Des. 2019, 182, 108001. [Google Scholar] [CrossRef]

- Karrar, G.; Galloway, A.; Toumpis, A.; Al-Badour, F.; Li, H. Prediction and validation of intermetallic compound formation during friction stir welding of AA6061 to commercially pure copper. Sci. Technol. Weld. Join. 2022, 27, 374–387. [Google Scholar] [CrossRef]

- Liu, R.; Chen, D.; Ou, M.; Liang, Y. The effect of initial grain size on the strength property of copper with gradient microstructure. J. Mater. Res. Technol. 2023, 24, 407–417. [Google Scholar] [CrossRef]

- Shukla, S.; Jaju, S.; Untawale, S.; Chavhan, J.; Vashishtha, N.; Dhakane, A.; Bansod, A.; Gahiga, G. Effect of martensitic reversal and grain size on the corrosion and wear behaviour of Cr-Mn steel. Mater. Res. Express 2024, 11, 036514. [Google Scholar] [CrossRef]

- Winarto, W.; Anis, M.; Febryansyah, B.E. Mechanical and Microstructural Properties of Friction Stir Welded Dissimilar Aluminum Alloys and Pure Copper Joints. MATEC Web Conf. 2019, 269, 01001. [Google Scholar] [CrossRef]

- Morawiński, Ł.; Jasiński, C.; Goliński, J.; Chmielewski, T.M. Friction welding of UFG copper using the W2Mi prototype machine. Arch. Civ. Mech. Eng. 2024, 24, 139. [Google Scholar] [CrossRef]

- A Guide to Working with Copper and Copper Alloys. Available online: www.antimicrobialcopper.com (accessed on 31 January 2024).

- Stershic, A.J.; D’Elia, C.; Beghini, L.; Hill, M.R.; Clausen, B.; Balch, D.; Maguire, M.; San Marchi, C.; Foulk, I.I.I.J.; Hanson, A.; et al. Multiphysics Modeling of Resistance Forge Welding with Adaptive Remeshing and Experimental Validation of Residual Stress. Available online: https://papers.ssrn.com/sol3/papers.cfm?abstract_id=4786242 (accessed on 31 January 2024).

- Wilms, M.B.; Rittinghaus, S.-K. Laser Additive Manufacturing of Oxide Dispersion-Strengthened Copper–Chromium–Niobium Alloys. J. Manuf. Mater. Process. 2022, 6, 102. [Google Scholar] [CrossRef]

- Albuquerque, A.; Louche, H.; Oliveira, D.; Brito, I. Rotary friction welding applied to Cu11.8Al0.45Be shape memory alloy. J. Adv. Join. Process. 2024, 10, 100233. [Google Scholar] [CrossRef]

- Fateh, A.; Aliofkhazraei, M.; Rezvanian, A. Review of corrosive environments for copper and its corrosion inhibitors. Arab. J. Chem. 2020, 13, 481–544. [Google Scholar] [CrossRef]

- Chen, K.; Leng, X.; Zhao, R.; Kang, Y.; Chen, H. Progress in the Copper-Based Diamond Composites for Thermal Conductivity Applications. Crystals 2023, 13, 906. [Google Scholar] [CrossRef]

- Dhaneswara, D.; Fatriansyah, J.F.; Ramadhan, R.; Ashari, A. The Effect of Melting Temperature Aluminum Metal Casting Using Mixed Degasser Based Sodium Fluoride and Sodium Nitrate. MATEC Web Conf. 2019, 269, 07001. [Google Scholar] [CrossRef]

- Wang, J.; Lin, P.; Yao, Q.; Huang, Y.; Xie, X.; Li, Z.; Zhang, L. Transient liquid phase bonding of Sn-Pb solder with added Cu particles. J. Physics Conf. Ser. 2024, 2671, 012022. [Google Scholar] [CrossRef]

- Govind, V.; Bharadwaj, S.; Ganesh, M.R.S.; Vishnu, J.; Shankar, K.V.; Shankar, B.; Rajesh, R. Antiviral properties of copper and its alloys to inactivate COVID-19 virus: A review. BioMetals 2021, 34, 1217–1235. [Google Scholar] [CrossRef]

- Czerwinski, F. Thermal Stability of Aluminum Alloys. Materials 2020, 13, 3441. [Google Scholar] [CrossRef] [PubMed]

- Han, L.; Yu, Z.; Yan, D.; Rao, Y.; Ma, L. Improved Interface Morphology and Failure Load of Ultrasonic-Assisted Friction Stir Lap Welding Joint of 2024 Aluminum Alloy to 304 Stainless Steel. Metals 2024, 14, 267. [Google Scholar] [CrossRef]

- Wendel, J.; Manchili, S.K.; Hryha, E.; Nyborg, L. Oxide reduction and oxygen removal in water-atomized iron powder: A kinetic study. J. Therm. Anal. Calorim. 2020, 142, 309–320. [Google Scholar] [CrossRef]

- Tang, J.X.; Shi, L.; Wu, C.S.; Wu, M.X.; Gao, S. Microstructure and Mechanical Properties of Dissimilar Double-Side Friction Stir Welds Between Medium-Thick 6061-T6 Aluminum and Pure Copper Plates. Acta Met. Sin. English Lett. 2022, 35, 2027–2046. [Google Scholar] [CrossRef]

- Wordofa, T.N.; Perumalla, J.R.; Sharma, A. Mechanical and microstructural characterization of AISI SAE 4130 steel welded joints made by robotic gas metal arc welding process: Influence of electrode work angle in ’T’ welded joints. Mater. Res. Express 2024, 11, 066518. [Google Scholar] [CrossRef]

- Lemos, G.V.B.; Farina, A.B.; Piaggio, H.; Bergmann, L.; Ferreira, J.Z.; dos Santos, J.F.; Voort, G.V.; Reguly, A. Mitigating the susceptibility to intergranular corrosion of alloy 625 by friction-stir welding. Sci. Rep. 2022, 12, 3482. [Google Scholar] [CrossRef]

- Kumar, S.; Gaur, V.; Wu, C. Machine learning for intelligent welding and manufacturing systems: Research progress and perspective review. Int. J. Adv. Manuf. Technol. 2022, 123, 3737–3765. [Google Scholar] [CrossRef]

- Silva, R.G.N.; De Meester, S.; Faes, K.; De Waele, W. Development and Evaluation of the Ultrasonic Welding Process for Copper-Aluminium Dissimilar Welding. J. Manuf. Mater. Process. 2022, 6, 6. [Google Scholar] [CrossRef]

- Mehdi, H.; Batra, L.; Singh, A.P.; Malla, C. Multi-response optimization of FSW process parameters of dissimilar aluminum alloys of AA2014 and AA6061 by response surface methodology (RSM). Int. J. Interact. Des. Manuf. (IJIDeM) 2024, 18, 1507–1522. [Google Scholar] [CrossRef]

- Subramanian, S.M.; Paulraj, S.; Haq, N.H.A. Effect of faying surfaces and characterization of aluminium AA6063–steel AISI304L dissimilar joints fabricated by friction welding with hemispherical bowl and threaded faying surfaces. Int. J. Adv. Manuf. Technol. 2021, 116, 629–666. [Google Scholar] [CrossRef]

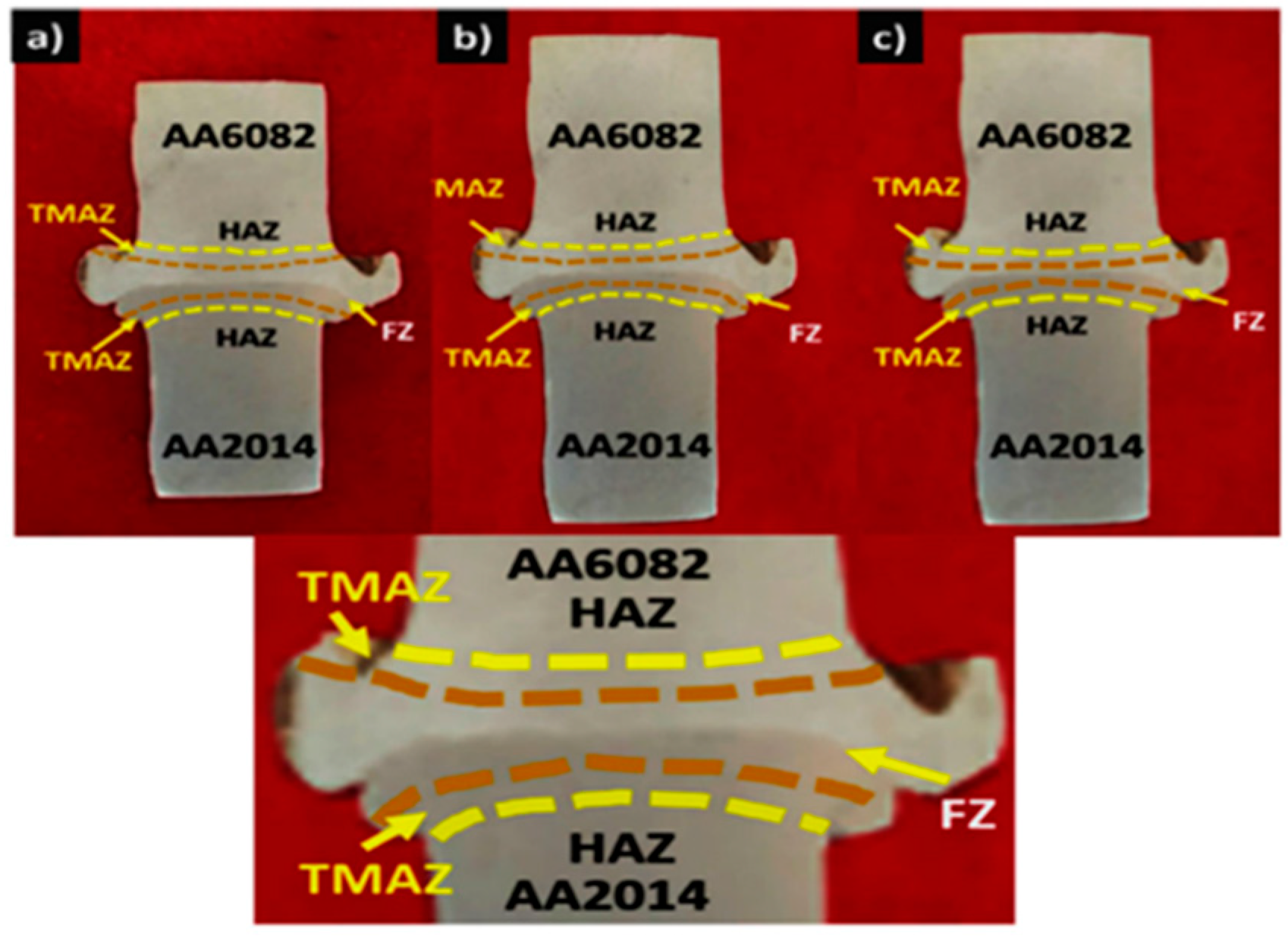

- Settu, N.; Kesavan, G.K.; Subramanian, A.; Ramasamy, M.; Rangesh, A.; Settu, R.; Mathivanan, T.; Praveenkumar, V.; Shankar, K.V.; Manu, K. Optimization of tensile properties by rotary friction welded dissimilar 2014 T6 and 6082 T6 aluminium alloys. Int. J. Interact. Des. Manuf. (IJIDeM) 2024. [Google Scholar] [CrossRef]

- Mikolajčík, M.; Kuchariková, L.; Tillová, E.; Sanchez, J.M.; Šurdová, Z.; Chalupová, M. Influence of Copper Addition on the Mechanical Properties and Corrosion Resistance of Self-Hardening Secondary Aluminium Alloy AlZn10Si8Mg. Metals 2024, 14, 776. [Google Scholar] [CrossRef]

- Sasmito, A.; Ilman, M.N.; Iswanto, P.T.; Muslih, R. Effect of Rotational Speed on Static and Fatigue Properties of Rotary Friction Welded Dissimilar AA7075/AA5083 Aluminium Alloy Joints. Metals 2022, 12, 99. [Google Scholar] [CrossRef]

- Chen, Y.; Jiang, H.; Zhou, Z.; Liu, C. Interfacial intermetallic compounds growth kinetics and mechanical characteristics of Ga-Cu interconnects prepared via transient liquid phase bonding. Mater. Today Commun. 2024, 38, 108401. [Google Scholar] [CrossRef]

- Khalfallah, F.; Boumerzoug, Z.; Rajakumar, S.; Raouache, E. Optimization by RSM on rotary friction welding of AA1100 aluminum alloy and mild steel. Int. Rev. Appl. Sci. Eng. 2020, 11, 34–42. [Google Scholar] [CrossRef]

- Abnar, B.; Javidani, M. Effect of Dispersing In Situ Al-Cu Intermetallic Compounds on Joint Strength in Friction Stir Welding of AA3003-H18 Sheets. Metals 2024, 14, 277. [Google Scholar] [CrossRef]

- Harati, E.; Harati, E.; Onochie, U. Effect of post-weld heat treatment on mechanical and microstructural properties of high strength steel weld metal. Weld. Int. 2024, 38, 422–429. [Google Scholar] [CrossRef]

- Brunow, J.; Spalek, N.; Mohammadi, F.; Rutner, M. A novel post-weld treatment using nanostructured metallic multilayer for superior fatigue strength. Sci. Rep. 2023, 13, 22215. [Google Scholar] [CrossRef]

| Elements | Cu + Ag | Fe | Bi | Sb | As | Pb | S |

|---|---|---|---|---|---|---|---|

| Copper | 99.90 | 0.005 | 0.001 | 0.002 | 0.002 | 0.005 | 0.005 |

| Materials | Mechanical Properties | Chemical Composition | Industrial Application |

|---|---|---|---|

| Copper | Soft; malleable; ductile; high thermal electrical conductivity | Copper available in nature in directly usable metal form | Widely used nonferrous metal. Electronics; electric power machineries |

| Materials | AI | Be | Cu | Mn | Zn | Si, Fe | Other Elements | Combination of Other Elements |

|---|---|---|---|---|---|---|---|---|

| Aluminium (wt%) | Min 99% | Max 0.00080 | 0.050–0.2 | Max 0.050 | Max 0.10 | Max 0.95 | Max 0.05 | Max 0.15 [17] |

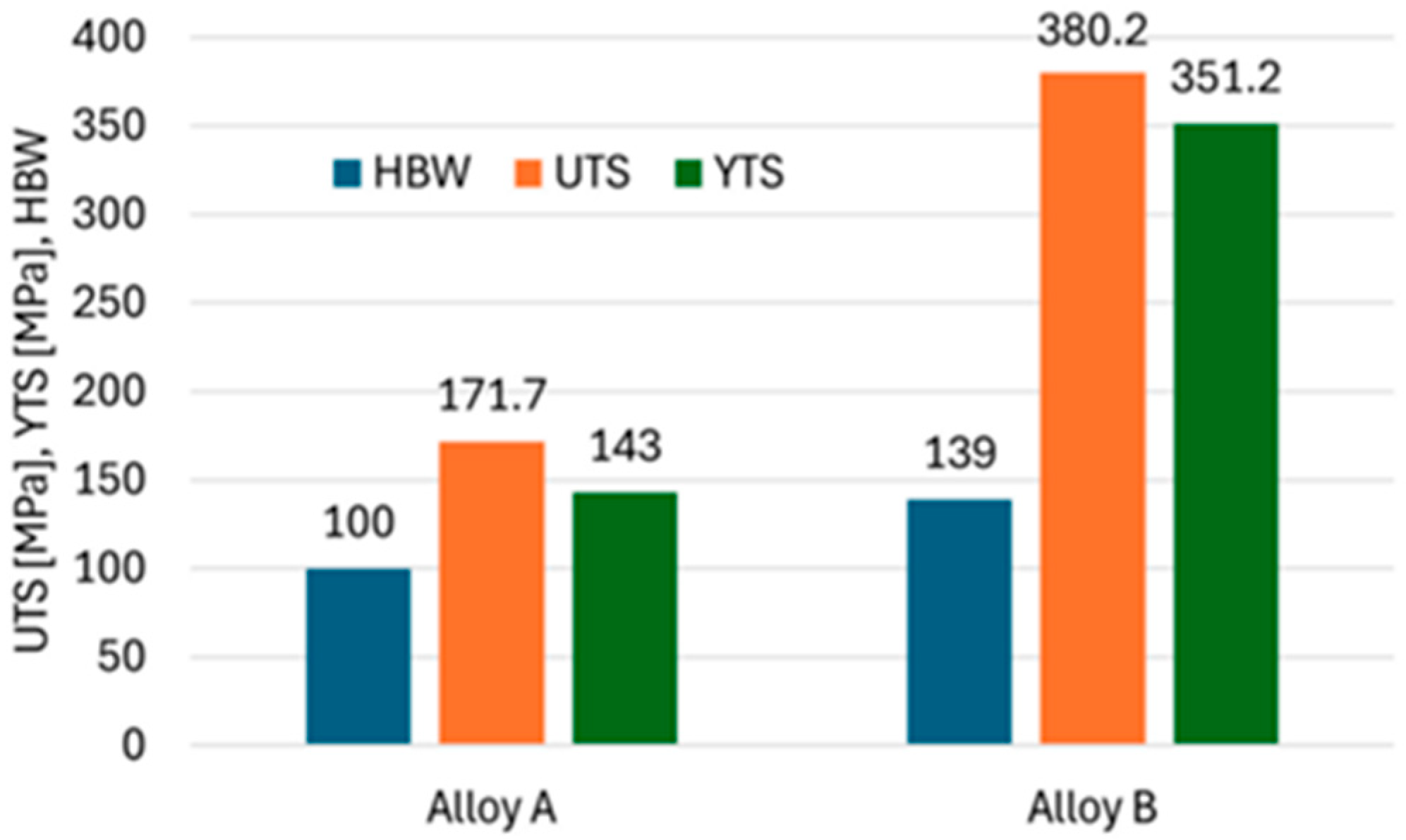

| Alloy | UTS [MPa] | YTS [MPa] | Ductility [%] | HBW 5/250/10 |

|---|---|---|---|---|

| A | 8171.7 ± 11 351.2 | 143 ± 37 | 0 | 100 ± 3 |

| B | 380.2 ± 8 | 351.2 ± 14 | 0.47 | 139 ± 3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ariyansah, R.; Prabowo, A.R.; Muhayat, N.; Nugroho, B.A.; Triyono, T. Comparative Review of Rotary Friction Welding Between Aluminium and Copper Alloys for Enhanced Joint Strength. Eng. Proc. 2025, 84, 92. https://doi.org/10.3390/engproc2025084092

Ariyansah R, Prabowo AR, Muhayat N, Nugroho BA, Triyono T. Comparative Review of Rotary Friction Welding Between Aluminium and Copper Alloys for Enhanced Joint Strength. Engineering Proceedings. 2025; 84(1):92. https://doi.org/10.3390/engproc2025084092

Chicago/Turabian StyleAriyansah, Riyan, Aditya Rio Prabowo, Nurul Muhayat, Bagus Anang Nugroho, and Triyono Triyono. 2025. "Comparative Review of Rotary Friction Welding Between Aluminium and Copper Alloys for Enhanced Joint Strength" Engineering Proceedings 84, no. 1: 92. https://doi.org/10.3390/engproc2025084092

APA StyleAriyansah, R., Prabowo, A. R., Muhayat, N., Nugroho, B. A., & Triyono, T. (2025). Comparative Review of Rotary Friction Welding Between Aluminium and Copper Alloys for Enhanced Joint Strength. Engineering Proceedings, 84(1), 92. https://doi.org/10.3390/engproc2025084092