Mechanical, Moisture Absorption and Thermal Stability of Banana Fiber/Egg Shell Powder-Based Epoxy Composites †

Abstract

1. Introduction

- Material Characterization: It aids in comprehending the composite material’s basic characteristics. These characteristics can have a big impact on how well and how long a material lasts in various applications.

- Performance Assessment: The composite’s ability to transport heat is evaluated using thermal conductivity measurements. This is essential in areas where temperature control is important, such as the automotive, aerospace, or building sectors. Designing materials that absorb or release heat depending on the situation might benefit from understanding thermal conductivity.

- Moisture Management: Materials that will be exposed to humidity or moisture must exhibit certain behaviors when it comes to absorbing moisture. It may affect the material’s overall performance, dimensional stability, and mechanical qualities. Controlling moisture absorption is crucial for durability in applications such as outdoor construction, maritime, or transportation.

- Quality Control: Manufacturers can develop quality control criteria to guarantee consistent and dependable material performance by measuring these attributes. This is crucial in businesses where dependable products are essential.

- Design Optimizations: Engineers and designers may optimize the composite material for particular applications by understanding heat conductivity and moisture retention behavior. They can modify the material’s structure and composition to match the needs of a certain environment or use case.

2. Experimental Works

2.1. Materials

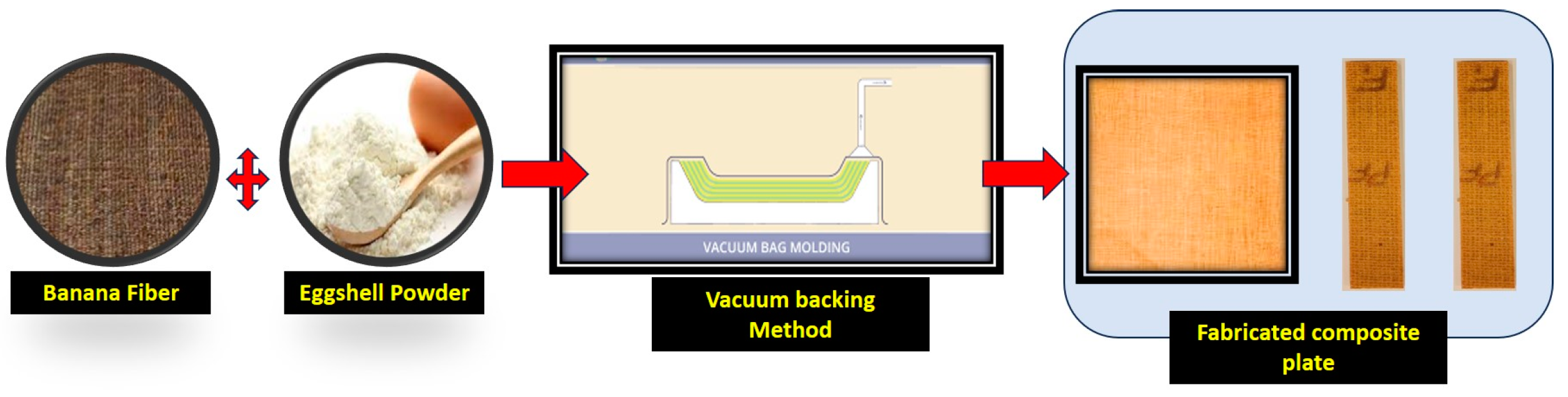

2.2. Composite Fabrication

2.3. Material Characterization

3. Results and Discussion

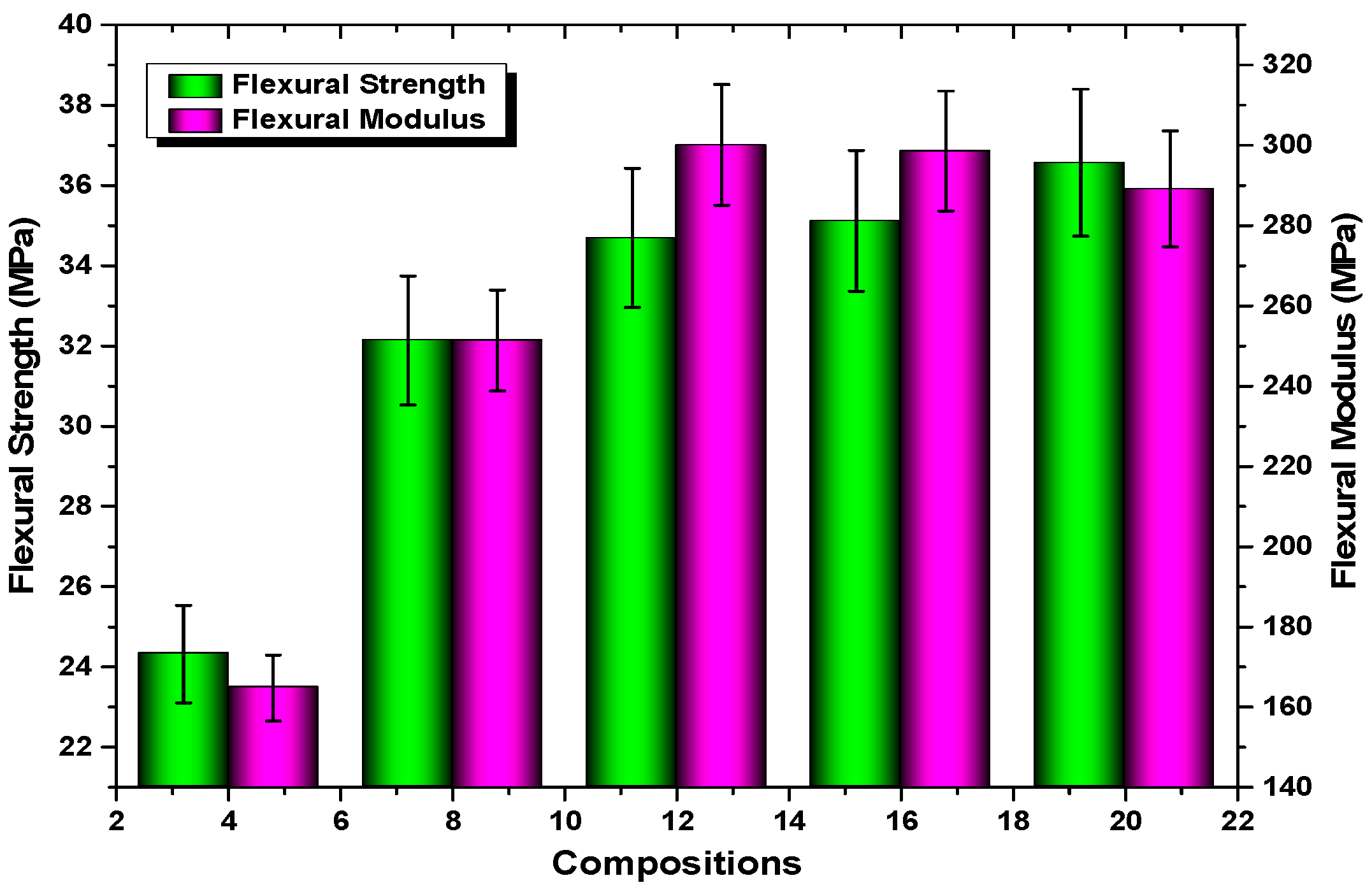

3.1. Flexural Strength

3.2. Thermal Conductivity

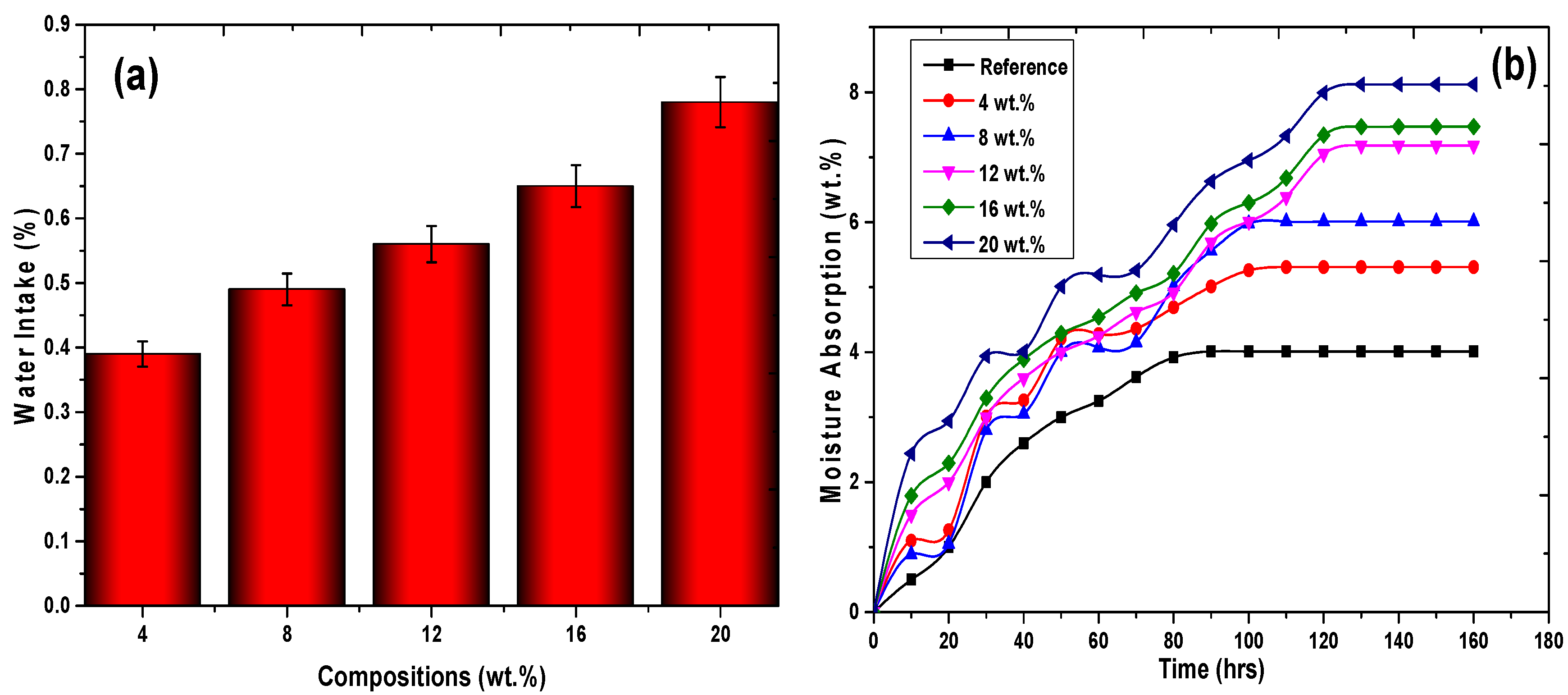

3.3. Moisture Absorption

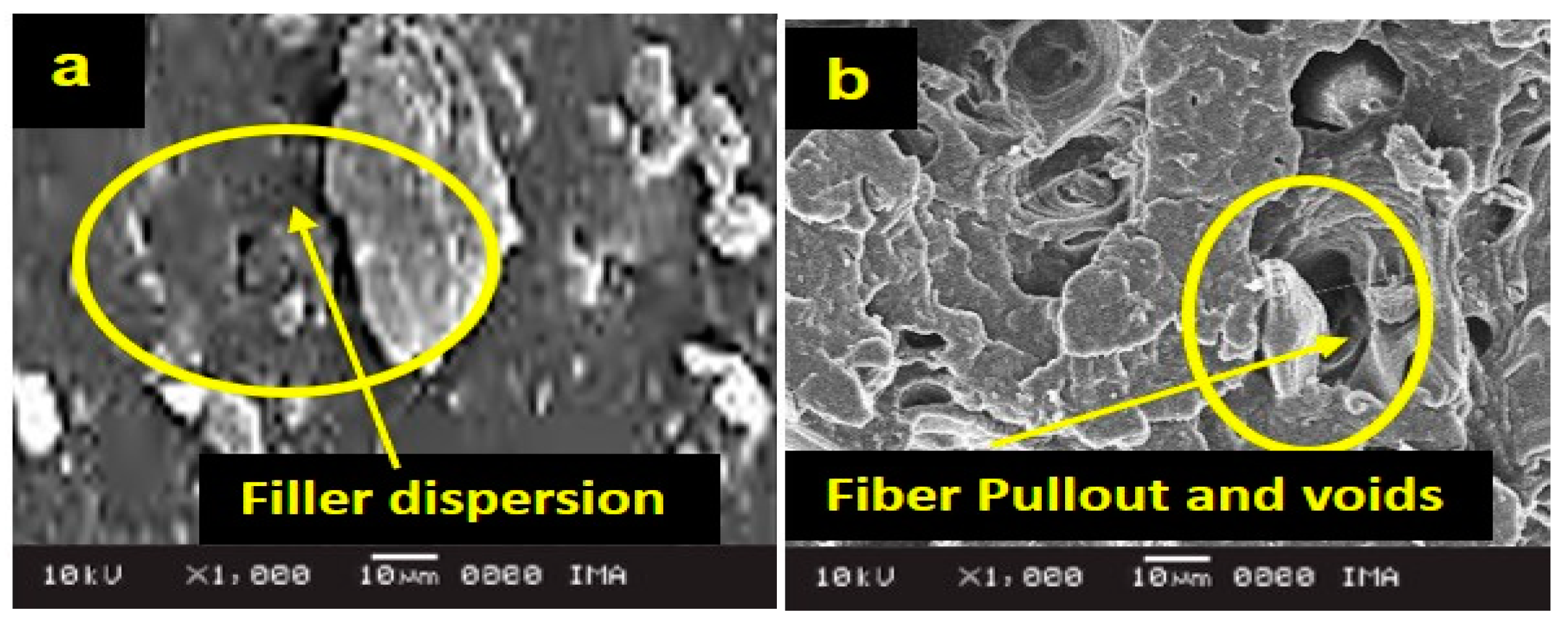

3.4. Microstructural Examination

4. Conclusions

- Mechanically, adding eggshell powder to the composite has shown promise, improving the materials’ flexural strength (36.57 MPa) and their modulus (300.12 MPa). This shows that these composites may be exploited as structural elements in a variety of sectors, utilizing the beneficial interactions between banana fibers and eggshell granules.

- The study found that when the concentration of CEP filler increased, along with natural banana fiber, it exhibited good thermal and increased water uptake properties. Because poor thermal conductivity suggests strong insulation and low water absorption indicates resistance to water retention, samples with 4% weight of CEP-TBF performed best in terms of insulation and water resistance.

5. Potential Applications of Present Research

- Insulation Materials: The 4% weight of CEP-TBF in the composite material, which shows strong thermal insulation capabilities, can be used in the building sector. Buildings can use it as insulation to increase energy efficiency and lessen heat transmission.

- Moisture-Resistant Components: The composite is appropriate for applications where moisture resistance is essential due to its resistance to water retention, particularly at greater weight fractions. It might be used, for instance, in outdoor furniture, marine parts, or any other application exposed to moist or humid situations.

- Structural Components: These composites may be employed as structural components in a variety of sectors, including automotive, aerospace, and construction, based on the reported improvement in flexural properties at weight fractions between 8 and 20%. They can offer both strength and durability.

- Packaging: In packing applications, composite products that withstand moisture can be employed, notably for goods that must stay dry throughout travel and storage. Food packaging, medical wrapping, and electronic containers are some examples of this.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- ArunRamnath, R.; Murugan, S.; Sanjay, M.R.; Vinod, A.; Indran, S.; Elnaggar, A.Y.; Fallatah, A.M.; Siengchin, S. Characterization of Novel Natural Cellulosic Fibers from Abutilon Indicum for Potential Reinforcement in Polymer Composites. Polym. Compos. 2023, 44, 340–355. [Google Scholar] [CrossRef]

- Hamou, K.B.; Kaddami, H.; Elisabete, F.; Erchiqui, F. Synergistic Association of Wood/Hemp Fibers Reinforcements on Mechanical, Physical and Thermal Properties of Polypropylene-Based Hybrid Composites. Ind. Crops Prod. 2023, 192, 116052. [Google Scholar] [CrossRef]

- Joshi, A.G.; Bharath, K.N.; Basavarajappa, S. Recent Progress in the Research on Natural Composite Brake Pads: A Comprehensive Review. Tribol.-Mater. Surf. Interfaces 2023, 17, 237–259. [Google Scholar] [CrossRef]

- Arpitha, G.R.; Jain, N.; Verma, A. Banana Biofiber and Glass Fiber Reinforced Hybrid Composite for Lightweight Structural Applications: Mechanical, Thermal, and Microstructural Characterization. Biomass Convers. Biorefinery 2023. [Google Scholar] [CrossRef]

- Mohammed, M.; Rahman, R.; Mohammed, A.M.; Adam, T.; Betar, B.O.; Osman, A.F.; Dahham, O.S. Surface Treatment to Improve Water Repellence and Compatibility of Natural Fiber with Polymer Matrix: Recent Advancement. Polym. Test. 2022, 115. [Google Scholar] [CrossRef]

- Kavitha, S.A.; Priya, R.K.; Arunachalam, K.P.; Avudaiappan, S.; Maureira-Carsalade, N.; Roco-Videla, Á. Investigation on Properties of Raw and Alkali Treated Novel Cellulosic Root Fibres of Zea Mays for Polymeric Composites. Polymers 2023, 15, 1802. [Google Scholar] [CrossRef]

- Bollino, F.; Giannella, V.; Armentani, E.; Sepe, R. Mechanical Behavior of Chemically-Treated Hemp Fibers Reinforced Composites Subjected to Moisture Absorption. J. Mater. Res. Technol. 2023, 22, 762–775. [Google Scholar] [CrossRef]

- Zhang, Z.; Li, B.; Wang, Z.; Liu, W.; Liu, X. Development of Reduced Thermal Conductivity Ductile Cement-Based Composite Material by Using Silica Aerogel and Silane. J. Build. Eng. 2023, 65, 105698. [Google Scholar] [CrossRef]

- Felix Sahayaraj, A.; Muthukrishnan, M.; Ramesh, M. Experimental Investigation on Physical, Mechanical, and Thermal Properties of Jute and Hemp Fibers Reinforced Hybrid Polylactic Acid Composites. Polym. Compos. 2022, 43, 2854–2863. [Google Scholar] [CrossRef]

- Ganesan, V.; Shanmugam, V.; Alagumalai, V. Composites Part C: Open Access Optimisation of Mechanical Behaviour of Calotropis Gigantea and Prosopis Juliflora Natural Fibre-Based Hybrid Composites by Using Taguchi-Grey Relational Analysis. Compos. Part C Open Access 2024, 13, 100433. [Google Scholar] [CrossRef]

- Velmurugan, G.; Natrayan, L. Experimental Investigations of Moisture Diffusion and Mechanical Properties of Interply Rearrangement of Glass/Kevlar-Based Hybrid Composites under Cryogenic Environment. J. Mater. Res. Technol. 2023, 23, 4513–4526. [Google Scholar] [CrossRef]

- Latha, A.D.; Kumar, A.S.; Singh, S.J.; Velmurugan, C. Experimental Investigations of Flammability, Mechanical and Moisture Absorption Properties of Natural Flax/NanoSiO2 Based Hybrid Polypropylene Composites. Silicon 2023. [Google Scholar] [CrossRef]

- Velmurugan, G.; Kumar, S.S.; Chohan, J.S.; Kumar, A.J.P.; Manikandan, T.; Raja, D.E.; Saranya, K.; Nagaraj, M.; Barmavatu, P. Experimental Investigations of Mechanical and Dynamic Mechanical Analysis of Bio-Synthesized CuO/Ramie Fiber-Based Hybrid Biocomposite. Fibers Polym. 2023. [Google Scholar] [CrossRef]

- Mohammad, H.; Stepashkin, A.A.; Tcherdyntsev, V. V Effect of Graphite Filler Type on the Thermal Conductivity and Mechanical Behavior of Polysulfone-Based Composites. Polymers 2022, 14, 399. [Google Scholar] [CrossRef]

- Alshahrani, H.; Prakash, V.R.A. Effect of Silane-Grafted Orange Peel Biochar and Areca Fibre on Mechanical, Thermal Conductivity and Dielectric Properties of Epoxy Resin Composites. Biomass Convers. Biorefinery 2022. [Google Scholar] [CrossRef]

- Balaji, A.; Kannan, S.; Purushothaman, R.; Mohanakannan, S.; Maideen, A.H.; Swaminathan, J.; Karthikeyan, B.; Premkumar, P. Banana Fiber and Particle-Reinforced Epoxy Biocomposites: Mechanical, Water Absorption, and Thermal Properties Investigation. Biomass Convers. Biorefinery 2022. [Google Scholar] [CrossRef]

- Sun, Y.; Zheng, Z.; Wang, Y.; Yang, B.; Wang, J.; Mu, W. PLA Composites Reinforced with Rice Residues or Glass Fiber—a Review of Mechanical Properties, Thermal Properties, and Biodegradation Properties. J. Polym. Res. 2022, 29, 422. [Google Scholar] [CrossRef]

- Samaei, S.E.; Mahabadi, H.A.; Mousavi, S.M.; Khavanin, A.; Faridan, M.; Taban, E. The Influence of Alkaline Treatment on Acoustical, Morphological, Tensile and Thermal Properties of Kenaf Natural Fibers. J. Ind. Text. 2022, 51, 8601S–8625S. [Google Scholar] [CrossRef]

- Sekar, S.; Suresh Kumar, S.; Vigneshwaran, S.; Velmurugan, G. Evaluation of Mechanical and Water Absorption Behavior of Natural Fiber-Reinforced Hybrid Biocomposites. J. Nat. Fibers 2022, 19, 1772–1782. [Google Scholar] [CrossRef]

- Arivendan, A.; Thangiah, W.J.J.; Ramakrishnan, S.; Desai, D.A. Biological Waste Water Hyacinth (Eichhornia Crassipes) Plant Powder Particle with Eggshell Filler-Reinforced Epoxy Polymer Composite Material Property Analysis. J. Bionic Eng. 2023, 20, 1386–1399. [Google Scholar] [CrossRef]

- Pokhriyal, M.; Rakesh, P.K.; Rangappa, S.M.; Siengchin, S. Effect of Alkali Treatment on Novel Natural Fiber Extracted from Himalayacalamus Falconeri Culms for Polymer Composite Applications. Biomass Convers. Biorefinery 2023. [Google Scholar] [CrossRef]

- Ganesan, V.; Kaliyamoorthy, B. Utilization of Taguchi Technique to Enhance the Interlaminar Shear Strength of Wood Dust Filled Woven Jute Fiber Reinforced Polyester Composites in Cryogenic Environment. J. Nat. Fibers 2022, 19, 1990–2001. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ganasan, V.; Chohan, J.S.; Subburaj, G.S.; Harika, K.; Yedari, V.; Sivakumar, N.S.; Raheena, S.; Durai, A.J. Mechanical, Moisture Absorption and Thermal Stability of Banana Fiber/Egg Shell Powder-Based Epoxy Composites. Eng. Proc. 2024, 61, 11. https://doi.org/10.3390/engproc2024061011

Ganasan V, Chohan JS, Subburaj GS, Harika K, Yedari V, Sivakumar NS, Raheena S, Durai AJ. Mechanical, Moisture Absorption and Thermal Stability of Banana Fiber/Egg Shell Powder-Based Epoxy Composites. Engineering Proceedings. 2024; 61(1):11. https://doi.org/10.3390/engproc2024061011

Chicago/Turabian StyleGanasan, Velmurugan, Jasgurpreet Singh Chohan, Ganga Shree Subburaj, Koluru Harika, Vithesh Yedari, Nithya Sree Sivakumar, Shaik Raheena, and Akash Johnchella Durai. 2024. "Mechanical, Moisture Absorption and Thermal Stability of Banana Fiber/Egg Shell Powder-Based Epoxy Composites" Engineering Proceedings 61, no. 1: 11. https://doi.org/10.3390/engproc2024061011

APA StyleGanasan, V., Chohan, J. S., Subburaj, G. S., Harika, K., Yedari, V., Sivakumar, N. S., Raheena, S., & Durai, A. J. (2024). Mechanical, Moisture Absorption and Thermal Stability of Banana Fiber/Egg Shell Powder-Based Epoxy Composites. Engineering Proceedings, 61(1), 11. https://doi.org/10.3390/engproc2024061011