Characterization of Post-Sintering Shrinkage of Ceramic-Based Lattice Structures Printed Using LCD Resin Printer †

Abstract

1. Introduction

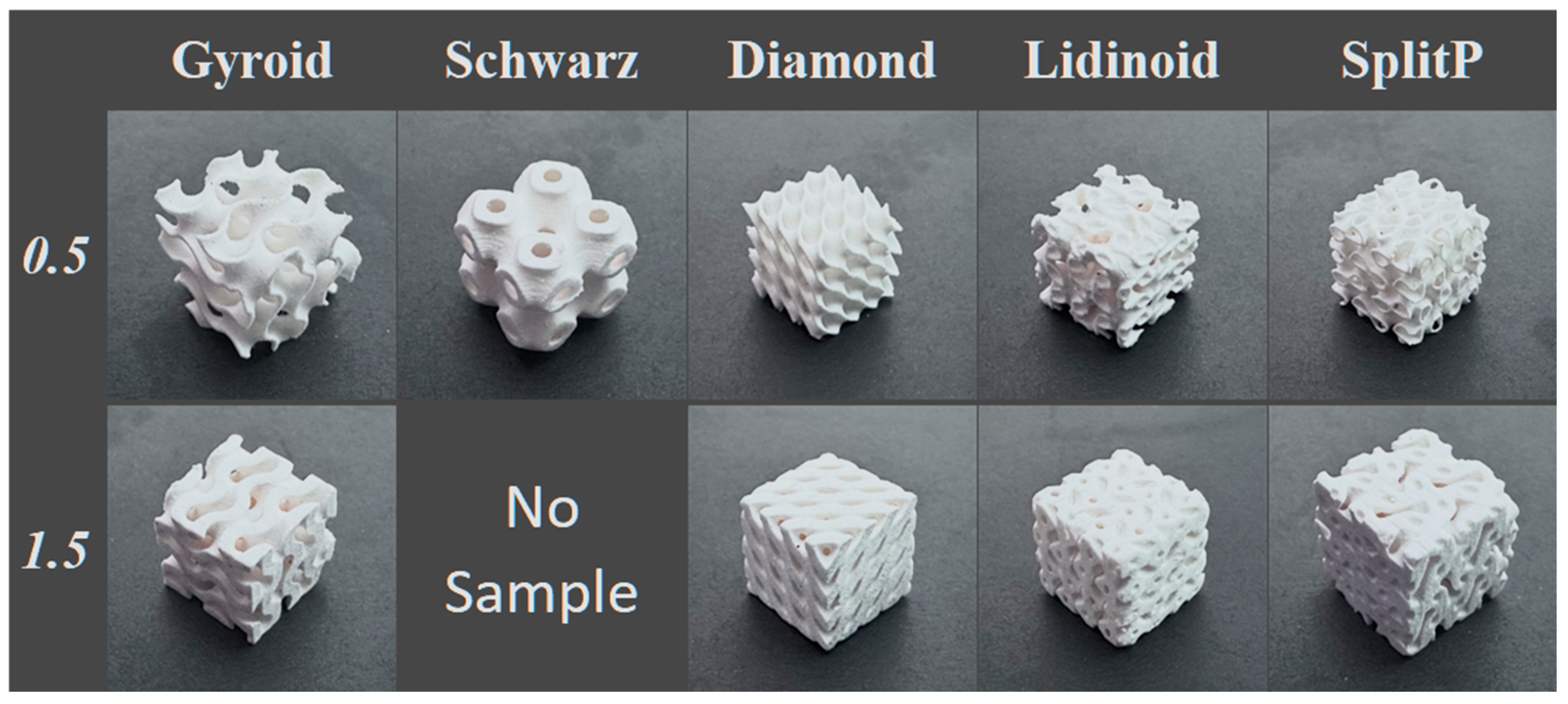

2. Methodology

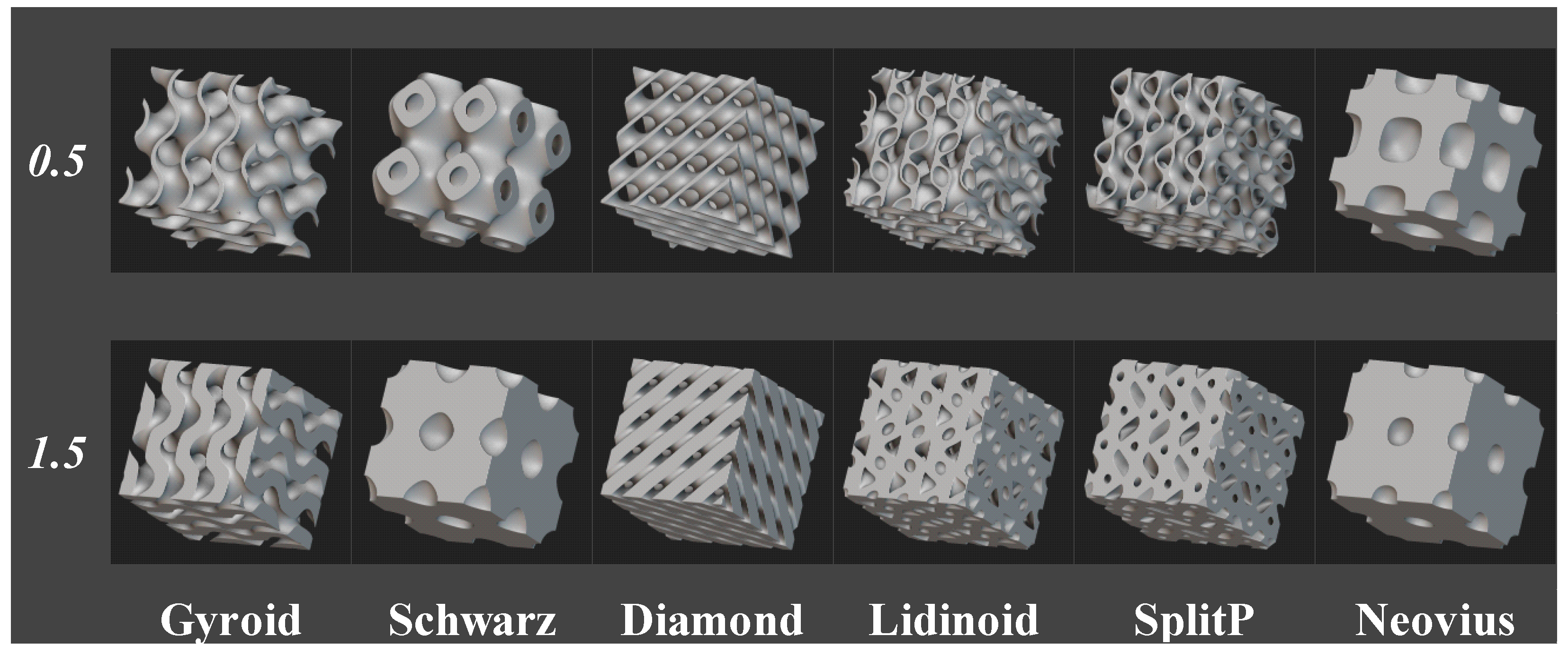

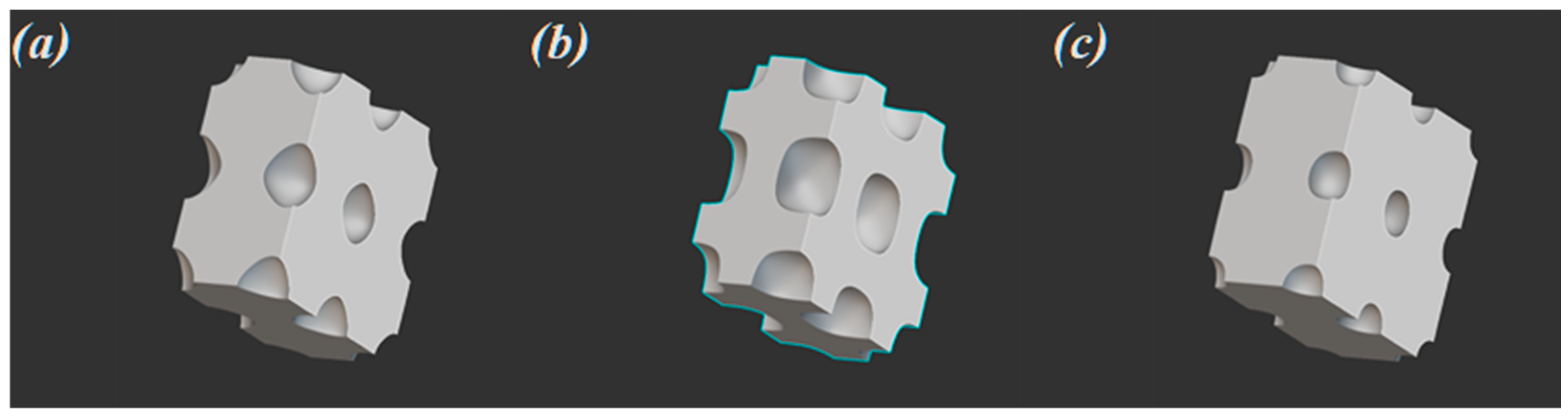

2.1. Lattice Generation

2.2. Print Parameters

2.3. Debinding and Sintering

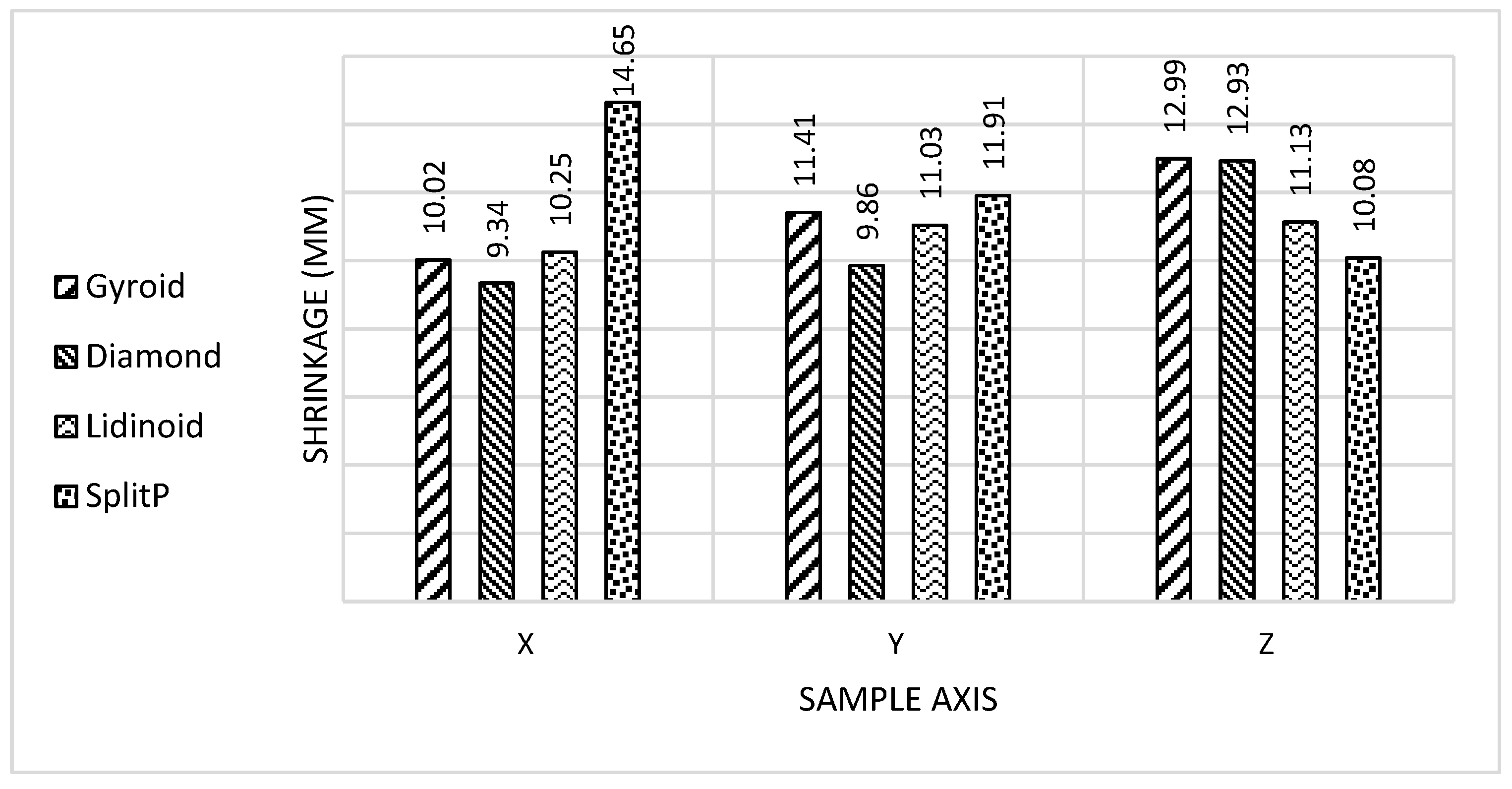

3. Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Khondoker, M.A.H.; Sameoto, D. Fabrication methods and applications of microstructured gallium based liquid metal alloys. Smart Mater. Struct. 2016, 25, 093001. [Google Scholar] [CrossRef]

- Khondoker, M.A.H.; Baheri, N.; Sameoto, D. Tendon-Driven Functionally Gradient Soft Robotic Gripper 3D Printed with Intermixed Extrudate of Hard and Soft Thermoplastics. 3D Print. Addit. Manuf. 2019, 6, 191–203. [Google Scholar] [CrossRef]

- Sakib-Uz-Zaman, C.; Khondoker, M.A.H. A Review on Extrusion Additive Manufacturing of Pure Copper. Metals 2023, 13, 859. [Google Scholar] [CrossRef]

- Lakhdar, Y.; Tuck, C.; Binner, J.; Terry, A.; Goodridge, R. Additive manufacturing of advanced ceramic materials. Prog. Mater. Sci. 2021, 116, 100736. [Google Scholar] [CrossRef]

- Li, J.; An, X.; Liang, J.; Zhou, Y.; Sun, X. Recent advances in the stereolithographic three-dimensional printing of ceramic cores: Challenges and prospects. J. Mater. Sci. Technol. 2022, 117, 79–98. [Google Scholar] [CrossRef]

- Li, Z.; Zhang, Y.; Chen, X.; Lu, L.; Yi, H.; Cheng, L.; Yu, Q.; Ma, J.; Yang, J.; Peng, F. Ceramic shell fabrication via Stereo Lithography Apparatus: Recent progress on cracking problems and preventive measures. J. Mater. Res. Technol. 2024, 28, 1341–1358. [Google Scholar] [CrossRef]

- Wu, S.; Yang, L.; Wang, C.; Yan, C.; Shi, Y. Si/SiC ceramic lattices with a triply periodic minimal surface structure prepared by laser powder bed fusion. Addit. Manuf. 2022, 56, 102910. [Google Scholar] [CrossRef]

- nTop. nTop Inc, 199 Lafayette St, 4th Floor New York, NY 10012. Available online: https://ntop.com (accessed on 22 December 2023).

- Fisher, J.W.; Miller, S.W.; Bartolai, J.; Simpson, T.W.; Yukish, M.A. Catalog of triply periodic minimal surfaces, equation-based lattice structures, and their homogenized property data. Data Brief 2023, 49, 109311. [Google Scholar] [CrossRef] [PubMed]

- Elegoo. ELEGOO Official. Available online: https://www.elegoo.com/pages/about-us (accessed on 8 February 2024).

- ELEGOO Mars 3—4K User-Friendly Desktop Resin 3D Printer. ELEGOO Official. Available online: https://www.elegoo.com/products/elegoo-mars-3-lcd-3d-printer (accessed on 8 February 2024).

- CHITUBOX|All-In-One SLA/DLP/LCD Slicer|3D Printing Preprocessing Software. Available online: https://www.chitubox.com/en/about (accessed on 8 February 2024).

- Tethon 3D. Available online: https://tethon3d.com/ (accessed on 8 February 2024).

| Layer Height: | 0.050 mm | Bottom Lift Distance: | 8.000 mm |

| Bottom Layer Count: | 10 | Lifting Distance: | 8.000 mm |

| Exposure Time: | 10.000 s | Bottom Retract Distance: | 8.000 mm |

| Bottom Exposure Time: | 30.000 s | Retract Distance: | 8.000 mm |

| Transition Layer Count: | 15 | Bottom Lift Speed: | 60.000 mm/min |

| Transition Type: | Linear | Lifting Speed: | 80.000 mm/min |

| Transition Time Decrement: | 1.250 s | Bottom Retract Speed: | 160.000 mm/min |

| Waiting Mode During Printing: | Light off delay | Retract Speed: | 160.000 mm/min |

| Light-off Delay: | 1.000 s | ||

| Bottom Light-off Delay | 1.500 s |

| Time (h) | 0 | 3.70 | 4.70 | 75.16 | 81.40 |

| Temp (°C) | 0 | 150 | 150 | 600 | 1100 |

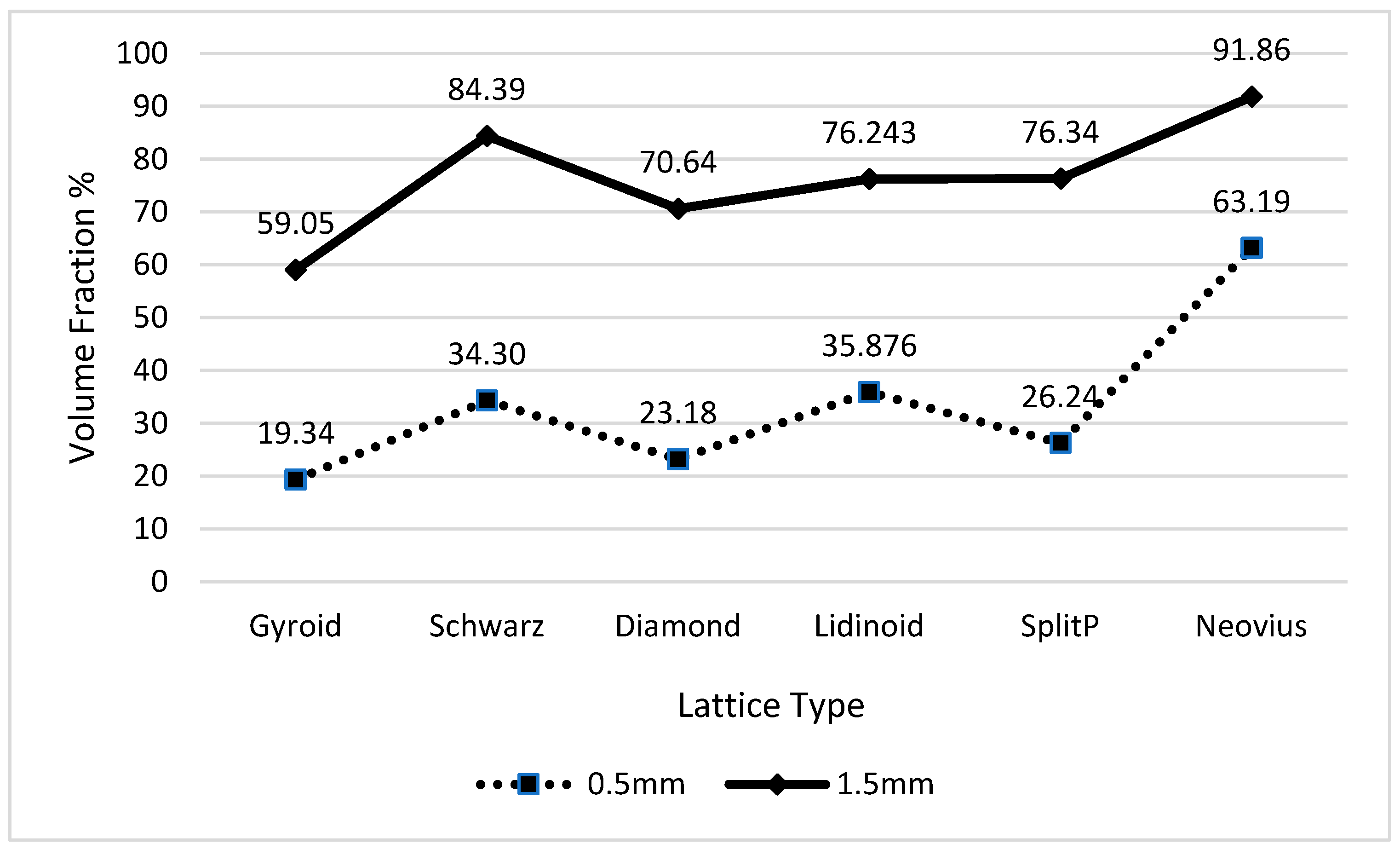

| Lattice Name | Shell Thickness (mm) | |

|---|---|---|

| 0.5 | 1.5 | |

| Gyroid | 19.34 | 59.053 |

| Schwarz | 34.303 | 84.391 |

| Diamond | 23.178 | 70.636 |

| Lidinoid | 35.876 | 76.243 |

| SplitP | 26.24078 | 76.344 |

| Neovius | 63.193 | 91.86 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alam, M.R.; Khondoker, M.A.H. Characterization of Post-Sintering Shrinkage of Ceramic-Based Lattice Structures Printed Using LCD Resin Printer. Eng. Proc. 2024, 76, 54. https://doi.org/10.3390/engproc2024076054

Alam MR, Khondoker MAH. Characterization of Post-Sintering Shrinkage of Ceramic-Based Lattice Structures Printed Using LCD Resin Printer. Engineering Proceedings. 2024; 76(1):54. https://doi.org/10.3390/engproc2024076054

Chicago/Turabian StyleAlam, Md Rashid, and Mohammad Abu Hasan Khondoker. 2024. "Characterization of Post-Sintering Shrinkage of Ceramic-Based Lattice Structures Printed Using LCD Resin Printer" Engineering Proceedings 76, no. 1: 54. https://doi.org/10.3390/engproc2024076054

APA StyleAlam, M. R., & Khondoker, M. A. H. (2024). Characterization of Post-Sintering Shrinkage of Ceramic-Based Lattice Structures Printed Using LCD Resin Printer. Engineering Proceedings, 76(1), 54. https://doi.org/10.3390/engproc2024076054