Optimization of Process Parameters of Aluminium 7075/TiCnp MMC Fabricated Using Powder Metallurgy Route †

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Composite Fabrication

2.3. Testing of Al7075Fortified Nanocomposites

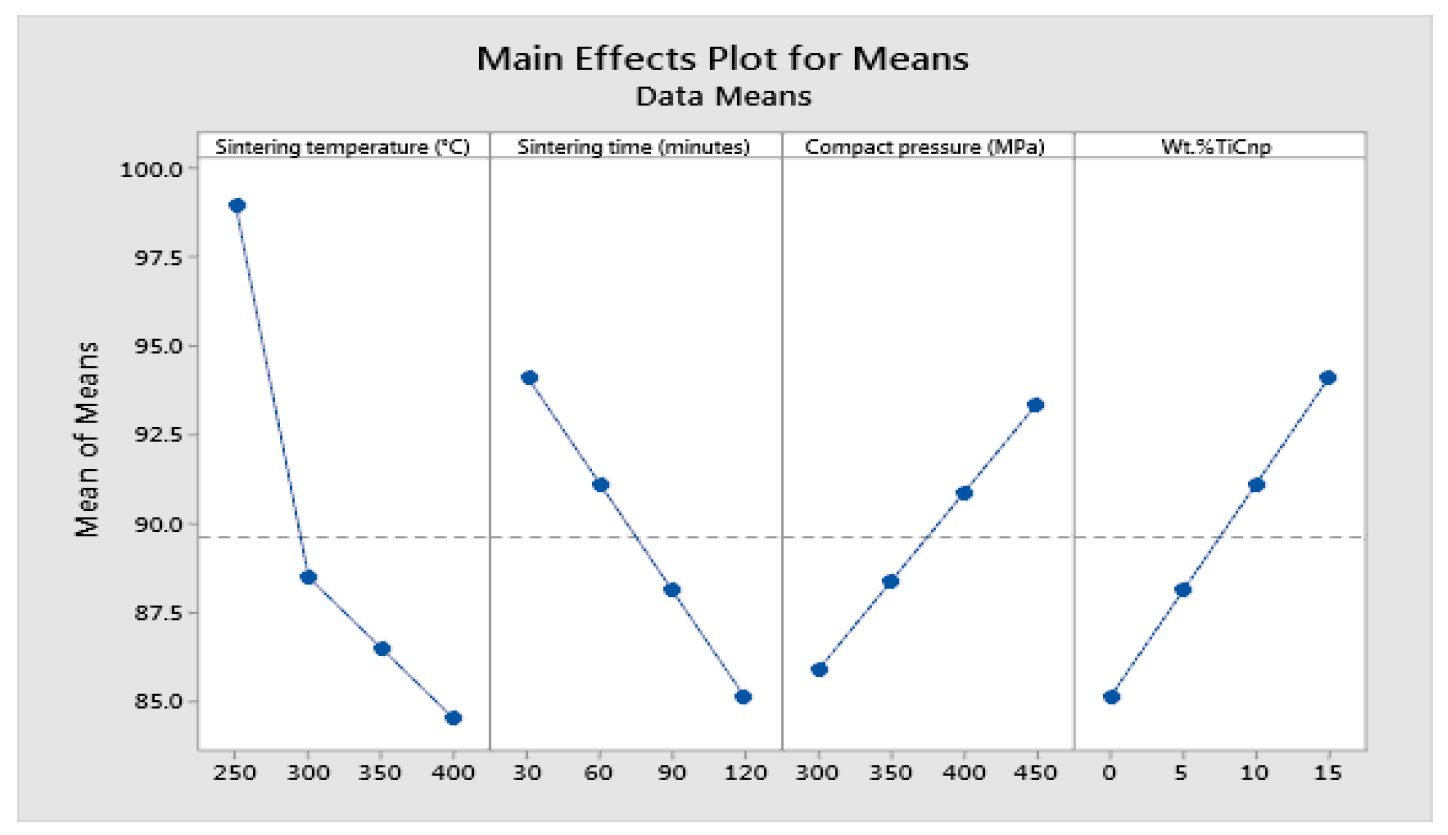

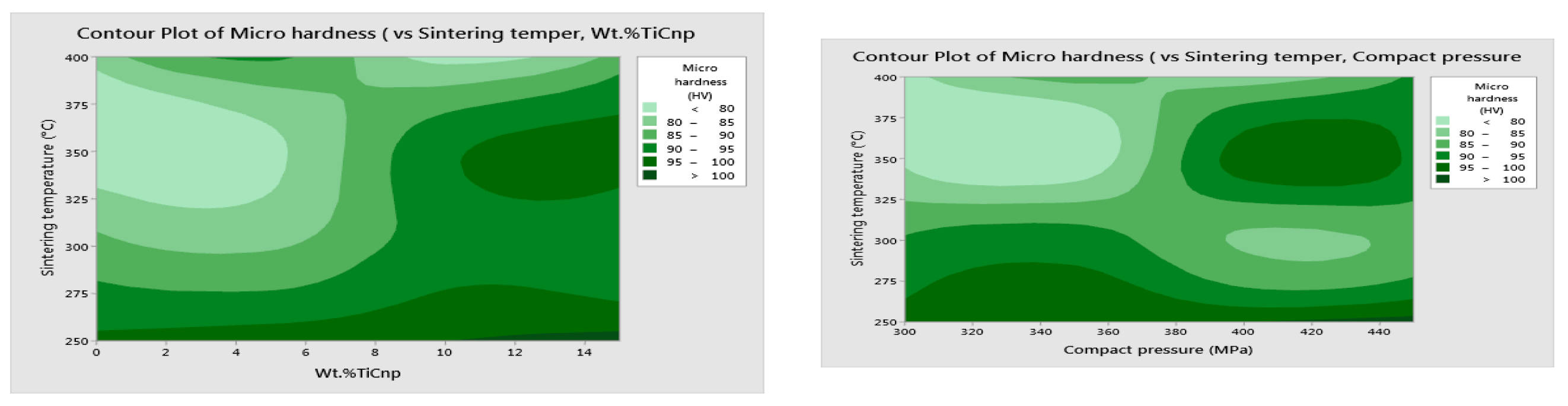

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Pranavi, U.; Venkateshwar Reddy, P.; Venukumar, S.; Cheepu, M. Evaluation of Mechanical and Wear Properties of Al 5059/B4C/Al2O3 Hybrid Metal Matrix Composites. J. Compos. Sci. 2022, 6, 86. [Google Scholar] [CrossRef]

- Srivastava, A.K.; Dixit, A.R.; Tiwari, S. Investigation of micro-structural and mechanical properties of metal matrix composite A359/B4C through electromagnetic stir casting. Indian J. Eng. Mater. Sci. 2016, 23, 171–180. [Google Scholar]

- Ujah, C.O.; Kallon, D.V.V. Trends in Aluminium Matrix Composite Development. Crystals 2022, 12, 1357. [Google Scholar] [CrossRef]

- Raju, P.; Arunnadevi, M.; Sandhya, P.; Krishnan, R.; Manikandan, R. Fabrication and Analysis of Aluminium based Metal Matrix Composites Reinforced with Aluminium Oxide. In Proceedings of the National Level Conference on Emerging Trends in Engineering Design & Manufacturing, Coimbatore, India, 22 March 2019. [Google Scholar]

- Lakshmikanthan, A.; Angadi, S.; Malik, V.; Saxena, K.K.; Prakash, C.; Dixit, S.; Mohammed, K.A. Mechanical and Tribological Properties of Aluminum-Based Metal-Matrix Composites. Materials 2022, 15, 6111. [Google Scholar] [CrossRef] [PubMed]

- Mazahery, A.; Shabani, M.O. Influence of the hard coated B4C particulates on wear resistance of Al–Cu alloys. Compos. Part B Eng. 2012, 43, 1302–1308. [Google Scholar] [CrossRef]

- Hassanabadi, H.M.; Rodrigue, D. Effect of Particle Size and Shape on the Reinforcing Efficiency of Nanoparticles in Polymer Nanocomposites. Macromol. Mater. Eng. 2014, 299, 1220–1231. [Google Scholar] [CrossRef]

- Yan, S.; Wang, K.; Wang, Z. A Comparative Study on the Microscale and Macroscale Mechanical Properties of Dental Resin Composites. Polymers 2023, 15, 1129. [Google Scholar] [CrossRef] [PubMed]

- Casati, R.; Vedani, M. Metal Matrix Composites Reinforced by Nano-Particles—A Review. Metals 2014, 4, 65–83. [Google Scholar] [CrossRef]

- Arora, G.S.; Saxena, K.K.; Mohammed, K.A.; Prakash, C.; Dixit, S. Manufacturing Techniques for Mg-Based Metal Matrix Composite with Different Reinforcements. Crystals 2022, 12, 945. [Google Scholar] [CrossRef]

- Aynalem, G.F. Processing Methods and Mechanical Properties of Aluminium Matrix Composites. Adv. Mater. Sci. Eng. 2020, 2020, 3765791. [Google Scholar] [CrossRef]

- Manohar, G.; Dey, A.; Pandey, K.M.; Maity, S.R. Fabrication of metal matrix composites by powder metallurgy: A review. AIP Conf. Proc. 2018, 1952, 020041. [Google Scholar] [CrossRef]

- Bedolla-Becerril, E.; Garcia-Guerra, J.; Lopez-Morelos, V.H.; Garcia-Renteria, M.A.; Falcon-Franco, L.A.; Martinez-Landeros, V.H.; García-Villarreal, S.; Flores-Villaseñor, S.E. Tribological Behaviour of Al-2024/TiC Metal Matrix Composites. Coatings 2023, 13, 77. [Google Scholar] [CrossRef]

- Rao, V.R.; Ramanaiah, N.; Sarcar, M.M. Tribological properties of Aluminium Metal Matrix Composites (AA7075 Reinforced with Titanium Carbide (TiC) Particles). Int. J. Adv. Sci. Technol. 2016, 88, 13–26. [Google Scholar] [CrossRef]

- Kumar, N.; Sharma, A.; Manoj, M.K.; Ahn, B. Taguchi optimization of tribological properties and corrosion behavior of self-lubricating Al–Mg–Si/MoS2 composite processed by powder metallurgy. J. Mater. Res. Technol. 2023, 26, 1185–1197. [Google Scholar] [CrossRef]

- Srinivas, P.N.; Rao, P.S.; Ramakrishna, P.; Reddy, D.R. Experimental investigation and optimization of multi layered aluminium based functionally graded material reinforced with silicon carbide, nickel and Zinc sterate through powder metallurgical process. Mater. Today Proc. 2022, 68, 2016–2025. [Google Scholar] [CrossRef]

- Naseri, J.; Ranjbar, K.; Reihanian, M. Optimizing the strength and electrical conductivity of graphene reinforced Cu–Cr–Zr alloy fabricated by powder metallurgy and spark plasma sintering. Mater. Chem. Phys. 2023, 300, 127524. [Google Scholar] [CrossRef]

- Cai, Z.; Cheng, X.; Chen, J.; Xiang, T.; Xie, G. Optimized mechanical properties of titanium-oxygen alloys by powder metallurgy. J. Mater. Res. Technol. 2022, 21, 4151–4163. [Google Scholar] [CrossRef]

- Wyatt, B.C.; Nemani, S.K.; Anasori, B. 2D transition metal carbides (MXenes) in metal and ceramic matrix composites. Nano Converg. 2021, 8, 16. [Google Scholar] [CrossRef] [PubMed]

- Binh, D.T.; Huy, T.D.; Thuong, T.V.; Binh, D.N.; Miyamoto, H. Fabrication, Microstructure, and Microhardness at High Temperature of In Situ Synthesized Ti3Al/Al2O3 Composites. Metals 2021, 11, 617. [Google Scholar] [CrossRef]

| Elements | Cr | Si | Mg | Zn | Cu | Ti | Fe | Mn | Al |

|---|---|---|---|---|---|---|---|---|---|

| wt.% | 0.21 | 0.07 | 2.3 | 5.7 | 1.4 | 0.06 | 0.23 | 0.05 | Bal. |

| Property | Tensile Strength | Melting Point | Density | Modulus of Elasticity (GPa) |

|---|---|---|---|---|

| Al7075 | 259 MPa | 570 °C | 2.81 g/cm3 | 187 |

| TiC | 335 MPa | 3150 °C | 4.94 g/cm3 | 412 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rajendran, A.R.; Dhanaraj, A.P.; Sadhasivam, J.K.; Mani, A.; Qureshi, M.A. Optimization of Process Parameters of Aluminium 7075/TiCnp MMC Fabricated Using Powder Metallurgy Route. Eng. Proc. 2024, 61, 49. https://doi.org/10.3390/engproc2024061049

Rajendran AR, Dhanaraj AP, Sadhasivam JK, Mani A, Qureshi MA. Optimization of Process Parameters of Aluminium 7075/TiCnp MMC Fabricated Using Powder Metallurgy Route. Engineering Proceedings. 2024; 61(1):49. https://doi.org/10.3390/engproc2024061049

Chicago/Turabian StyleRajendran, Ashok Raj, Antony Prabu Dhanaraj, Jayakumar Kandhasamy Sadhasivam, Ananthakumar Mani, and Mohd Aamir Qureshi. 2024. "Optimization of Process Parameters of Aluminium 7075/TiCnp MMC Fabricated Using Powder Metallurgy Route" Engineering Proceedings 61, no. 1: 49. https://doi.org/10.3390/engproc2024061049

APA StyleRajendran, A. R., Dhanaraj, A. P., Sadhasivam, J. K., Mani, A., & Qureshi, M. A. (2024). Optimization of Process Parameters of Aluminium 7075/TiCnp MMC Fabricated Using Powder Metallurgy Route. Engineering Proceedings, 61(1), 49. https://doi.org/10.3390/engproc2024061049