The Effect of Fly Ash Nanoparticles on Foam Stability for CO2 Flooding †

Abstract

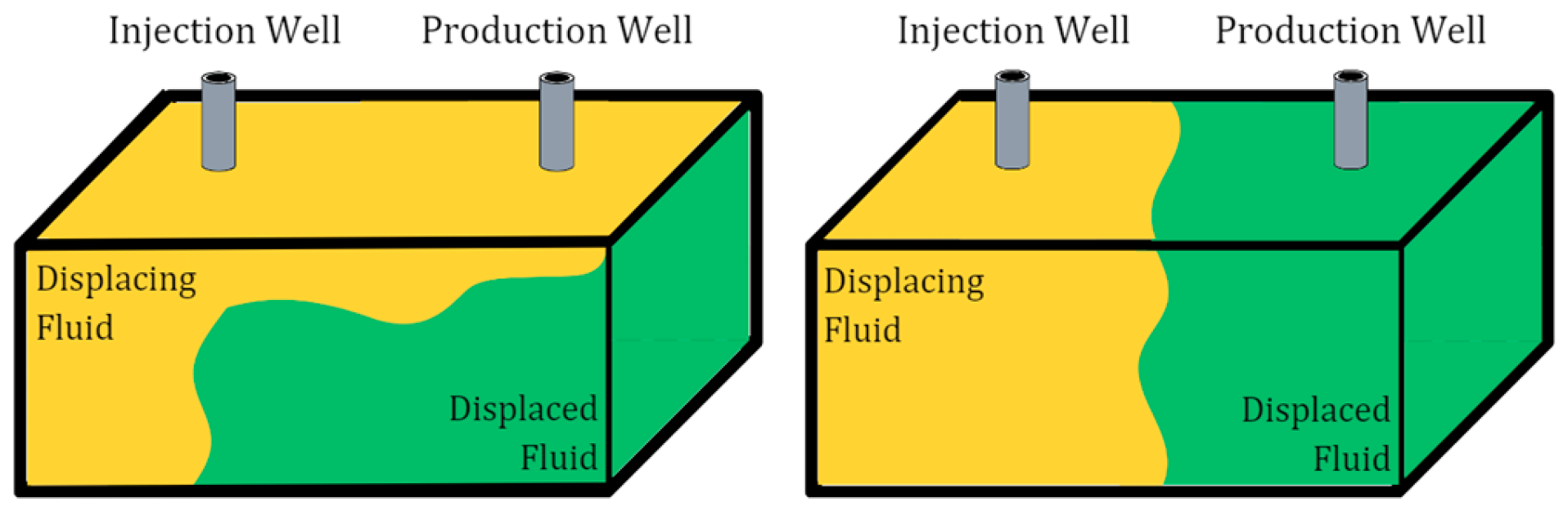

1. Introduction

2. Materials and Methods

2.1. Nanoparticle Characterizations

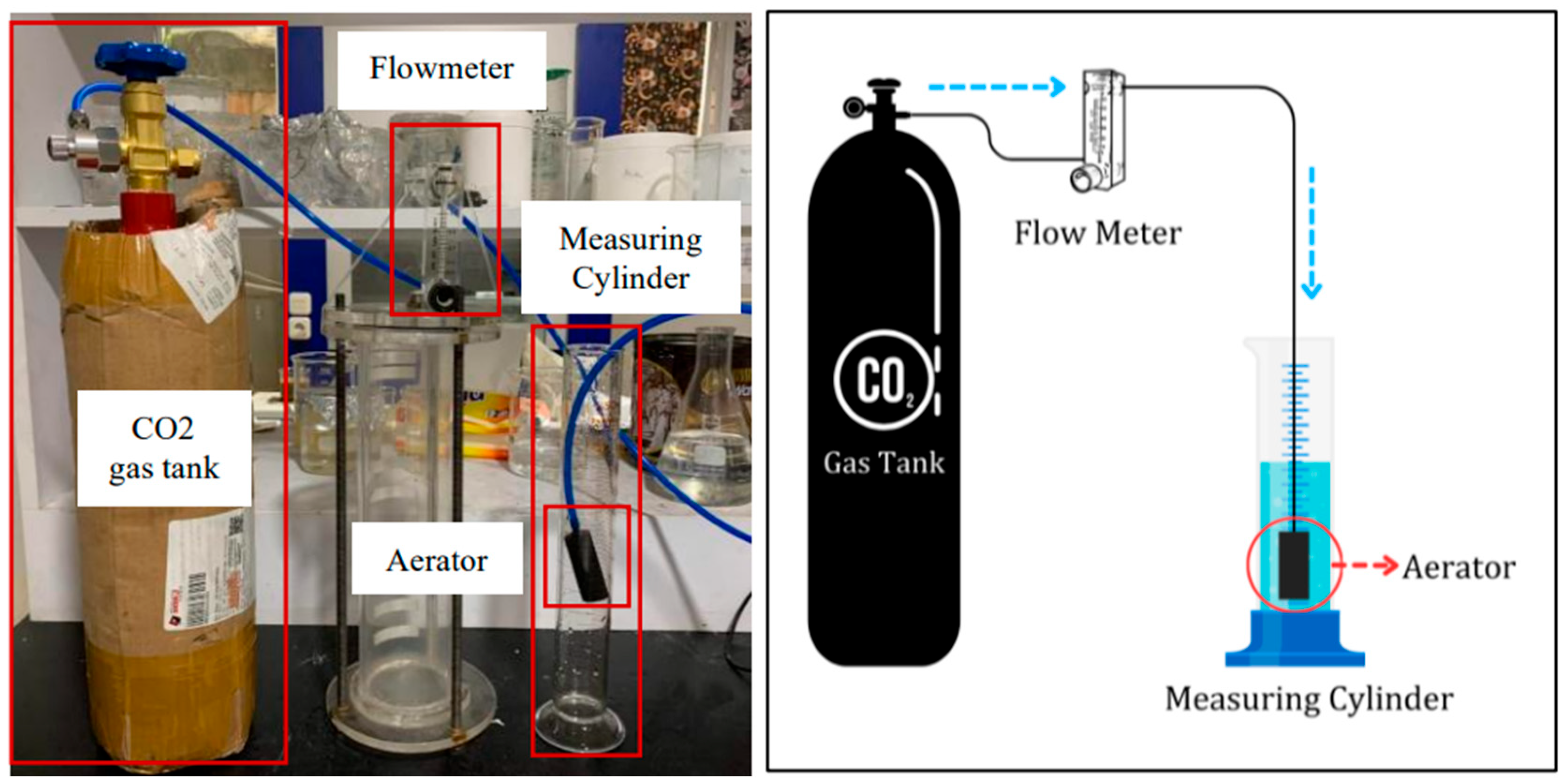

2.2. Foam Stability Test

3. Results

3.1. X-Ray Diffraction (XRD)

3.2. Particle Size Analysis

3.3. Bulk Foam Test

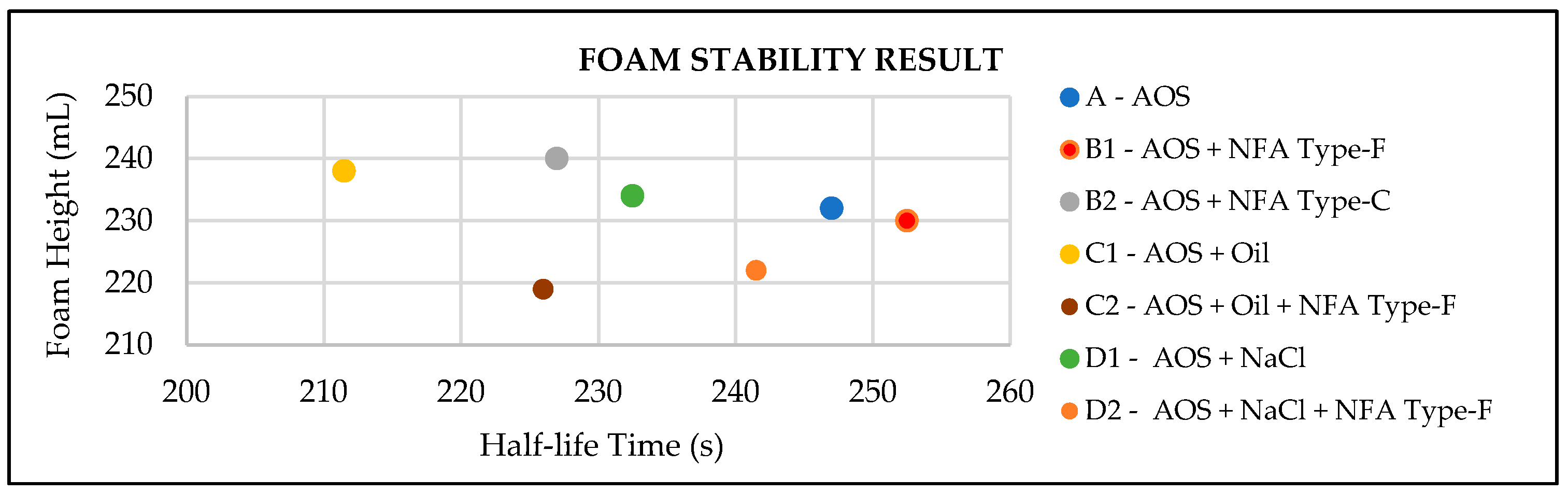

4. Discussion

4.1. Nanoparticle Characteristizations

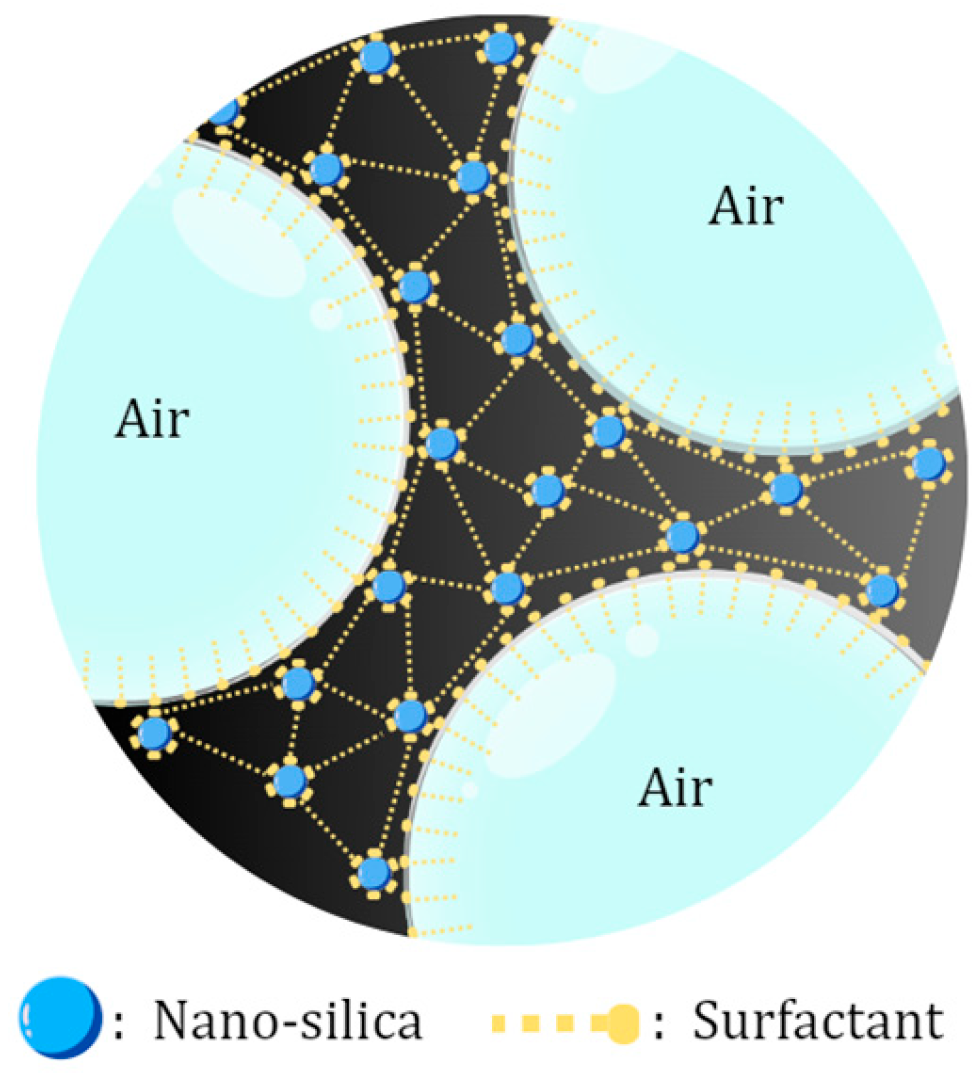

4.2. Nano Fly Ash Effect on Foam Stability

4.2.1. Foam Stability in Light Oil Presence

4.2.2. Foam Stability in Salinity Conditions

5. Conclusions

- 1 wt% Type-F nano fly ash (NFA) stabilized the foam, which was observed by increasing the half-life time, which has been shown in Sample B1, C2, and D2.

- Type-C NFA was not suitable as a foam stabilizer due to the cementitious characteristics because it contains high CaO, which decreased the half-life time of the foam.

- The presence of light oil caused foam film rupture, which could be prevented by adding Type-F NFA as a foam stabilizer.

- Adding 2 wt% NaCl to increase the salinity decreased the zeta potential value, which made the foam film more unstable, and adding Type-F NFA did not result in a significant improvement in foam stability due to aggregation rate acceleration.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Cui, K.; Li, H.; Chen, P.; Li, Y.; Jiang, W.; Guo, K. New Technique for Enhancing Residual Oil Recovery from Low-Permeability Reservoirs: The Cooperation of Petroleum Hydrocarbon-Degrading Bacteria and SiO(2) Nanoparticles. Microorganisms 2022, 10, 2104. [Google Scholar] [CrossRef] [PubMed]

- Sircar, A.; Rayavarapu, K.; Bist, N.; Yadav, K.; Singh, S. Applications of nanoparticles in enhanced oil recovery. Pet. Res. 2022, 7, 77–90. [Google Scholar] [CrossRef]

- Liao, G.; He, D.; Wang, G.; Wang, L.; Wang, Z.; Su, C.; Qin, Q.; Bai, J.; Hu, Z.; Huang, Z.; et al. Discussion on the limit recovery factor of carbon dioxide flooding in a permanent sequestration scenario. Pet. Explor. Dev. 2022, 49, 1463–1470. [Google Scholar] [CrossRef]

- Dziejarski, B.; Krzyżyńska, R.; Andersson, K. Current status of carbon capture, utilization, and storage technologies in the global economy: A survey of technical assessment. Fuel 2023, 342, 127776. [Google Scholar] [CrossRef]

- Environmental Protection Agency. Inventory of U.S. Greenhouse Gas Emissions and Sinks; U.S. Environmental Protection Agency: Washington, DC, USA, 2023. [Google Scholar]

- Massarweh, O.; Abushaikha, A.S. A review of recent developments in CO2 mobility control in enhanced oil recovery. Petroleum 2022, 8, 291–317. [Google Scholar] [CrossRef]

- Enick, R.M.; Olsen, D.; Ammer, J.; Schuller, W. Mobility and Conformance Control for CO2 EOR via Thickeners, Foams, and Gels—A Literature Review of 40 Years of Research and Pilot Tests. In Proceedings of the Eighteenth SPE Improved Oil Recovery Symposium, Tulsa, OK, USA, 14–18 April 2012; Society of Petroleum Engineers: Dallas, TX, USA, 2012. [Google Scholar]

- Tungdumrongsub, S.; Muggeridge, A. Layering and Oil Recovery: The Impact of Permeability Contrast, Gravity, Viscosity and Dispersion. In Proceedings of the SPE EUROPEC/EAGE Annual Conference and Exhibition, Barcelona, Spain, 14–17 June 2010; Society of Petroleum Engineers: Dallas, TX, USA, 2010. [Google Scholar]

- Føyen, T.; Alcorn, Z.; Fernø, M.; Barrabino, A.; Holt, T. CO2 mobility reduction using foam stabilized by CO2- and water-soluble surfactants. J. Pet. Sci. Eng. 2021, 196, 107651. [Google Scholar] [CrossRef]

- AlYousif, Z.; Kokal, S.; Alabdulwahab, A.; Gizzatov, A. CO2-Foam Rheology: Effect of Surfactant Concentration, Shear Rate and Injection Quality. In Proceedings of the SPE Kingdom of Saudi Arabia Annual Technical Symposium and Exhibition, Dammam, Saudi Arabia, 23–26 April 2018; Society of Petroleum Engineers: Dallas, TX, USA, 2018. [Google Scholar]

- Agrawal, D.; Xu, K.; Darugar, Q.; Khabashesku, V. Enhanced Oil Recovery by Nanoparticle-Induced Crude Oil Swelling: Pore-Scale Experiments and Understanding. In Proceedings of the SPE Asia Pacific Oil & Gas Conference and Exhibition, Brisbane, Australia, 23–25 October 2018; Society of Petroleum Engineers: Dallas, TX, USA, 2018. [Google Scholar]

- Afekare, D.; Garno, J.; Rao, D. Enhancing oil recovery using silica nanoparticles: Nanoscale wettability alteration effects and implications for shale oil recovery. J. Pet. Sci. Eng. 2021, 203, 108897. [Google Scholar] [CrossRef]

- Yang, Y.; Cheng, T.; You, Z.; Liang, T.; Hou, J. Profile Control Using Fly Ash Three-Phase Foam Assisted by Microspheres with an Adhesive Coating. Appl. Sci. 2021, 11, 3616. [Google Scholar] [CrossRef]

- Mathapati, M.; Amate, K.; Prasad, C.D.; Jayavardhana, M.; Raju, T.H. A review on fly ash utilization. Mater. Today Proc. 2022, 50, 1535–1540. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, Q.; Ye, H.; Yang, L.; Luo, D.; Peng, B. Nanoparticles as foam stabilizer: Mechanism, control parameters and application in foam flooding for enhanced oil recovery. J. Pet. Sci. Eng. 2021, 202, 108561. [Google Scholar] [CrossRef]

- Ibrahim, A.F.; Nasr-El-Din, H.A. CO2 Foam for Enhanced Oil Recovery Applications. In Foams—Emerging Technologies; Intechopen: London, UK, 2019. [Google Scholar]

- Mourdikoudis, S.; Pallares, R.M.; Thanh, N.T.K. Characterization techniques for nanoparticles: Comparison and complementarity upon studying nanoparticle properties. Nanoscale 2018, 10, 12871–12934. [Google Scholar] [CrossRef] [PubMed]

- Blott, S.J.; Croft, D.J.; Pye, K.; Saye, S.E.; Wilson, H.E. Particle size analysis by laser diffraction. Geol. Soc. Lond. Spéc. Publ. 2004, 232, 63–73. [Google Scholar] [CrossRef]

- Hitesh; Wattal, R.; Lata, S. Development and characterization of coal fly ash through low-energy ball milling. Mater. Today Proc. 2021, 47, 2970–2975. [Google Scholar] [CrossRef]

- Rao, S.; Song, Y.; Peddie, F.; Evans, A. Particle size reduction to the nanometer range: A promising approach to improve buccal absorption of poorly water-soluble drugs. Int. J. Nanomed. 2011, 6, 1245–1251. [Google Scholar]

- Phong, G.M.; Pilus, R.M.; Mustaffa, A.; Thangavel, L.; Mohamed, N.M. Relationship between fly ash nanoparticle-stabilized-foam and oil production in core displacement and simulation studies. Fuel 2020, 266, 117033. [Google Scholar] [CrossRef]

- Sugihardjo, S. Surfactant Properties Evaluation for Chemical Flooding. Sci. Contrib. Oil Gas 2008, 31, 34–39. [Google Scholar] [CrossRef]

- Eftekhari, A.A.; Krastev, R.; Farajzadeh, R. Foam Stabilized by Fly Ash Nanoparticles for Enhancing Oil Recovery. Ind. Eng. Chem. Res. 2015, 54, 12482–12491. [Google Scholar] [CrossRef]

- Osei-Bonsu, K.; Shokri, N.; Grassia, P. Foam stability in the presence and absence of hydrocarbons: From bubble- to bulk-scale. Colloids Surf. A Physicochem. Eng. Asp. 2015, 481, 514–526. [Google Scholar] [CrossRef]

- Ibrahim, A.F.; Nasr-El-Din, H.A. Stability Improvement of Carbon Dioxide Foam Using Nanoparticles and Viscoelastic Surfactants for Enhanced-Oil-Recovery Applications. SPE Reserv. Eval. Eng. 2020, 23, 414–430. [Google Scholar] [CrossRef]

- Emami, H.; Tanha, A.A.; Manshad, A.K.; Mohammadi, A.H. Experimental Investigation of Foam Flooding Using Anionic and Nonionic Surfactants: A Screening Scenario to Assess the Effects of Salinity and pH on Foam Stability and Foam Height. ACS Omega 2022, 7, 14832–14847. [Google Scholar] [CrossRef] [PubMed]

- Latif, W.M.S.M.; Sharbini, S.N.; Sulaiman, W.R.W.; Idris, A.K. Utilization of silicon dioxide nanoparticles in foam enhanced oil recovery—A comprehensive review. In Proceedings of the 1st International Postgraduate Conference on Mechanical Engineering (IPCME2018), Pahang, Malaysia, 31 October 2018. [Google Scholar]

| Compounds | Type-C | Type-F | ||

|---|---|---|---|---|

| Fly Ash | Nano Fly Ash | Fly Ash | Nano Fly Ash | |

| SiO2 | 50% | 9.2% | 93.80% | 59.70% |

| 3CaO·Al2O3 | 46.1% | - | 4.20% | - |

| Fe | 3.9% | - | - | 40.30% |

| Al2O3 | - | 29.4% | - | - |

| Ca3Al2O6 | - | 43.7% | - | - |

| Fe2O3 | - | 17.7% | 2% | - |

| Parameter | Fly Ash | Nano Fly Ash | ||

|---|---|---|---|---|

| Type-C | Type-F | Type-C | Type-F | |

| Particle Size | 1923.7 | 4279.2 | 409.8 | 640.8 |

| Polydispersity Index | 0.661 | 0.74 | 0.293 | 0.304 |

| Label | Compounds | Half-Life Time (s) | Foam Height (mL) |

|---|---|---|---|

| A | AOS | 247 | 232 |

| B1 | AOS + NFA Type-F | 252.5 | 230 |

| B2 | AOS + NFA Type-C | 227 | 240 |

| C1 | AOS + Oil | 212.5 | 238 |

| C2 | AOS + Oil + NFA Type-F | 226 | 219 |

| D1 | AOS + NaCl | 232.5 | 234 |

| D2 | AOS + NaCl + NFA Type-F | 241.5 | 222 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ramadhani, G.W.; Ridha, S.; Pramana, A.A.; Maharsi, D.A.; Yusuf, M.; Ibrahim, H. The Effect of Fly Ash Nanoparticles on Foam Stability for CO2 Flooding. Eng. Proc. 2024, 76, 111. https://doi.org/10.3390/engproc2024076111

Ramadhani GW, Ridha S, Pramana AA, Maharsi DA, Yusuf M, Ibrahim H. The Effect of Fly Ash Nanoparticles on Foam Stability for CO2 Flooding. Engineering Proceedings. 2024; 76(1):111. https://doi.org/10.3390/engproc2024076111

Chicago/Turabian StyleRamadhani, Gadis Wahyu, Syahrir Ridha, Astra Agus Pramana, Dara Ayuda Maharsi, Mohammad Yusuf, and Hussameldin Ibrahim. 2024. "The Effect of Fly Ash Nanoparticles on Foam Stability for CO2 Flooding" Engineering Proceedings 76, no. 1: 111. https://doi.org/10.3390/engproc2024076111

APA StyleRamadhani, G. W., Ridha, S., Pramana, A. A., Maharsi, D. A., Yusuf, M., & Ibrahim, H. (2024). The Effect of Fly Ash Nanoparticles on Foam Stability for CO2 Flooding. Engineering Proceedings, 76(1), 111. https://doi.org/10.3390/engproc2024076111