Abstract

This research was conducted to determine the effect of composite flour composition on the elongation, tensile strength, and acceptability of wet noodles. Experimental research was conducted with three different ratios of sorghum flour:mocaf:wheat, namely, A (40:30:30), B (30:35:35), and C (20:40:40). Elongation and tensile strength were tested using a Universal Testing Machine. Acceptability was tested by a hedonic test using data from 35 slightly trained panelists. Elongation and tensile strength data were analyzed by a one-way ANOVA test. Acceptability was analyzed using the Kruskal–Wallis test. The average noodle elongation in the A, B, and C treatments was 7.26%, 10.74%, and 12.96%. The average noodle tensile strength in the A, B, and C treatments was 0.0350 MPa, 0.0375 MPa, and 0.0378 MPa. The average hedonic test results for the A, B, and C treatments based on overall preference were 3.14, 3.49, and 3.86. The composite flour composition ratio significantly affected elongation and acceptability of color, taste, texture, and overall preference, but did it not significantly affect tensile strength and aroma acceptability.

1. Introduction

Dry and wet noodles are carbohydrate sources. Wet noodles are created by mixing high-protein wheat flour, water, eggs, and salt into a smooth dough, molding it into strands, and boiling it before selling [1]. Wet noodle consumption in Indonesia was 1.89 kg/capita/year in 2017 [2]. The rising consumption of noodles increases the requirement for wheat flour, which affects Indonesian wheat imports. Indonesia imports the most wheat in the world, amounting to 11.48 million tons in 2021, according to FAO data [3]. Low rupiah exchange rates will affect Indonesia’s wheat imports.

One popular substitute for wheat flour in wet noodles is mocaf. Lactic acid bacteria produce pectinolytic and cellulolytic enzymes that break down cassava cell walls and hydrolyze starch into organic acids to make mocaf [4]. Wet noodles made with 75% wheat flour and 25% mocaf have the best elasticity, flavor, color, scent, and elasticity [5]. Flour with less than 1.4% ash makes bright-colored noodles. A low ash level in mocaf (0.4%) can yield brilliant noodle hues [6]. Mocaf has 19% amylose [7]. High amylose levels prevent noodles from breaking because amylose binds to the binding matrix [8]. A study found that wet noodles with more mocaf instead of sago flour had higher elongation [9].

Wet noodles require 9–13% protein flour [6]. Because it provides 11% protein and is water-soluble, sorghum flour might be used with wheat flour to make wet noodles [10,11]. One study found that panelists liked 50% sorghum flour noodles [12]. Another study found that substituting sorghum flour in wet noodles did not affect their scent, flavor, or texture, but it did affect their color [13].

Wet noodles with good tensile strength are chewy, elastic, non-sticky, and smooth [14]. Noodle strength is measured by elongation and tensile strength. Elongation, stated in percent, is the maximum noodle length change under tensile stress. Tensile strength—Pa units—is the force needed to break noodles [15]. Gluten, which acts as an adhesive, amylose, amylopectin, protein, and dough composition affect noodle strength [16].

The hedonic test measures wet noodle acceptability. The hedonic or affective test measures relative preference. An affective test is performed by slightly trained or untrained panelists, who represent a customer group, to assess product acceptability. Organoleptic property scores are provided by panelists [17].

Indonesia can cut wheat imports by making wet noodles from composite flour (sorghum, mocaf, and wheat flour). However, wet noodle quality can alter public approval. This study examined how the composite flour mix affects wet noodle elongation, tensile strength, and acceptance.

2. Material and Methods

This research is experimental. This study used a completely randomized design with the following three sorghum flour:mocaf:wheat composition ratios: A (40:30:30), B (30:35:35), and C (20:40:40). To evaluate how composite flour content affected elongation, tensile strength, and noodle acceptability, each treatment was repeated twice and analyzed twice. The Health Research Ethics Committee of RSUD Dr. Moewardi granted permission for this study with number 1.0506/VIII/HREC/2023. The Food Science Laboratory, Nutrition Science Department, Faculty of Health Sciences, Muhammadiyah University of Surakarta, made the wet noodles used in this study and performed the hedonic tests. The Food Engineering Laboratory, Faculty of Agricultural Technology UGM, tested elongation and tensile strength.

2.1. Tools and Materials

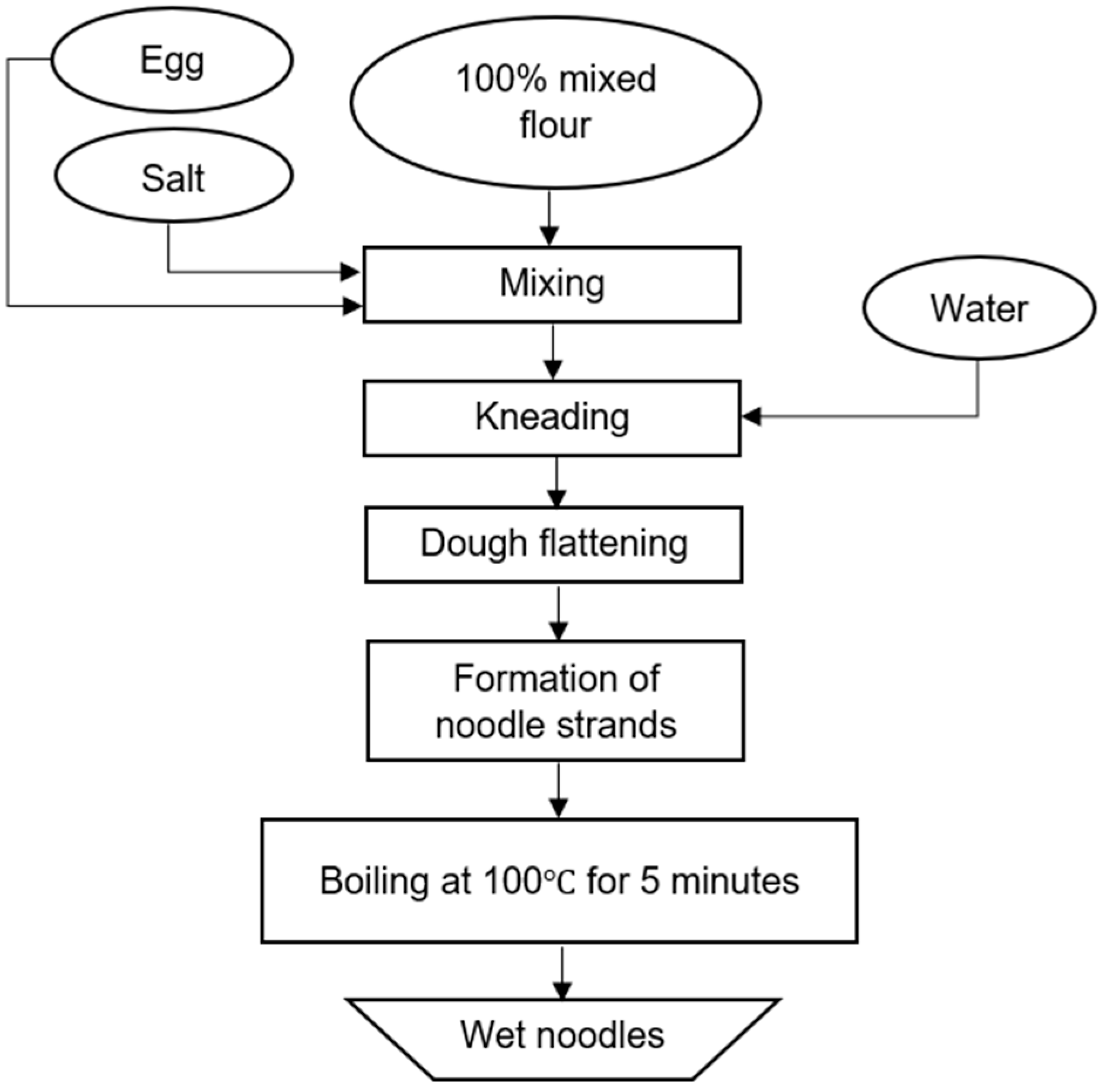

Wet noodles were made with digital scales, basins, flour sifters, noodle makers, pans, sieves, measuring cups, burners, trays, and tongs. Elongation and tensile strength were tested with a Universal Testing Machine. Acceptability was tested utilizing a hedonic form. The wet noodles required white sorghum flour, mocaf, high-protein wheat flour, water, eggs, and salt. The components of the wet noodles are shown in Figure 1. The wet noodles were used to measure elongation and tensile strength. Hedonic tests used wet noodle samples and water as a neutralizer.

Figure 1.

The ingredients in wet noodles.

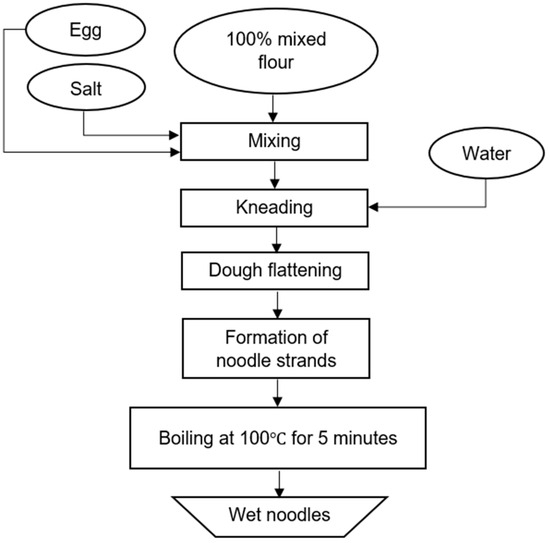

2.2. Procedure for Making Wet Noodles

There were three treatment variations in the composition ratio of sorghum flour:mocaf:wheat, namely, A (40:30:30), B (30:35:35), and C (20:40:40). The procedure for making wet noodles can be seen in Figure 2. The noodles from each variation can be seen in Figure 3.

Figure 2.

Procedure for making wet noodles.

Figure 3.

Noodles with (A) 40% sorghum flour: 30% mocaf: 30% wheat; (B) 30% sorghum flour: 35% mocaf: 35% wheat; and (C) 20% sorghum flour: 40% mocaf: 40% wheat.

2.3. Elongation and Tensile Strength Test Procedure

Noodles were wrapped around a Universal Testing Machine measuring device, and then the noodles were pulled by the tool until the noodles broke. Elongation and tensile strength values appeared on the sensor instrument connected to the measuring device [18].

2.4. Acceptability Test Procedure

For the hedonic test, 35 slightly trained participants were asked to rate color, flavor, scent, texture, and overall acceptability on a 1–5 scale. Aroma was assessed by sniffing wet noodles, texture by biting, pushing, and tugging, and flavor by tasting. The panelists did not ingest the samples and rinsed their lips after each test [17].

2.5. Data Analysis

Data analysis was performed with SPSS 26. The Shapiro–Wilk test was used to determine data normality. A one-way ANOVA test was used to determine the effect of composite flour composition on elongation and tensile strength. The composition of composite flour significantly affected the elongation of wet noodles (p < 0.05). The Duncan Multiple Range Test (DMRT) was used to analyze the differences between treatments. The Kruskal–Wallis test was used to determine how composite flour content affects noodle acceptability. A significant correlation (p < 0.05) existed between composite flour composition and color, flavor, texture, and overall acceptability. The Dunnett test was used to compare each treatment.

3. Result and Discussion

3.1. Elongation

The results of the elongation test on composite flour wet noodles can be seen in Table 1. The one-way ANOVA statistical test shows a p-value of 0.003 (p < 0.05), which means there is a significant influence between the comparison of composite flour composition and the elongation of wet noodles. The result of the Duncan test shows that the elongation value in the A treatment is significantly different from the B and C treatments. The elongation value in the B treatment is not significantly different from the C treatment.

Table 1.

Elongation of composite flour wet noodles (sorghum, mocaf, and wheat).

C had the largest elongation value, 12.96%, and A had the lowest, 7.26%. Wet noodles become longer when sorghum flour decreases and wheat flour and mocaf increase. According to prior studies, the lower the content of sorghum flour substituted for wheat flour in wet noodles, the longer the noodles [13].

Gluten—a chewy protein—is found in wheat flour. Gluten allows noodles to not break easily because gliadin glues the dough and glutenin expands and forms pores to make it strong [16,19]. Wet noodle tensile strength is affected by gluten and amylose. The high amylose concentration makes the noodles chewy and break-resistant. Wheat flour has 25–28% amylose, which is more than mocaf (19%) and sorghum flour (10.8–18.72%); hence, wet noodles with higher amylose concentrations are longer [7,20,21].

3.2. Tensile Strength

The result of the tensile strength test can be seen in Table 2. The one-way ANOVA statistical test shows a p-value of 0.693 (p > 0.05), which means there is no significant influence between the comparison of composite flour composition and the tensile strength of wet noodles.

Table 2.

Tensile strength of composite flour wet noodles (sorghum, mocaf, and wheat).

Wet noodles in the C treatment had the maximum tensile strength, 0.0378 MPa, while those in the A treatment had the lowest, 0.0350 MPa. The tensile strength of wet noodles rises with decreasing sorghum flour content and increasing wheat flour and mocaf content. This research supports prior findings that composite flour made from reduced wheat flour composition yields lower tensile strength wet noodles. This is due to less dough gluten. Gluten closes starch granule connections, making dough more stretch-resistant [22].

The protein content, amylose/amylopectin ratio, and dough mix affect noodle tensile strength. Protein boosts noodle tensile strength. Breaking peptide bonds requires more energy as they lengthen. Wheat flour has 14.45% protein, which is more than sorghum (11%) and mocaf (1.2%) [10]. Noodles with more amylose are more difficult to break. Amylose is needed for gelatinization. Additionally, amylose increases starch granule molecular resistance, making the gel stronger. High amylopectin interferes with gel formation, reducing noodle-breaking strength [8,22].

The noodles’ physical qualities depend on the dough ingredients such as water, salt, and eggs. The water added to noodle dough forms gluten with gliadin and glutenin, making wet noodles stronger. Salt increases gluten binding. Eggs make dough compact and less fragile [23].

3.3. Acceptability

The composite flour wet noodle acceptability test was carried out by 35 slightly trained panelists who gave a preference rating regarding color, flavor, aroma, texture, and overall acceptability. This assessment was carried out by providing a numerical score in the interval of 1—5 with the following details: grade 1 (very dislike), grade 2 (dislike), grade 3 (neutral), grade 4 (like), and grade 5 (very like). The Kruskal–Wallis test was carried out to determine the effect of composite flour composition on the acceptability of wet noodles. The results of the wet noodle acceptability test can be seen in Table 3.

Table 3.

Acceptability test results for the composite flour wet noodles.

Based on the Kruskal–Wallis statistical test results, the comparison of the composition of composite flour has a significant influence (p < 0.05) on the color, flavor, texture, and overall aspects, each with a p-value of 0.000, 0.001, 0.000, and 0.000. The comparison of the composition of composite flour did not have a significant effect on the aroma aspect, with a p-value of 0.132 (p > 0.05).

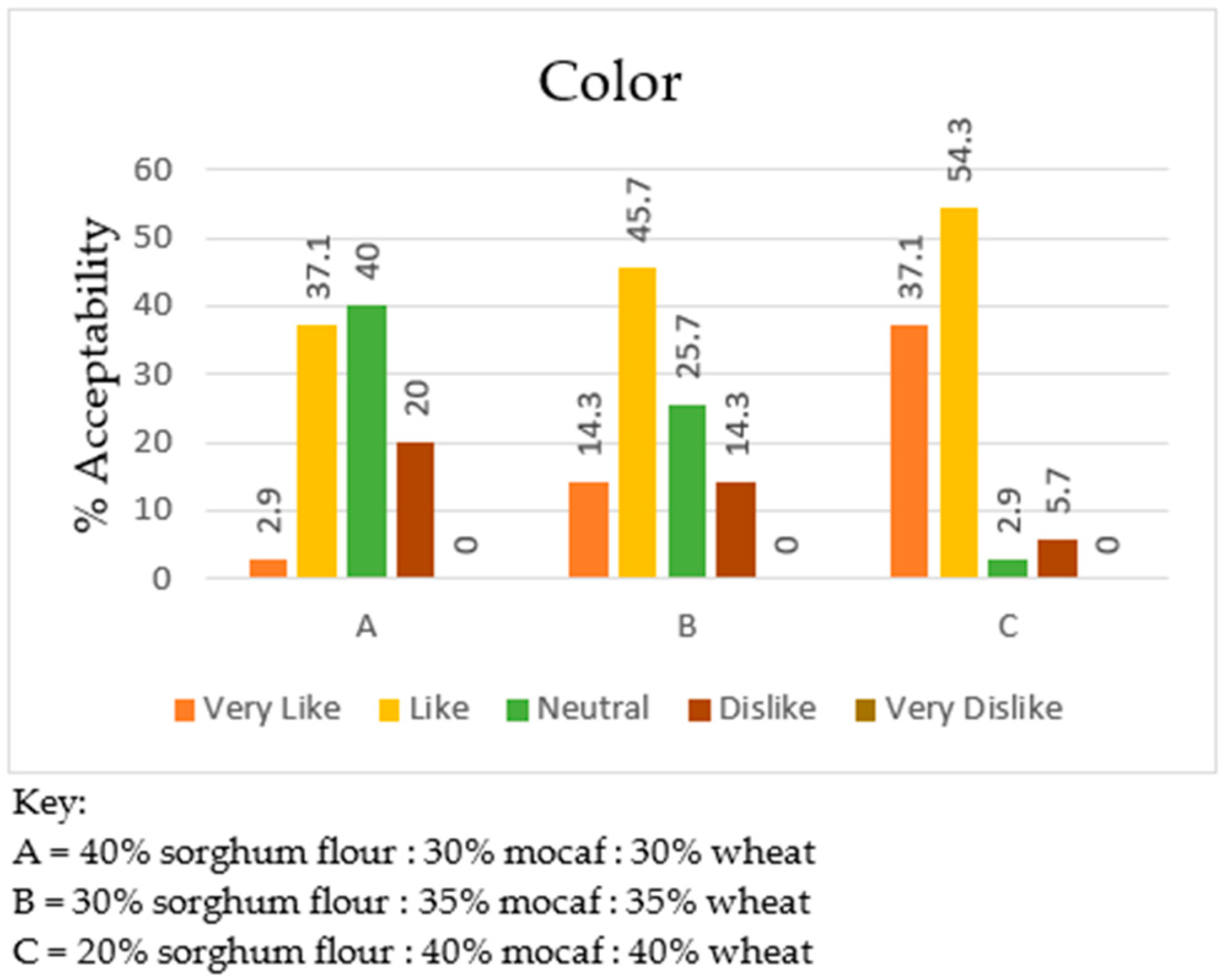

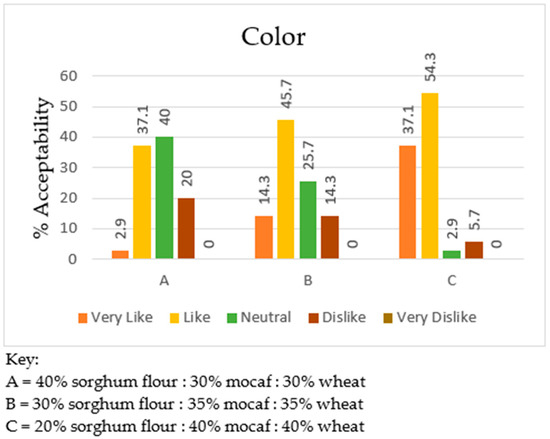

3.3.1. Color

Color can increase consumer appeal. The color acceptability test results of the composite flour wet noodles can be seen in Figure 4.

Figure 4.

Color acceptance chart of composite flour wet noodles.

The panelists preferred the color of wet noodles with less sorghum flour and more wheat and mocaf. The panelists preferred the C treatment wet noodles the best (4.23) and the A treatment noodles the least (3.23). The Dunnett test demonstrated a substantial color difference in the C treatment. The color of the A and B treatments was similar.

Ash colorizes wet noodles. More ash results in darker noodles [6]. Mocaf has 0.4% ash compared with 1.49% in sorghum flour [24]. More sorghum flour in the composite flour results in darker noodles. The Panelists disliked dark noodles. The color of wet noodles is similarly affected by the Maillard reaction. Wet noodles turn brownish-yellow due to the Maillard reaction between amine groups and reducing sugars [25]. Mocaf has less protein than wheat (14.45%) and sorghum flour (11%), at 1.2% [10]. Noodles with less sorghum flour and more mocaf have fewer amine groups. Reducing the amine group reduces the Maillard reaction, which turns noodles brownish yellow [25]. Thus, compositions with less sorghum flour and more mocaf produced brighter noodles, and more panelists enjoyed them.

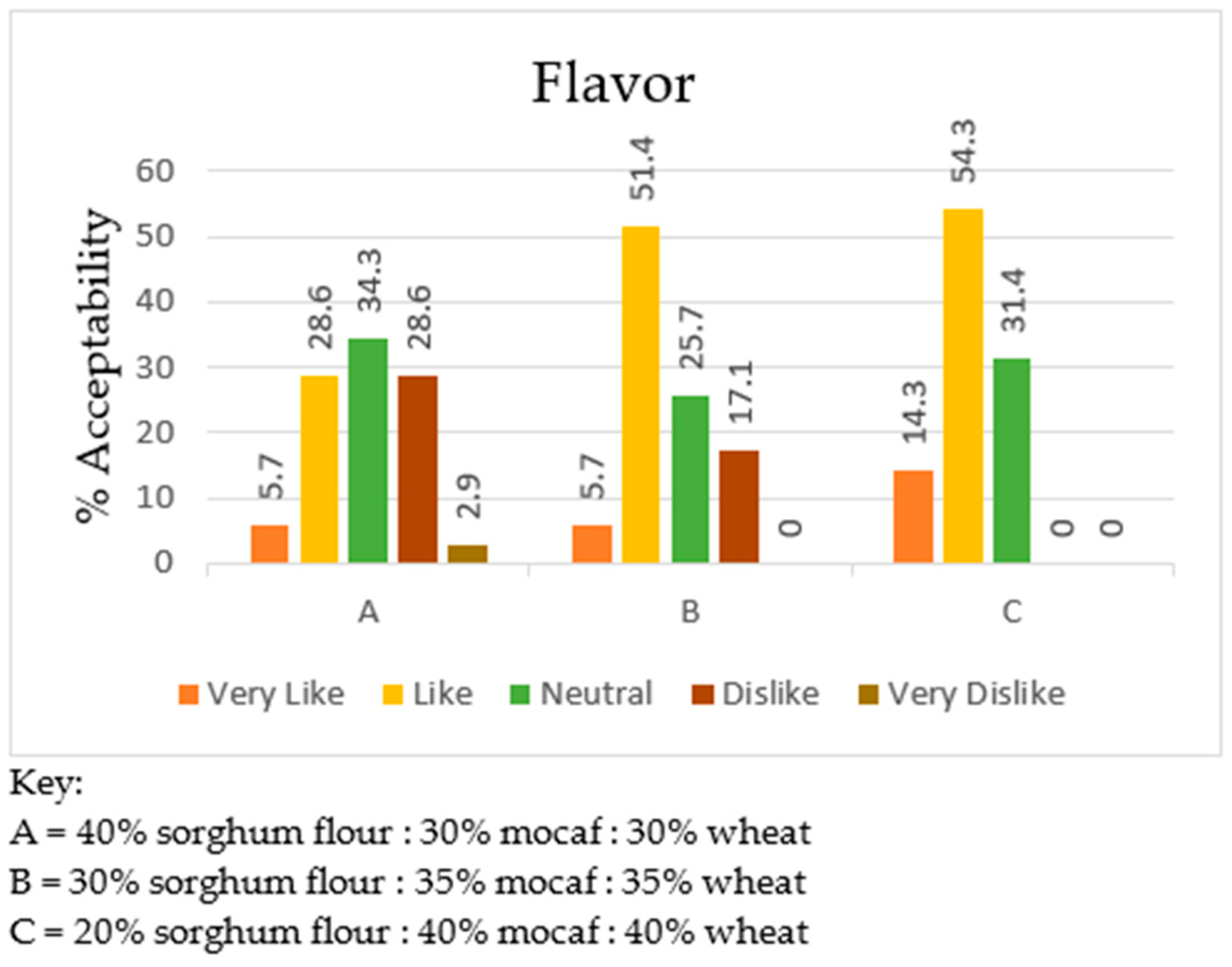

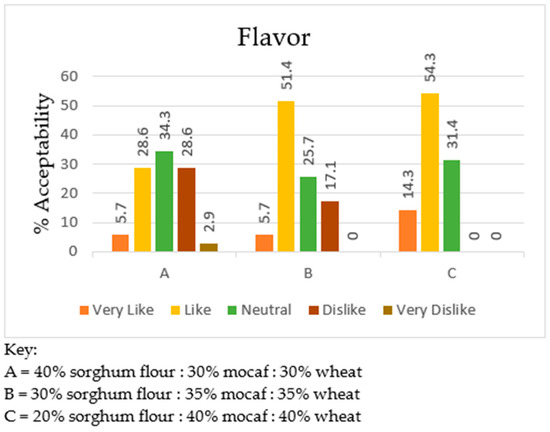

3.3.2. Flavor

Flavor can be assessed through the tongue as the sense of taste. The flavor acceptability test results of composite flour wet noodles can be seen in Figure 5.

Figure 5.

Flavor acceptance chart of composite flour wet noodles.

The level of the panelists’ preference for the flavor of wet noodles increased as the composition of sorghum flour decreased and the composition of wheat and mocaf increased. The flavor of wet noodles in the C treatment was most liked by the panelists (3.83), and the flavor of wet noodles in the A treatment was least liked by the panelists (3.06). The results of the Dunnett test showed that there was a significant difference in flavor in the A treatment. The flavor of wet noodles in the B treatment was not significantly different from the C treatment. Tannin is a phenolic compound found in sorghum flour. The tannin content in sorghum flour is 0.82–5.6%, which causes an astringent flavor in wet noodles [26]. The panelists did not like the astringent taste; therefore, the panelists’ preference for the flavor of wet noodles decreased as the composition of sorghum flour increased.

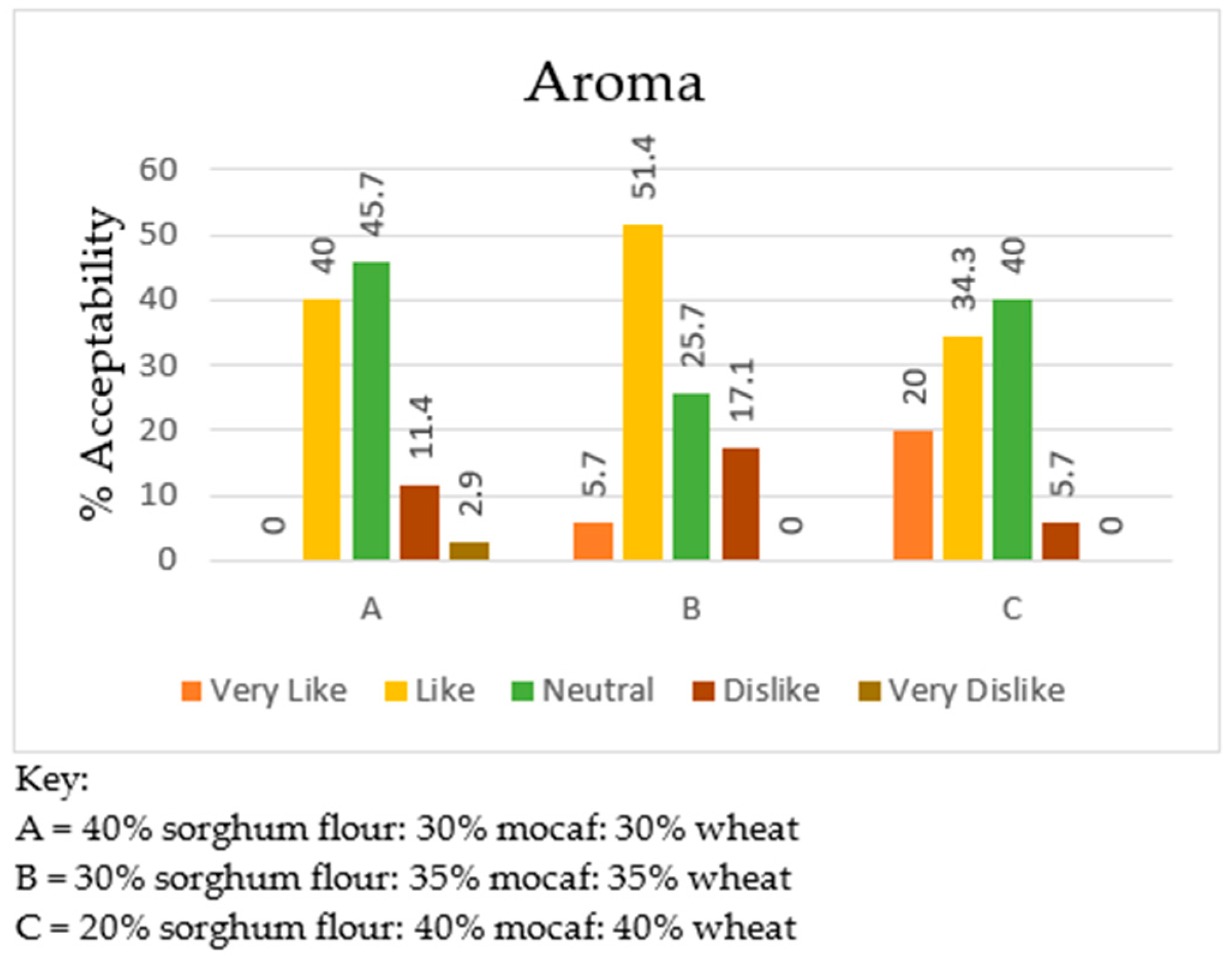

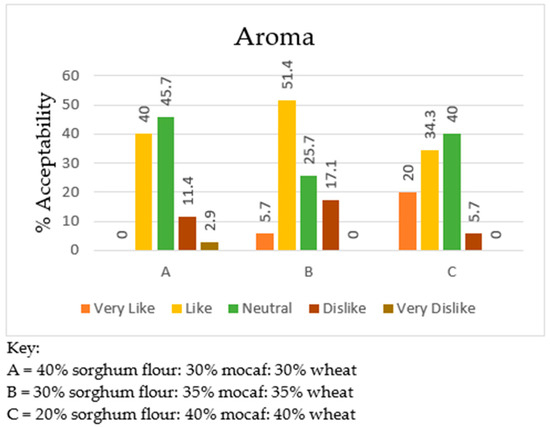

3.3.3. Aroma

Aroma can be assessed using the nose as a sense of smell. The aroma acceptability test results of composite flour wet noodles can be seen in Figure 6.

Figure 6.

Aroma acceptance chart of composite flour wet noodles.

The level of the panelists’ preference for the aroma of wet noodles increased as the composition of sorghum flour decreased and the composition of wheat and mocaf increased. The aroma of wet noodles in the C treatment was most liked by the panelists (3.69), and the aroma of wet noodles in the A treatment was least liked by the panelists (3.23). The results of the Kruskal–Wallis test showed that the composition ratio of composite flour had no significant effect on the aroma of wet noodles with a p-value of 0.132 (p > 0.05). The distinctive aroma of mocaf slightly resembles cassava, while sorghum has a characteristic aroma similar to damp wood [4,11]. An aroma similar to damp wood tended to be disliked by the panelists, so the level of the panelists’ preference for the aroma of wet noodles increased as the composition of sorghum flour decreased.

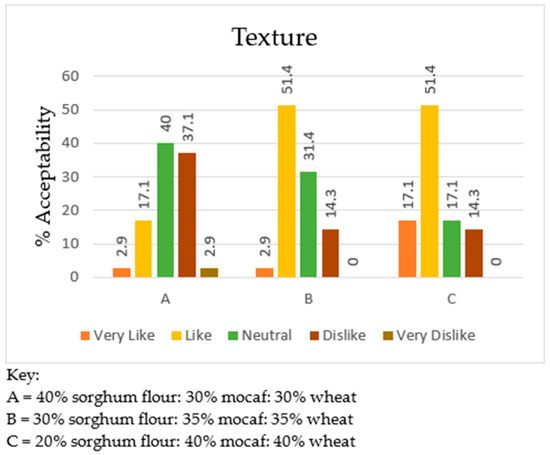

3.3.4. Texture

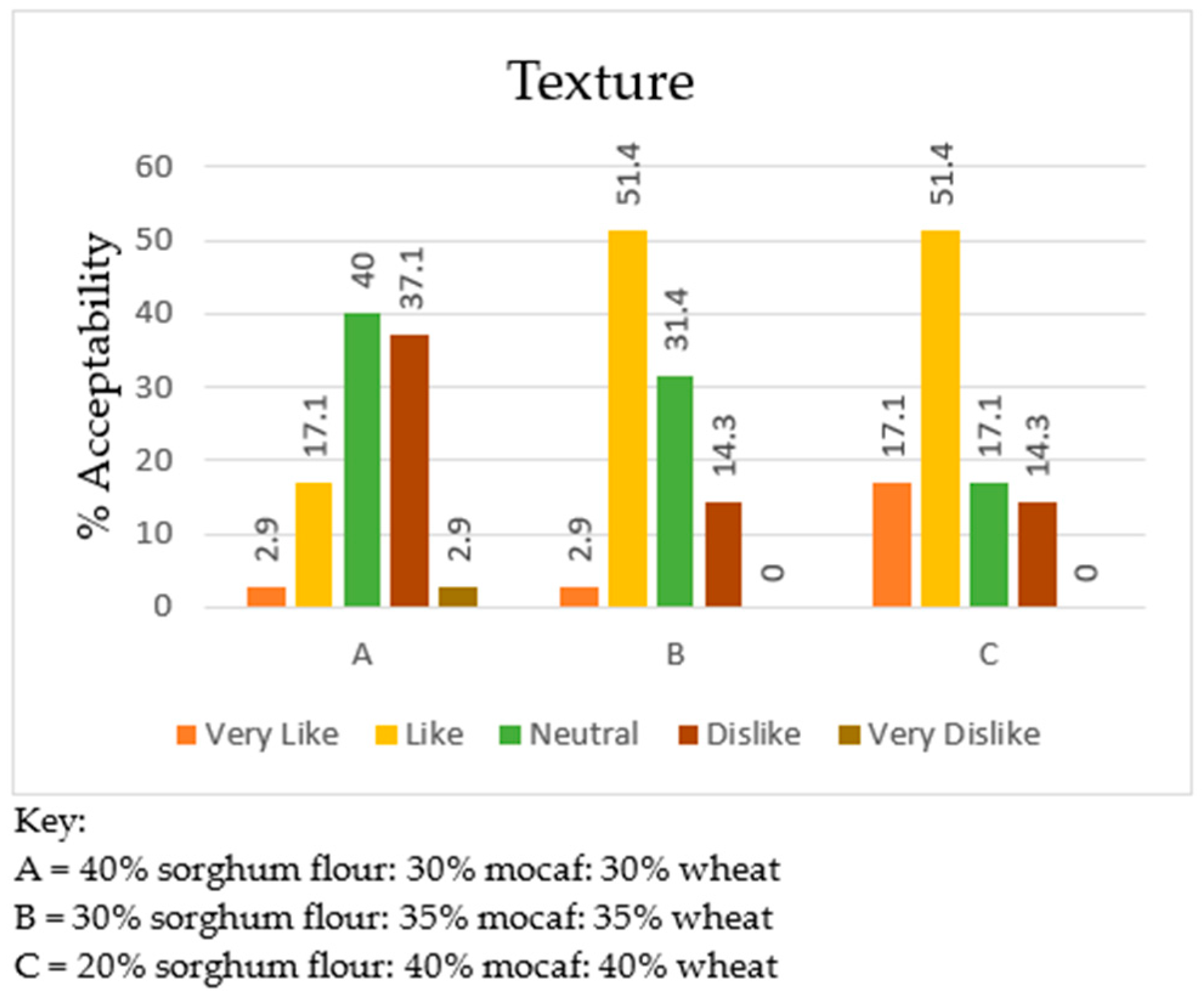

Texture can be assessed by touching, biting, and chewing. The texture acceptability test results of composite flour wet noodles can be seen in Figure 7.

Figure 7.

Texture acceptance chart of composite flour wet noodles.

The level of the panelists’ preference for the texture of wet noodles increased as the composition of sorghum flour decreased and the composition of wheat and mocaf increased. The texture of wet noodles in the C treatment was most liked by the panelists (3.71), and the texture of wet noodles in the A treatment was least liked by the panelists (2.80). The results of the Dunnett test showed that there was a significant difference in the texture in the A treatment. The texture of the wet noodles in the B treatment was not significantly different from those in the C treatment.

The panelists liked noodles with a chewy texture. The elasticity of noodles is influenced by gluten protein. Gluten compounds make the starch gel stronger and more resistant to tensile force because the bonds between starch granules are tighter [22]. Apart from gluten, amylose also affects the elasticity of noodles. Amylose can increase the durability of molecules in starch granules so that the dough becomes stronger [8].

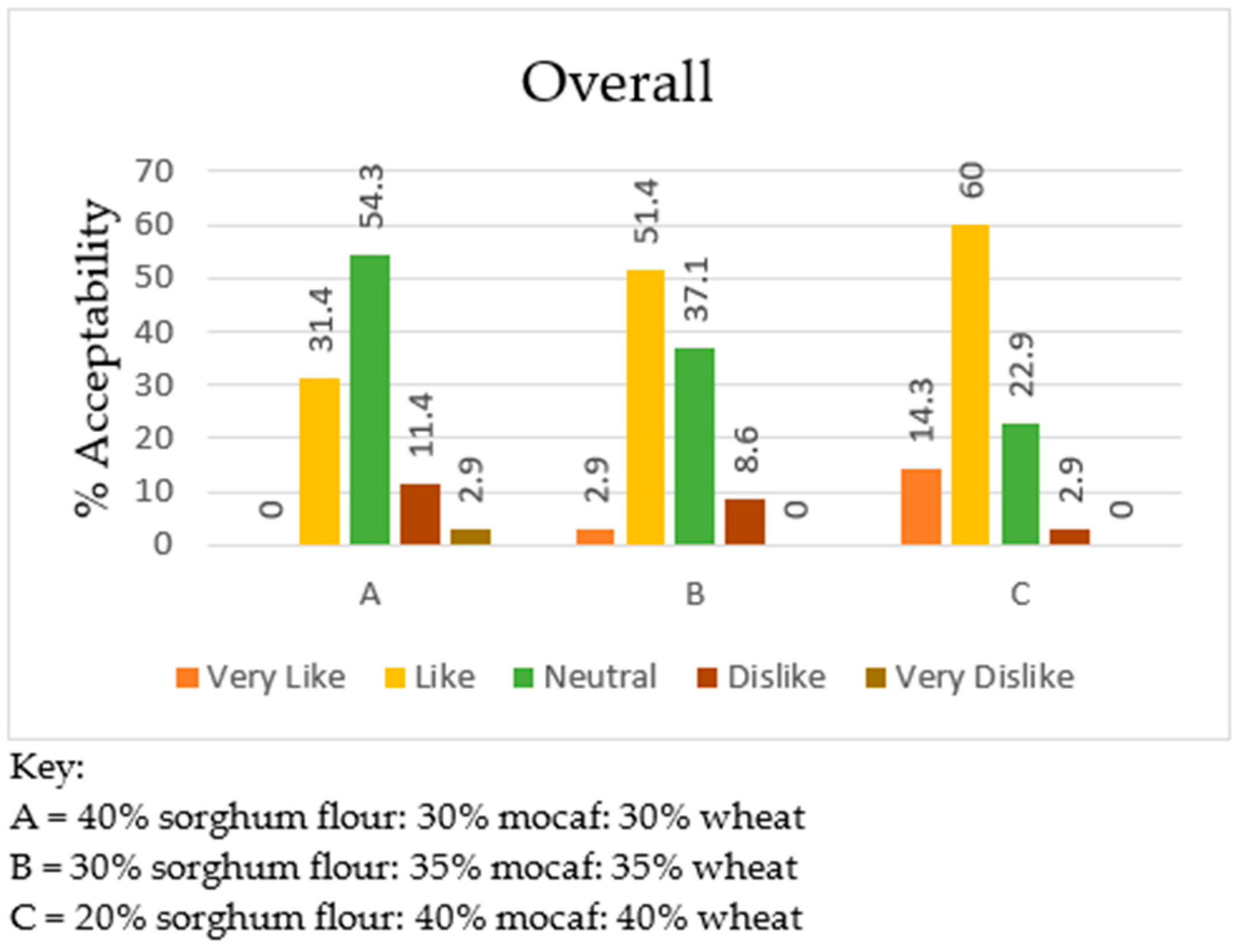

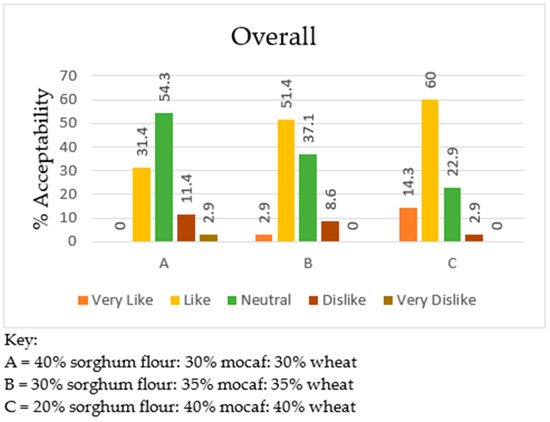

3.3.5. Overall Acceptability

The score given by the panelists for the overall acceptability describes the panelists’ overall level of preference for composite flour wet noodles. The overall acceptability test results of composite flour wet noodles can be seen in Figure 8.

Figure 8.

Overall acceptance chart of composite flour wet noodles.

The level of the panelists’ preference for wet noodles increased as the composition of sorghum flour decreased and the composition of wheat and mocaf increased. The wet noodles in the C treatment were most liked by the panelists based on overall acceptability (3.86), and the wet noodles in the A treatment were liked least by the panelists (3.14). The results of the Dunnett test showed that the overall preference for noodles in the A treatment was not significantly different from those in the B treatment but significantly different from those in the C treatment. The overall preference for noodles in the B treatment was not significantly different from those in the A treatment and the C treatment.

This research is in line with previous research, which stated that the more sorghum in the flour composition, the lower the panelists’ preference for noodles [13]. The panelists’ preferences for composite flour wet noodles were influenced by the color, flavor, aroma, and texture of the noodles.

4. Conclusions

The composite flour composition (sorghum, mocaf, and wheat) has a significant effect on the elongation, acceptability of color, flavor, texture, and overall preference of wet noodles but has no significant effect on tensile strength and aroma acceptability. The lower the composition of sorghum flour and the higher the composition of wheat and mocaf in wet noodles, the higher the elongation, tensile strength, and acceptability of wet noodles. The wet noodles in the C treatment were the most liked by the panelists and had the highest elongation and tensile strength scores. Therefore, it is hoped that noodle producers can produce noodles made from composite flour with a ratio of 20% sorghum flour: 40% mocaf: 40% wheat to help reduce the number of wheat imports in Indonesia.

Author Contributions

Conceptualization, D.A.P. and E.P.; methodology, D.A.P. and E.P.; software, D.A.P.; validation, D.A.P. and E.P.; formal analysis, D.A.P.; investigation, D.A.P.; resources, D.A.P.; data curation, D.A.P.; writing—original draft preparation, D.A.P.; writing—review and editing, D.A.P.; visualization, D.A.P.; supervision, D.A.P.; project administration, D.A.P.; funding acquisition, D.A.P. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

The Health Research Ethics Committee of RSUD Dr. Moewardi granted permission for this study with number 1.0506/VIII/HREC/2023.

Informed Consent Statement

Informed consent was obtained from all subjects involved in the study. Written informed consent has been obtained from the panelist(s) to publish this paper.

Data Availability Statement

Data are contained within the article.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Kurniawan, A.; Estiasih, T.; Nugrahini, N.I.P. Mie dari Umbi Garut (Maranta arundinacea L.): Kajian Pustaka. J. Pangan Dan Agroindustri 2015, 3, 847–854. [Google Scholar]

- Badan Ketahanan Pangan Kementrian Pertanian. Direktori Perkembangan Konsumsi Pangan; Badan Ketahanan Pangan: Jakarta, Indonesia, 2019; p. 79. [Google Scholar]

- Food and Agriculture Organization of the United Nations. Top 10 Country Importers, Import Quantity of Wheat. Available online: https://www.fao.org/faostat/en/#rankings/countries_by_commodity_imports (accessed on 9 June 2023).

- Triyono, B.; Handoyo, S.; Laili, N. Analysis for Development of Mocaf-Based Functional Food Industry in Indonesia. J. Socioecon. Dev. 2019, 2, 73–87. [Google Scholar] [CrossRef]

- Ramadhan, A.; Sari, E.R. Variasi PerbandinganTepung Terigu dan Mocaf (Modified cassava Flour) Dalam Pembuatan Mie Mocaf. AGRITEPA. 2015, 1, 211–219. [Google Scholar] [CrossRef]

- Rosmeri, V.I.; Monica, B.N. Pemanfaatan Tepung Umbi Gadung (Dioscorea hispida Dennst) dan Tepung Mocaf (Modified cassava Flour) Sebagai Bahan Substitusi dalam Pembuatan Mie Basah, Mie Kering, dan Mie Instan. J. Teknol. Kim. Dan Ind. 2013, 2, 246–256. Available online: https://ejournal3.undip.ac.id/index.php/jtki/article/view/2636 (accessed on 9 June 2023).

- Wanita, Y.P.; Wisnu, E. Pengaruh Cara Pembuatan Mocaf Terhadap Kandungan Amilosa dan Derajat Putih Tepung. In Proceeding Seminar Hasil Penelitian Tanaman Aneka Kacang dan Umbi; Pusat Penelitian dan Pengembangan Tanaman Pangan Badan Penelitian dan Pengembangan Pertanian: Bogor, Indonesia, 2013; pp. 588–596. [Google Scholar]

- Rahim, V.S.; Liputo, S.A.; Maspeke, P.N.S. Sifat Fisikokimia dan Organoleptik Mie Basah dengan Substitusi Tepung Ketan Hitam Termodifikasi Heat Moisture Treatment (HMT). Jambura J. Food Technol. 2021, 3, 42–56. [Google Scholar] [CrossRef]

- Putri, R.M.; Kurnia, P. Pemanfaatan MOCAF (Modified cassava Flour) dengan Sagu (Metroxylon sago Rottb) Terhadap Sifat Elongasi dan Daya Terima Mie Basah. In Proceedings of the 6th University Research Colloquium, Magelang, Indonesia, 9 September 2017; pp. 241–248. [Google Scholar]

- Mustika, A.; Wahyuningsih; Paramita, O. Pengaruh Teknik Perendaman pada Pembuatan Tepung Sorgum Merah (Bicolor L.) Ditinjau dari Kualitas Butter Cookies. Teknobuga 2019, 7, 22–30. [Google Scholar]

- Setyanti, F.; Pranata, F.S.; Purwijantiningsih, L.M.E. Kualitas Muffin Dengan Kombinasi Tepung Sorgum (Sorghum bicolor) dan Tepung Terigu (Triticum aestivum). Undergraduate Thesis, Universitas Atma Jaya Yogyakarta, Yogyakarta, Indonesia, 2015. [Google Scholar]

- Akajiaku, L.O.; Nwosu, J.N.; Kabuo, N.O.; Odimegwu, E.N.; Umelo, M.C.; Unegbu, V.C. Using Sorghum Flour as Part Substitute of Wheat Flour in Noodles Making. MOJ Food Process. Technol. 2017, 5, 250–257. [Google Scholar] [CrossRef][Green Version]

- Fitriani, R.J.; Rauf, R.; Purwani, E. Substitusi Tepung Sorgum Terhadap Elongasi dan Daya Terima Mie Basah dengan Volume Air yang Proporsional. Undergraduate Thesis, Universitas Muhammadiyah Surakarta, Surakarta, Indonesia, 2016. [Google Scholar]

- Obadi, M.; Xu, B. Review on the physicochemical properties, modifications, and applications of starches and its common modified forms used in noodle products. Food Hydrocoll. 2021, 112, 1–25. [Google Scholar] [CrossRef]

- Murdiati, A.; Anggrahini, S.; Supriyanto; Alim, A. Peningkatan Kandungan Protein Mie Basah Dari Tapioka dengan Substitusi Tepung Koro Pedang Putih (Canavalia ensiformis L.). Agritech 2015, 35, 251–260. [Google Scholar] [CrossRef]

- Rosalina, L.; Suyanto, A.; Yusuf, M. Kadar Protein, Elastisitas, dan Mutu Hedonik Mie Basah dengan Substitusi Tepung Ganyong. J. Pangan Dan Gizi 2018, 8, 1–10. [Google Scholar]

- Suryono, C.; Ningrum, L.; Dewi, T.R. Uji Kesukaan dan Organoleptik Terhadap 5 Kemasan Dan Produk Kepulauan Seribu Secara Deskriptif. J. Pariwisata 2018, 5, 95–106. [Google Scholar] [CrossRef]

- Darmawan, M.R.; Andreas, P.; Jos, B.; Sumardiono, S. Modifikasi Ubi Kayu Dengan Proses Fermentasi Menggunakan Starter Lactobacillus casei Untuk Produk Pangan. J. Teknol. Kim. Dan Ind. 2013, 2, 137–145. [Google Scholar]

- Biesiekierski, J.R. What is gluten? J. Gastroenterol. Hepatol. 2017, 32, 78–81. [Google Scholar] [CrossRef] [PubMed]

- Ee, K.Y.; Eng, M.K.; Lee, M.L. Physicochemical, Thermal, and Rheological Properties of Commercial Wheat Flours and Corresponding Starches. Food Sci. Technol. 2020, 40, 51–59. [Google Scholar] [CrossRef]

- Prabawa, S.; Zoelnanda, A.; Anam, C. Evaluasi Kualitas Sensoris dan Fisikokimia Mi Basah Sorgum (Sorghum bicolor L. Moench) Sebagai Pangan Fungsional. J. Teknol. Has. Pertan. 2023, 16, 13–28. [Google Scholar] [CrossRef]

- Umri, A.W.; Wikanastri, H. Kadar Protein, Tensile Strength, dan Sifat Organoleptik Mie Basah dengan Substitusi Tepung Mocaf. J. Pangan Dan Gizi 2017, 7, 38–47. [Google Scholar]

- Putra, J.G.; Estiasih, T. Mie dari Umbi Kimpul (Xanthosoma sagittifolium): Kajian Pustaka. J. Pangan Dan Agroindustri 2014, 2, 127–134. [Google Scholar]

- Avif, A.N.; Oktaviana, A. Analisis Sifat Kimia Tepung dan Pati Sorgum dari Varietas Bioguma dan Lokal di Provinsi Nusa Tenggara Timur, Indonesia. Lantanida J. 2020, 8, 96–188. [Google Scholar] [CrossRef]

- Irsalina, R.; Lestari, S.D.; Herpandi, H. Karakteristik Fisiko-Kimia dan Sensori Mie Kering dengan Penambahan Tepung Ikan Motan (Thynnichthys thynnoides). J. FishtecH 2016, 5, 32–42. [Google Scholar] [CrossRef]

- Suarni, S. Peranan Sifat Fisikokimia Sorgum dalam Diversifikasi Pangan dan Industri serta Prospek Pengembangannya. J. Penelit. Pengemb. Pertan. 2016, 35, 99. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).