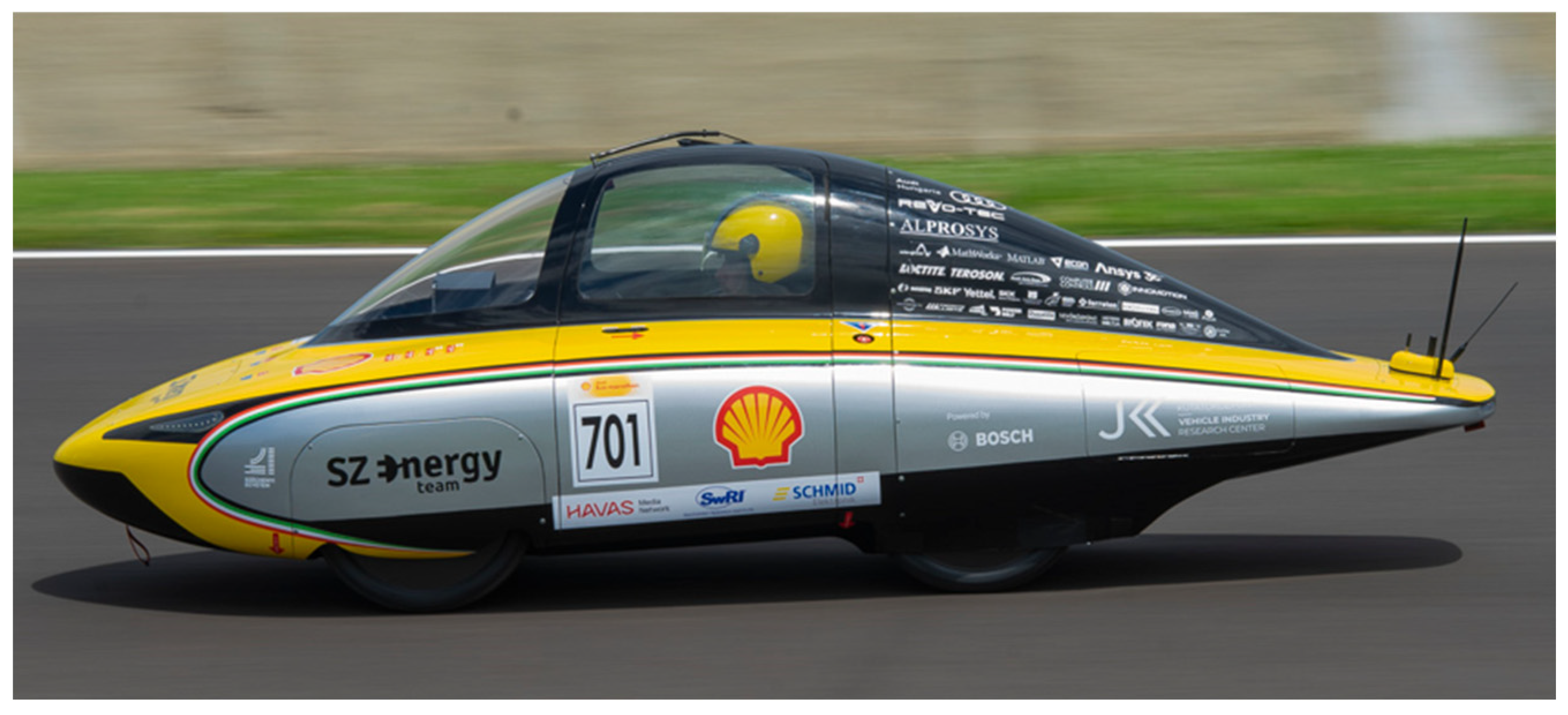

Driving Strategy Optimization in Experimental Electric Vehicles: A Study on Optimization Algorithms †

Abstract

1. Introduction

2. Vehicle Modeling and Driving Strategy Optimization

3. Applied Optimization Algorithms

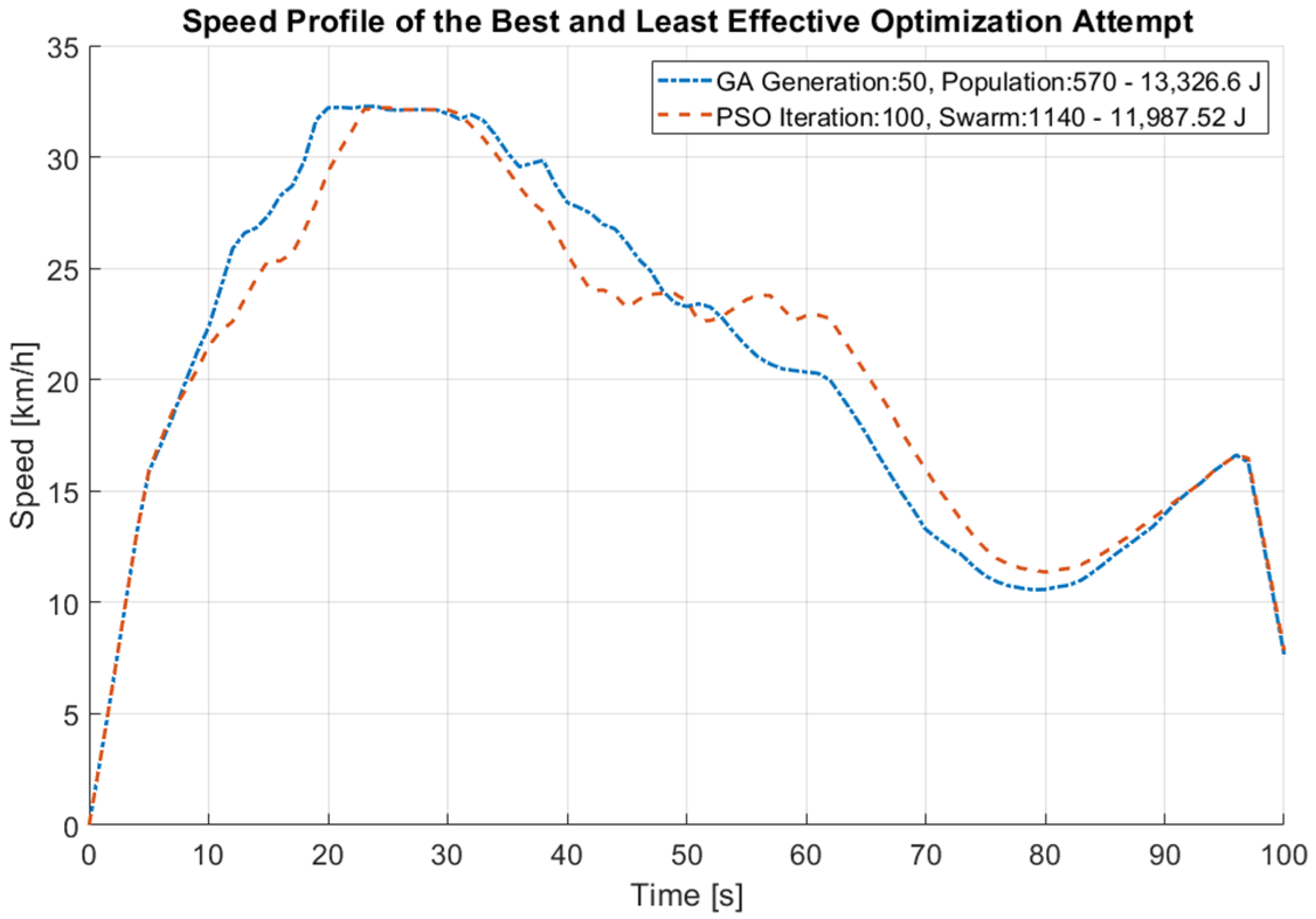

4. Optimization Results

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Das, P.K.; Bhat, M.Y.; Sajith, S. Life Cycle Assessment of Electric Vehicles: A Systematic Review of Literature. Environ. Sci. Pollut. Res. 2024, 31, 73–89. [Google Scholar] [CrossRef]

- Milev, G.; Al-Habaibeh, A.; Shin, D. Impact of Replacing Conventional Cars with Electric Vehicles on UK Electricity Grid and Carbon Emissions. In Energy and Sustainable Futures, Proceedings of the 2nd International Conference on Energy and Sustainable Futures (ICESF 2020), Hatfield, UK, 10–11 September 2020; Mporas, I., Kourtessis, P., Al-Habaibeh, A., Asthana, A., Vukovic, V., Senior, J., Eds.; Springer International Publishing: Cham, Switzerland, 2021; pp. 199–206. [Google Scholar] [CrossRef]

- Czerwinski, F. Current Trends in Automotive Lightweighting Strategies and Materials. Materials 2021, 14, 6631. [Google Scholar] [CrossRef] [PubMed]

- Pusztai, Z.; Kőrös, P.; Friedler, F. Vehicle Model for Driving Strategy Optimization of Energy Efficient Lightweight Vehicle. Chem. Eng. Trans. 2021, 88, 385–390. [Google Scholar] [CrossRef]

- Sawulski, J.; Ławryńczuk, M. Optimization of Control Strategy for a Low Fuel Consumption Vehicle Engine. Inf. Sci. 2019, 493, 192–216. [Google Scholar] [CrossRef]

- Stabile, P.; Ballo, F.; Previati, G.; Mastinu, G.; Gobbi, M. Eco-Driving Strategy Implementation for Ultra-Efficient Lightweight Electric Vehicles in Realistic Driving Scenarios. Energies 2023, 16, 1394. [Google Scholar] [CrossRef]

- Chen, Z.; Xiong, R.; Wang, K.; Jiao, B. Optimal Energy Management Strategy of a Plug-in Hybrid Electric Vehicle Based on a Particle Swarm Optimization Algorithm. Energies 2015, 8, 3661–3678. [Google Scholar] [CrossRef]

- Olivier, J.C.; Wasselynck, G.; Chevalier, S.; Auvity, B.; Josset, C.; Trichet, D.; Squadrito, G.; Bernard, N. Multiphysics Modeling and Optimization of the Driving Strategy of a Light Duty Fuel Cell Vehicle. Int. J. Hydrogen Energy 2017, 42, 26943–26955. [Google Scholar] [CrossRef]

- Pusztai, Z.; Kőrös, P.; Szauter, F.; Friedler, F. Vehicle Model-Based Driving Strategy Optimization for Lightweight Vehicle. Energies 2022, 15, 3631. [Google Scholar] [CrossRef]

- Banks, A.; Vincent, J.; Anyakoha, C. A Review of Particle Swarm Optimization. Part I: Background and Development. Nat. Comput. 2007, 6, 467–484. [Google Scholar] [CrossRef]

- Palangpour, P.; Mitra, P.; Ray, S.; Venayagamoorthy, G.K. DSP-Based PSO Implementation for Online Optimization of Power System Stabilizers. In Proceedings of the Proceedings of the 2008 NASA/ESA Conference on Adaptive Hardware and Systems, Noordwijk, The Netherlands, 22–25 June 2008; IEEE: New York, NY, USA, 2008; pp. 379–384. [Google Scholar] [CrossRef]

- Perez, R.E.; Behdinan, K.; Perez, R.E.; Behdinan, K. Particle Swarm Optimization in Structural Design. In Swarm Intelligence, Focus on Ant and Particle Swarm Optimization; IntechOpen: London, UK, 2007; ISBN 978-3-902613-09-7.1. [Google Scholar]

| Metrics | Attempt 1 | Attempt 2 | Attempt 3 | Attempt 4 | Attempt 5 | Attempt 6 | Attempt 7 | Attempt 8 |

|---|---|---|---|---|---|---|---|---|

| Algorithm | GA | GA | GA | GA | PSO | PSO | PSO | PSO |

| Generation/Iteration | 50 | 50 | 100 | 100 | 50 | 50 | 100 | 100 |

| Population/Swarm | 570 | 1140 | 570 | 1140 | 570 | 1140 | 570 | 1140 |

| Best Score [J] | 13,326.60 | 13,332.32 | 13,133.88 | 13,050.42 | 12,549.60 | 12,375.29 | 12,355.95 | 12,179.32 |

| Difference | 8.61% | 8.65% | 7.27% | 6.67% | 2.95% | 1.58% | 1.43% | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pusztai, Z.; Szauter, F.; Friedler, F. Driving Strategy Optimization in Experimental Electric Vehicles: A Study on Optimization Algorithms. Eng. Proc. 2024, 79, 42. https://doi.org/10.3390/engproc2024079042

Pusztai Z, Szauter F, Friedler F. Driving Strategy Optimization in Experimental Electric Vehicles: A Study on Optimization Algorithms. Engineering Proceedings. 2024; 79(1):42. https://doi.org/10.3390/engproc2024079042

Chicago/Turabian StylePusztai, Zoltán, Ferenc Szauter, and Ferenc Friedler. 2024. "Driving Strategy Optimization in Experimental Electric Vehicles: A Study on Optimization Algorithms" Engineering Proceedings 79, no. 1: 42. https://doi.org/10.3390/engproc2024079042

APA StylePusztai, Z., Szauter, F., & Friedler, F. (2024). Driving Strategy Optimization in Experimental Electric Vehicles: A Study on Optimization Algorithms. Engineering Proceedings, 79(1), 42. https://doi.org/10.3390/engproc2024079042