Design and Construction of a Controlled Solid-State Relay with Variable Duty Ratio for DOMOTIC Applications †

Abstract

1. Introduction

2. Materials and Methods

2.1. Solid-State Relays

2.2. Power Semiconductor

2.3. Design of the Solid-State Relay

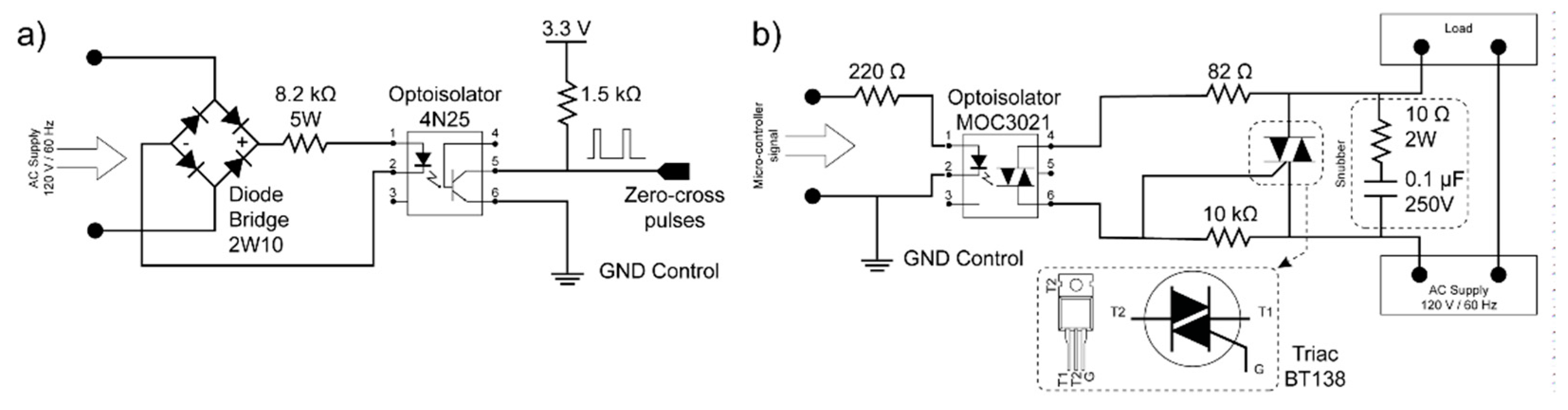

2.3.1. Zero-Crossing Detector Circuit

2.3.2. TRIAC Selection

2.3.3. TRIAC Trigger Circuit

2.3.4. Snubber Network and Heat-Sink

2.4. Power Measurement System

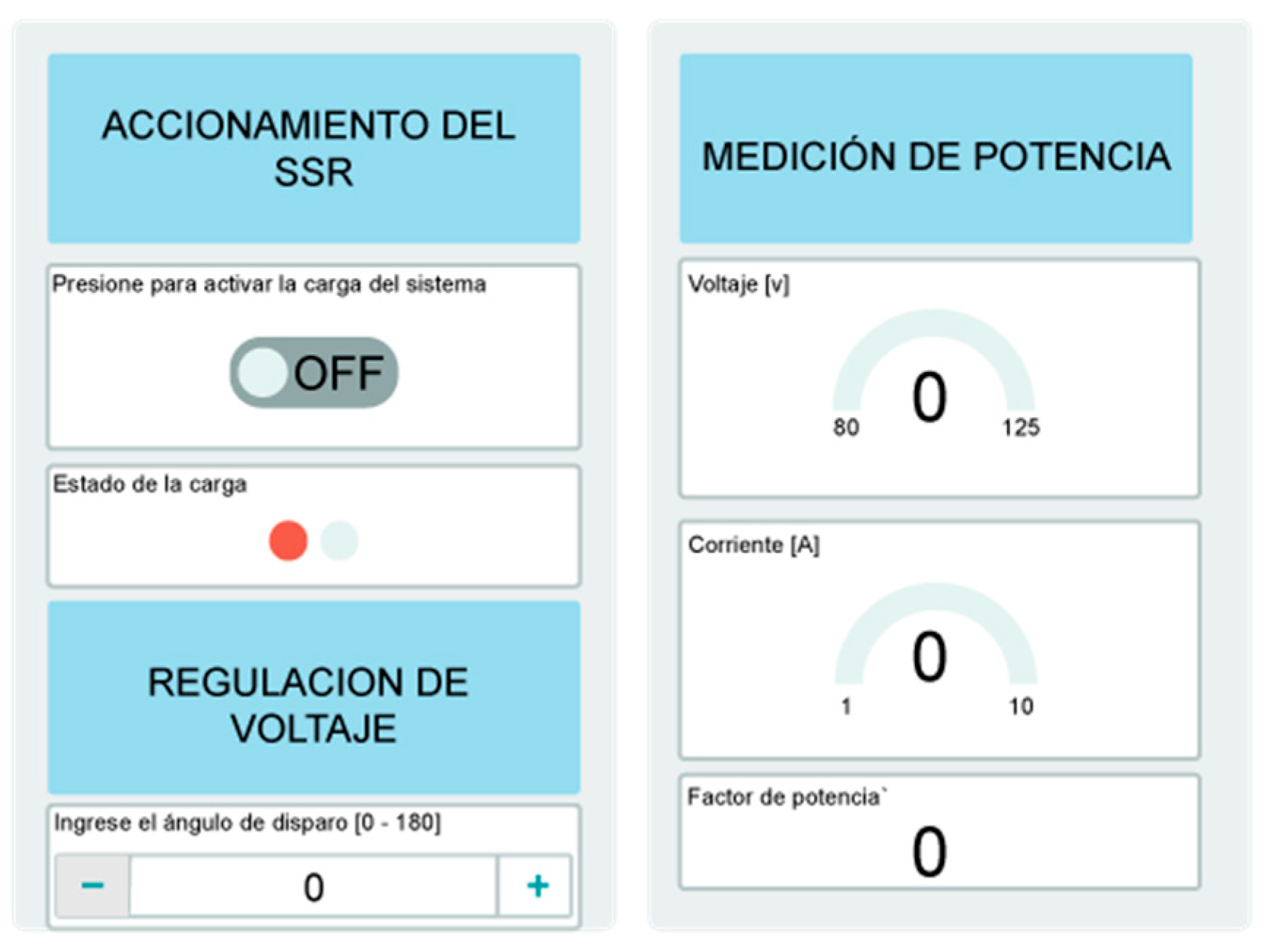

2.5. Android Application for Remote Driving and Monitoring of the Solid-State Relay Using WIFIi

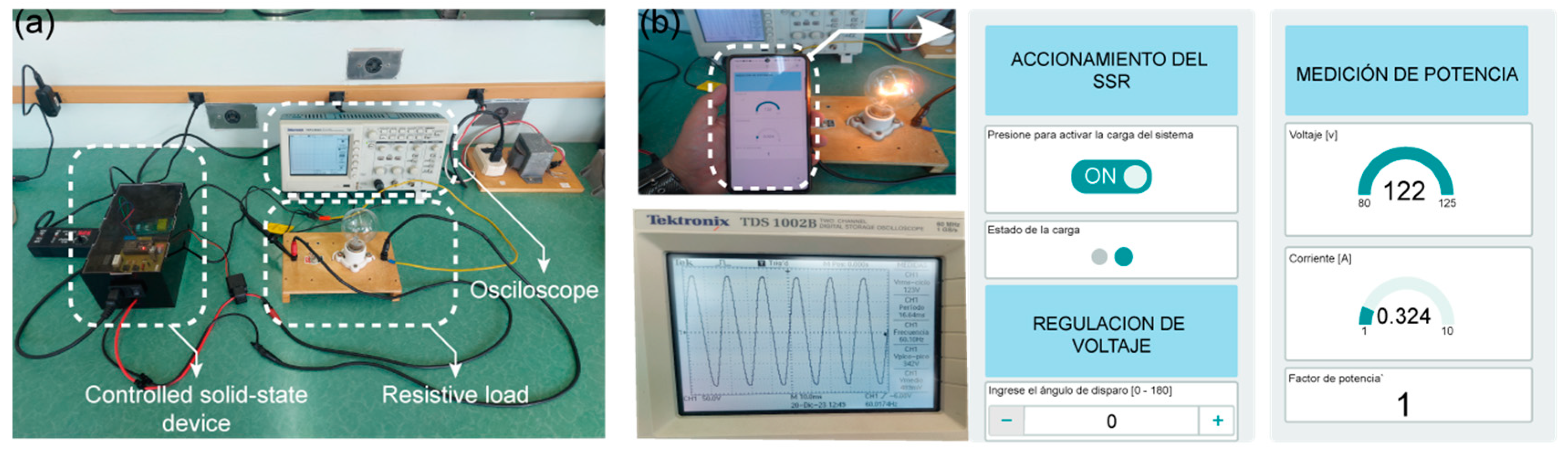

3. Results and Discussion

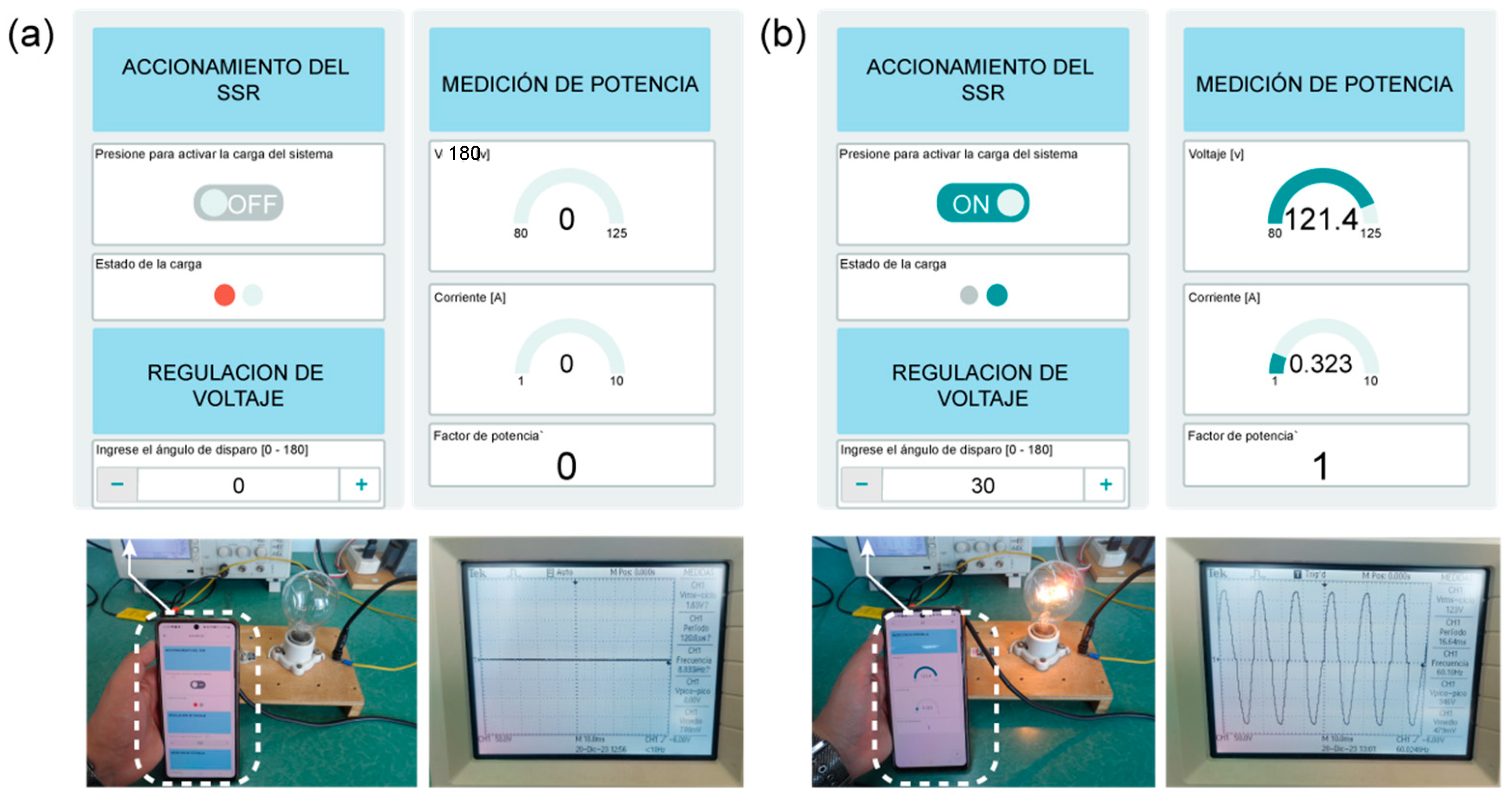

3.1. Resistive Load (R) Tests

3.2. Resistive–Inductive Load (RL) Test

3.3. Prototype Tests and Theoretical Results Comparison

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Revista ElectroIndustria. ¿Qué es un Relé de Estado Sólido? 2020. Available online: https://www.emb.cl/electroindustria/articulo.mvc?xid=3691&ni=que-es-un-rele-de-estado-solido# (accessed on 18 July 2023).

- GEYA. Aplicaciones y Usos de Relés de Estado Sólido. 2022. Available online: https://www.geya.net/es/8-solid-state-relay-applications-and-uses/#:~:text=Los%20rel%C3%A9s%20de%20estado%20s%C3%B3lido%20se%20utilizan%20ampliamente%20en%20los,se%20pueden%20utilizar%20otros%20dispositivos (accessed on 18 July 2023).

- Cerem Comunicación. Por qué el Internet de las Cosas (iot) Promete Cambiar la Vida del ser Humano. 2022. Available online: https://www.cerem.es/blog/porque-el-internet-de-las-cosas-iot-promete-cambiar-la-vida-del-ser-humano#:~:text=Con%20IoT%20se%20puede%20programar,las%20personas%20a%20nivel%20mundial (accessed on 18 July 2023).

- Shaw, K. ¿Qué es el Wi-Fi y Por Qué es tan Importante? 2020. Available online: https://concepto.de/wifi/#:~:text=El%20wifi%20da%20acceso%20a%20Internet%20a%20lo,o%20en%20cada%20piso%20de%20un%20edificio%20peque%C3%B1o. (accessed on 18 July 2023).

- International Journal of Engineering and Advanced Technology (IJEAT). IoT Based Relay Operation. 2019. Available online: https://www.ijeat.org/wp-content/uploads/papers/v9i1/A1415109119.pdf (accessed on 29 July 2024). [CrossRef]

- Miletiev, R.; Yordanov, R. Compact smart solid-state relay with WiFi connectivity. In Proceedings of the 2022 International Conference on Emerging Trends in Engineering, Technology, and Science (ETETSS), Sozopol, Bulgaria, 13–15 September 2022; pp. 67–72. [Google Scholar] [CrossRef]

- Risteska Stojkoska, B.L.; Trivodaliev, K.V. A review of Internet of Things for smart home: Challenges and solutions. J. Clean. Prod. 2017, 140, 1454–1464. [Google Scholar] [CrossRef]

- Mocrii, D.; Chen, Y.; Musilek, P. IoT-based smart homes: A review of system architecture, software, communications, privacy, and security. Internet Things 2018, 1–2, 81–98. [Google Scholar] [CrossRef]

- Alaa, M.; Zaidan, A.A.; Zaidan, B.B.; Talal, M.; Kiah, M.L.M. A review of smart home applications based on Internet of Things. J. Netw. Comput. Appl. 2017, 97, 48–65. [Google Scholar] [CrossRef]

- Budiyanto, S.; Silalahi, L.M.; Silaban, F.A.; Salamah, K.S.; Rahayu, F.; Wahyuddin, M.I.; Andryana, S. Design of control and monitoring tools for electricity use loads, and home security systems with internet of things system based on Arduino Mega 2560. IOP Conf. Ser. Mater. Sci. Eng. 2020, 909, 012020. [Google Scholar] [CrossRef]

- Fernández, M.; Perpiñà, X.; Rebollo, J.; Vellvehi, M.; Sánchez, D.; Cabeza, T.; Llorente, S.; Jordà, X. Solid-State Relay Solutions for Induction Cooking Applications Based on Advanced Power Semiconductor Devices. IEEE Trans. Ind. Electron. 2019, 66, 1832–1841. [Google Scholar] [CrossRef]

- Abduraimov, E.; Khalma, D. Development of contactless solid state voltage relay. In Proceedings of the 2020 RSES International Conference, Kazan, Russia, 21–26 September 2020. [Google Scholar] [CrossRef]

- Mu, J.; Wang, L. Research on main circuit topology for a novel DC solid-state circuit breaker. In Proceedings of the IEEE Conference on Industrial Electronics and Applications, Taichung, Taiwan; 2010; pp. 926–930. [Google Scholar] [CrossRef]

- OMEGA. Relés de Estado Sólido. 2021. Available online: https://es.omega.com/temperature/pdf/SSRL240_660.pdf (accessed on 19 September 2023).

- Crydom SSR Ltd. Output Switching Functions of Solid-State Relays. 2011. Available online: https://pim.galco.com/Manufacturer/Crydom/TechDocument/Application%20Note/ssr_switching_functions_app3.pdf (accessed on 19 September 2023).

- Barkana, A.; Cook, G.; McVey, E.S. A Solid-State Relay. IEEE Trans. Ind. Gen. Appl. 1973, IGA-9, 589–594. [Google Scholar] [CrossRef]

- Schweber, B. Cómo Regular la Corriente o el Voltaje de Forma Segura y Eficiente con los SSR. DigiKEY, 26 February 2019. Available online: https://www.digikey.com/es/articles/how-to-safely-and-efficiently-switch-current-or-voltage-using-ssrs (accessed on 19 September 2023).

- Venugopal, K.B.; Srivani, S.G. Design and Analysis of MOSFET’s as Solid-State Relays for Precise AC Load Control. In Proceedings of the 2023 International Conference on Smart Technologies in Computing, Electrical and Electronics (CSITSS), Bangalore, India, 2–4 November 2023. [Google Scholar] [CrossRef]

- Fernández, M.; Perpiñá, X.; Vellvehi, M.; Jordà, X.; Cabeza, T.; Llorente, S. Analysis of solid state relay solutions based on different semiconductor technologies. In Proceedings of the 2017 19th European Conference on Power Electronics and Applications (EPE’17 ECCE Europe), Warsaw, Poland, 11–14 September 2017. [Google Scholar] [CrossRef]

- Philips Semiconductors. Triacs BT138 Series. 1997. Available online: https://pdf1.alldatasheet.com/datasheet-pdf/view/16781/PHILIPS/BT138.html (accessed on 21 November 2023).

- Valle, C. Diseño, Simulación y Control de Temperatura de un Horno Eléctrico Empleando Resistencias—Control Electrónico al Lado AC. Bachelor’s Thesis, Escuela Politécnica Nacional, Quito, Ecuador, 2022. [Google Scholar]

- González, M. Dispositivos Semiconductores de Potencia. 2015. Available online: http://orga.blog.unq.edu.ar/wp-content/uploads/sites/71/2015/06/Dispositivos-de-potencia.pdf (accessed on 30 September 2023).

- Cornell Dubilier. Application Guide Snubber Capacitors. Available online: https://www.cde.com/resources/technical-papers/igbtAPPguide.pdf (accessed on 13 November 2023).

- Philips Semiconductors. AN10384 Triacs: How to Calculate Power and Predict Tjmax. 2005. Available online: https://www.farnell.com/datasheets/1760767.pdf (accessed on 22 November 2023).

- Dillon, E.; Palma, P. Diseño de Un Sistema Automático de Regulación de Voltaje y Frecuencia Generados por una Micro-Central Hidro-Eléctrica. Bachelor’s Thesis, Escuela Politécnica Nacional, Quito, Ecuador, 2014. [Google Scholar]

- DISIPA. Catálogo General 3.0. 2019. Available online: https://disipa.net/catalogos-1 (accessed on 14 November 2023).

- Peacefair Electronic Technology. PZEM-004T V3.0 User Manual. Available online: https://innovatorsguru.com/wp-content/uploads/2019/06/PZEM-004T-V3.0-Datasheet-User-Manual.pdf (accessed on 24 November 2023).

- Espressif Systems. ESP32 ESP-IDF Programming Guide. 2023. Available online: https://docs.espressif.com/projects/esp-idf/en/latest/esp32/esp-idf-en-master-esp32.pdf (accessed on 26 November 2023).

- Rashid, M.H. Electrónica de Potencia: Circuitos, Dispositivos y Aplicaciones, 2nd ed.; Prentice Hall Hispanoamericana: Naucalpan de Juárez, Mexico, 1995. [Google Scholar]

- OMRON. Technical Explanation for Solid-state Relays. Available online: https://www.ia.omron.com/data_pdf/guide/18/ssr_tg_e_9_2.pdf (accessed on 14 October 2024).

- INFINEON. From Electromechanical Relays to Robust Semiconductor Solutions: Solid-State Relays with Optimized Superjunction FET Technology. Available online: https://www.infineon.com/dgdl/Infineon-Solid-state_relays_with_optimized_SJ_FET_technology-Whitepaper-v01_00-EN.pdf?fileId=8ac78c8c7bb971ed017bbaf30d3c02af&da=t (accessed on 14 October 2024).

- SHARP. “S108T02 Series”. Available online: https://files.seeedstudio.com/wiki/Grove-Solid_State_Relay/res/S208t02_datasheet.pdf (accessed on 14 October 2024).

| Parameter | Symbol | Value |

|---|---|---|

| Repetitive peak off-state voltage | 600 V | |

| RMS on-state current | 12 A | |

| Gate trigger voltage | 1.5 V | |

| Operating junction temperature | 125 °C | |

| Thermal resistance junction to mounting base | 1.5 K/W |

| Firing Angle () | Prototype Results | Theoretical Results | Percentage Errors | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Voltage [V] | Current [A] | Power Factor | Voltage [V] | Current [A] | Power Factor | Voltage | Current | Power Factor | |

| 0° | 122 | 0.324 | 1 | 120 | 0.324 | 1 | 1.67 | 0 | 0 |

| 30° | 121.4 | 0.323 | 1 | 118.26 | 0.32 | 0.99 | 2.66 | 0.94 | 1.01 |

| 50° | 115.9 | 0.156 | 1 | 115.5 | 0.152 | 0.94 | 0.35 | 2.63 | 6.38 |

| 70° | 103.8 | 0.142 | 0.98 | 101.36 | 0.137 | 0.85 | 2.41 | 3.65 | 15.29 |

| 180° | 0 | 0 | 0 | 0 | 0 | 0 | - | - | - |

| Firing Angle () | Prototype Results | Theoretical Results | Percentage Errors | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Voltage [V] | Current [A] | Power Factor | Voltage [V] | Current [A] | Power Factor | Voltage | Current | Power Factor | |

| 16° | 122.6 | 0.312 | 0.97 | 120 | 0.316 | 0.97 | 2.17 | 1.27 | 0 |

| 25° | 119.4 | 0.309 | 0.97 | 117 | 0.306 | 0.97 | 2.05 | 0.98 | 0 |

| 70° | 105.9 | 0.275 | 0.95 | 100.42 | 0.263 | 0.97 | 5.46 | 4.56 | 2.06 |

| 80° | 98.5 | 0.266 | 0.93 | 96.29 | 0.252 | 0.97 | 2.3 | 5.56 | 4.12 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Medina, J.; Barros, K.; Chamorro, W.; Ramírez, J. Design and Construction of a Controlled Solid-State Relay with Variable Duty Ratio for DOMOTIC Applications. Eng. Proc. 2024, 77, 14. https://doi.org/10.3390/engproc2024077014

Medina J, Barros K, Chamorro W, Ramírez J. Design and Construction of a Controlled Solid-State Relay with Variable Duty Ratio for DOMOTIC Applications. Engineering Proceedings. 2024; 77(1):14. https://doi.org/10.3390/engproc2024077014

Chicago/Turabian StyleMedina, Jorge, Kevin Barros, William Chamorro, and Juan Ramírez. 2024. "Design and Construction of a Controlled Solid-State Relay with Variable Duty Ratio for DOMOTIC Applications" Engineering Proceedings 77, no. 1: 14. https://doi.org/10.3390/engproc2024077014

APA StyleMedina, J., Barros, K., Chamorro, W., & Ramírez, J. (2024). Design and Construction of a Controlled Solid-State Relay with Variable Duty Ratio for DOMOTIC Applications. Engineering Proceedings, 77(1), 14. https://doi.org/10.3390/engproc2024077014