A Comparative Study of Titanium-Based Coatings Prepared by Magnetron Sputtering for Biomedical Applications †

Abstract

1. Introduction

2. Materials and Methods

2.1. Deposition Protocol

2.2. Characterization Methods

3. Results and Discussion

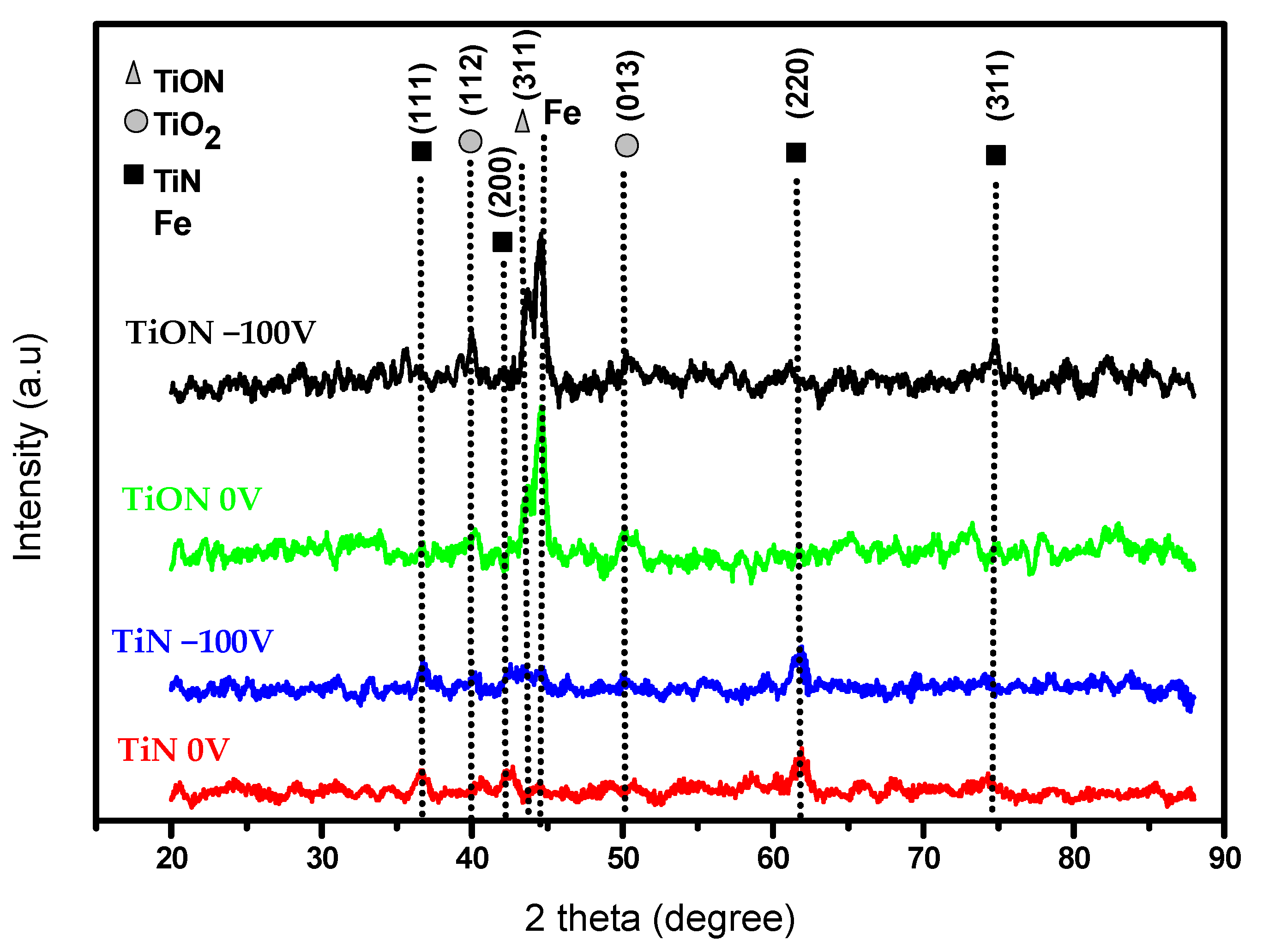

3.1. Structure

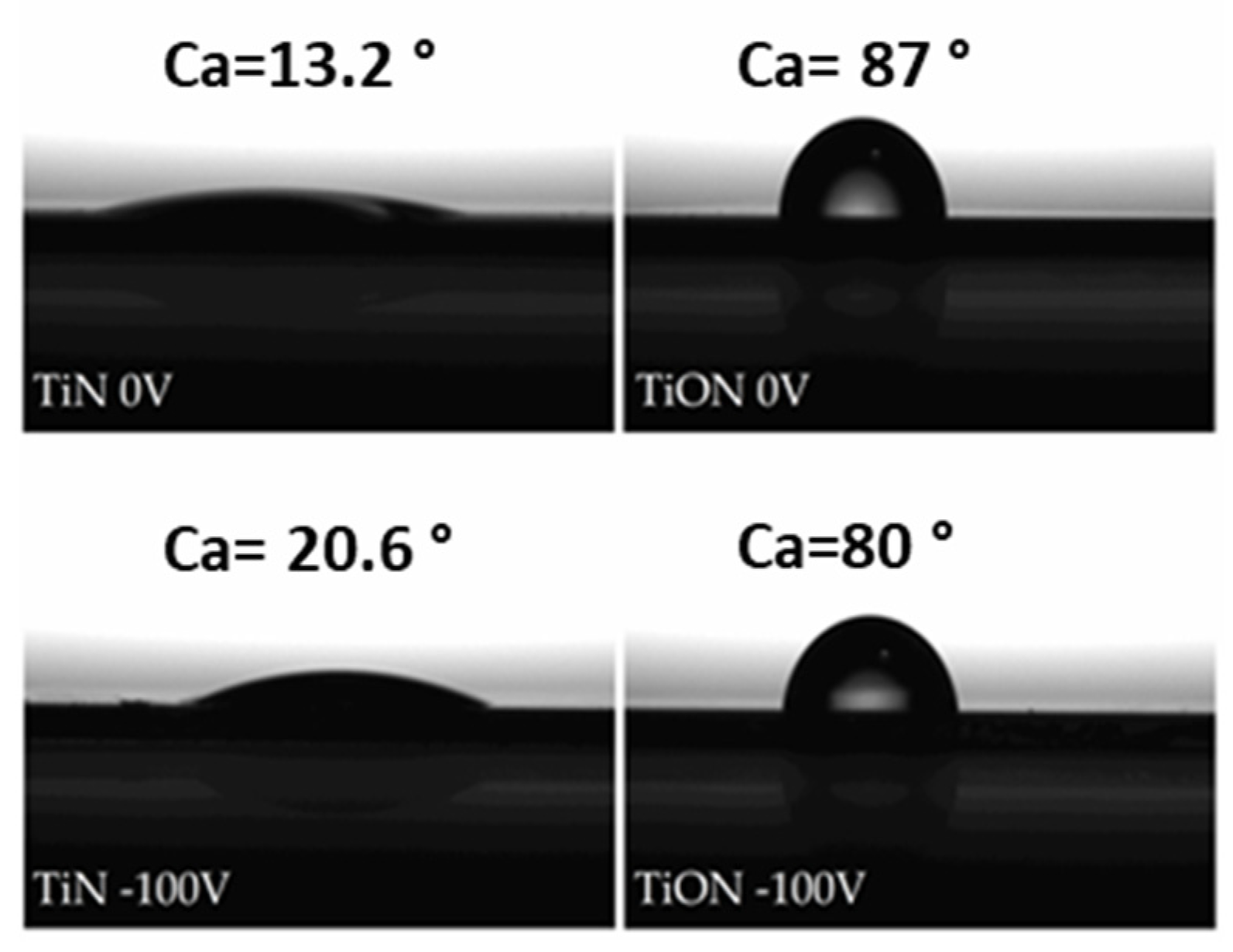

3.2. Surface Wettability

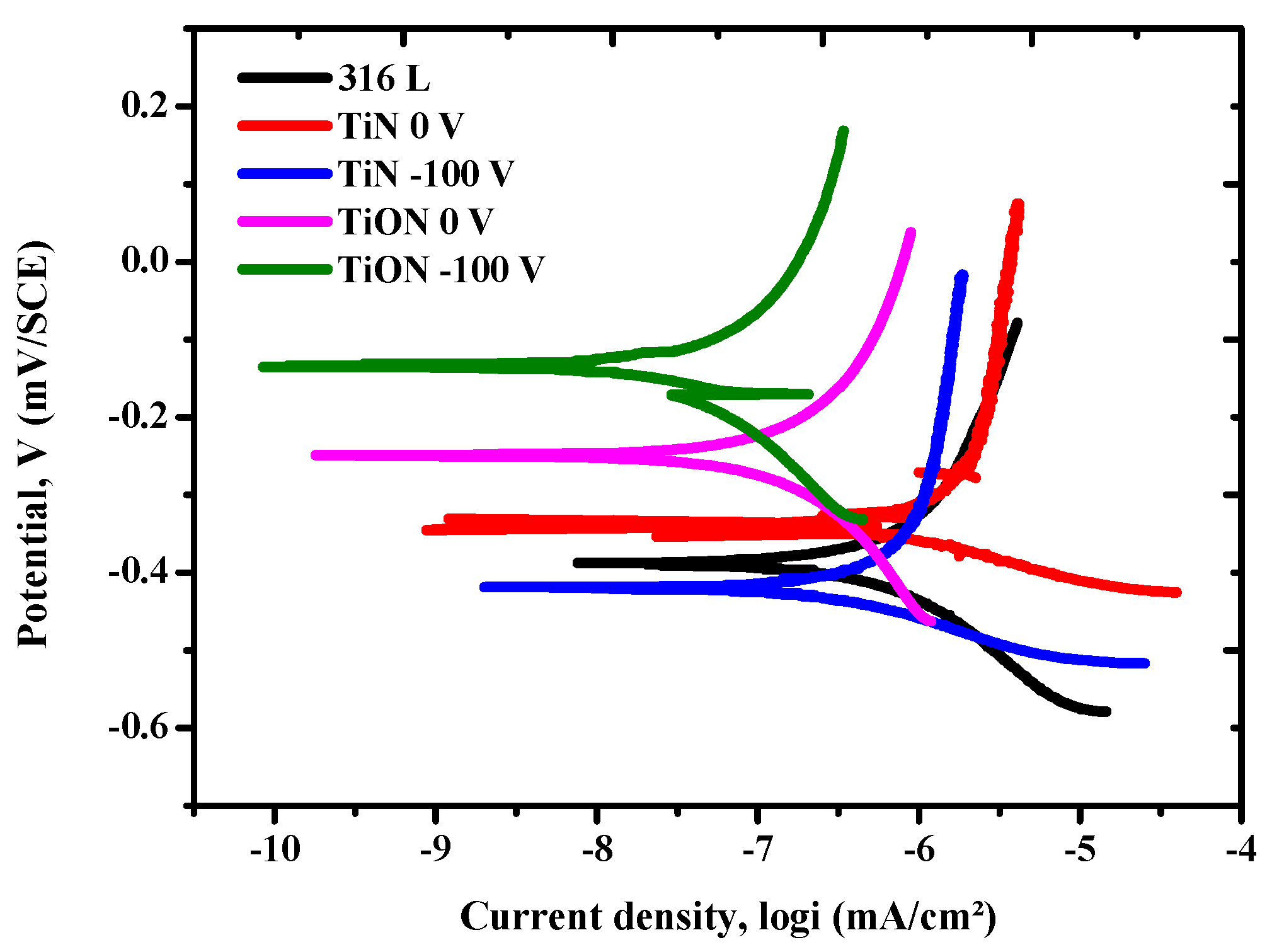

3.3. Corrosion Test

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Jimenez-Marcos, C.; Mirza-Rosca, J.C.; Baltatu, M.S.; Vizureanu, P. Experimental research on new developed titanium alloys for biomedical applications. Bioengineering 2022, 9, 686. [Google Scholar] [CrossRef] [PubMed]

- Quinn, J.; McFadden, R.; Chan, C.-W.; Carson, L. Titanium for orthopedic applications: An overview of surface modification to improve biocompatibility and prevent bacterial biofilm formation. iScience 2020, 23, 5–6. [Google Scholar] [CrossRef] [PubMed]

- Bekmurzayeva, A.; Duncanson, W.J.; Azevedo, H.S.; Kanayeva, D. Surface modification of stainless steel for biomedical applications: Revisiting a century-old material. Mater. Sci. Eng. C 2018, 93, 1073–1089. [Google Scholar] [CrossRef] [PubMed]

- Mejía, C.P.; Vanegas, H.S.; Olaya, J.J. Electrochemical and optical behavior of ZrN-Ag coatings deposited by means of DC reactive magnetron sputtering technique. Coatings 2022, 12, 754. [Google Scholar] [CrossRef]

- Rajan, S.T.; Arockiarajan, A. Thin film metallic glasses for bioimplants and surgical tools: A review. J. Alloys Compd. 2021, 876, 159939. [Google Scholar] [CrossRef]

- Amirtharaj Mosas, K.K.; Chandrasekar, A.R.; Dasan, A.; Pakseresht, A.; Galusek, D. Recent advancements in materials and coatings for biomedical implants. Gels 2022, 8, 323. [Google Scholar] [CrossRef] [PubMed]

- Atmani, D.; Saoula, N.; Chouchane, K.; Lalmi, M.; Abdi, A.; Olaru, P. Study of Mg-Rich Sulfato-Calcium Hydroxyapatite Coating on Anodized Ti6Al4V-Alloy for Biomedical Applications. J. Mater. Eng. Perform. 2024, 1–15. [Google Scholar] [CrossRef]

- Madaoui, N.; Saoula, N.; Kheyar, K.; Nezar, S.; Tadjine, R.; Hammouche, A.; Belhousse, S. The effect of substrate bias voltage on the electrochemical corrosion behaviors of thin film deposited on stainless steel by r. f magnetron sputtering. Prot. Met. Phys. Chem. Surf. 2017, 53, 527–533. [Google Scholar] [CrossRef]

- Jiang, Q.; Ma, D.; Li, Y.; Chen, C. The Deposition and Properties of Titanium Films Prepared by High Power Pulsed Magnetron Sputtering. Materials 2023, 16, 7294. [Google Scholar] [CrossRef] [PubMed]

- Yan, Y.; Lizhen, Y.; Zhongwei, L.; Qiang, C. High power impulse magnetron sputtering and its applications. Plasma Sci. Technol. 2018, 20, 065501. [Google Scholar] [CrossRef]

- Yang, K.; Shi, J.; Wang, L.; Chen, Y.; Liang, C.; Yang, L.; Wang, L.-N. Bacterial anti-adhesion surface design: Surface patterning, roughness and wettability: A review. J. Mater. Sci. Technol. 2022, 99, 82–100. [Google Scholar] [CrossRef]

- Zinai, N.; Bouzidi, A.; Saoula, N.; Miloua, R.; Medles, M.; Filali, W.; Garoudja, E.; Azibi, M.; Connelly, P.; Nakrela, A. Tailoring the structural and optical properties of HiPIMS TiO2 thin films for photovoltaic applications. Opt. Mater. 2022, 131, 112590. [Google Scholar] [CrossRef]

- Azibi, M.; Saoula, N.; Madaoui, N.; Aknouche, H. Effects of nitrogen content on the structural, mechanical, and corrosion properties of ZrN thin films grown on AISI 316L by radiofrequency magnetron sputtering. Cryst. Res. Technol. 2021, 56, 2100096. [Google Scholar] [CrossRef]

- Hunt, J.; Soletta, I.; Battezzati, L.; Cowlam, N.; Cocco, G. On the influence of gaseous impurities in the amorphization reaction of some titanium-based alloys. J. Alloys Compd. 1993, 194, 311–317. [Google Scholar] [CrossRef]

- Čolović, B.; Kisić, D.; Jokanović, B.; Rakočević, Z.; Nasov, I.; Petkoska, A.T.; Jokanović, V. Wetting properties of titanium oxides, oxynitrides and nitrides obtained by DC and pulsed magnetron sputtering and cathodic arc evaporation. Mater. Sci.-Pol. 2019, 37, 173–181. [Google Scholar] [CrossRef]

- Koerner, R.; Butterworth, L.; Mayer, I.; Dasbach, R.; Busscher, H. Bacterial adhesion to titanium-oxy-nitride (TiNOX) coatings with different resistivities: A novel approach for the development of biomaterials. Biomaterials 2002, 23, 2835–2840. [Google Scholar] [CrossRef] [PubMed]

- Estrada-Martínez, J.; Reyes-Gasga, J.; García-García, R.; Vargas-Becerril, N.; Zapata-Torres, M.G.; Gallardo-Rivas, N.V.; Mendoza-Martínez, A.M.; Paramo-García, U. Wettability modification of the AISI 304 and 316 stainless steel and glass surfaces by titanium oxide and titanium nitride coating. Surf. Coat. Technol. 2017, 330, 61–70. [Google Scholar] [CrossRef]

- Mrabet, C.; Mahdhi, N.; Boukhachem, A.; Amlouk, M.; Manoubi, T. Effects of surface oxygen vacancies content on wettability of zinc oxide nanorods doped with lanthanum. J. Alloys Compd. 2016, 688, 122–132. [Google Scholar] [CrossRef]

- Azibi, M.; Madaoui, N.; Saoula, N.; Idir, B.; Sam, S.; Khelladi, M.R. Tailoring Zr-N Thin Film Characteristics on Ti-6Al-4 V Alloy: Effect of Nitrogen and Bias Voltage. Braz. J. Phys. 2024, 54, 90. [Google Scholar] [CrossRef]

- Piallat, F.; Gassilloud, R.; Caubet, P.; Vallée, C. Investigation of TiN thin film oxidation depending on the substrate temperature at vacuum break. J. Vac. Sci. Technol. A 2016, 34, 051508. [Google Scholar] [CrossRef]

| Compounds | Quantity g/L |

|---|---|

| NaCl | 8 |

| KCl | 0.4 |

| CaCl2 | 0.18 |

| KH2PO4 | 0.06 |

| NaHCO3 | 0.35 |

| Na2HPO4 | 0.0475 |

| MgCl2·6H2O | 0.10 |

| MgSO4·7H2O | 0.10 |

| C6H12O6 | 1 |

| Bias Substrate Voltage (V) | Thickness H (nm) | Grain Size (nm) | Roughness Ra (nm) |

|---|---|---|---|

| TiN 0 | 500 | 16 | 7.4 |

| TiN −100 | 450 | 12 | 1.5 |

| TiON 0 | <100 | 16 | 1.4 |

| TiON −100 | <100 | 20 | 1.5 |

| Samples | Ecorr (mV vs. SCE) | Icorr (nA/cm2) | Rp (KΩ.cm2) | Cr (mm/an) | Pe (%) |

|---|---|---|---|---|---|

| 316L SS | −380.435 | 114.012 | 274.29 | 0.0043 | -- |

| TiN 0 | −335.065 | 760.671 | 30.196 | 0.0347 | 0 |

| TiN −100 | −417.186 | 461.744 | 80.958 | 0.013 | 0 |

| TiON 0 | −248.738 | 85.271 | 335.426 | 0.0036 | 25 |

| TiON −100 | −139.168 | 29.156 | 708.378 | 0.0017 | 74 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lemdani, F.; Saoula, N.; Madaoui, N.; Azibi, M.; Azzoug, Y.; Chettouh, G.; Hammouche, A. A Comparative Study of Titanium-Based Coatings Prepared by Magnetron Sputtering for Biomedical Applications. Eng. Proc. 2024, 81, 9. https://doi.org/10.3390/engproc2024081009

Lemdani F, Saoula N, Madaoui N, Azibi M, Azzoug Y, Chettouh G, Hammouche A. A Comparative Study of Titanium-Based Coatings Prepared by Magnetron Sputtering for Biomedical Applications. Engineering Proceedings. 2024; 81(1):9. https://doi.org/10.3390/engproc2024081009

Chicago/Turabian StyleLemdani, Ferroudja, Nadia Saoula, Noureddine Madaoui, Mourad Azibi, Yassine Azzoug, Gaya Chettouh, and Abdelkader Hammouche. 2024. "A Comparative Study of Titanium-Based Coatings Prepared by Magnetron Sputtering for Biomedical Applications" Engineering Proceedings 81, no. 1: 9. https://doi.org/10.3390/engproc2024081009

APA StyleLemdani, F., Saoula, N., Madaoui, N., Azibi, M., Azzoug, Y., Chettouh, G., & Hammouche, A. (2024). A Comparative Study of Titanium-Based Coatings Prepared by Magnetron Sputtering for Biomedical Applications. Engineering Proceedings, 81(1), 9. https://doi.org/10.3390/engproc2024081009