Analysis of the Use of Fly Ash Variations as a Partial Cement Substitute for Roller Compacted Concrete (RCC) Mixtures †

Abstract

1. Introduction

2. Materials and Method

Concrete Making Method

3. Result and Discussion

3.1. Vebe Time Test

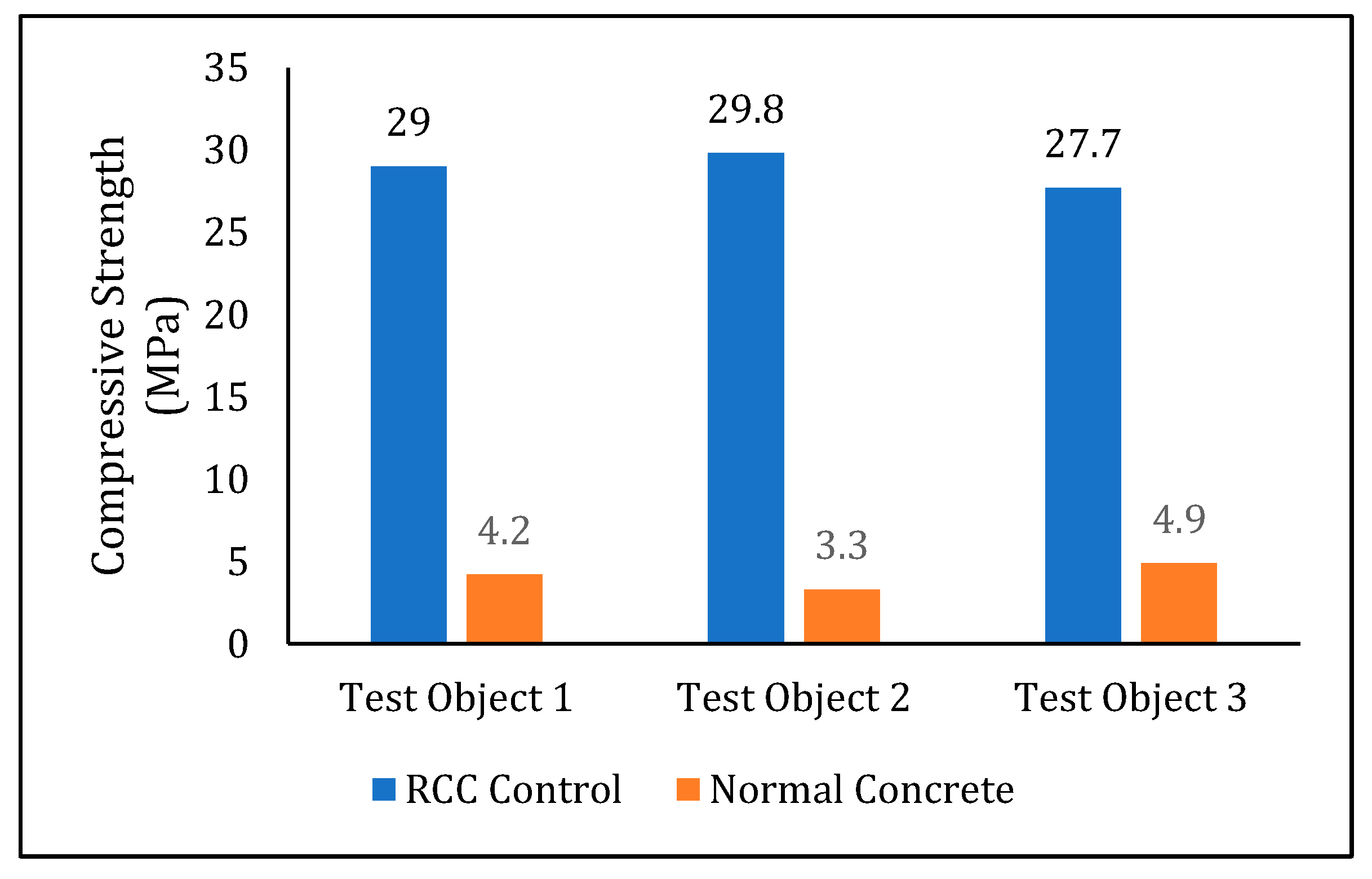

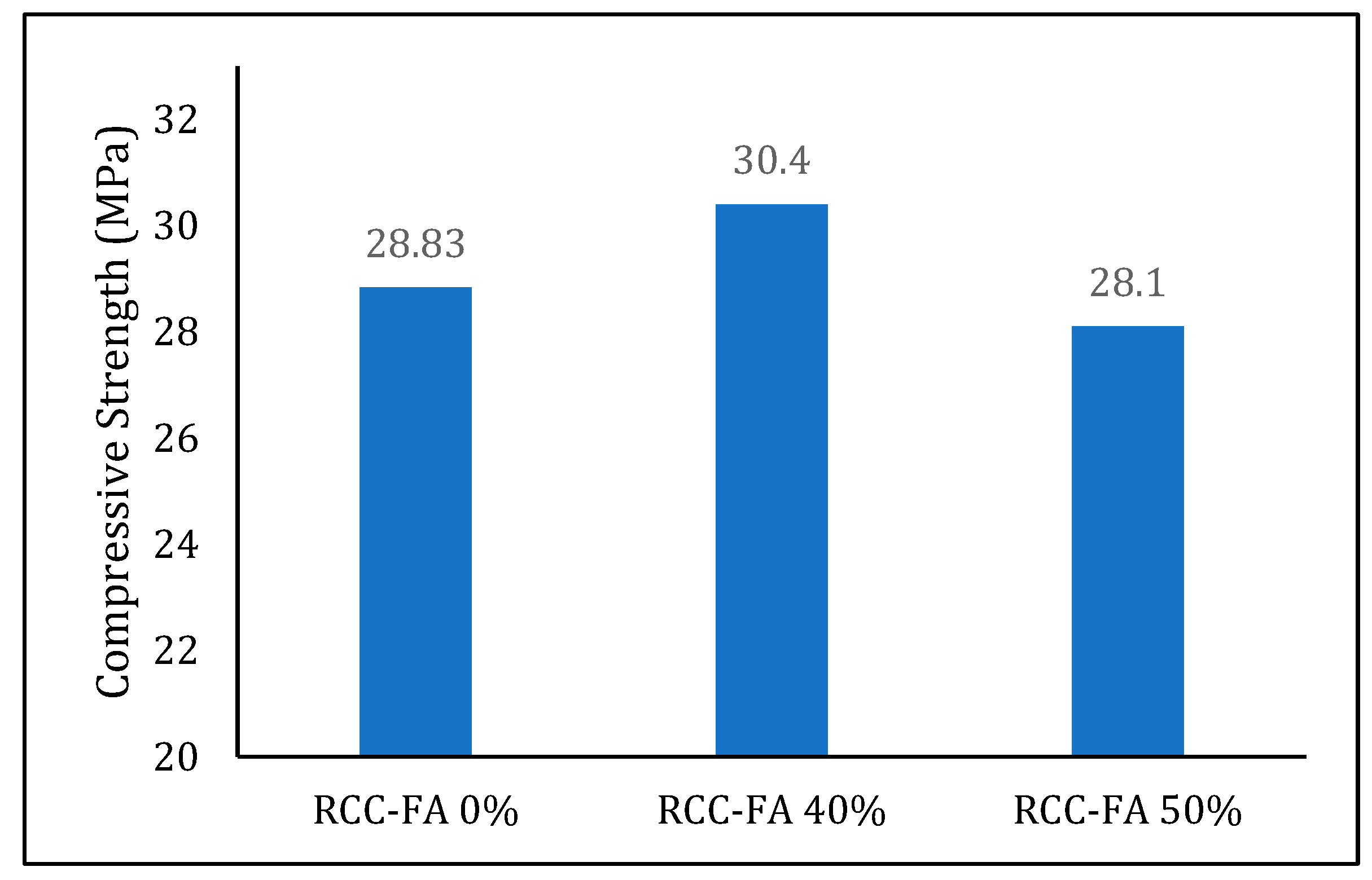

3.2. Compressive Strength Test

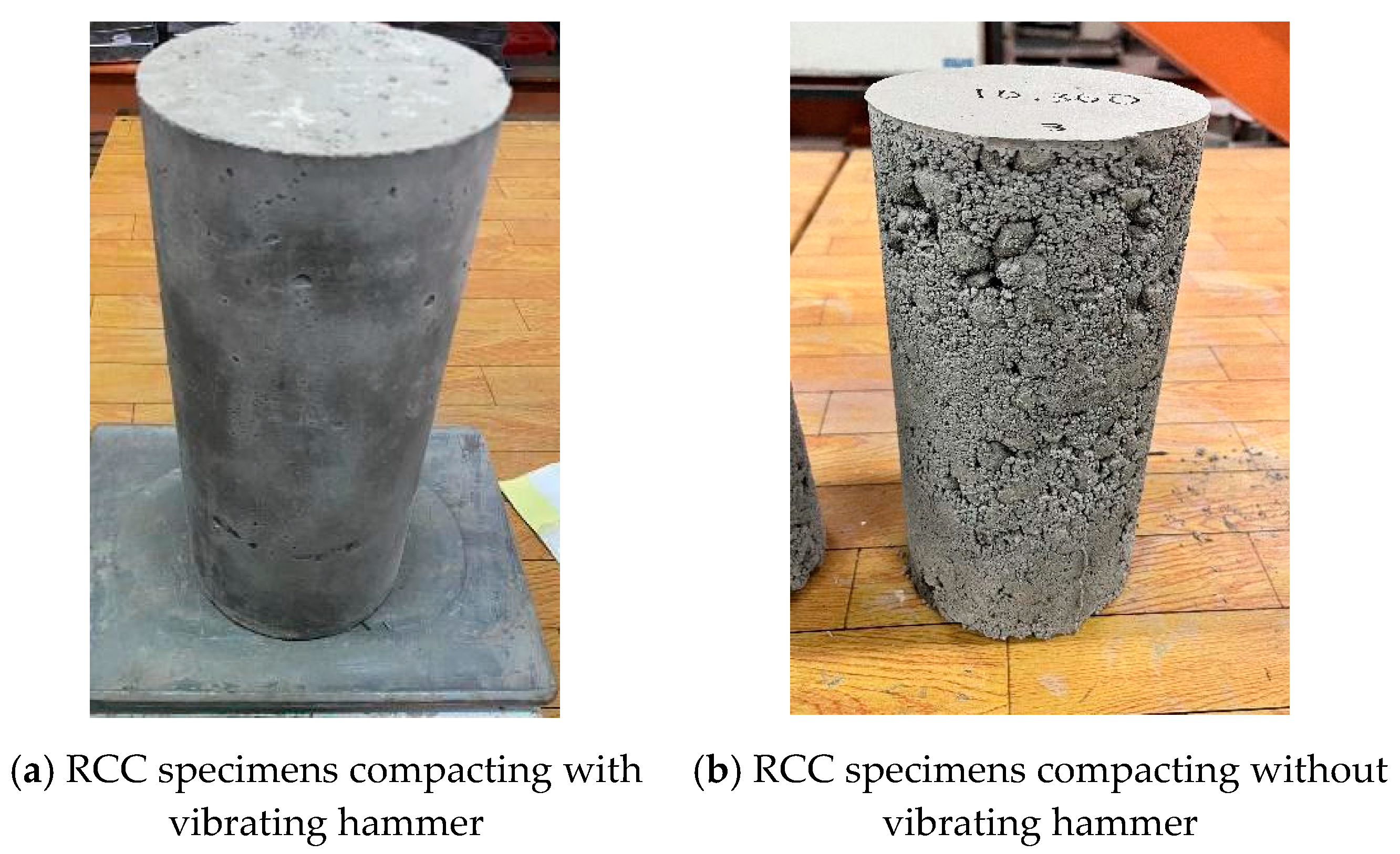

3.2.1. Comparison of Vibrating Hammer Compaction with Normal Concrete Compaction on RCC Mixture

3.2.2. Roller Compacted Concrete Compressive Strength Tests Using Variations in Fly Ash

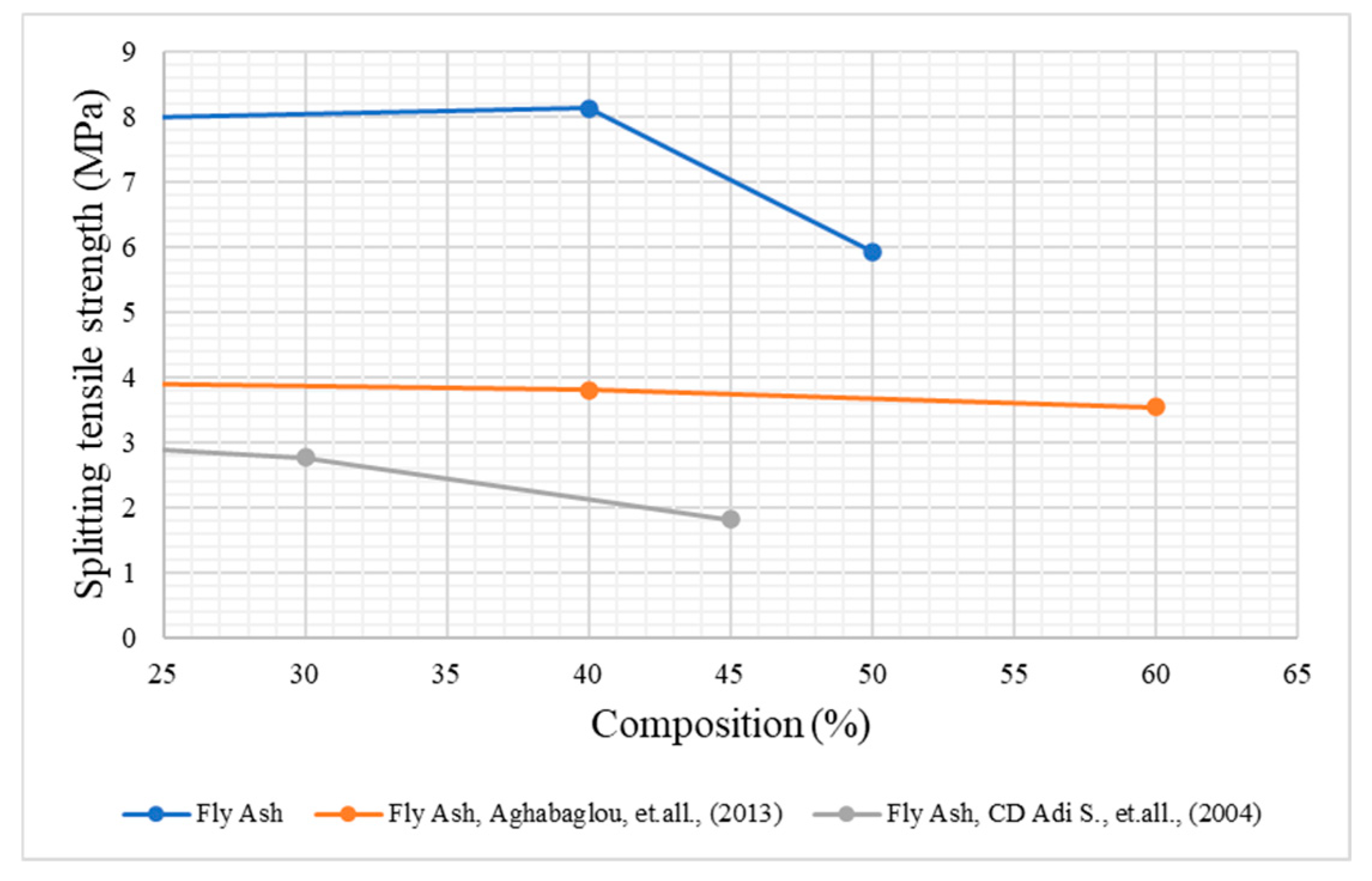

3.3. Split Tensile Strength Test

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Subakti, A. Teknologi Beton Dalam Praktek; Jurusan Teknik Sipil FTSP, Institut Teknologi: Surabaya, Indonesia, 1995. [Google Scholar]

- Marga, D.J.B. Manual Perkerasan Jalan, Kementrian Pekerjaan Umum dan Perumahan Rakyat Direktorat Jendral Bina Marga. 2017, pp. 1–235. Available online: https://binamarga.pu.go.id/v3/uploads/files/112/manual-desain-perkerasan-jalan.pdf (accessed on 8 November 2024).

- Khayat, K.H.; Libre, N.A. Roller Compacted Concrete: Field Evaluation and Mixture Optimization. 2014. Available online: https://www.researchgate.net/publication/264734306 (accessed on 8 October 2024).

- Srinivas, K.; Vijaya, S.K.; Jagadeeswari, K. Concrete with ceramic and granite waste as coarse aggregate. Mater. Today Proc. 2020, 37 Pt 2, 2089–2092. [Google Scholar] [CrossRef]

- Global Warming Impact on the Cement and Aggregates Industries Davidovits-1 [Internet]. Available online: www.geopolymer.org (accessed on 10 November 2024).

- SNI 03-2491-2002; Metode Pengujian Kuat Tarik Belah Beton. Badan Standar Nasional: Jakarta, Indonesia, 2002; p. 14.

- Pavan, S.; Rao, S.K. Effect of Fly ash on Strength Characteristics of Roller Compacted Concrete Pavement. IOSR J. Mech. Civ. Eng. (IOSR-JMCE) 2014, 11, 4–8. Available online: www.iosrjournals.org (accessed on 20 October 2024). [CrossRef]

- Desliono, W.; Parung, H.; Rapang Tonapa, S. Pemanfaatan FIy Ash Sebagai Substitusi Semen Dan Batu Gamping Sebagai Agregat Pada Beton. Paulus Civ. Eng. J. 2021, 3, 209–216. [Google Scholar] [CrossRef]

- Mardani-Aghabaglou, A.; Ramyar, K. Mechanical properties of high-volume fly ash roller compacted concrete designed by maximum density method. Constr. Build. Mater. 2013, 38, 356–364. [Google Scholar] [CrossRef]

- Lam, M.N.T.; Le, D.H.; Jaritngam, S. Compressive strength and durability properties of roller-compacted concrete pavement containing electric arc furnace slag aggregate and fly ash. Constr. Build. Mater. 2018, 191, 912–922. [Google Scholar] [CrossRef]

- Harrington, D.; Abdo, F.; Ceylan, H.; Adaska, W.; Hazaree, C.; Bektas, F. Guide for Roller-Compacted Concrete Pavements; National Concrete Pavement Technology Center: Ames, IA, USA, 2010. [Google Scholar]

- ACI 207.5R-11; Roller Compacted Concrete. American Concrete Institute (ACI): Farmington Hills, MI, USA, 2011.

- Chhorn, C.; Kim, Y.K.; Hong, S.J.; Park, J.Y.; Lee, S.W. A study on performance of roller-compacted concrete pavement in accelerated pavement tests. J. Test. Eval. 2018, 48, 2611–2623. [Google Scholar] [CrossRef]

- Tangaramvong, S.; Nuaklong, P.; Khine, M.T.; Jongvivatsakul, P. The influences of granite industry waste on concrete properties with different strength grades. Case Stud. Constr. Mater. 2021, 15, e00669. [Google Scholar] [CrossRef]

- ACI 325-10; State of Art Report. On Roller Compacted Concrete Pavements. American Concrete Institute (ACI): Farmington Hills, MI, USA, 2010.

- ASTM C1176/C1176M-20; Standard Practice for Making Roller-Compacted Concrete in Cylinder Molds Using a Vibrating Table. ASTM: West Conshohocken, PA, USA, 2020.

- ASTM C1435-99; Standard Practice for Molding Roller-Compacted Concrete in Cylinder Molds Using a Vibrating Hammer. ASTMInt’l: West Conshohocken, PA, USA, 2009.

- Selvam, M.; Singh, S. Tailoring of Compaction Parameters of the Vibratory Table and Vibratory Hammer for Roller Compacted Concrete Pavements to Resemble Field Properties. Transp. Res. Rec. 2024, 2678, 242–258. [Google Scholar] [CrossRef]

- Şengün, E.; Alam, B.; Shabani, R.; Yaman, I.O. The effects of compaction methods and mix parameters on the properties of roller compacted concrete mixtures. Constr. Build. Mater. 2019, 228, 116807. [Google Scholar] [CrossRef]

- BS EN 12350-3:2009; Testing Fresh Concrete Part 3: Vebe Test. British Standard: London, UK, 2009.

- Setiawati, M. Fly Ash Sebagai Bahan Pengganti Semen Pada Beton. In Proceedings of the Seminar Nasional Sains Dan Teknologi, Central Jakarta, Indonesia, 17 October 2018; pp. 1–8. [Google Scholar]

- ACI 325.10R-95; Report on Roller-Compacted Concrete. American Concrre Institute (ACI): Farmington Hills, MI, USA, 1995.

- Sengun, E.; Shabani, R.; Alam, B.; Aykutlu, M.; Yaman, I. Comparison of Several Laboratory Compaction Practices Applied on Roller Compacted Concrete Pavements. 2018, pp. 12–14. Available online: https://www.researchgate.net/publication/339850771 (accessed on 28 October 2024).

- SNI 1974–2011; Cara Uji Kuat Tekan Beton Dengan Benda Uji Silinder. Badan Standardisasi Nasional: Jakarta, Indonesia, 2011; p. 20.

- Rahmani, E.; Sharbatdar, M.K.; HABeygi, M. A comprehensive investigation into the effect of water to cement ratios and cement contents on the physical and mechanical properties of Roller Compacted Concrete Pavement (RCCP). Constr. Build. Mater. 2020, 253, 119177. [Google Scholar] [CrossRef]

- Chhorn, C.; Hong, S.J.; Lee, S.W. Relationship between compressive and tensile strengths of roller-compacted concrete. J. Traffic Transp. Eng. (Engl. Ed.) 2018, 5, 215–223. [Google Scholar] [CrossRef]

- Atiş, C.D.; Sevim, U.K.; Özcan, F.; Bilim, C.; Karahan, O.K.A.N.; Tanrikulu, A.H.; Ekşi, A. Strength properties of roller compacted concrete containing a non-standard high calcium fly ash. Mater. Lett. 2004, 58, 1446–1450. [Google Scholar] [CrossRef]

- Agustiany, A.A.; Nanik, S.B. Pembuatan Beton Mutu Tinggi Dengan Variasi Bahan Tambah Fly Ash, Silica Fume dan Superplasticizer; Universitas Islam Indonesia: Yogyakarta, Indonesia, 1998. [Google Scholar]

- Tabaiyan, M.F.Y.; Prasetyaningtiyas, G.A. Pengaruh Penambahan Zat Aditifgrolen HP10+ dan Additon HE Water Reducing Retarding Admixture Superplasticizer terhadap Kuat Tekan Beton, Prosiding Seminar Nasional Teknik Sipil UMS 2023, Universitas Muhammadiyah Surakarta. 2023. Available online: https://proceedings.ums.ac.id/sipil/article/view/2688 (accessed on 15 October 2024).

- Puro, S.; Atmiwyastuti, N.; Restina, N. Kritik dan Pemecahan Penggunaan Konstruksi Beton cor pada Rekayasa Jalan Dalam Upaya Membangun Konstruksi Jalan Yang Berkelanjutan. Media Tek. Sipil 2015, 12. [Google Scholar] [CrossRef]

| Type of Concrete | w/b | Cement | Fine Aggregate | Coarse Aggregate | Water | Fly Ash |

|---|---|---|---|---|---|---|

| (kg) | (kg) | (kg) | (kg) | (kg) | ||

| RCC-FA 0% | 0.47 | 299.01 | 1045.35 | 763.55 | 140.01 | - |

| RCC-FA 40% | 0.47 | 179,41 | 1045.35 | 763.55 | 140.01 | 119.61 |

| RCC-FA 50% | 0.47 | 149.51 | 1045.35 | 763.55 | 140.01 | 149.51 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Solikin, M.; Izutholibin, G.A.A.; Handayani, N.K.; Nurchasanah, Y. Analysis of the Use of Fly Ash Variations as a Partial Cement Substitute for Roller Compacted Concrete (RCC) Mixtures. Eng. Proc. 2025, 84, 38. https://doi.org/10.3390/engproc2025084038

Solikin M, Izutholibin GAA, Handayani NK, Nurchasanah Y. Analysis of the Use of Fly Ash Variations as a Partial Cement Substitute for Roller Compacted Concrete (RCC) Mixtures. Engineering Proceedings. 2025; 84(1):38. https://doi.org/10.3390/engproc2025084038

Chicago/Turabian StyleSolikin, Mochamad, Gilang Arwiyan Ahmad Izutholibin, Nur Khotimah Handayani, and Yenny Nurchasanah. 2025. "Analysis of the Use of Fly Ash Variations as a Partial Cement Substitute for Roller Compacted Concrete (RCC) Mixtures" Engineering Proceedings 84, no. 1: 38. https://doi.org/10.3390/engproc2025084038

APA StyleSolikin, M., Izutholibin, G. A. A., Handayani, N. K., & Nurchasanah, Y. (2025). Analysis of the Use of Fly Ash Variations as a Partial Cement Substitute for Roller Compacted Concrete (RCC) Mixtures. Engineering Proceedings, 84(1), 38. https://doi.org/10.3390/engproc2025084038