Review of Vehicle Motion Planning and Control Techniques to Reproduce Human-like Curve-Driving Behavior †

Abstract

1. Introduction

- Inverse-dynamic models;

- Compensatory models;

- Feedforward models.

2. Materials and Methods

2.1. Methods

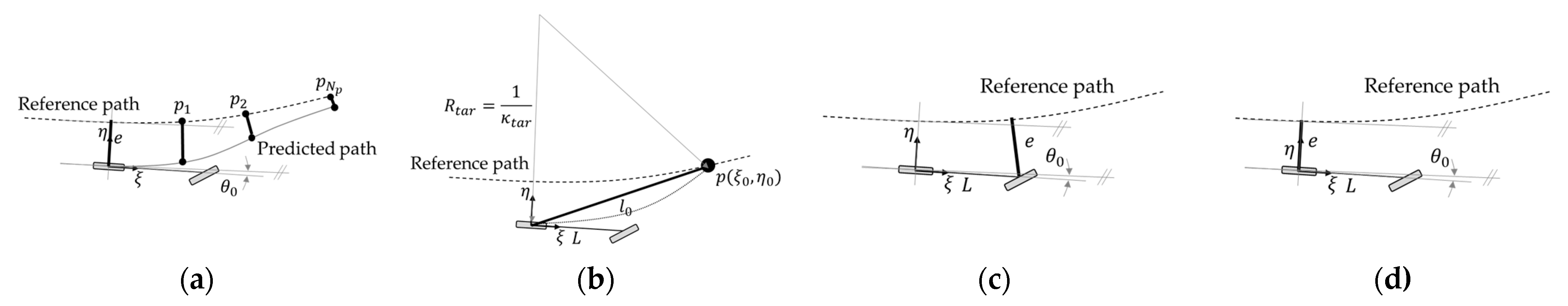

2.2. Model Predictive Control

- Prediction of the vehicle states , , given the input vector on the prediction horizon , and the output , where is the number of outputs;

- Calculating the reference output, given the prior path , where is the prediction horizon and is the representation of the prior path;

- Calculating the cost .

2.3. Pure-Pursuit Controller

2.4. Stanley Controller

2.5. Compensatory Driver Model

3. Results

3.1. Evaluation Criteria

- —lane offset to the centerline;

- —front road wheel angle, which is the input of the system;

- —computational time/simulation cycle, measured in MATLAB.

3.2. Experiments

- Test I: Neutral behavior, which is the compromise between the steering wheel oscillation and the tracking accuracy;

- Test II: Mistune—to produce a behavior that deviates from the neutral behavior.

4. Conclusions

4.1. Contribution

4.2. Limitations

4.3. Outlook

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- United Nations. Economic and Social Council: Proposal for a new UN Regulation on uniform provisions concerning the approval of vehicles with regards to Automated Lane Keeping System. In Proceedings of the ECE/TRANS/WP.29/2020/81, Geneva, Switzerland, 23–25 June 2020. [Google Scholar]

- Werling, M.; Ziegler, J.; Kammel, S.; Thrun, S. Optimal trajectory generation for dynamic street scenarios in a Frenét frame. In Proceedings of the 2010 IEEE International Conference on Robotics and Automation, Anchorage, AK, USA, 3–7 May 2010; pp. 987–993. [Google Scholar]

- Osa, T. Multimodal trajectory optimization for motion planning. Int. J. Robot. Res. 2020, 39, 983–1001. [Google Scholar] [CrossRef]

- Li, A.; Jiang, H.; Li, Z.; Zhou, J.; Zhou, X. Human-like trajectory planning on curved road: Learning from human drivers. IEEE Trans. Intell. Transp. Syst. 2020, 21, 3388–3397. [Google Scholar] [CrossRef]

- Yu, C.; Ni, A.; Luo, J.; Wang, J.; Zhang, C.; Chen, Q.; Tu, Y. A novel dynamic lane-changing trajectory planning model for automated vehicles based on reinforcement learning. J. Adv. Transp. 2022, 2022, 8351543. [Google Scholar] [CrossRef]

- Zhang, J.; Chen, H.; Song, S.; Hu, F. Reinforcement learning-based motion planning for automatic parking system. IEEE Access 2020, 8, 154485–154486. [Google Scholar] [CrossRef]

- Chen, L.; Jiang, Z.; Cheng, L.; Knoll, A.C.; Zhou, M. Deep reinforcement learning based trajectory planning under uncertain constraints. Front. Neurorobot. 2022, 16, 883562. [Google Scholar] [CrossRef] [PubMed]

- Yu, S.; Shen, C.; Ersal, T. Nonlinear Model Predictive Planning and Control for High-Speed Autonomous Vehicles on 3D Terrains. IFAC-PapersOnLine 2021, 54, 412–417. [Google Scholar] [CrossRef]

- Eilbrecht, J.; Bieshaar, M.; Zernetsch, S.; Doll, K.; Sick, B.; Stursberg, O. Model-Predictive Planning for Autonomous Vehicles Anticipating Intentions of Vulnerable Road Users by Artificial Neural Networks. In Proceedings of the IEEE Symposium Series on Computational Intelligence (SSCI), Honolulu, HI, USA, 27 November–1 December 2017. [Google Scholar]

- Peters, B.; Nilsson, L. Modelling the driver in control. In Modelling Driver Behaviour in Automotive Environments; Springer: London, UK, 2007; pp. 85–104. [Google Scholar]

- Coulter, R.C. Implementation of the Pure Pursuit Path Tracking Algorithm; Carnegie Mellon University, Robotics Institute: Pittsburgh, PA, USA, 1992. [Google Scholar]

- Hoffmann, G.M.; Tomlin, C.J.; Montemerlo, M.; Thrun, S. Autonomous Automobile Trajectory Tracking for Off-Road Driving: Controller Design, Experimental Validation and Racing. In Proceeding of the American Control Conference, New York, NY, USA, 9–13 July 2007. [Google Scholar]

- Rathgeber, C.; Winkler, F.; Odenthal, D.; Müller, S. Lateral trajectory tracking control for autonomous vehicles. In Proceedings of the European Control Conference (ECC), Strasbourg, France, 24–27 June 2014. [Google Scholar]

- Salvucci, D.D.; Gray, R. A two-point visual control model of steering. Perception 2004, 33, 1233–1248. [Google Scholar] [CrossRef] [PubMed]

- Ungoren, A.Y.; Peng, H. An Adaptive Lateral Preview Driver Model. Veh. Syst. Dyn. 2005, 43, 245–259. [Google Scholar] [CrossRef]

- Hess, R.A.; Modjtahedzadeh, A. A control theoretic model of driver steering behavior. IEEE Control Syst. Mag. 1990, 10, 3–8. [Google Scholar] [CrossRef]

- McAdam, C.C. An Optimal Preview Control for Linear Systems. J. Dyn. Syst. Meas. Control 1980, 1, 188–190. [Google Scholar] [CrossRef]

- Morari, M.; Garcia, C.E.; Prett, D.M. Model Predictive Control: Theory and practice. In Proceedings of the IFAC Model Based Process Control, Atlanta, GA, USA, 13–14 June 1988. [Google Scholar]

- Katriniok, A.; Maschuw, J.P.; Christen, F.; Eckstein, L.; Abel, D. Optimal vehicle dynamics control for combined longitudinal and lateral autonomous vehicle guidance. In Proceedings of European Control Conference, Zürich, Switzerland, 17–19 July 2013. [Google Scholar]

- Jiang, H.; Tian, H.; Hua, Y. Model predictive driver model considering the steering characteristics of the skilled drivers. Adv. Mech. Eng. 2019, 11, 1687814019829337. [Google Scholar] [CrossRef]

| MPC | Pure-Pursuit | Stanley | PID | |

|---|---|---|---|---|

| Test I. | ||||

| Test II. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ignéczi, G.; Horváth, E. Review of Vehicle Motion Planning and Control Techniques to Reproduce Human-like Curve-Driving Behavior. Eng. Proc. 2024, 79, 20. https://doi.org/10.3390/engproc2024079020

Ignéczi G, Horváth E. Review of Vehicle Motion Planning and Control Techniques to Reproduce Human-like Curve-Driving Behavior. Engineering Proceedings. 2024; 79(1):20. https://doi.org/10.3390/engproc2024079020

Chicago/Turabian StyleIgnéczi, Gergő, and Ernő Horváth. 2024. "Review of Vehicle Motion Planning and Control Techniques to Reproduce Human-like Curve-Driving Behavior" Engineering Proceedings 79, no. 1: 20. https://doi.org/10.3390/engproc2024079020

APA StyleIgnéczi, G., & Horváth, E. (2024). Review of Vehicle Motion Planning and Control Techniques to Reproduce Human-like Curve-Driving Behavior. Engineering Proceedings, 79(1), 20. https://doi.org/10.3390/engproc2024079020