1. Introduction

Furniture refers to essential elements in interior design. Furniture serves as a connection between architecture and the occupants of a space. It provides a transition and functionality in terms of form and size between interior spaces and the people who inhabit them. Furniture makes a room more comfortable and functional for various activities carried out by its occupants [

1]. The furniture industry is one of the industries with the potential for export to other countries [

2]. Without furniture, a room is just an empty space with very little usefulness for its occupants. Therefore, furniture makes a room significantly more functional according to its intended purpose.

One of the industries operating in the furniture and woodworking sector is CV. VSU. CV. VSU was established in 1999, rooted in the trust of the government, business partners, and the community, supported by market opportunities and high demand for furniture abroad. The company covers an area of approximately 12,000 square meters and is located at Jalan Solo Purwodadi, Karanganyar Regency, Central Java. The company’s primary focus is on producing garden furniture. CV. VSU is an extension of a previous furniture company, CV. Roda Jati, located in the same subdistrict in Karanganyar Regency. The company was established in response to abundant market opportunities, particularly from Europe, America, Australia, and Asia. The company employs around 165 workers and has already marketed and exported its products internationally. CV. VSU produces furniture such as tables and chairs made from teak wood.

The management of CV. VSU continuously strives to create a good working system for its employees. A work system design fundamentally begins with an ergonomic analysis. Ergonomics is the science that studies the relationship between humans and their work environment, considering aspects of psychology, physiology, anatomy, management, engineering, and design [

3]. Ergonomics is defined as the science that analyzes various aspects and characteristics of humans in the work environment, studies the relationship between humans, machines, and the environment, and is followed by facilities that facilitate, maintain health, and ensure work safety [

4]. The work postures or positions commonly adopted by workers include sitting, standing, bending, squatting, walking, and others. These work positions are determined by the conditions within the existing work system [

5].

One of the most critical divisions in the production system at CV. VSU is the raw material division. In this division, there are at least four types of machines, including two band saw machines, three metal band saw machines, three rip saw machines, and four cross-cut machines, with each machine operated by one worker. The raw material division is the first step in the furniture production process at CV. VSU. In this division, the main material, large teak wood, is split and then cut into specific shapes and sizes according to needs. Workers often complain of injuries to certain parts of their bodies due to non-ergonomic working postures, which is a problem in the raw material division of CV. VSU.

In response to this issue, the research will focus on evaluating the existing work system in the raw material division of CV. VSU through an ergonomic approach to assess the non-ergonomic working postures using the RULA (Rapid Upper Limb Assessment) approach and the Nordic Body Map questionnaire. RULA is a research approach that can be applied to investigate disorders in the upper body parts of workers [

6]. The RULA method measures the risk of Musculoskeletal Disorders (MSDs) complaints related to upper body parts based on the assessment of posture, force, and movement during activities [

7]. On the other hand, the Nordic Body Map is a questionnaire tool often used to identify discomfort or pain in workers’ bodies [

8]. The Nordic Body Map (NBM) aims to identify problems and complaints experienced by workers related to the current production process [

9].

Observations were conducted on 12 workers in the raw material division, each operating a machine, including two band saw machines, three metal band saw machines, three rip saw machines, and four cross-cut machines, making a total of 12 machines with four different types of machines (see

Table 1). After observing the working postures of the 12 workers in the raw material division, the next step was to distribute the NBM questionnaire to the 12 respective workers. The results of the NBM questionnaire recap are as follows.

From the recapitulation table of the NBM questionnaire for workers in the Raw Material Division above (see

Table 2), it can be seen that the machine with the highest average score is the cross-cut machine. The following are the detailed NBM questionnaire results for the cross-cut machine operators.

From the results of the NBM score calculation table (see

Table 2), it can be observed that the complaint locations with the highest to lowest percentages are the left upper arm and right upper arm, each with a percentage of 7.82%, followed by the left shoulder and right shoulder, each with a percentage of 6.70%, the waist with a percentage of 6.70%, the lower waist with a percentage of 6.15%, the back with a percentage of 4.47%, the left and right calves, each with a percentage of 4.47%, and the buttocks with a percentage of 3.91%. Workers did not report any pain in other parts of the body. In response to these findings, the research will focus on evaluating the working postures of workers operating the cross-cut machine. The study will also assess the work equipment used by the operators of the cross-cut machine.

2. Methods

The research procedure is a systematic series of steps undertaken to achieve the research objectives. The implementation of the research procedure includes several stages, which are as follows:

2.1. Preliminary Study

The preliminary study is the initial step in starting research. At this stage, the researcher will directly observe the research object, specifically the posture of workers operating the cross-cut machine in the raw material division at CV. VSU.

2.2. Literartur Review

The literature review is conducted to gather relevant information or references related to the research topic, which then serves as the basis for problem-solving. The sources of data in the literature review come from journals, books, and previous research reports.

2.3. Problem Identification

The problem identification process involves direct observation and interviews with relevant parties to understand the workers’ postures while performing their tasks and to obtain information about any complaints the workers may have.

2.4. Problem Formulation

Problem formulation is a critical stage in identifying the key points of the issue under investigation. It is derived from the results of the problem identification conducted earlier.

2.5. Research Objectives

The research objectives are the specific goals that the research aims to achieve in addressing the problem formulation. The objectives of this study are to identify the posture of workers operating the cross-cut machine in the raw material division at CV. VSU, evaluate the ergonomics level of the workers’ posture at the cross-cut machine, and provide recommendations for improving the workers’ posture at the cross-cut machine.

2.6. Data Collection

The data collection process used in this research involves direct observation through interviews and the distribution of the NBM questionnaire to workers operating the cross-cut machine in the raw material division. Additionally, data collection is carried out by documenting the workers’ posture through photos and videos while they are using the cross-cut machine in the raw material division.

2.7. Data Processing

Data processing using the RULA method is conducted by observing and capturing images or videos of the workers’ posture while they are working. Rapid Upper Limb Assessment (RULA) is a research approach used to evaluate upper body musculoskeletal disorders. This approach was introduced by Lynn McAtamney and Nigel Corlett in 1993 and provides calculations on the level of musculoskeletal load in work activities that pose a risk to body parts from the waist to the neck or upper limbs [

6]. Several variables evaluated in the RULA approach include static work posture, workload intensity, duration of work, and muscle energy utilization [

10].

The RULA approach uses posture images and three scoring tables to assess risk aspects. The risk aspects analyzed include external loads, such as movement frequency, static muscle work, required force, and the alignment of work posture with the supporting environmental conditions. These conditions refer to the work environment that allows workers to work comfortably, safely, and in relation to work facilities [

11].

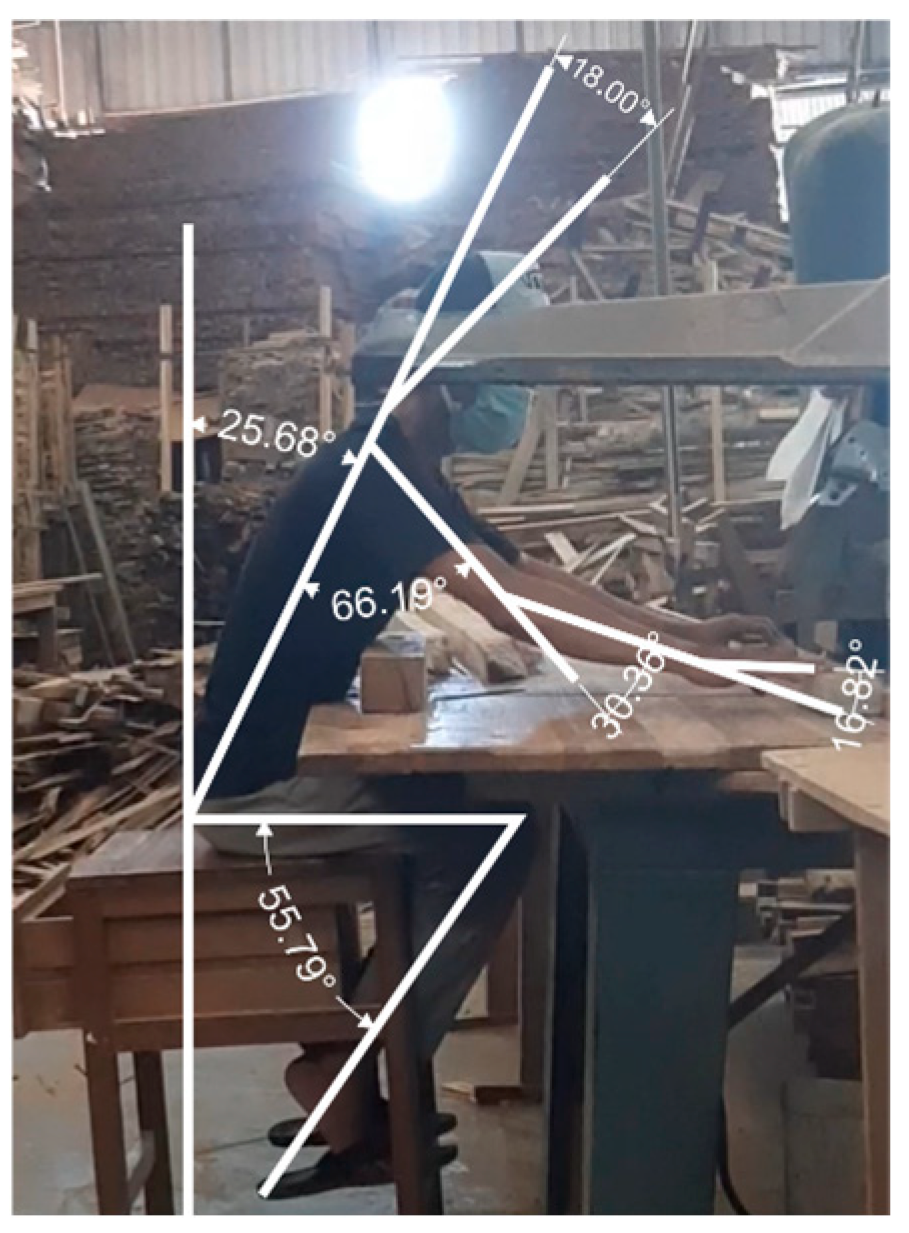

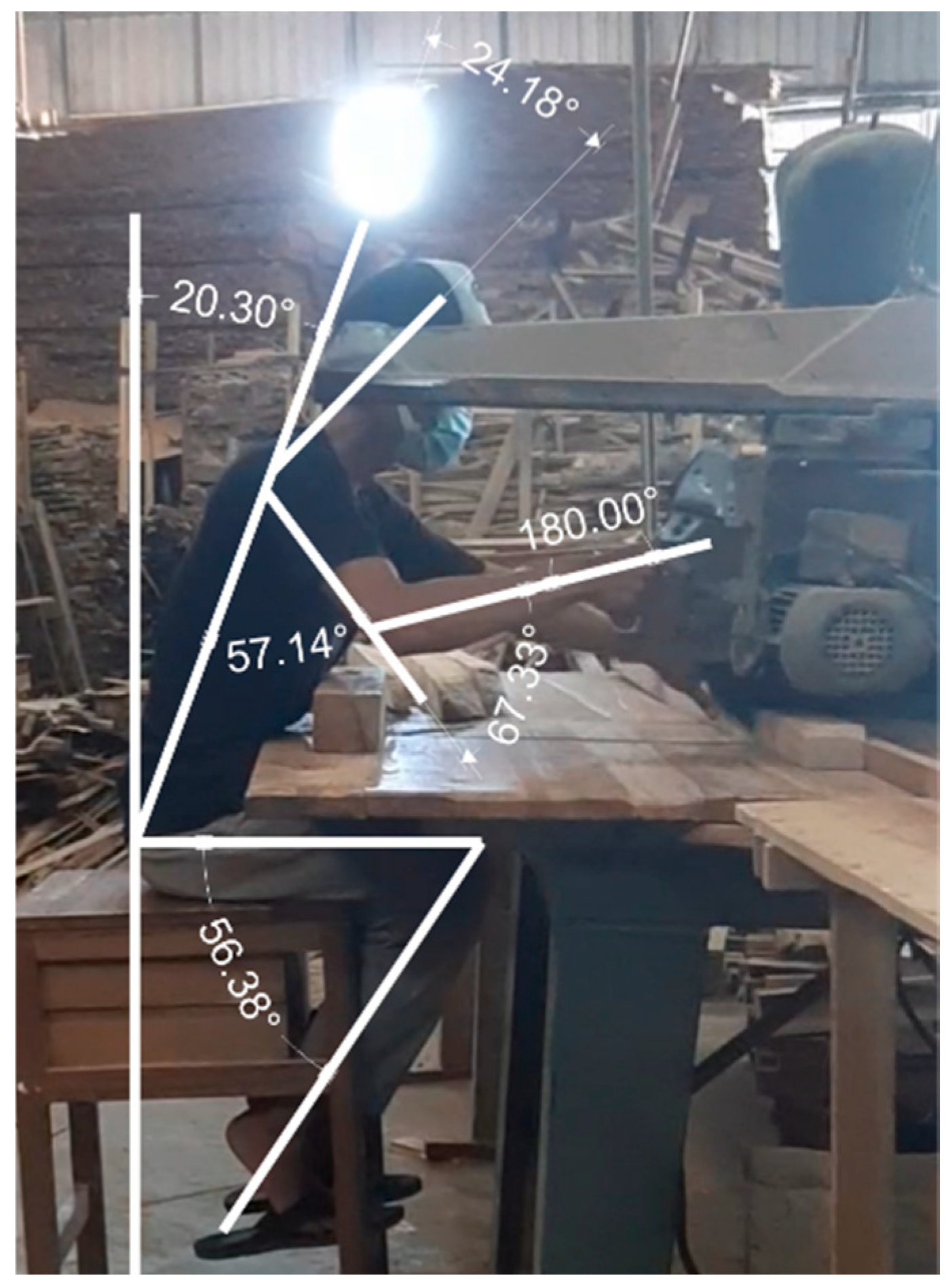

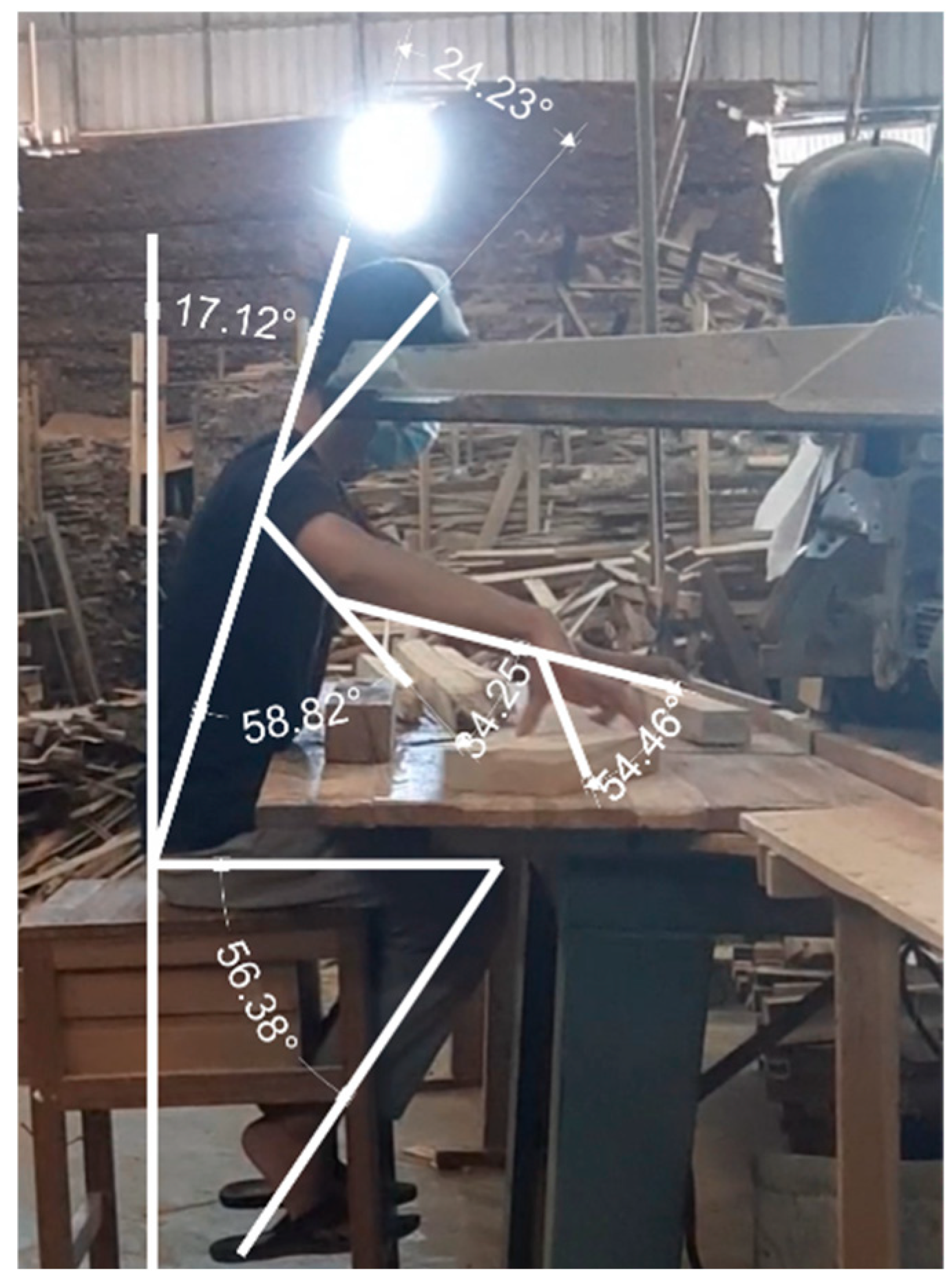

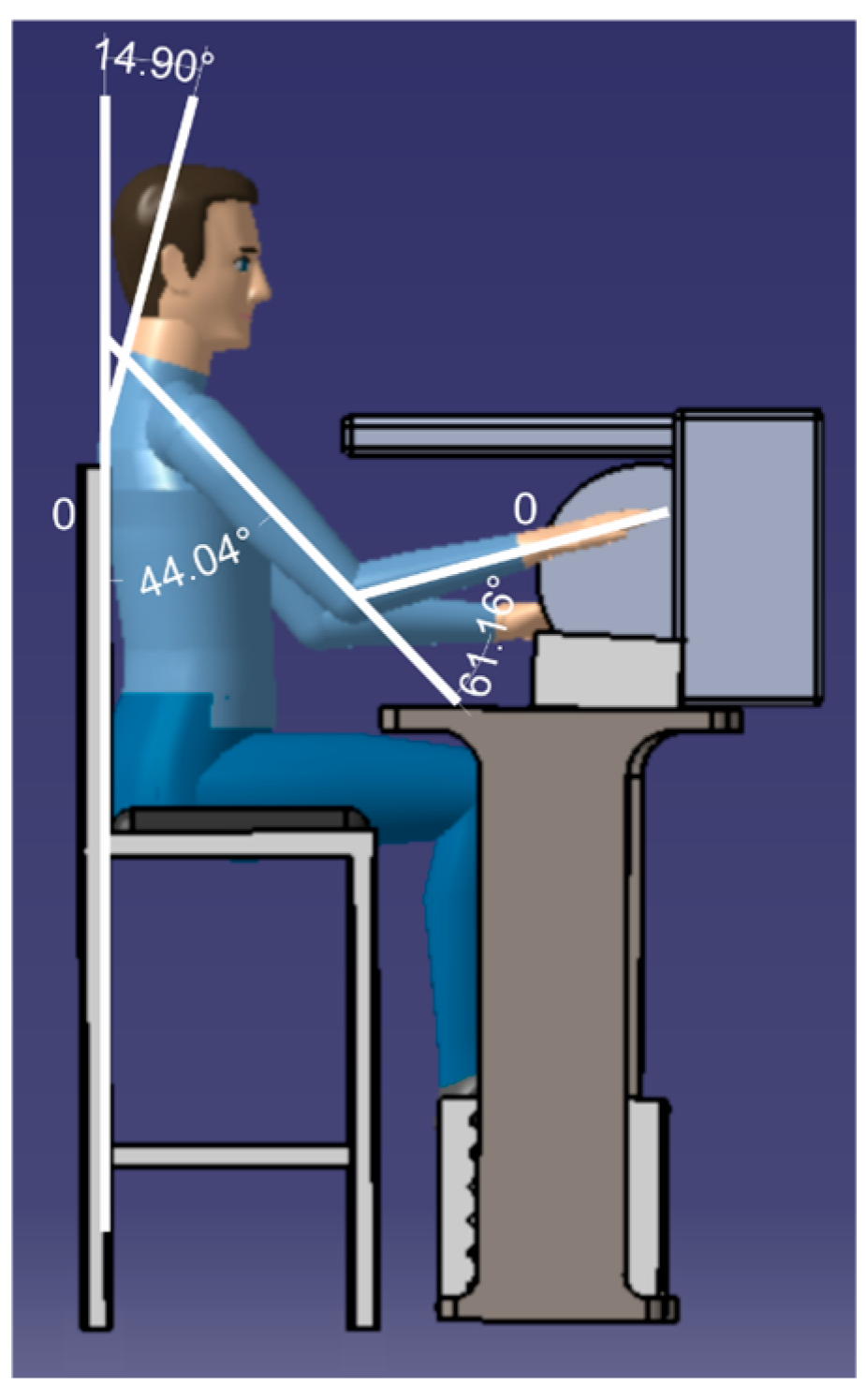

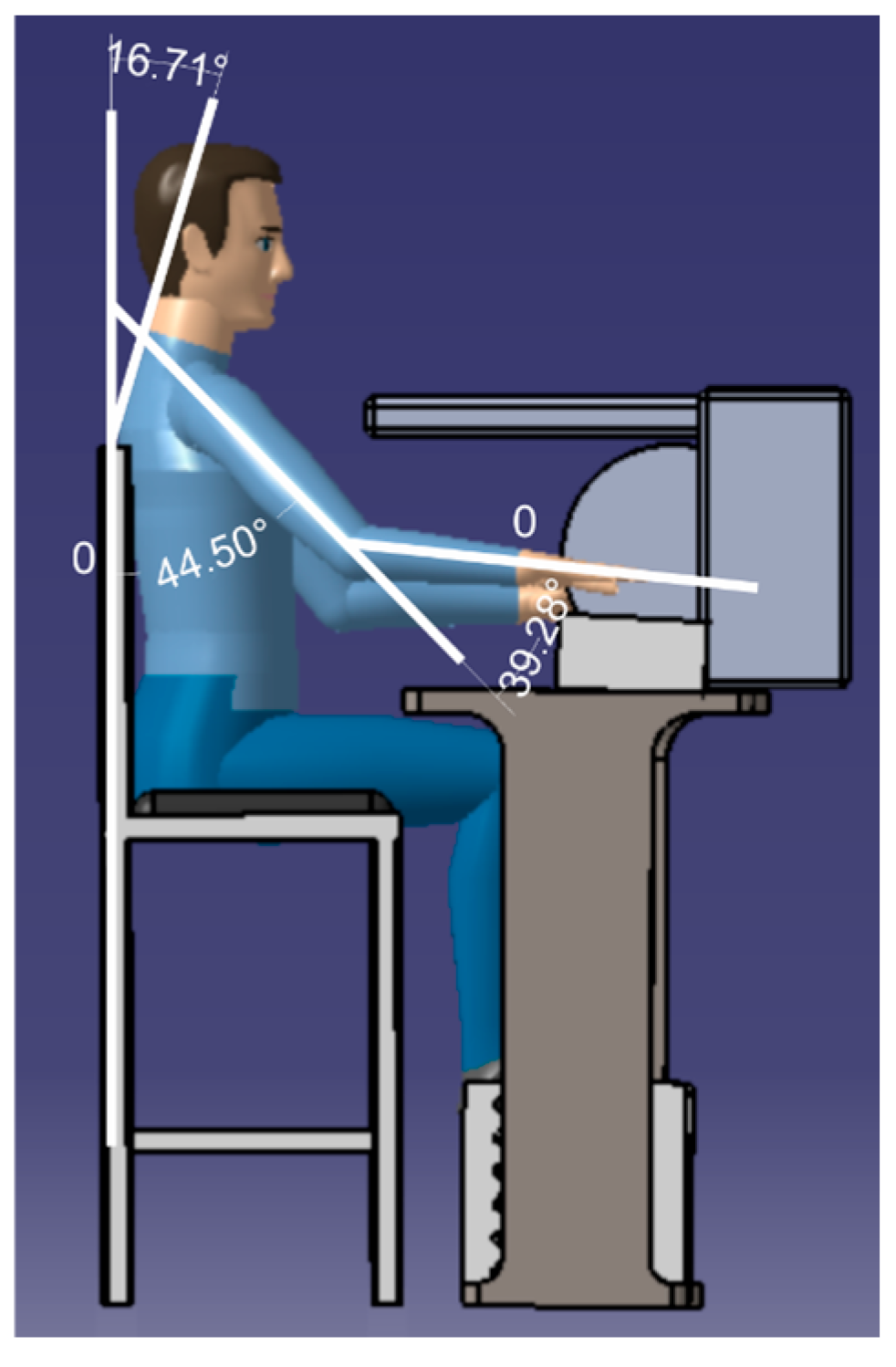

The captured images or videos of the workers are then analyzed. The body parts analyzed using the RULA approach include the angles formed by the upper arm and forearm, considering whether the forearm movement crosses the midline of the worker’s body or is outside of it; the angles formed by the wrist and wrist movements; the angle formed by wrist rotation; the angle formed by neck position and considering rotational and lateral neck movements; the angle formed by torso position and considering lateral and rotational body movements; the position of the workers’ feet, and whether the body is well supported by both feet; and the assessment of the load level and muscle utilization in body Group A and Group B. The results of the analysis are then calculated using the RULA worksheet. Once the data is processed using the RULA worksheet (see

Figure 1), the final risk level score of the workers is obtained.

2.8. Data Analysis

The analysis and discussion of data derived from processing NBM and RULA data on work posture is a crucial stage of data analysis. This stage can serve as a reference for proposing improvements based on the risk level and worker activities in the raw material division of CV. VSU.

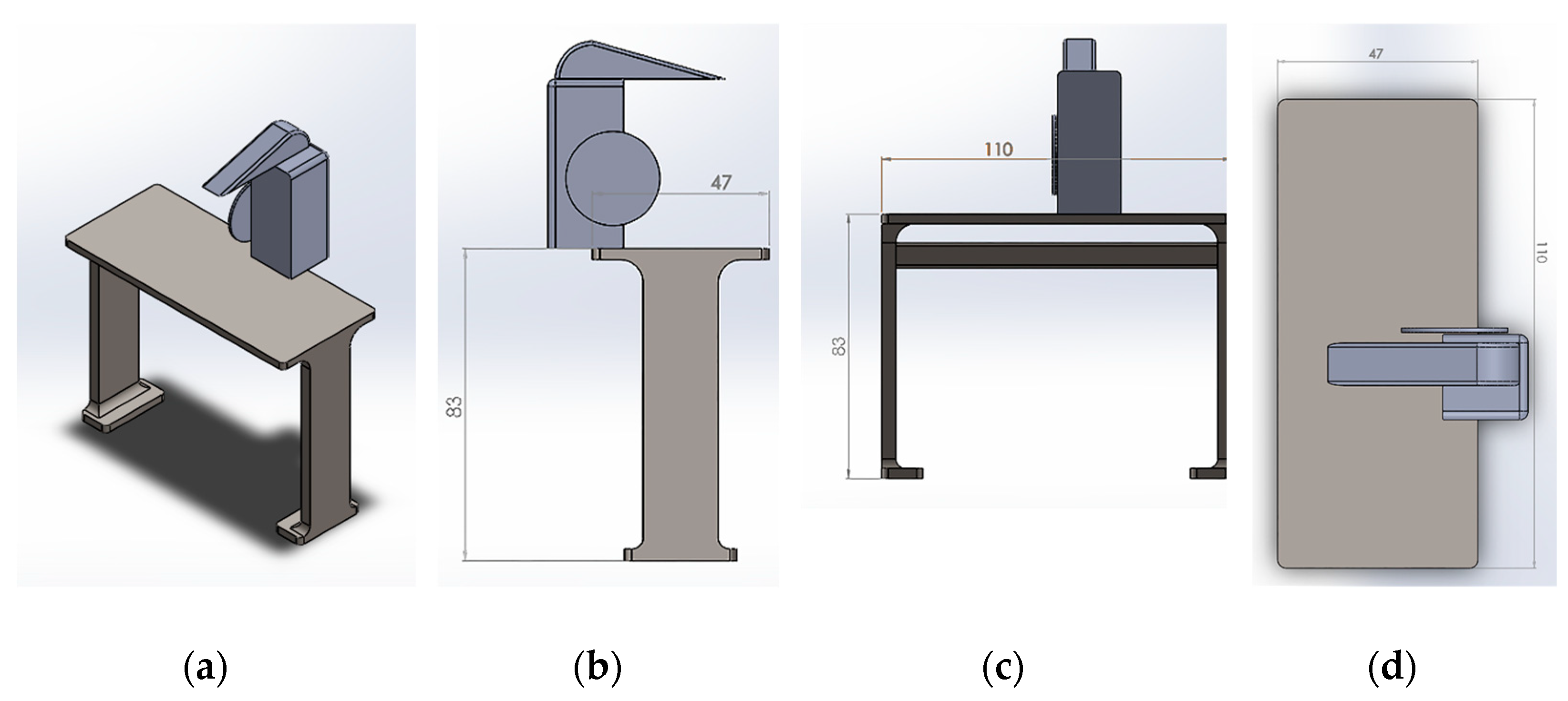

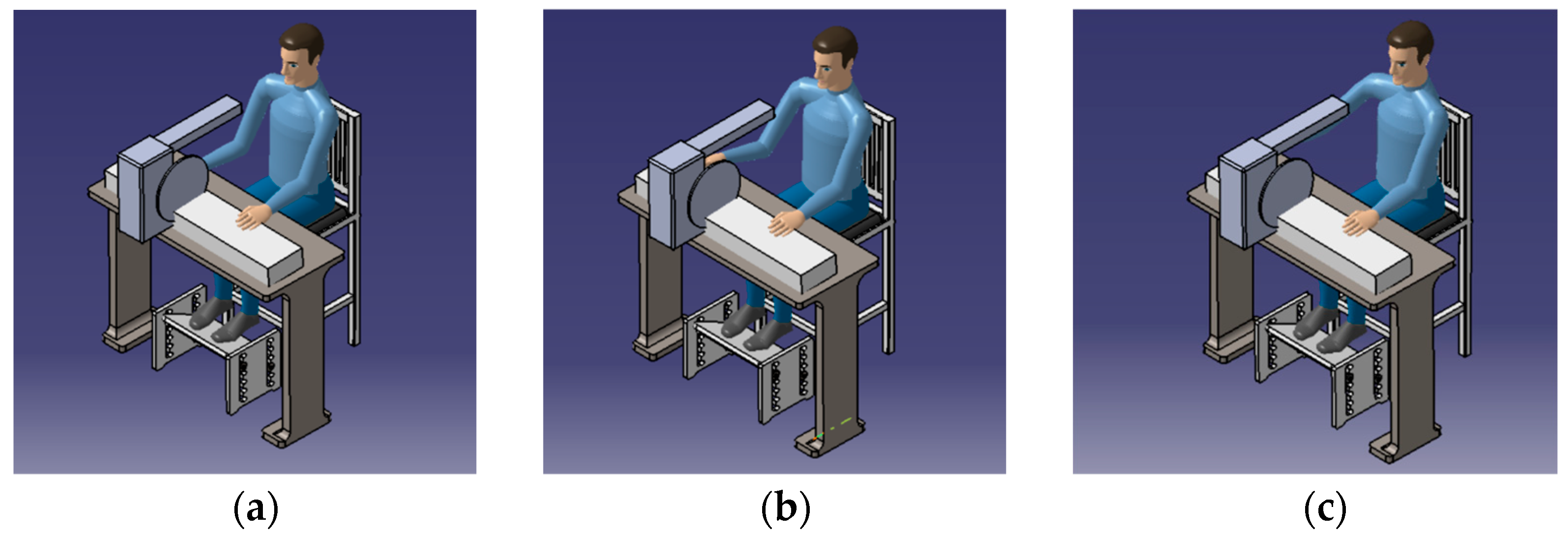

2.9. Improvement Proposals

Improvement proposals are provided for the cross-cut machine workstation, which was found to have a high-risk level during the study. The proposed improvements are expected to assist workers in improving their posture while performing their tasks. These suggestions are also intended to help the company’s management in implementing a work system that is ergonomic and comfortable for the workers.

2.10. Conclusion and Recommendations

Based on the data evaluation, conclusions can be drawn, summarizing the data analysis and discussion outcomes. The recommendations provided are intended to guide the company’s management in promoting a work system and proper body posture that is safe for workers, aiming to reduce the risk of MSDs.

4. Conclusions

After further research into workers’ complaints of pain, it was found that this discomfort stemmed from the operator’s work posture, which was not yet ergonomic. This finding aligns with the study by [

15], which states that the causes of musculoskeletal complaints include excessive muscle stretching, unnatural work positions, repetitive activities, and excessive load.

Data processing and analysis using the RULA method showed that the work posture of the cross-cut machine operator in the raw material division of CV. VSU received RULA scores of 6 for positioning the wood, 5 for pulling the saw, and 6 for dropping the cut wood. These postures were not yet ergonomic and required immediate improvement. This is consistent with the study by [

16], which concluded that a RULA score of 6 indicates a medium risk level that requires further investigation and prompt changes.

To reduce workers’ complaints, immediate improvements are necessary. This is supported by [

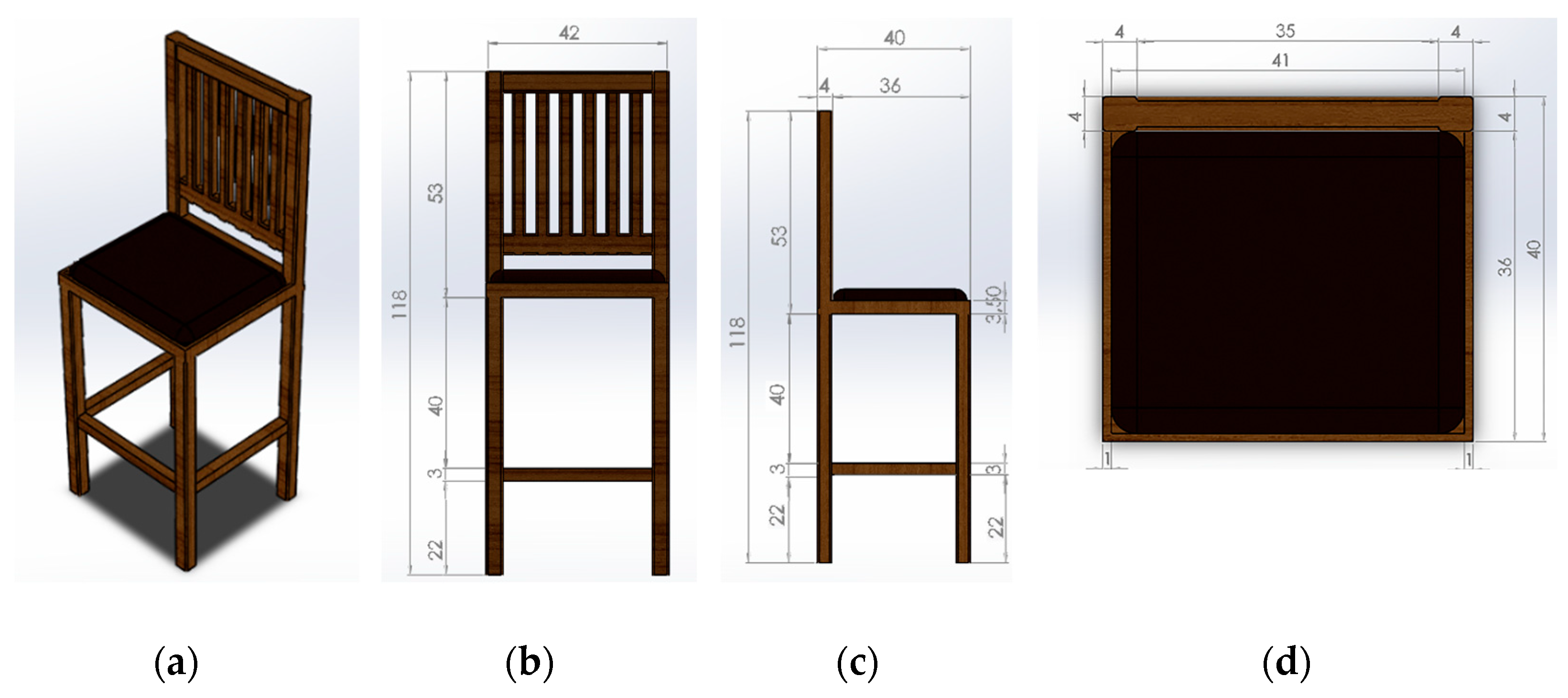

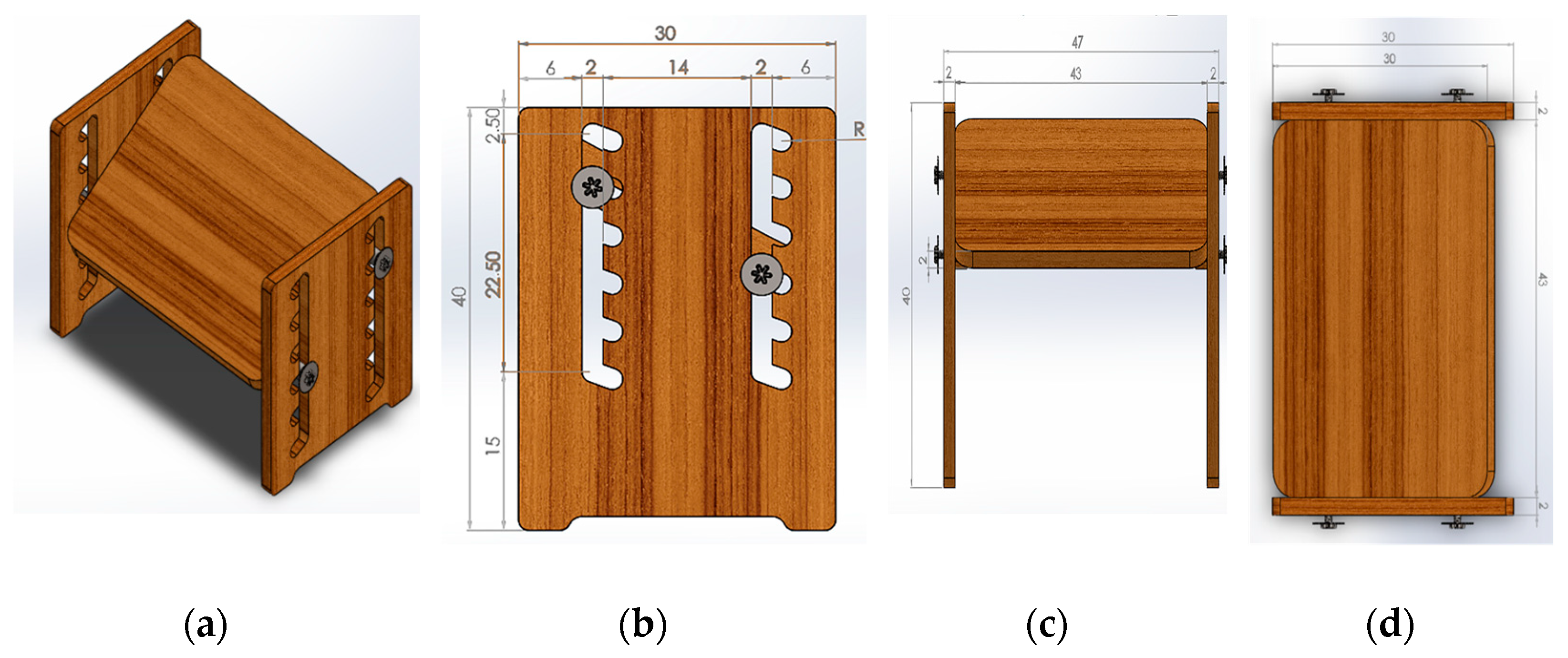

17], who stated that proposed improvements are expected to reduce workers’ complaints. The proposed improvements include changing the width of the cross-cut machine workbench to prevent workers from bending over while positioning the wood and operating the machine. Another suggested improvement is to redesign the worker’s chair, which is currently inadequate and not ergonomic. The proposed chair design considers ergonomic principles and is based on human anthropometric data. An additional suggestion is to provide a footrest with adjustable height to allow workers to position their feet comfortably during work.

An ergonomic workstation design is crucial in maintaining workers’ posture and preventing injury risks, as emphasized by [

18], who stated that an ergonomic chair design is essential for avoiding muscle injury risks during work. After simulating the proposed improvements, the next step was to analyze the work posture using the RULA method. The analysis revealed that the RULA score for the first work posture decreased from 6 to 3, the score for the second posture decreased from 5 to 4, and the score for the third posture decreased from 6 to 3 after the improvements.

Based on this analysis, the proposed improvements were deemed effective in significantly reducing the RULA scores, thereby decreasing the risk of muscle injury for cross-cut machine operators in the raw material division of CV. VSU. This is consistent with the study by [

19], which found that using an ergonomic chair designed according to the RULA risk scale can reduce the risk of MSDs.