Study of the Effect of Bending Deformation on the Performance of Flexible Polymer Layered Humidity Sensor †

Abstract

:1. Introduction

2. Materials and Methods

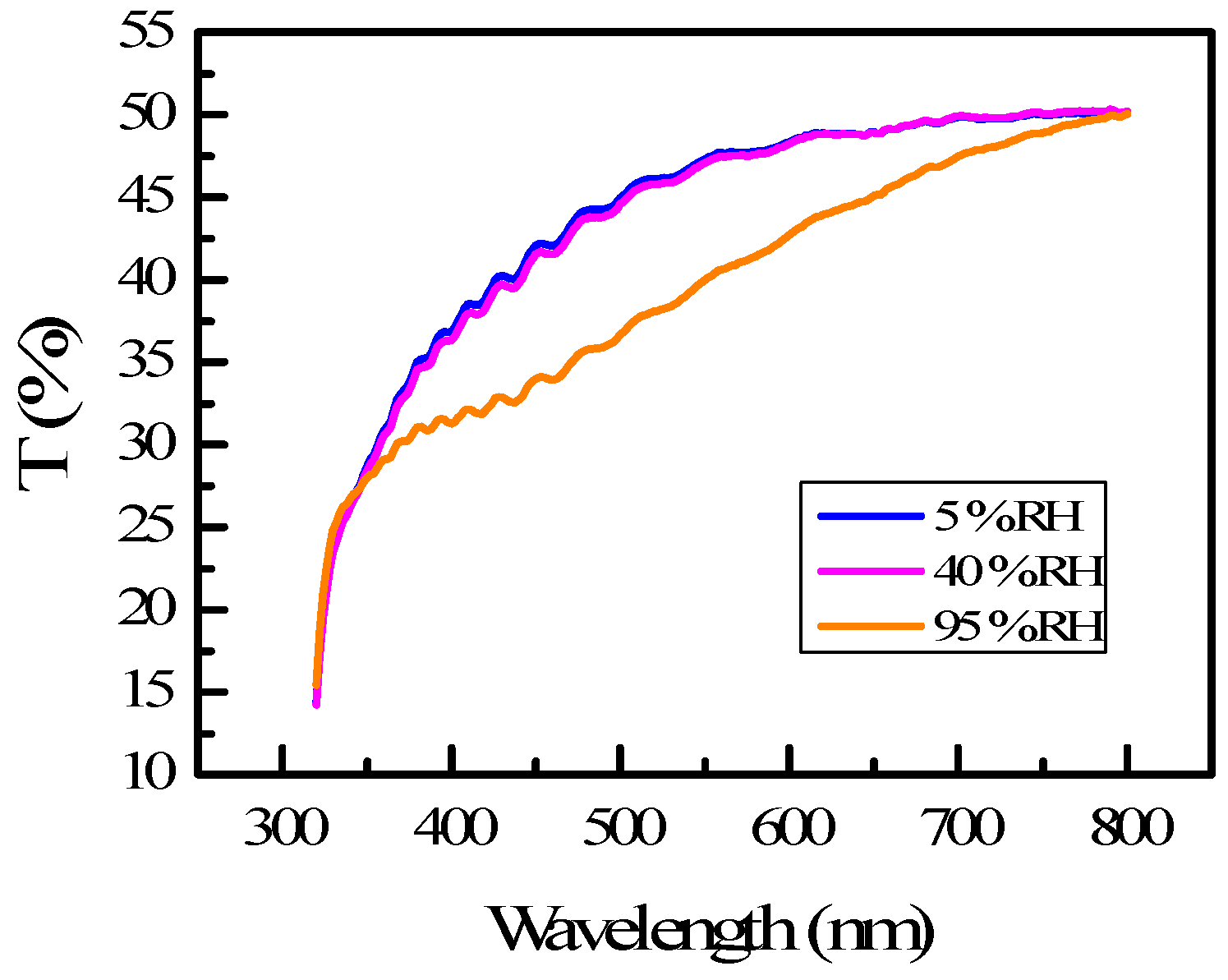

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Zhang, J.; Zhong, J.; Fang, Y.; Wang, J.; Huang, G.; Cui, X.; Mei, Y. Roll up polymer/oxide/polymer nanomembranes as a hybrid optical microcavity for humidity sensing. Nanoscale 2014, 6, 13646–13650. [Google Scholar] [CrossRef]

- Naydenova, I.; Jallapuram, R.; Toal, V.; Martin, S. A visual indication of environmental humidity using a color changing hologram recorded in a self-developing photopolymer. Appl. Phys. Lett. 2008, 92, 031109. [Google Scholar] [CrossRef]

- Naydenova, I.; Grand, J.; Mikulchyk, T.; Martin, S.; Toal, V.; Georgieva, V.; Thomas, S.; Mintova, S. Hybrid Sensors Fabricated by Inkjet Printing and Holographic Patterning. Chem. Mater. 2015, 27, 6097–6101. [Google Scholar] [CrossRef]

- Wei, M.; Gao, Y.; Li, X.; Serpe, M.J. Stimuli responsive polymers and their applications. Polym. Chem. 2017, 8, 127–143. [Google Scholar] [CrossRef]

- Christova, D.; Ivanova, S.; Ivanova, G. Water-soluble temperature-responsive poly(viny1 alcohol-co-vinyl acetal)s. Polym. Bull. 2003, 50, 367–372. [Google Scholar] [CrossRef]

- Lazarova, K.; Bozhilova, S.; Novakov, C.; Christova, D.; Babeva, T. Amphiphilic Poly(vinyl Alcohol) Copolymers Designed for Optical Sensor Applications—Synthesis and Properties. Coatings 2020, 10, 460. [Google Scholar] [CrossRef]

- Lazarova, K.; Bozhilova, S.; Ivanova, S.; Christova, D.; Babeva, T. Moisture-responsive polymer films on flexible substrates for optical sensing of humidity. Eng. Proc. 2020, 2, 19. [Google Scholar]

- Lazarova, K.; Bozhilova, S.; Christova, D.; Babeva, T. Poly(vinyl alcohol)-based thin films for optical humidity sensing. J. Phys. Conf. Ser. 2020, 1492. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lazarova, K.; Bozhilova, S.; Ivanova, S.; Christova, D.; Babeva, T. Study of the Effect of Bending Deformation on the Performance of Flexible Polymer Layered Humidity Sensor. Eng. Proc. 2021, 6, 6. https://doi.org/10.3390/I3S2021Dresden-10069

Lazarova K, Bozhilova S, Ivanova S, Christova D, Babeva T. Study of the Effect of Bending Deformation on the Performance of Flexible Polymer Layered Humidity Sensor. Engineering Proceedings. 2021; 6(1):6. https://doi.org/10.3390/I3S2021Dresden-10069

Chicago/Turabian StyleLazarova, Katerina, Silvia Bozhilova, Sijka Ivanova, Darinka Christova, and Tsvetanka Babeva. 2021. "Study of the Effect of Bending Deformation on the Performance of Flexible Polymer Layered Humidity Sensor" Engineering Proceedings 6, no. 1: 6. https://doi.org/10.3390/I3S2021Dresden-10069

APA StyleLazarova, K., Bozhilova, S., Ivanova, S., Christova, D., & Babeva, T. (2021). Study of the Effect of Bending Deformation on the Performance of Flexible Polymer Layered Humidity Sensor. Engineering Proceedings, 6(1), 6. https://doi.org/10.3390/I3S2021Dresden-10069