Abstract

This study compares the environmental impacts of diesel and LNG-powered tractors under varying loads, by utilizing a cost-effective measurement system on the ZalaZONE Proving Ground. The same test cycles and scenarios were conducted with both trucks simultaneously on the closed test track modules and the research highlights LNG’s advantages in reducing CO2 emissions, particularly under lower load conditions. This innovative approach, based on the fuel consumption rather than expensive exhaust gas analyzers, underscores LNG’s potential in meeting EU emission targets. The results support LNG as a competitive and sustainable alternative to diesel, promoting greener freight transport solutions for the future.

1. Introduction

A significant portion of the global harmful and greenhouse gas emissions originates from vehicle exhaust gases. Nowadays, more regulations are introduced in the vehicle industry to reduce the emission of harmful substances and mitigate the greenhouse effect. These regulations apply to passenger vehicles and to commercial trucks. Among the various options for reducing harmful emissions, our article focuses on alternative fuels, specifically the less common LNG (Liquefied Natural Gas) technology in HDV (Heavy Duty Vehicle) sector. According to available studies, this solution emits significantly fewer harmful substances into the atmosphere compared to petroleum derivatives used so far [1]. In our study, we present a comparison to determine the CO2 (Carbon-dioxide) emissions and consumption changes of an internal combustion diesel truck and an internal combustion LNG truck under different loads. Additionally, we discuss the production of LNG, highlighting its advantages and disadvantages. Our tests were conducted on a closed test track to minimize the downtime caused by traffic and to reduce external influences. We present our measurement system, which collects the necessary data by connecting to the tractor’s communication network.

A study has examined the emission of harmful substances from diesel and LNG vehicles using expensive gas analyzers to monitor and analyze exhaust gas composition [2]. Instead of this costly method, we aimed to develop a relatively inexpensive solution that does not require expensive devices. We used the consumption data from the vehicle’s communication network to extract the necessary information and calculate CO2 emissions using simple mathematical formulas. Our approach focuses on load mass, as it is the primary factor influencing consumption and consequently, the emission of harmful substances in tractors.

1.1. Production of LNG as a Fuel Source

LNG is playing an increasingly important role in energy supply, as it is a high-energy-density carrier, similar to petroleum, that can be easily transported and stored at a relatively low cost. Since the composition of natural gas extracted from the ground is very diverse, further refining is required, similar to crude oil [3,4,5].

There are four methods for liquefying natural gas, which are based on compression and cooling in three stages: C3MR or APCI procedure, the Conoco Phillips process, the DMR and the Linde process [3].

Before reaching these final procedures, preventive cleaning technologies must be implemented due to the contamination of natural gas:

- Removal of water and hydrates;

- Sweetening of natural gas [6].

1.2. Comparison of Emissions of LNG and Diesel Vehicles

The most damaging factor to human health is pollutants. These pollutants not only harm the human body but also the environment. The large amount of carbon dioxide emitted by vehicles significantly contributes to the greenhouse effect. As a result of the increased vehicle fleet, emissions have increased by 25% in the last 30 years. To reduce this, the EU has set a goal of reducing CO2 emissions by at least 40% by 2030 compared to the 1990 value [7,8].

We can distinguish three stages during the lifetime of fuels and their resulting emissions: production, distribution, and combustion [5].

Natural gas products are non-corrosive chemical substances, with methane (CH4) content that can reach up to 98%. Methane oxidizes with extremely high efficiency, achieving nearly perfect combustion, which produces no ash and results in minimal emissions of carbon monoxide (CO), nitrogen oxides (NOx), and sulfur dioxide (SOx) [9].

LNG presents an advantageous alternative to CNG (Compressed Natural Gas) in long-distance transportation due to its higher energy density. According to a study, LNG can be up to 2.4 times denser than CNG, allowing for longer driving ranges [3]. At −163 °C and atmospheric pressure, LNG has a density of 466 kg/m3, while CNG’s density is 215 kg/m3 at 250 bar pressure and room temperature. Although LNG has a lower energy content than diesel, the liquefaction process reduces the volume of natural gas by 600 times, making it more economical to transport [10]. The drawback of LNG is that it requires larger storage tanks, as the volumetric energy density of diesel (35.8 MJ/L) is nearly twice that of LNG (21.2 MJ/L) [9].

Another negative side effect of LNG systems is that the fuel tanks can release flammable gas into the environment through the PRV (Pressure Relief Valve) when the vehicle is stationary, and the fuel is not used. This can happen after 6 days, if the tank is full, whereas with diesel fuel, such a problem cannot occur [11].

The increasing size of the LNG market can be inferred from the above facts. According to experts, by 2050, it is unlikely that an alternative will replace diesel fuel for trucks [12].

2. Material and Methods

During this research, we used two different types of tractor units, one with diesel and one with LNG. The technical parameters of the test vehicles are included in Table 1. The measurement methods were simple and cost-effective. Our goal was to avoid using expensive and complicated devices.

Table 1.

Technical parameters of test vehicles.

2.1. Determination of Measurement Route

After examining the test vehicles, we determined the measurement route and scenarios to ensure that the test cases could be reproduced as reliably as possible.

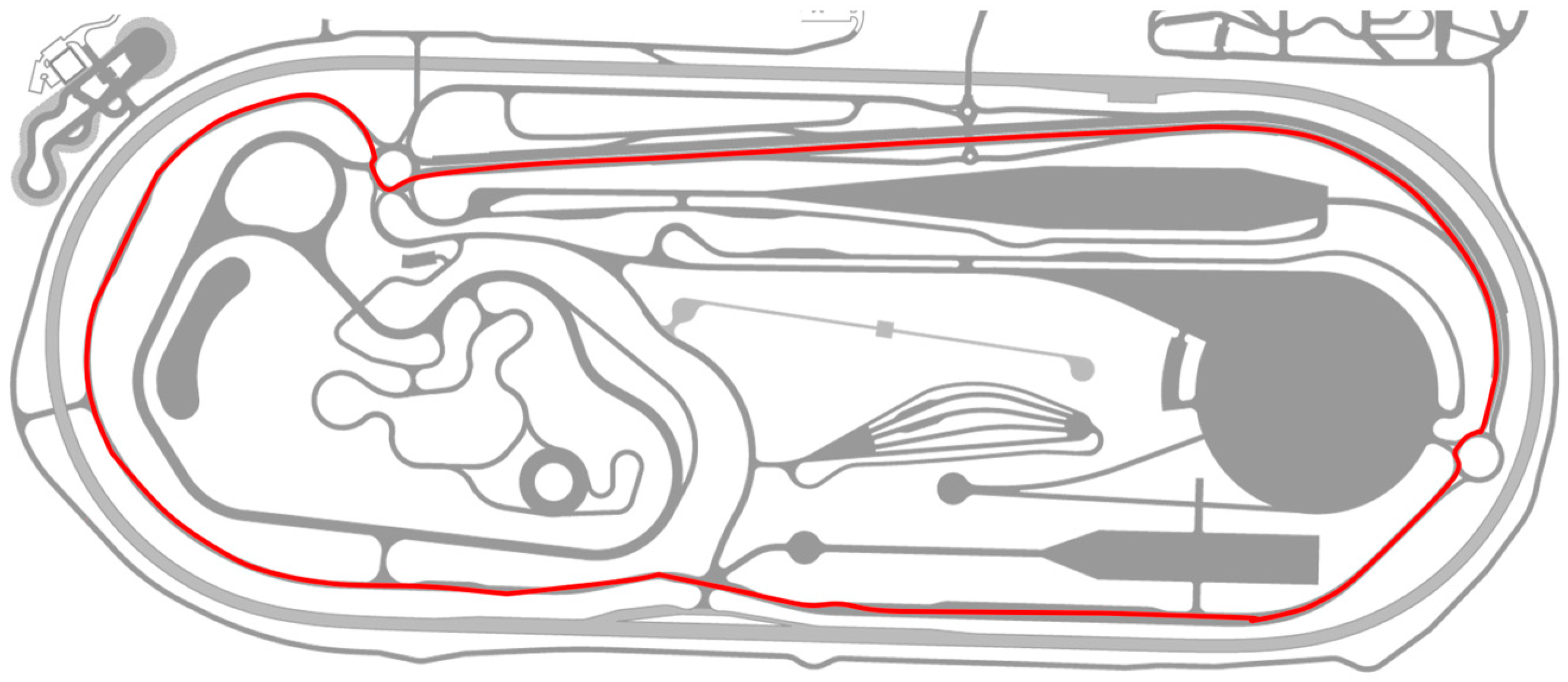

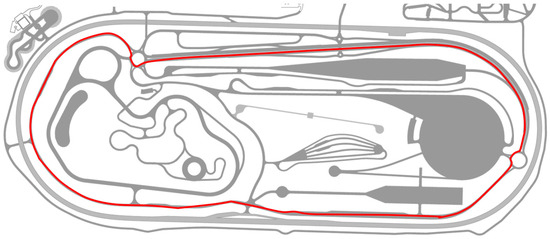

The testing location that best met the requirements defined above was a test track environment. Consequently, we chose the test facility located in the Zalaegerszeg Industrial Park, which met our predefined conditions. The individual track elements can be made free of traffic if required, and there are both fast and slow sections available. In terms of modules, we chose the Rural Road and Highway section in the ZalaZONE Proving Ground (https://zalazone.hu/en/ (accessed on 29 July 2024)) [13]. These two track elements are connected via roundabouts, allowing us to use them as a complete circuit during the measurements (Figure 1).

Figure 1.

Road section designated for measurement.

2.2. Definition of Measurement Scenarios

Since the maximum length of the designated road section is only 4.2 km, we defined a measurement cycle as 20 laps. This resulted in a scenario of 84 km which was repeated 4 times under the same conditions. The tests were conducted with the diesel trailer loaded (13,560 kg) and unloaded (8360 kg), as well as with the LNG loaded (12,200 kg) and unloaded (7000 kg). To avoid difficulties associated with a large set of data, the measurement variations were performed in several stages, and then integrated into a single dataset after evaluation. The measurements were performed based on our predetermined scenarios, where we defined the driving characteristics for each case, so the driving style was not affecting the obtained data.

2.3. Extraction and Recording of Vehicle Data

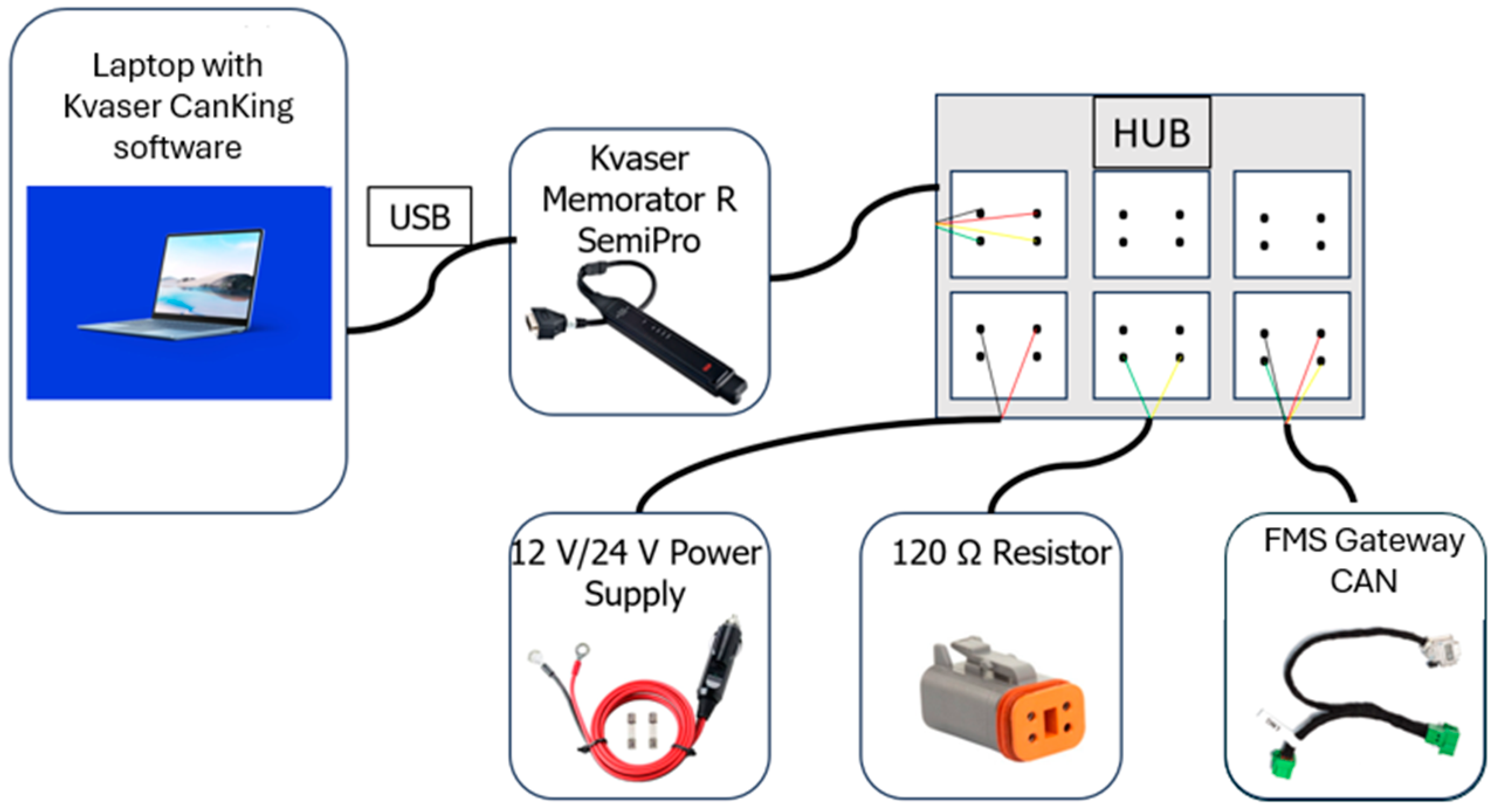

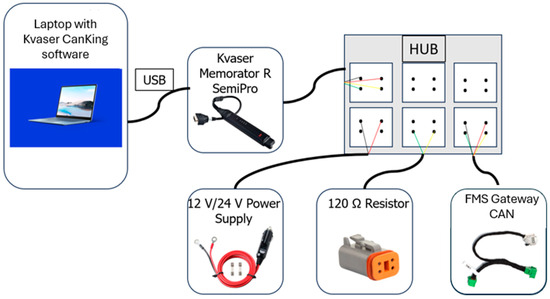

Already mentioned in this study, we did not want to use expensive devices during our measurements, as our goal was to develop a cost-effective solution. For this reason, we used the standard FMS (Fleet Management System) Gateway placed in the vehicle by the manufacturer, as well as its communication network to extract the necessary data. Since the tachograph installed in the vehicle also receives the necessary information from this unit, we needed a common piece for the connection. The standard connector of the FMS Gateway is a product available on the market and is connected in accordance with the standard [14]. In our case, a “y” junction (Figure 2) was connected to the CAN (Controller Area Network) communication network, because the information we needed was transmitted through this channel. To connect to the used measurement system, this connection point was created using an “RS232” port.

Figure 2.

Construction of an applied measuring system.

Since the data was collected from the CAN network of the FMS Gateway, we needed a measuring system that allowed us to monitor the measurement results via a computer, and we also needed the option of recording them for later data processing.

The measurement system we used is shown in the figure below (Figure 2):

One of the main elements of the system is the HUB, which connects the various components. A 120 Ω resistor was used to terminate the CAN lines and eliminate possible reflection. The connection to the vehicle’s CAN network was facilitated by the custom connector we made, and the power supply was provided through the automobile auxiliary power outlet. For monitoring on the computer, we also needed an interface to perform the analog-to-digital conversion.

Using this system, we were able to read the “raw” data through the vehicle’s FMS Gateway connector. This data needed to be decoded for further processing and interpretation, for which the necessary information is available online. During the measurements, we monitored several parameters of the vehicle, but the most important for us were the consumption values, as we could determine the CO2 emissions from them. The information required to decode the raw data can be found in the standardized FMS documentation [15]. With this method, we did not need any calibrated external consumption meter, because we used the data of the vehicle’s factory-calibrated sensors to monitor the consumption.

3. Results

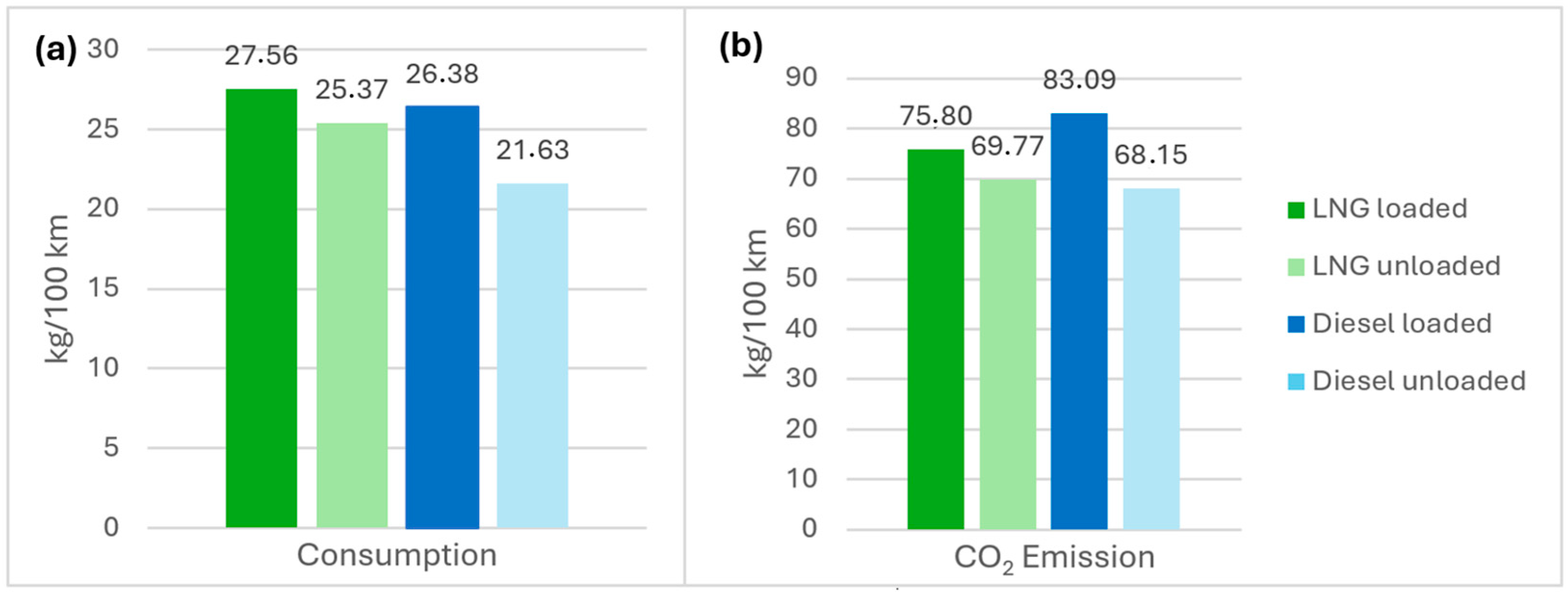

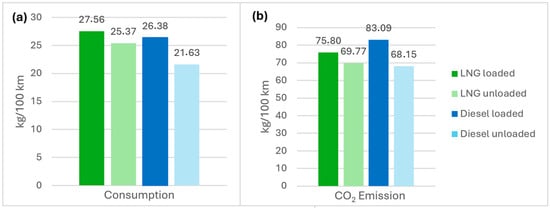

We obtained the consumption data for all the fuel used for the tractor’s production, recorded in liters for diesel and in kilograms for LNG with a resolution of 0.5. From these values, we were able to determine the amount of fuel consumed under the given scenario. To ensure consistent measurement units, we converted the diesel tractor’s consumption to kilograms to match the CO2 emission values, which are calculated in kilograms. The conversion was done by multiplying the quantity consumed in liters by the specific density of diesel fuel. In our case, the measurements were made in summer, so we used a specific density of 850 kg/m3 for diesel fuel. To standardize the results, the consumption for both tractors was extrapolated to 100 km compared to the actual 84 km. The results of the measurements are shown in Figure 3.

Figure 3.

Comparison of loaded and unloaded consumption (a) and emission (b) of tractors/100 km.

The fuel consumption of the two tractors shows only a small difference when loaded, with LNG having a 1 kg advantage per 100 km. However, in an unloaded state, the difference becomes significant, as the diesel tractor consumes 4 kg less per 100 km.

Since we did not have information about the exact composition of the fuels, we determined the amount of CO2 produced from burning 1 kg of diesel and 1 kg of LNG using the following stoichiometric calculations. For further calculations, we used the average value obtained in this manner [1,2,16,17]:

where:

CO2 emission = C% ∗ (MCO2/MC),

- C%, carbon content of the current fuel (by mass; 0.86 for diesel and 0.75 for LNG);

- MCO2, the molar mass of carbon dioxide is 44.01 [g/mol];

- MC, molar mass of carbon 12.01 [g/mol].

By performing the calculation, we find that burning 1 kg of diesel produces 3.15 kg of CO2, whereas burning 1 kg of LNG produces 2.75 kg of CO2. By multiplying these consumption data, we can calculate the total emissions for the given scenario, as shown in Figure 3.

Given that carbon dioxide emissions are directly related to the amount of fuel consumed, it would be expected that LNG emissions would be higher due to greater consumption. However, since diesel contains significantly more carbon than LNG, burning 1 kg of diesel generates more CO2. The data shows that per 100 km, the diesel tractor emitted nearly 10 kg more CO2 during the loaded test. The differences between the loaded and unloaded states are also clear, with the performance of the two tractors being nearly identical.

In terms of consumption, LNG burned more fuel in both loaded and unloaded conditions, but the additional weight had a more pronounced effect on the diesel vehicle.

As a result of the increased load, the diesel tractor’s consumption rose significantly. While it does not reach 10% for an LNG truck, this value is close to a 25% increase in use for diesel.

4. Conclusions

In this study, we compared the consumption and CO2 emissions of diesel and LNG-powered tractors under different load conditions. The purpose was to determine which drivetrain is more efficient and environmentally friendly for transporting goods. Based on real-life measurements performed on the ZalaZONE test track, it can be concluded that LNG-powered trucks have certain advantages compared to diesel-powered ones, particularly in terms of carbon dioxide (CO2) emissions.

One of the main advantages of LNG technology is its lower emissions, which contribute to reducing the greenhouse effect. While LNG trucks have lower CO2 emissions compared to diesel trucks in loaded conditions, the reduction is less than 10%. In unloaded conditions, the CO2 emissions of LNG trucks are almost the same as, or slightly higher than those of diesel trucks, even though the weight of the LNG-powered trucks is lower. Additionally, the production and storage of LNG fuel is relatively cost-effective, making it a competitive alternative to traditional diesel fuel in the long term. The simple and cost-effective methods used during the measurements provided an opportunity to evaluate the efficiency and emission characteristics of both types of fuel under real operating conditions. The research highlighted that while LNG technology can offer environmental benefits and a more sustainable solution for meeting future regulations and environmental protection goals, its performance in terms of CO2 emissions is comparable to or slightly worse than that of diesel in unloaded conditions.

Overall, the results of this study support the fact that the use of LNG-powered tractors can contribute to achieving the emission reduction targets set by the European Union and can promote greener and more sustainable road transport.

The development and spread of LNG technology is expected to further increase its competitiveness and, in the long term, can play a significant role in making road freight transport greener.

Author Contributions

Conceptualization, M.J.; methodology, B.B. and G.S.; software, B.B. and G.S.; validation, M.J.; investigation, B.B. and G.L.T.; data evaluation, B.B., G.S., and M.J.; writing—original draft preparation, B.B., M.J., and G.S.; writing—review and editing, B.B.; visualization, B.B. and G.L.T. All authors have read and agreed to the published version of the manuscript.

Funding

This research and the APC were funded by Széchenyi István University.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data are contained within the article.

Acknowledgments

Acknowledgements for the organizations supporting the project and tests behind this research as Némotrans Ltd., ECO-tech visiON Ltd. with IVECO vehicles, Shell Hungary, ZalaZONE Innotech Ltd.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Hu, S.; Chen, H. Comparative Life-Cycle Assessment of Liquefied Natural Gas and Diesel Tractor-Trailer in China. Energies 2022, 15, 392. [Google Scholar] [CrossRef]

- Vermeulen, A.R.; Verbeek, R.; van Goethem, S. Emissions Testing of Two Euro VI LNG Heavy-Duty Vehicles in the Netherlands: Tank-to-Wheel Emissions; Emissions Testing Report; Earth, Life & Social Sciences: The Hague, The Netherlands, 2017; Available online: https://publications.tno.nl/publication/34625802/QoDRSe/TNO-2017-R11336.pdf (accessed on 13 September 2024).

- Szilágyi, Z. LNG Amit Tudni Illik a Cseppfolyós Földgázról. Available online: https://www.vgfszaklap.hu/lapszamok/2013/junius/2836-lng-a-mit-tudni-illik-a-cseppfolyos-foldgazrol (accessed on 9 July 2024).

- Foss, M.M. INTRODUCTION TO LNG: An Overview on Liquefied Natural Gas (LNG), Its Properties, the LNG Industry, and Safety Considerations. Available online: https://www.beg.utexas.edu/files/energyecon/global-gas-and-lng/INTRODUCTION%20TO%20LNG%20Update%202012.pdf (accessed on 13 September 2024).

- Molnár, J.A.; Szabó, K.D. Kriogenikus Energia Visszanyerése Lng Üzemű Kamionból. Bachelor’s Thesis, Budapest University of Technology and Economics, Budapest, Hungary, 2021. Available online: https://energia.bme.hu/~imreattila/munkakozegek/kamion/projekt_molnar_szabo%20jav.pdf (accessed on 13 September 2024).

- Zoltán, B.; Zoltán, B.; Henrik, D.; Dezső, F.; Attila, L.; István, S. A cseppfolyósított gáz (LNG) előállításának, logisztikájának és hasznosításának technológiái. Mezőgazdasági Technika 2020. Available online: http://technika.gmgi.hu/uploads/termek_1777/2020_januar_ok.pdf (accessed on 13 September 2024).

- Gnap, J.; Dočkalik, M. Impact of the operation of LNG trucks on the environment. Open Eng. 2021, 11, 937–947. [Google Scholar] [CrossRef]

- Kumar, S.; Kwon, H.-T.; Choi, K.-H.; Lim, W.; Cho, J.H.; Tak, K.; Moon, I. LNG: An eco-friendly cryogenic fuel for sustainable development. Appl. Energy 2011, 88, 4264–4273. [Google Scholar] [CrossRef]

- Schwarzkopf, M.E. Alternatív hajtású nyerges vontató magyarországi bevezetésének vizsgálata. Bachelor’s Thesis, Budapest University of Technology and Economics, Budapest, Hungary, 2019. [Google Scholar]

- Smajla, I.; Sedlar, D.K.; Drljača, B.; Jukić, L. Fuel switch to LNG in heavy truck traffic. Energies 2019, 12, 515. [Google Scholar] [CrossRef]

- Barelli, L.; Bidini, G.; Perla, M.; Pilo, F.; Trombetti, L. Boil-off gas emission from the fuel tank of a LNG powered truck. Fuel 2022, 325, 124954. [Google Scholar] [CrossRef]

- Askin, A.C.; Barter, G.E.; West, T.H.; Manley, D.K. The heavy-duty vehicle future in the United States: A parametric analysis of technology and policy tradeoffs. Energy Policy 2015, 81, 1–13. [Google Scholar] [CrossRef]

- AVL-ZalaZONE Test Tracks. Available online: https://zalazone.hu/en/ (accessed on 29 July 2024).

- Teltonika FMS CABLE—For Getting the CAN Data from FMS. Available online: https://voip.world/Teltonika-FMS-CABLE-for-getting-the-CAN-data-from-FMS (accessed on 10 July 2024).

- HDEI/BCEI Task Force. FMS_Standard Description. Available online: https://www.fms-standard.com/Truck/down_load/fms%20document_v_04_vers.13.10.2017.pdf (accessed on 13 September 2024).

- Dezsényi, G.; Emőd, I.; Finichiu, L. Belsőégésű Motorok Tervezése és Vizsgálata; Nemzeti Tankönyvkiadó: Budapest, Hungary, 2009. [Google Scholar]

- Zöldy, M. Energiahatékonyságnövelő- és Emissziócsökkentő Megoldások Fejlesztése Közúti Járművek Számára. Ph.D. Thesis, Budapest University of Technology and Economics, Budapest, Hungary, 2021. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).