Abstract

The Indonesian government is currently focusing on infrastructure development, including military infrastructure to strengthen national defense. One of these projects is the development of the Indonesian Army Central Hospital, which is being continually expanded with facilities such as proton beam therapy. Due to its underground construction, special attention must be given to construction safety to prevent workplace accidents. This study focuses on assessing construction safety risks at the military hospital using activity-based failure modes and effects analysis (FMEA). The research methodology employed is a mixed-method approach involving 5 construction safety experts and 100 respondents directly involved in underground structure construction. Descriptive data analysis was conducted, serving as the basis for calculating risk priority numbers (RPN) using the FMEA method. Three main activities were identified with very high risks ranked from 1 to 10: lifting of contiguous pile casing, basement excavation, and installation of cast in situ bored pile gutter. These activities entail safety risks with RPN values ranging from 100 to 125, including worker’s hands being caught in tools/materials, being struck by tools/materials, falling/slipping into excavations, and being buried/struck by excavated soil. This research has positive implications as a reference for developing construction safety plans that include risk identification, risk assessment, and determination of control measures.

1. Introduction

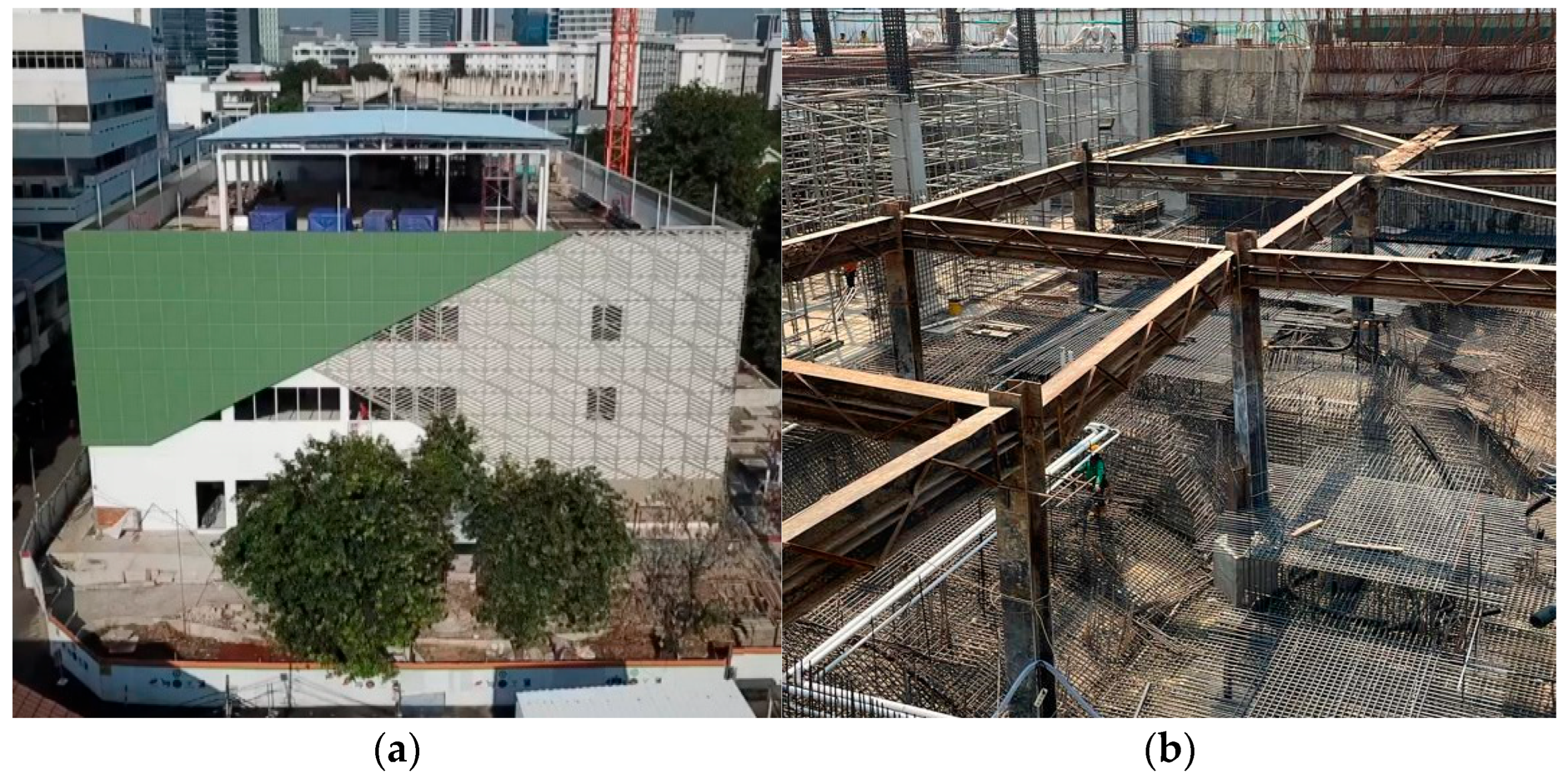

The Indonesian government is currently placing special emphasis on the development sector, encompassing both civil infrastructure and military construction. The development of military construction projects demonstrates the Indonesian government’s commitment to strengthening national defense to face future threats [1]. One type of military construction is the military hospital. A military hospital is specifically designed to support the healthcare functions required by military institutions. These hospitals are planned, constructed, and operated by the military. The Central Army Hospital of Indonesia is one such military construction project currently under development. This development includes a proton beam therapy facility that employs an underground structure. This building is unique compared to others, with a total area of 4319 square meters, and features a basement dedicated to proton beam therapy with specially reinforced structural integrity. The construction process can be seen in Figure 1.

Figure 1.

(a) Front view of the construction process of military hospital; (b) underground structure construction of military hospital using top-down method.

In addition to being unique, construction projects are inherently complicated and complex [2]. The complexity of a construction project is determined by the construction methods employed [2]. The underground structure work on this military hospital project utilizes the top-down construction method. Consequently, this project has garnered special attention [3] due to its high construction safety risks.

Furthermore, the project is large, complex, and challenging, which can contribute to numerous workplace accidents [2,4]. These accidents pose serious issues. A series of construction accidents have occurred in Indonesia over recent years due to the increasing number of infrastructure projects being undertaken. In 2020, 19% of workplace accidents in construction projects involved incidents of workers being struck by falling objects or materials [5]. Meanwhile, 16% of construction accidents, occurring in 2019, resulted in 30 fatalities and 9 severe injuries [5]. Workplace accidents can have negative impacts on project management, such as increased project costs, delays in project completion, and damage to the company’s reputation, in addition to adversely affecting workers [3,6].

Therefore, controlling construction safety risks is crucial as part of the project’s safety plan, developed based on activities [7], which is derived from the work breakdown structure (WBS) [8]. Construction work and risks are two perspectives for delineating projects and constructing work breakdown structure and risk breakdown structure (RBS) trees, building cross-matrixes between WBS and RBS [9]. WBS–RBS is used to systematically and comprehensively identify risks [9]. Construction safety risks are identified based on activities [7]. Meanwhile, activities in construction work are identified from WBS [10,11] and are at level 5 [12], because each activity poses its hazards [13] and risks [2,8,14,15]. These risks are then analyzed for their likelihood and impact levels [16].

Construction accident risks can be analyzed and assessed using the failure mode and effects analysis (FMEA) method [17]. FMEA is a technique used to systematically analyze problems within system gaps [18]. The FMEA method is highly suitable and has been successfully applied across various types of industries due to its high visibility [19]. In conducting safety analysis, the use of FMEA is highly beneficial, making it renowned for its ease of use [19]. It also serves as a tool to assist project stakeholders in identifying risks, categorizing them, and formulating appropriate management actions [20]. Risk evaluation in FMEA is conducted by constructing a risk priority number (RPN) [21]. An RPN is a common assessment performed in FMEA [22]. Mathematically, the RPN is calculated by multiplying severity (S), occurrence (O), and detection (D) values [22]. FMEA is typically used for quality risk assessment of a product and rarely for safety risk assessment in construction projects.

In previous studies, construction safety risks have been identified and assessed based on activities such as building structures, bridges, ports, airports, tunnels, dams, irrigation, and other structures. However, no assessment has been conducted on construction safety risks for military construction projects, particularly hospitals. Additionally, previous research has not employed the FMEA method for construction safety risk assessment.

Therefore, this study focuses on assessing construction safety risks in military hospital projects using activity-based FMEA. This research has positive implications for identifying construction safety risks through a different approach. The findings of this study can also serve as a basis for determining further actions in managing construction safety risks.

2. Methodology

This study employs a mixed-method research approach. This emphasizes a quantitative approach through respondent surveys. It is also supported by a qualitative approach, gathering opinions from construction safety experts in the field.

The research consists of two main stages. The first stage involves applying Project Management Institute (PMI) tools and techniques to identify risks through expert judgment [10,11]. This stage aims to obtain expert opinions on the identified risks to ensure validity. Once construction safety risks have been identified, the next stage involves risk assessment using the FMEA method.

The study involves 5 construction safety experts and 100 respondents involved in underground structure construction. The minimum educational requirement for the experts is a bachelor’s degree in engineering or equivalent, while for the respondents, the minimum requirement is a diploma in engineering. The required experience in the construction sector is twenty years for experts and five years for respondents. The minimum job level for experts is manager, and for respondents, it is engineer.

The data used in this study are primary data, collected directly from the experts and respondents. Data collection techniques include expert surveys and brief interviews with experts. In conducting the risk assessment, several parameters are evaluated, such as the level of severity, the level of occurrence, and the level of detection, through a closed questionnaire survey of the respondents.

The data analysis employed is descriptive, presenting descriptive statistical values. The collected data are then tested for validity and reliability according to statistical requirements. Once the data are deemed valid and reliable, conclusions will be drawn. The conclusions for each variable are then used as a basis for calculating the RPN using the FMEA method. Once the RPN values are obtained, the subsequent analysis involves ranking the risks based on activities according to their RPN values.

3. Result and Discussion

3.1. Risk Identification

Risk identification is an initial and crucial step [2]. After safety risks are identified, expert judgment is employed to validate these risks [10]. This study includes five expert respondents directly involved in military hospital projects, holding strategic positions in project management. The profiles of these expert respondents are presented in Table 1.

Table 1.

Profile of expert respondents.

The expert judgment analysis was conducted descriptively to conclude whether the experts agreed or disagreed on the identified risks associated with each activity, including their impacts, contributing factors, and the current control measures implemented. Table 2 presents a partial summary of the expert judgment analysis conducted. There are 32 activities that were categorized from the foundation work package, including bored pile, contiguous pile, earth excavation, pile cap, tie beam, ground column, ground beam, bunker wall, and proton wall. Among these activities, 113 work safety risks were identified. In addition to safety risks, impacts, contributing factors, and current control measures were collectively identified to facilitate further analysis using FMEA.

Table 2.

The results of expert judgment analysis.

3.2. Failure Mode and Effect Analysis (FMEA)

The probability impact matrix (PIM) method for assessing construction safety risks, in line with PMI standards [10], has been applied in previous studies on several projects, particularly bridge infrastructure [2,7,8,13,14,15]. PIM assesses risk based on the probability and impact values of each risk [10], which then form the basis for calculating the risk level and determining control actions accordingly [10]. However, the risk assessment approach using the PIM does not evaluate detection based on existing control actions. In contrast, the FMEA assessment method incorporates existing control actions into the risk assessment by including a detection value [20,21,22]. Therefore, the FMEA risk assessment results are considered more comprehensive, as they take into account risk severity, occurrence, and detection values of existing controls.

Risk assessment using the FMEA method involved 100 survey respondents. Each survey respondent involved in this study adheres to predefined criteria. The characteristics of the survey respondents included their positions, education, and years of work experience.

Respondent positions were categorized as 48 safety officers/site engineers, 38 assistant managers/supervisors, and 14 managers. The educational backgrounds of the survey respondents varied, with 33 respondents holding a diploma degree, 52 respondents having a bachelor’s degree, and 15 respondents having a master’s degree. Regarding work experience, 52 respondents had 5–10 years of experience, 36 respondents had 11–20 years, and 12 respondents had more than 20 years. The characteristics of the survey respondents are presented in Table 3.

Table 3.

Characteristics of survey respondents.

The following activities are involved in underground structure construction with high safety risks, such as lifting of contiguous pile casing, basement excavation, and installation of cast in situ bored pile gutter, present safety risks including worker’s hands being caught in tools/materials, being struck by tools/materials, falling/slipping into excavations, and being buried/struck by excavated soil. Based on the FMEA results, these safety risks have high RPNs ranging from 100 to 125. After ranking, these safety risks are among the top 10 priorities. They should be prioritized for further management to reduce their severity, occurrence, and detection ratings, which will automatically lower their RPN values. The complete and detailed results of the FMEA based on these activities are presented in Table 4.

Table 4.

FMEA safety risks based on activities.

4. Conclusions

Based on the analysis conducted in this study, several key findings can be summarized:

- There are three main activities with very high risks ranked from 1 to 10, namely lifting of contiguous pile casing, basement excavation, and installation of cast in situ bored pile gutter.

- These activities entail safety risks with RPN ranging from 100 to 125, including worker’s hands being caught in tools/materials, struck by tools/materials, falling/slipping into excavations, and being buried/struck by excavated soil.

- Based on the risk assessment results using the FMEA method, the recommendation is to prioritize the immediate implementation of advanced control measures. This involves developing strategic steps focused on construction activities and safety risks, which should be incorporated into a policy, planning, and actionable measures.

This research can serve as a reference for similar projects. However, the results should not be universally applied to all projects due to varying project characteristics. Therefore, reassessment and activity-based analysis are necessary to enhance validity. Future studies could expand this research by applying it to other types of buildings or infrastructure to compare results with conventional risk analysis methods.

Author Contributions

Conceptualization, P.D.S.; methodology, P.D.S., M.H.F. and A.A.L.; software, A.A.L.; data collection, M.R. and M.N.B.S.; formal analysis, M.R. and M.N.B.S.; resources, M.R. and M.N.B.S.; writing—original draft preparation, P.D.S., M.H.F. and A.A.L.; writing—review and editing, P.D.S., M.H.F. and A.A.L.; visualization, P.D.S., M.H.F. and A.A.L.; supervision, P.D.S.; project administration, M.R. and M.N.B.S.; funding acquisition, P.D.S., M.H.F. and A.A.L. All authors have read and agreed to the published version of the manuscript.

Funding

The researchers extend their profound gratitude to the Republic of Indonesia Defense University for providing financial support through an internal grant managed by the Institute for Research and Community Service, under contract number 021/PK/VI/2024/LPPM Unhan RI.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data are contained within the article.

Acknowledgments

The researchers wish to express their appreciation to the Center for Construction, Defense Facilities Agency, Ministry of Defense of the Republic of Indonesia for granting research permissions and other support.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Rusdiana, D.; Ali, Y.; Thamrin, S.; Widodo, R. Strategi Pembangunan Industri Pertahanan Pada Negara Kepulauan Guna Mendukung Pertahanan Negara. J. Acad. Praja 2021, 4, 427–440. [Google Scholar] [CrossRef]

- Saputra, P.D.; Latief, Y. Development of Safety Plan Based on Work Breakdown Structure to Determine Safety Cost for Precast Concrete Bridge Construction Projects. Case Study: Girder Erection with Launching Gantry Method. Civ. Eng. Archit. 2020, 8, 297–304. [Google Scholar] [CrossRef]

- Cui, Z.D.; Zang, Z.L.; Yuan, L.; Zhan, Z.X.; Zhang, W.K. (Eds.) Design of Underground Structures. In Design of Underground Structures; Springer Nature: Singapore, 2020; pp. 731–762. [Google Scholar]

- Cheng, E.W.L.; Li, H.; Fang, D.P.; Xie, F. Construction safety management: An exploratory study from China. Constr. Innov. 2004, 4, 229–241. [Google Scholar] [CrossRef]

- Bria, T.A.; Chen, W.T.; Muhammad, M.; Rantelembang, M.B. Analysis of Fatal Construction Accidents in Indonesia—A Case Study. Buildings 2024, 14, 1010. [Google Scholar] [CrossRef]

- Chan, A.P.C.; Wong, F.K.W.; Chan, D.W.M.; Yam, M.C.H.; Kwok, A.W.K.; Lam, E.W.M.; Cheung, E. Work at Height Fatalities in the Repair, Maintenance, Alteration, and Addition Works. J. Constr. Eng. Manag. 2008, 134, 527–535. [Google Scholar] [CrossRef]

- Saputra, P.D.; Laksmi, A.A.; Purwanti, N.; Fansuri, M.H. Development of Activity-Based Safety Plan for Precast Parapet Panel Work in Elevated Construction. In Lecture Notes in Civil Engineering; Lie, H.A., Sutrisna, M., Prasetijo, J., Hadikusumo, B.H., Putranto, L.S., Eds.; Springer Nature: Singapore, 2022; Volume 216, pp. 459–470. [Google Scholar]

- Saputra, P.D.; Latief, Y. Analysis of Safety Cost Structure in Infrastructure Project of Precast Concrete Bridge Based on Work Breakdown Structure (WBS). In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2020; Volume 830, p. 022074. [Google Scholar]

- Yang, J.; Zhang, H. Study on the dynamic risk management of WBS and RBS. Sci. Technol. Eng. 2009, 9, 4086. [Google Scholar]

- PMI. Project Management Body of Knowledge; Project Management Institut, Inc.: Newtown Square, PA, USA, 2017. [Google Scholar]

- PMI. Construction Extension to the Project Management Body of Knowledge Guide; Project Management Institut, Inc.: Newtown Square, PA, USA, 2017. [Google Scholar]

- Sejati, P.A.; Isvara, W.; Latief, Y. Identification of Roof Truss Work Activities for The Jakarta International Stadium Project with HeavyLifting Construction Method Using Strand JackSystem. In AIP Conference Proceedings, Proceedings of the 3rd Borobudur International Symposium of Science and Technology 2021, Magelang, Indonesia, 15 December 2021; AIP Publishing: New York, NY, USA, 2023; Volume 2706, p. 020118. [Google Scholar]

- Nicodemus, A.M.; Latief, Y. Identify of Occupational Health and Safety (OHS) cost component for Flyover Project by developing of safety plan based on Work Breakdown Structure (Case study: Erection girder using tandem crane). In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2021; Volume 1098, p. 022048. [Google Scholar]

- Fitriani, R.; Latief, Y. A Conceptual Framework of Cost of Safety Model in Infrastructure Project Based on Work Breakdown Structure (WBS) To Improve Safety Policy In Indonesia. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2019; Volume 650, p. 012003. [Google Scholar]

- Putra, A.S.P.; Latief, Y. Analysis of Safety Cost Structure in Infrastructure Project of Cable Stayed Bridge Based on Work Breakdown Structure (WBS). In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2020; Volume 830, p. 022075. [Google Scholar]

- Fang, X.; Zhang, W.; Lin, J. Optimization of evaluation index cost risk-based system from power transmission project on rough seta theory. J. Civ. Eng. Manag. 2015, 32, 40–47. [Google Scholar]

- Santiara, N.; Rosiyadi, D. Work Accident Analysis on the project at PT. X based on the Failure Mode & Effect Analysis (FMEA) Method. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2020; Volume 879, p. 012082. [Google Scholar]

- Griffin, P.M.; Nembhard, H.B.; DeFlitch, C.J.; Bastian, N.D.; Kang, H.; Munoz, D.A. Healthcare Systems Engineering; John Wiley & Sons Inc.: Hoboken, NJ, USA, 2016. [Google Scholar]

- Huang, J.; You, J.-X.; Liu, H.-C.; Song, M.-S. Failure mode and effect analysis improvement: A systematic literature review and future research agenda. Reliab. Eng. Syst. Saf. 2020, 199, 106885. [Google Scholar] [CrossRef]

- Atin, S.; Lubis, R. Implementation of the Failure Mode and Effects Analysis (FMEA) Method to Determine Project Risk Priority. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2020; Volume 879, p. 012026. [Google Scholar]

- Şimşek, B.; İç, Y.T. Fuzzy failure mode and effect analysis application to reduce risk level in a ready-mixed concrete plant: A fuzzy rule-based system modelling approach. Math. Comput. Simul. 2020, 178, 549–587. [Google Scholar] [CrossRef]

- Wang, R.; Feng, Y.; Yang, H. Construction Project Risk Evaluation Based on FMEA. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2019; Volume 330, p. 022041. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).