1. Introduction

Surge protection in water distribution systems has been a longstanding concern, prompting the exploration of innovative passive check valves as alternatives to traditional protection devices. Among these, the Tesla valve has emerged as a promising solution, offering a fixed geometry design devoid of moving parts.

The concept of the Tesla valve, devised by Nikola Tesla in 1920, aimed to address the need for a valve that permits fluid flow in one direction while restricting it in the opposite direction—a fundamental requirement in mechanical energy applications where fluid impulses are directed accordingly. Although the notion of such fluid movements had been contemplated earlier in the design of valve components, prior implementations failed to fully capitalize on the concept’s potential. Earlier valves relied on moving parts to control fluid impulses, rendering them prone to wear, intricate in design, expensive to manufacture, and inadequate for handling sudden impulses effectively. Tesla introduced a unique channel through valvular action within the valve, thereby creating a No-Moving-Parts (NMP) valve, as highlighted by [

1], capable of meeting the desired operational requirements. NMP valves offer reliability owing to their lack of apparent abrasion compared to conventional valves comprising moving parts.

The fixed geometry of Tesla valves, compared to the moving parts in traditional valves, addresses concerns related to wear, fatigue, and maintenance. This inherent design has prompted investigations into the viability of Tesla valves as surge protection devices.

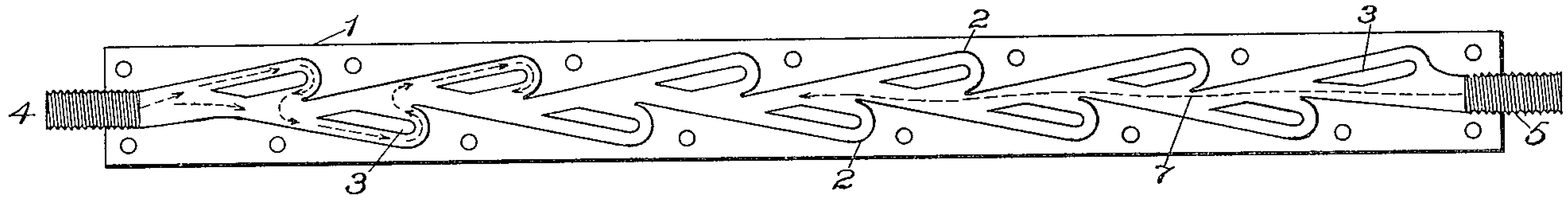

In

Figure 1, the forward direction is from right to left. The intricate design of the channels ensures that fluid can only travel in one direction, facilitating unobstructed flow, while impeding flow in the opposite direction through geometric constraints. As a result, fluid within the Tesla valve follows a zigzag trajectory, encountering minimal resistance in the forward direction.

The Tesla valve functions as a fluid channel designed to modulate flow resistance based on the direction of fluid motion. It comprises a series of loops that interact with the passing fluid. The channel geometry is specifically engineered to enable unimpeded flow in one direction while imposing significant resistance or deceleration when flow occurs in the opposite direction. Unlike conventional valves, the Tesla valve achieves this flow modulation without the need for mechanical moving parts [

2].

2. Materials and Methods

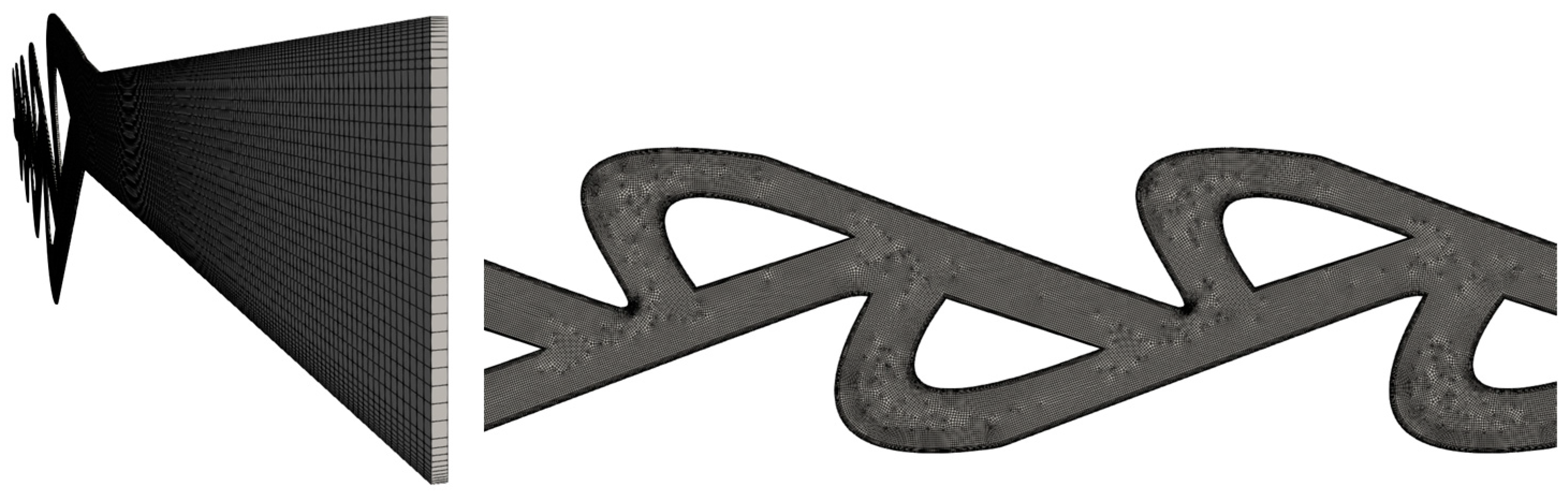

The geometry creations and fluid simulations were performed using the ANSYS 2023 R1 software and its modules. The geometry is based on a three-dimensional model freely available from grabcad.com. This geometry was cleaned, and all unnecessary parts were cut off using SpaceClaim (Concord, MA, USA) to create the flow domain. Its width was set to contain only one cell to generate geometry for the two-dimensional simulations, as seen in

Figure 2.

Mesh independence analysis is a crucial first step in CFD analysis to define a mesh, where the results of the simulations are independent of the mesh [

3,

4]. A mesh independency analysis was performed by running transient simulations in the Tesla valve geometry with mesh sizes from 48,000 cells to 410,000 cells and calculating the maximum peak pressure and the time it takes to reach 10% of the peak pressure. Based on the independence analysis, the reference mesh size for the Tesla valve was chosen to be 150,000 cells (

Figure 2). This mesh was generated by setting the target size of the hexahedral cells to be 0.004 mm and the first element height of the inflation layer at the wall was set as 0.0004 mm with a growth rate of 1.2.

3. Results

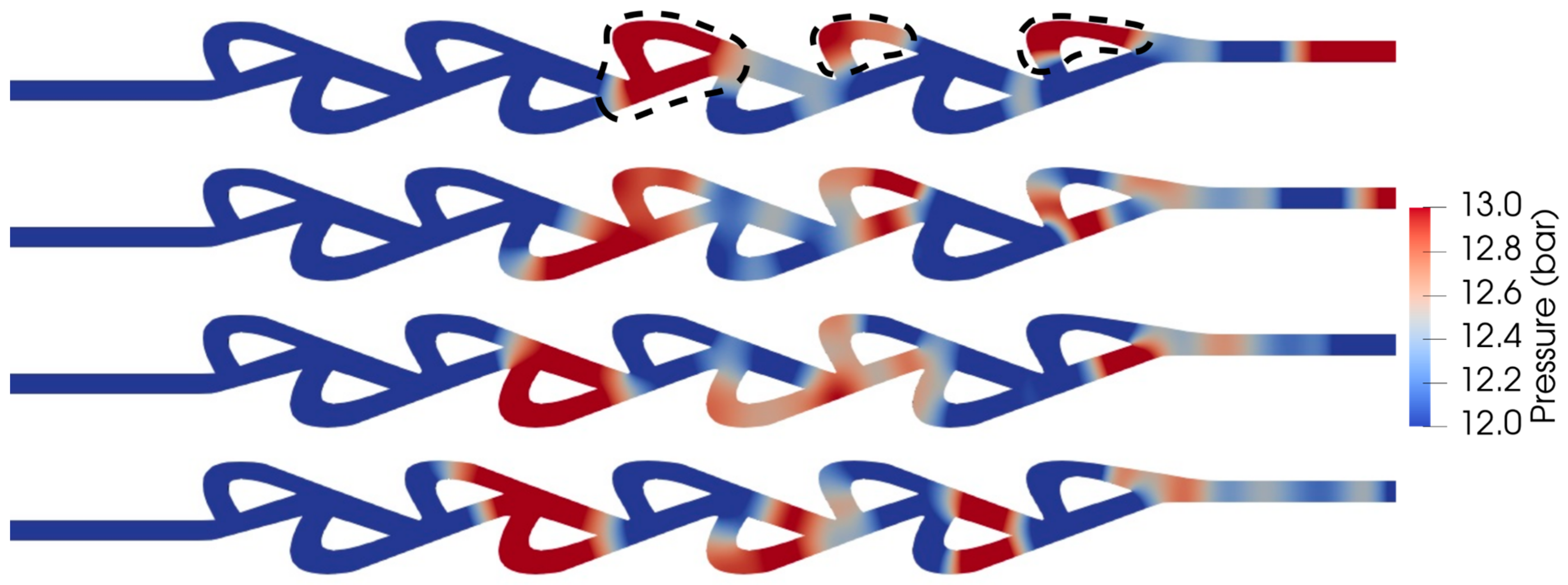

These results illustrate potential scenarios of pressure pockets within the Tesla valve, highlighting the interactions between high-pressure fronts and low-pressure zones. This visualization aligns with the hypothesis underlying the ability of the Tesla valve to mitigate pressure transients. By depicting the spatial distribution of pressure variations and the corresponding force vectors,

Figure 3 provides valuable insights into the dynamic behavior of fluid flow within the Tesla valve configuration. Through this visualization, we seek to elucidate the mechanisms through which the Tesla valve effectively attenuates pressure transients, contributing to a deeper understanding of its functionality and potential applications in fluid control systems.

Figure 3 focuses on the distinctive phenomenon of pressure pockets within the Tesla valve during transient events. Sub-figures at different time steps illustrate the evolution and presence of pressure pockets. These pockets contribute to the prolonged duration of transient pressure events and are crucial in understanding the unique behavior of Tesla valves. From

Figure 3, we can see the pressure inside the channel was significantly reduced after the convergence of the main flow and the secondary flow, which further indicated that the hedging of the two water flows could produce relatively large head loss and achieve a good energy dissipation effect.

4. Discussion

This study provides comprehensive insights into the transient flow dynamics of Tesla valve configurations, emphasizing their potential applications in water distribution systems. Through our simulations, we enhanced our understanding of the transient flow dynamics within Tesla valves, focusing on elucidating the interference of pressure waves within the valve and their influence on pressure wave propagation. This study demonstrates the efficacy of Tesla valves as transient protection devices in water distribution systems through CFD simulations. The results clearly depict the damping effect of Tesla valves, effectively reducing pressure wave amplitudes and highlighting their promising potential as a cost-effective solution for managing pressure transients in WDSs. Notably, our analysis has revealed the emergence of distinct pressure pockets within the valve, both between different chambers and within the chambers themselves, significantly influencing the non-uniform propagation of pressure. Moreover, we observed a temporal phase shift between pressure amplitudes at various points within the valve, indicating dynamic interactions that substantially impact flow dynamics. These interactions play a crucial role in modulating the amplitude and duration of transient pressure events. Overall, Tesla valves offer significant advantages, including resistance to wear and fatigue, scalability, durability, and ease of fabrication. While our study provides valuable insights, further research and optimization of Tesla valve designs are warranted to fully exploit their potential in real-world applications. By continuing to refine Tesla valve designs and exploring their implementation in diverse scenarios, we can advance transient protection strategies in water distribution systems and contribute to more resilient and efficient infrastructure.

Author Contributions

Conceptualization, M.Z. and A.O.; methodology, M.Z., R.W. and M.N.; software, R.W., M.N. and D.Y.; formal analysis, M.Z., M.N.; writing—M.Z.; writing—review and editing, G.R.A., R.W.; visualization, R.W., M.N. and D.Y.; supervision, A.O. All authors have read and agreed to the published version of the manuscript.

Funding

Project no. TKP-6-6/PALY-2021 has been implemented with the support provided by the Ministry of Culture and Innovation of Hungary from the National Research, Development and Innovation Fund, financed under the TKP2021-NVA funding scheme. This research was also supported by The Bernard M. Gordon Center for Systems Engineering at the Technion.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

All data are available upon request.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Zhang, S.; Winoto, S.H.; Low, H.T. Performance simulations of Tesla microfluidic valves. In Proceedings of the International Conference on Integration and Commercialization of Micro and Nanosystems, Sanya, China, 10–13 January 2007. [Google Scholar]

- Bäckman, E.; Willén, M. Tesla Valve for Hydrogen Decompression: Fluid Dynamic Analysis. Bachelor’s Thesis, KTH Industrial Engineering and Management, Stockholm, Sweden, 10 June 2019. [Google Scholar]

- Katz, A.; Sankaran, V. Mesh quality effects on the accuracy of CFD solutions on unstructured meshes. J. Comput. Phys. 2011, 230, 7670–7686. [Google Scholar] [CrossRef]

- Alauzet, F.; Frey, P.J.; George, P.L.; Mohammadi, B. 3D transient fixed point mesh adaptation for time-dependent problems: Application to CFD simulations. J. Comput. Phys. 2007, 222, 592–623. [Google Scholar] [CrossRef]

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).