Abstract

This study investigates cellular negative stiffness honeycomb (NSH) structures in the prospect of energy absorption and vibration isolation. The energy absorption properties for different geometrical parameters have been investigated for a specific displacement in the range of linear compression. The force–displacement characteristics of NSH structures with various AM materials have been investigated using the finite element analysis method. The results have revealed the parametric relation of the NSH with the energy absorbed, specific energy absorption, stiffness, and compressive stress. The analysis highlights the NSH structures’ potential to enhance material efficiency and performance optimization, contributing to material and manufacturing engineering.

1. Introduction

The focus on energy absorbers in recent engineering applications involves converting kinetic energy into various forms through the permanent deformation of materials [1]. Traditional single-use absorbers, limited by application and energy considerations, led to innovations like honeycomb crash boxes, which are more efficient in volume [2]. Sahid Hassan et al. explored metamaterial smart structures with shape recovery through specific additive manufacturing materials [3]. Flexible and tunable material additive fabrication processes enabled the development of smart structures for applications like soft robotics and vibrational energy harvesting [4]. Addressing energy and reusability limitations, D. Correa invented the negative stiffness honeycomb (NSH) structure, combining snap-through behavior with energy absorption [5]. Inspired by the works of Klatt et al. [6], Kashdan et al. [7], and Fulcher et al. [8], Correa introduced snap-through behavior in honeycomb structures by adding a central beam, eliminating undesired expansions and rotations during loading [9]. The modified cell array exhibited a remarkable 65% absorption capacity and full shape recovery post-loading, sparking interest in engineering applications. The eminent feature of smart NSH structures is that they can be used multiple times, whereas the conventional energy absorption techniques result in permanent deformation of the material by linear or nonlinear buckling or failure mode to absorb the energy [10]. Correa’s call for further investigation into geometric factors and force-displacement sensitivity was affirmed by subsequent studies proposing diverse NSH applications [9]. Debeau et al. demonstrated NSH’s use for repetitive mechanical shock isolation, limiting the threshold at a predetermined level [11]. Zakatayev et al. proposed a design strategy for custom NSH designs in specific buckling sequences in NSH mesostructures [12]. Chen et al. pioneered NSH structural composites, exploring force–displacement patterns and absorption sensitivity with two different elastic materials [13]. Ganilova et al. extended research, investigating NSH structures in car crumple zones alongside traditional energy absorbers [14]. Pennsylvania State University researchers examined NSH structures for tail design [15], while Tan et al. explored negative stiffness beams’ impact and energy absorption properties [16], later investigating cushioning performance [17]. Compared to the traditional crash-type absorbers, the energy absorbed by the NSH structure’s inelastic buckling is modest, making them suitable for shock and vibration isolation in semi-sensitive devices as well as the packaging of products [18].

Understanding the influence of geometrical parameters on the performance of negative stiffness honeycomb structures is crucial for optimizing their mechanical properties. By controlling parameters such as cell size, wall thickness, and shape, engineers can tailor the structures to meet specific application requirements, including stiffness, strength, and energy absorption. This optimization process enables the design of lightweight, efficient structures with enhanced mechanical performance for a wide range of applications in the aerospace, automotive, biomedical, and protective equipment industries. Shuai Chen et al. investigated the effect of structural parameters of additively manufactured gradient negative stiffness honeycomb structures by considering five different configurations [19]. However, the result was not usable for designers due to the absence of a parametric relationship between the structural parameters. Tan et al. performed a parametric analysis between the height, length, and thickness, but the work focused on reusable NS metallic structures [16]. Hence, the gap for structural parametric analysis for additively manufactured NS honeycomb structures has not yet been met. This can aid engineers in designing the structure for small energy absorption applications. Hence, the current study on NSH designs emphasizes the crucial geometric relationship with cell performance, allowing customization for specific energy-isolating applications.

2. Methodology

The impact characteristics of an NSH structure depend upon the force–displacement pattern. The force–displacement curve of a curved beam for transverse displacement is given by

Q represents the ratio of height (h) to thickness (t) and ∆ denotes the displacement (d) normalized by height (h) [20]. Equation (1) highlights the impact performances’ dependence on geometrical parameters like thickness and curved beam height.

A validated numerical model was used for the specific NSH structure in this study. Energy absorption in the honeycomb structure was assessed using ABAQUS V6.14 FEA software. After specifying boundary conditions, a 5 mm compression was applied to the geometry using a static general solver.

Energy absorbed for that specific compression was calculated from the force–displacement curves for each geometry. Specific energy absorption and other parameters described below were also determined to compare the models. Specific energy absorption (SEA) is calculated by dividing the total energy by the mass of the model. Mathematically,

where EA is the total energy absorbed, and m is the mass of the honeycomb geometry. EA is a well-considered property of negative stiffness structures. The designs for various low to high energy requirements generally differ. For mechanical energy absorbances, in most cases, NSH structures typically show low EA values, which is ideal for sensitive devices to be balanced against vibrations of energy impacts. The SEA depicts both the mass and the volumetric efficiency of a structure. Hence, it is another valuable parameter to compare against various designs for design efficiency.

SEA = EA/m

3. Structural and Design Parameters

The 3D geometry of the negative stiffness honeycomb model was modeled using the computer-aided software Solidworks 2018. The model used by D. Correa was considered the base model. The equation of the transversely loaded negative stiffness beam is

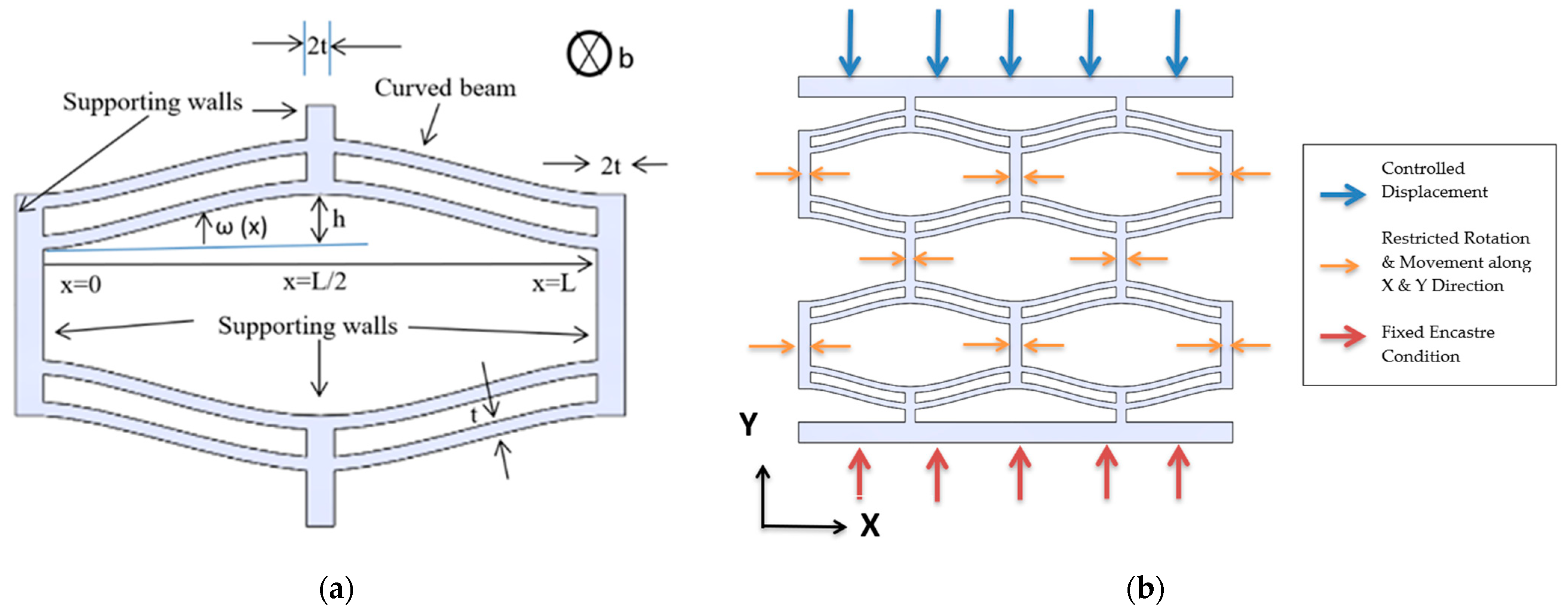

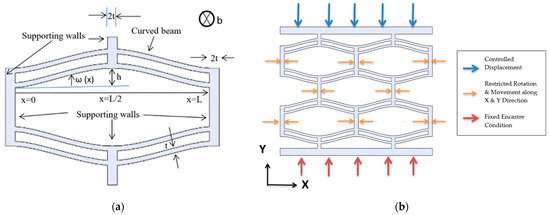

The base geometric parameters in the above equation are shown in Figure 1a, as used in D. Correa’s works.

Figure 1.

(a) Geometric parameters of an NSH cell; (b) boundary conditions for FEA analysis [9].

Following D. Correa’s suggestion, crucial values for this study were chosen that were derived from a moderate increment and influenced by S. Chen’s research on the effects of geometric parameters in the NSH unit cell [16].

4. Numerical Modeling

4.1. Boundary Condition

The bottom geometry surface was fixed using the ENCASTRE condition. A displacement-controlled loading of 5 mm was applied to the top boundary surface. To prevent transverse expansion and undesired rotation, the vertical faces were left free only in the Z direction, restricting movement along the X and Y axes. The imposed boundary conditions are also illustrated in Figure 1b.

4.2. Material Properties

The elastic buckling properties of flexible materials play a pivotal role in realizing shape recovery. This study considered four commercially significant flexible AM materials, which were mainly chosen because of their ability to fabricate complex structures. The required mechanical properties of these materials are shown in Table 1.

As this study focuses solely on the elastic behavior of materials, plastic deformation mapping was not employed for either material. Based on a previous study on NSH structures with flexible materials, PA 11 was selected for parametric analysis models (1A-3C) due to its superior toughness among commonly available additively manufactured materials, resulting in more excellent energy absorption in mid-range shock isolation [21].

Table 1.

Mechanical properties of selected AM materials [5,22,23].

Table 1.

Mechanical properties of selected AM materials [5,22,23].

| Material | Polyamide-11 (PA) | TPE |

| Commercial Name | Nylon 11 | Taulman PCTPE |

| Density (Kg/m3) | 1040 | 1250 |

| Young’s Modulus (MPa) | 1582 | 73 |

| Poisson’s Ratio | 0.33 | 0.50 |

| Material | Nylon 645 | TPU |

| Commercial Name | Taulman Natural 645 Nylon | Cheetah™ |

| Density (Kg/m3) | 1300 | 1220 |

| Young’s Modulus (MPa) | 212 | 26 |

| Poisson’s Ratio | 0.42 | 0.39 |

4.3. Mesh Dependency Test

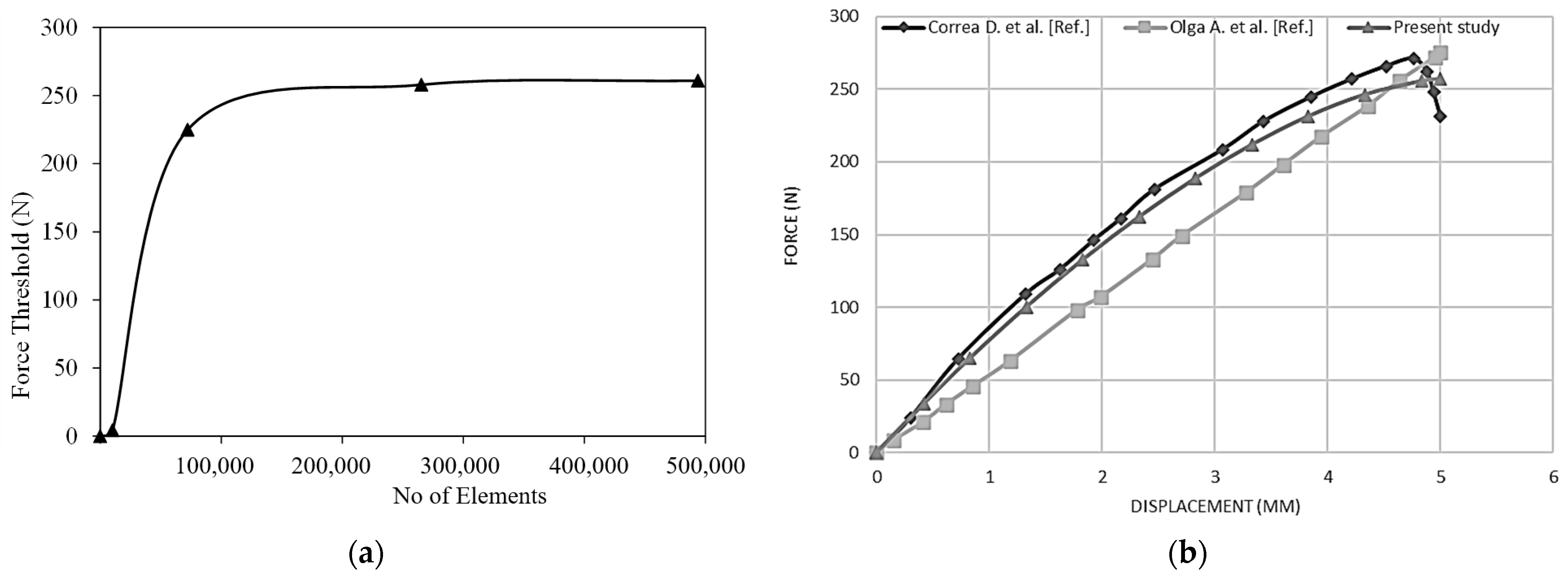

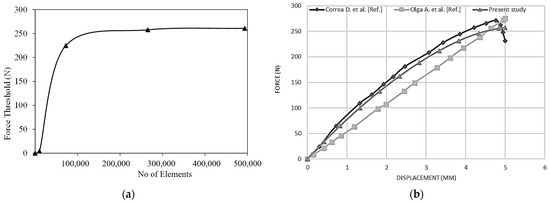

To ensure mesh independence, a mesh dependency analysis was conducted using the general finite element platform ABAQUS. Model 1A was employed for this test, utilizing a C3D8R type hexagonal mesh for smooth finite analysis. To determine the most efficient mesh size for the overall analysis, various mesh sizes between 0.4 and 1.5 mm were used to analyze the force–displacement characteristics of Model 1A. For the convergence test, all models were compared based on the peak threshold force for the 5 mm displacement. The results showed significant variation within the 10,000 to 100,000 elements range, with a nearly flat slope observed beyond 150,000 elements, indicating an efficient mesh size. Considering computation load, accuracy, and precision, a 0.5 mm mesh size appeared suitable for further analysis, as indicated by the convergence graph illustrated in Figure 2a.

Figure 2.

(a) Convergence graph for mesh dependence test; (b) comparison of force–displacement curve with previous works [5,14].

5. Results

5.1. Model Verification

For validating the computer models, the experimental and numerical results from D. Correa [5] and Olga [14] were considered and compared with the identical model 1A from our study, as shown in Figure 2. The force–displacement curve showed a similar pattern for both models, allowing a precise comparison by measuring peak resistance force. D. Correa recorded a threshold force of 273 N, while Olga obtained 275 N. The numerical analysis in this study revealed a peak resistance of 257 N, closely aligning with both authors’ results. In the physical experiment, D. Correa achieved a lower value than his numerical peak resistance of 273 N due to the absence of visco-elastic properties and slight plastic deformations in stressed points. With a deviation of only 5.86% from D. Correa’s work, the current model corresponds well with previously validated models, indicating its suitability for further study.

5.2. Displacement, Stress, and Energy

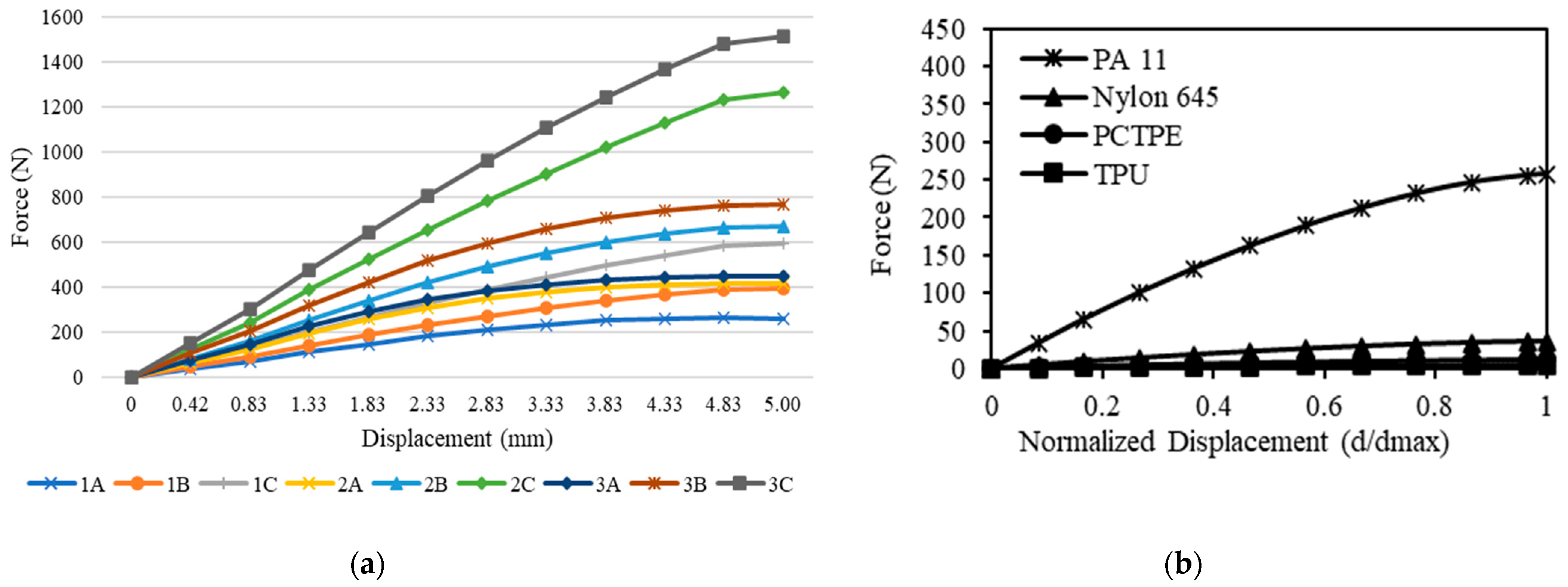

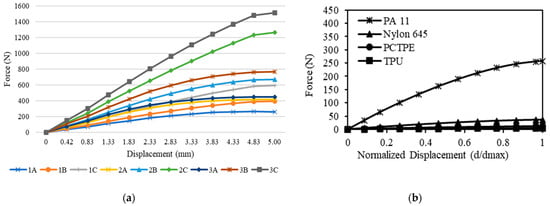

Force–displacement patterns play a significant role in a material’s behavior under various loading conditions. Figure 3b depicts the stiffness behavior of the structure for considered materials for the configuration of the 1A model. A regular smooth curve was seen for almost all the plots. As expected [24], the pattern reveals that the material with the more elastic modulus gives the most stiffness throughout the compression session.

Figure 3.

(a) Force–displacement curves for Model 1A-3C; (b) force–normalized displacement curve for Model 1A with different materials.

Figure 3a illustrates the response from material PA-11 with various models. No irregularities in the curve recognize that the geometric effect is gradual for the NSH models. In the beginning models (1A-1C), the displacement of 5 mm seemed to be the first buckling load as the curve slope became flat at the nearby point. However, the snap-through behavior was assured by the presence of a negative stiffness plateau in the force–displacement curve in another analysis of 1A, expanding the loading up to 26 mm.

However, the main work was limited to 5 mm displacement because of the lower displacement requirement for moderate shock isolation applications. The EA and SEA were calculated from the simulation output for the force–displacement curves.

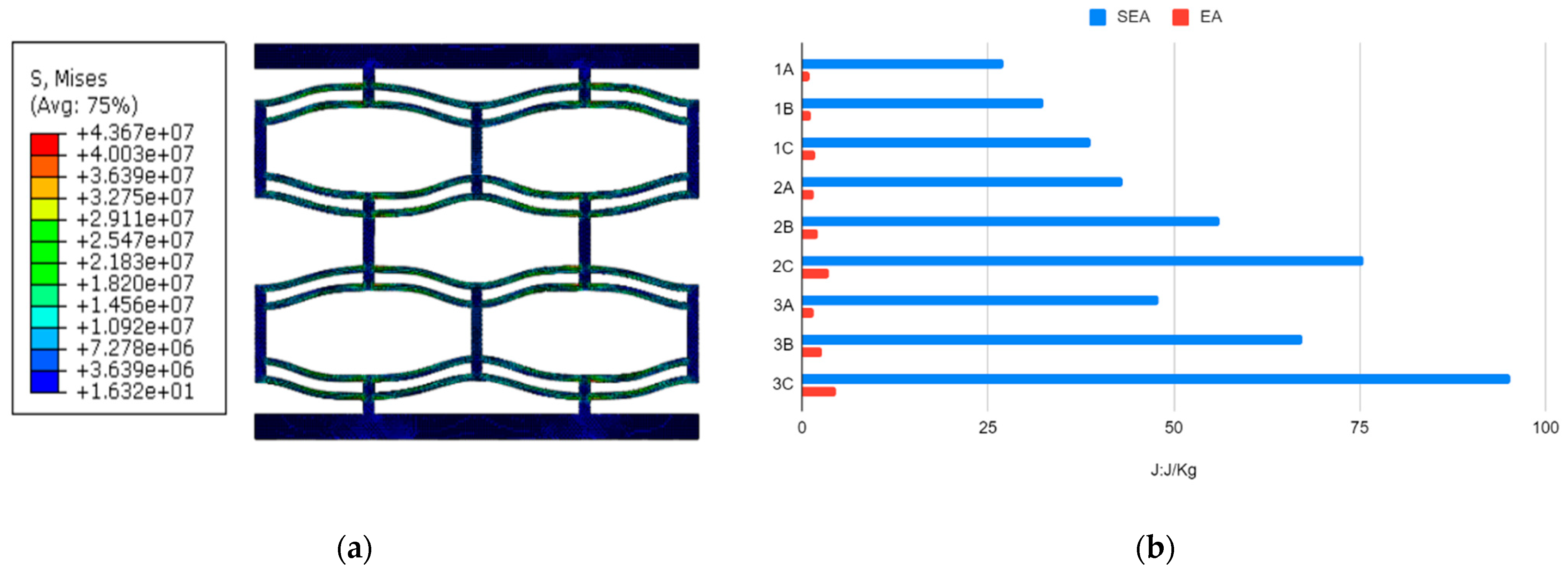

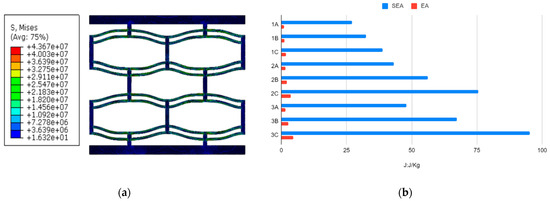

From the energy absorbed (J) and SEA (J/Kg) plots, it is evident that there was a gradual climb for both from Models 1A to 2C, but Model 3A could not retain the value, as seen in Figure 4b. This indicates that the height h has a dominant impact on structural behavior. Over that, the thickness t becomes more prominent. In that case, the height-to-length ratio was 0.15. However, all the model results suggest that increasing both height and thickness comes with better energy absorption. However, another investigation needs to be conducted to analyze the limit of these parameters, withholding the buckling ability.

Figure 4.

(a) Stress distribution of Model 1A; (b) energy absorption for Models 1A-3C.

5.3. Parametric Analysis

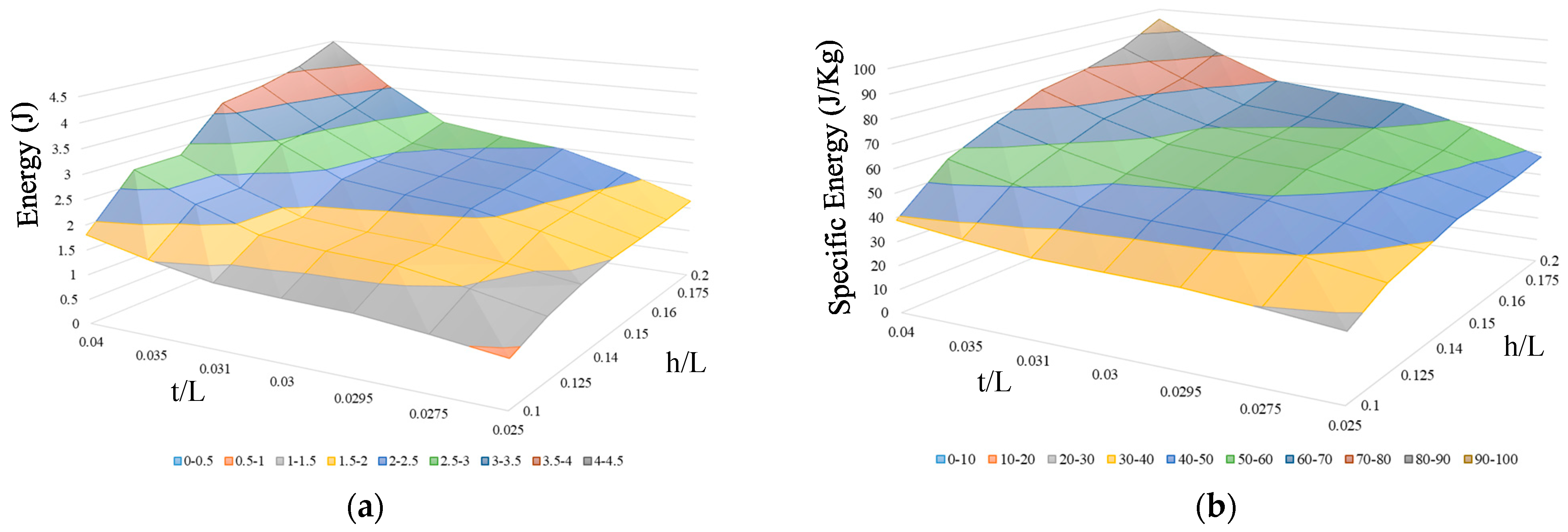

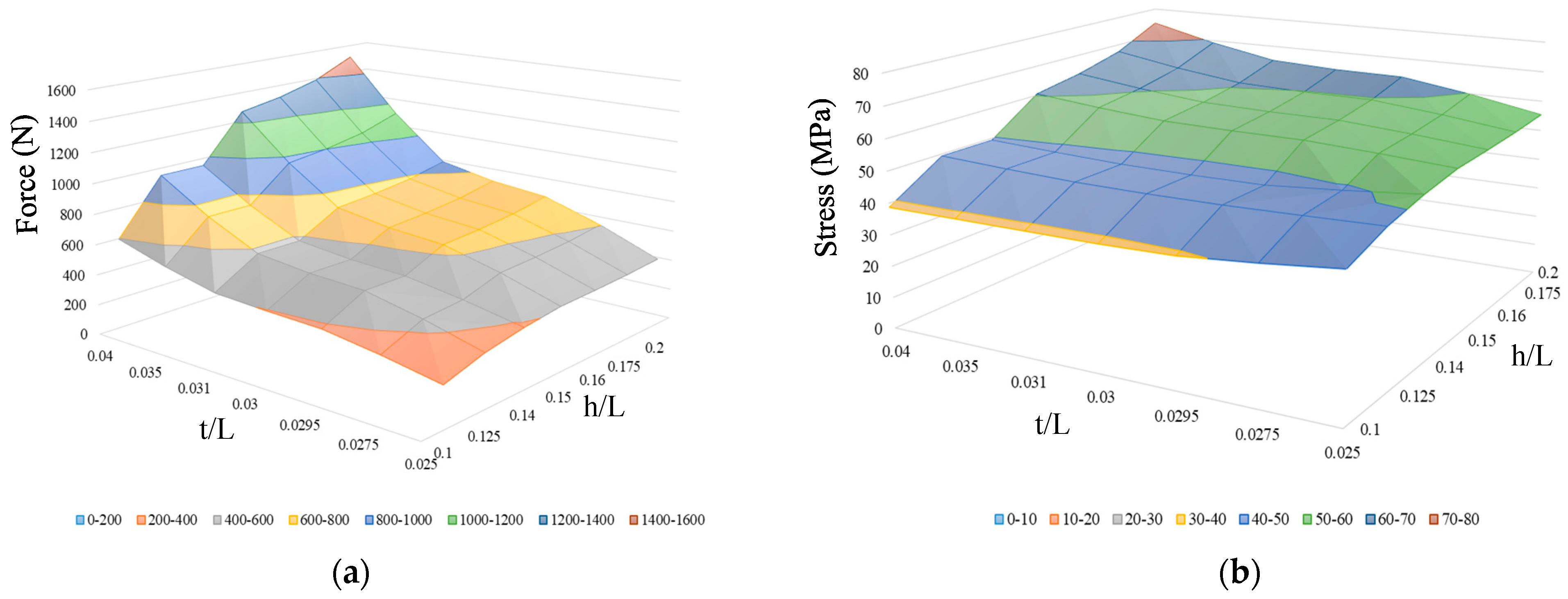

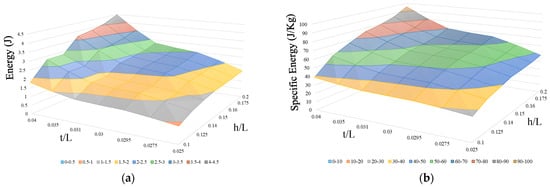

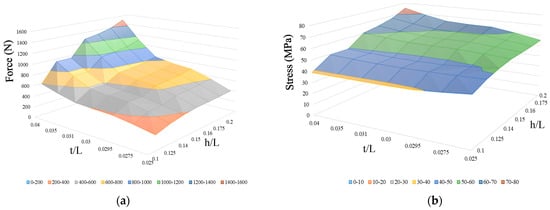

Since parametric values have a significant impact on the structural behavior, the energy absorbed, SEA, compressive stress, and threshold force were plotted against the parametric ratios of h/L and t/L. The ratio of h/L varied from 0.1 to 0.2, whereas the ratio was between 0.025 and 0.04 for the t/L. The surfaces shown in Figure 5 and Figure 6 demonstrate the influence of geometric parameters on various characteristics of NSHs.

Figure 5.

(a) Parametric effect on energy absorption; (b) Parametric effect on specific energy absorption.

Figure 6.

(a) Parametric effect on the stiffness; (b) parametric effect on stress threshold.

As can be seen from Figure 5a, the energy absorbed was improved with the increase in both h/L and t/L ratios. An identical pattern was noticed in Figure 5a and Figure 6b. However, for both energy absorption and specific energy absorption, for the parametric effect of h/L and t/L, the impact of one on the other is insignificant at lower values. Especially for the SEA, at the lower point of h/L, the effect of the beam thickness on the absorption capacity is null. However, with greater values of either h/L or t/L, the absorption capacity noticeably improves.

The h/L increase indicates the promoted NS behavior, which may prevent high stress from forming and deflecting quickly. In the buckling stages, no excess stress formation was noticed in the structure for the rise of height to length ratio. Hence, the matrix for the t/L and h/L seems more flattened for this reason.

6. Conclusions

This study extensively analyzes the NSHs to explore the impact of their geometric parameters. Due to its limited absorption capacity, NSH is suggested for shock and vibration isolation rather than the large-scale absorption typically achieved through plastic deformation. Nylon-11, a popular additive manufacturing material, was chosen for its better stiffness in bent beams, resulting in increased energy absorption compared to other AM materials. Combining geometric and parametric results, the numerically verified model revealed the positive effects of h/L and t/L ratios on NSH structures’ mechanical behavior, providing valuable insights for shock absorber redesign. The numbers indicate that NSH is suitable for isolating vibrations in semi-sensitive devices, such as 3D printers, small robots, and packaging. The output graph data help determine design parameters for creating a shock/vibration controller to meet specific energy and force–displacement requirements for these devices. However, the parametric analysis was focused on the PA-11 material. Future work will include finding the energy absorption mapping for other flexible materials with further experimental analysis.

Author Contributions

Conceptualization, methodology, and investigation, S.C.; formal analysis, visualization, A.R. and M.A.W.; writing—original draft preparation, M.A.W.; writing—review and editing, S.C.; supervision, A.H. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data are contained within the article.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Johnson, W.; Reid, S.R. Metallic energy dissipating systems. Appl. Mech. Rev. 1978, 31, 277–288. [Google Scholar]

- Li, M.; Deng, Z.; Guo, H.; Liu, R.; Ding, B. Optimizing crashworthiness design of square honeycomb structure. J. Cent. South Univ. 2014, 21, 912–919. [Google Scholar] [CrossRef]

- Hassan, M.S.; Chavez, L.A.; Chou, C.; Hall, S.E.; Tseng, T.; Lin, Y. Mechanical response of shape-recovering metamaterial structures fabricated by additive manufacturing. Mater. Res. Express 2021, 8, 115801. [Google Scholar] [CrossRef]

- Regis, J.E.; Renteria, A.; Hall, S.E.; Hassan, M.S.; Marquez, C.; Lin, Y. Recent trends and innovation in additive manufacturing of soft functional materials. Materials 2021, 14, 4521. [Google Scholar] [CrossRef] [PubMed]

- Correa, D.M.; Seepersad, C.C.; Haberman, M.R. Mechanical design of negative stiffness honeycomb materials. Integr. Mater. Manuf. Innov. 2015, 4, 165–175. [Google Scholar] [CrossRef]

- Klatt, T.; Haberman, M.; Conner Seepersad, C. Selective laser sintering of negative stiffness mesostructures for recoverable, nearly-ideal shock isolation. In Proceedings of the 2013 International Solid Freeform Fabrication Symposium, University of Texas at Austin, Austin, TX, USA, 12–14 August 2013. [Google Scholar]

- Kashdan, L.; Seepersad, C.C.; Haberman, M.; Wilson, P.S. Design, fabrication, and evaluation of negative stiffness elements using SLS. Rapid Prototyp. J. 2012, 18, 194–200. [Google Scholar] [CrossRef]

- Fulcher, B.A.; Shahan, D.W.; Haberman, M.R.; Conner Seepersad, C.; Wilson, P.S. Analytical and experimental investigation of buckled beams as negative stiffness elements for passive vibration and shock isolation systems. J. Vib. Acoust. 2014, 136, 031009. [Google Scholar] [CrossRef]

- Correa, D.M.; Klatt, T.; Cortes, S.; Haberman, M.; Kovar, D.; Seepersad, C. Negative stiffness honeycombs for recoverable shock isolation. Rapid Prototyp. J. 2015, 21, 193–200. [Google Scholar] [CrossRef]

- Mehreganian, N.; Fallah, A.S.; Sareh, P. Structural mechanics of negative stiffness honeycomb metamaterials. J. Appl. Mech. 2021, 88, 051006. [Google Scholar] [CrossRef]

- Debeau, D.A.; Seepersad, C.C.; Haberman, M.R. Impact behavior of negative stiffness honeycomb materials. J. Mater. Res. 2018, 33, 290–299. [Google Scholar] [CrossRef]

- Zhakatayev, A.; Kappassov, Z.; Varol, H.A. Analytical modeling and design of negative stiffness honeycombs. Smart Mater. Struct. 2020, 29, 045024. [Google Scholar] [CrossRef]

- Chen, S.; Wang, B.; Zhu, S.; Tan, X.; Hu, J.; Lian, X.; Wang, L.; Wu, L. A novel composite negative stiffness structure for recoverable trapping energy. Compos. Part A Appl. Sci. Manuf. 2020, 129, 105697. [Google Scholar] [CrossRef]

- Ganilova, O.A.; Low, J.J. Application of smart honeycomb structures for automotive passive safety. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2018, 232, 797–811. [Google Scholar] [CrossRef]

- Bonner, D.; Pellegrini, S.; Rudolph, M.; Hilbere, M. Sensitive Payload Shock Absorber; The Pennsylvania State University: University Park, PA, USA, 2016. [Google Scholar]

- Tan, X.; Chen, S.; Zhu, S.; Wang, B.; Xu, P.; Yao, K.; Sun, Y. Reusable metamaterial via inelastic instability for energy absorption. Int. J. Mech. Sci. 2019, 155, 509–517. [Google Scholar] [CrossRef]

- Tan, X.; Wang, B.; Chen, S.; Zhu, S.; Sun, Y. A novel cylindrical negative stiffness structure for shock isolation. Compos. Struct. 2019, 214, 397–405. [Google Scholar] [CrossRef]

- University of Texas at Austin New Honeycomb-Inspired Design Delivers Superior Protection from Impact. ScienceDaily 2015. Available online: www.sciencedaily.com/releases/2015/06/150615142849.htm (accessed on 6 October 2022).

- Chen, S.; Tan, X.; Hu, J.; Zhu, S.; Wang, B.; Wang, L.; Jin, Y.; Wu, L. A novel gradient negative stiffness honeycomb for recoverable energy absorption. Compos. Part B Eng. 2021, 215, 108745. [Google Scholar] [CrossRef]

- Qiu, J.; Lang, J.H.; Slocum, A.H. A curved-beam bistable mechanism. J. Microelectromech. Syst. 2004, 13, 137–146. [Google Scholar] [CrossRef]

- Chanda, S.; Hasib, M.A.; Alam, M. Numerical analysis of recoverable Negative Stiffness Smart Structures for energy absorption in shock isolation. In Proceedings of the International Conference on Mechanical, Industrial and Energy Engineering 2020, Khulna, Bangladesh, 19–21 December 2020. [Google Scholar]

- PCTPE Specifications. Available online: https://filament2print.com/en/nylon-pa/610-4465-taulman-pctpe.html (accessed on 25 May 2022).

- Nylon 645 Specifications. Available online: https://re3d.zendesk.com/hc/en-us/articles/360039399311-Taulman-Nylon-645 (accessed on 25 May 2022).

- Hao, G.; Mullins, J. On the comprehensive static characteristic analysis of a translational bistable mechanism. Proc. Inst. Mech. Eng. Part C 2016, 230, 3803–3817. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).