A Review on Graphitic Carbon Nitride and Conducting Polymer Nanocomposite Electrodes for Supercapacitors †

Abstract

1. Introduction

| Property | Description | Applications | Ref. |

|---|---|---|---|

| Optical Band Gap | ~2.6 eV | Photocatalysis, Solar cells, Photovoltaics | [13,29] |

| Chemical Stability | Stable under various conditions | Catalyst, Gas separation membranes | [30] |

| Specific Surface Area | High specific surface area (porous structure) | Energy storage devices (Batteries and SCs) | [31] |

| Thermal Stability | Stable up to ~550 °C | Catalysis under high-temperature conditions | [32] |

| Electrical Conductivity | Low electrical conductivity | Photodetectors, Light-emitting devices | [33] |

| Photocatalytic Activity | Efficient under visible light irradiation | Hydrogen Evolution and Water-Splitting | [34,35] |

| Chemical Inertness | Chemically inert under certain conditions | Corrosion-resistant coatings, Chemical sensors | [36] |

| Water Absorption Capacity | Hydrophilic nature | Water purification, Humidity sensors | [37,38] |

| Biocompatibility | Non-toxic and biocompatible | Biomedical, Environmental remediation | [39] |

2. Synthetic Methods of g-CN/CP Nanocomposites

3. g-CN/Conducting Polymer Electrodes

| Electrode | Fabrication Method | Electrolyte | Specific Capacitance (F/g) | Retention Rate (Cycles) | Ref. |

|---|---|---|---|---|---|

| NiO/g-C3N4/PANI/Ni-MOF | Reflux method | 1 M H2SO4 | 2420 | 99.5%, 3000 | [52] |

| Ag/PANI/g-C3N4 | In situ oxidative polymerization | 1 M H2SO4 | 797.8 | 84.43%, 1000 | [60] |

| Ag/g-C3N4@ppy | In situ polymerization | 1 M H2SO4 | 602.2 | 95.23%, 10,000 | [61] |

| PANI/g-C3N4/MXene | In situ chemical polymerization and a vacuum-assisted filtration | 1 M H2SO4 | 570 | 91.1%, 1000 | [62] |

| C3N4/PPy/MnO2 | In situ chemical procedure | 1 M Na2SO4 | 509.4 | 95.7%, 5000 | [63] |

| g-C3N4/PPy | Chemical oxidation method | 6 M KOH | 471 | 71%, 5000 | [64] |

| PIn/g-C3N4 | Reflux method | 1 M H2SO4 | 440.8 | 72%, 5000 | [58] |

| MnO2@PANI-G-C3N4 | Electrochemical deposition | 0.5 M H2SO4 | 318 | 80.62%, 1000 | [65] |

| TG-CN /PANI | In situ polymerization | 0.5 M H2SO4 | 298.31 | 5000 | [66] |

| PEDOT: PSS@g-C3N4 | The simple direct mixing process | 1 M H2SO4 | 277 | 5000 | [47] |

| g-C3N4/PANI | In situ polymerization | 3 M KOH | 234 | 86.2%, 10,000 | [67] |

4. Conclusions and Future Perspectives

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Salkuti, S.R. Energy Storage and Electric Vehicles: Technology, Operation, Challenges, and Cost-Benefit Analysis. Int. J. Adv. Comput. Sci. Appl. 2021, 12, 40–45. [Google Scholar] [CrossRef]

- Barakzehi, M.; Montazer, M.; Sharif, F.; Norby, T. A textile-based wearable supercapacitor using reduced graphene oxide/polypyrrole composite. Electrochim. Acta 2019, 305, 187–196. [Google Scholar] [CrossRef]

- Ragupathy, P.; Bhat, S.D.; Kalaiselvi, N. Electrochemical energy storage and conversion: An overview. Wiley Interdiscip. Rev. Energy Environ. 2023, 12, e464. [Google Scholar] [CrossRef]

- Chukwuka, C.; Folly, K.A. Batteries and super-capacitors. In Proceedings of the IEEE Power and Energy Society Conference and Exposition in Africa: Intelligent Grid Integration of Renewable Energy Resources, PowerAfrica, Cape Town, South Africa, 9–13 July 2012. [Google Scholar] [CrossRef]

- Office of the Principal Scientific Adviser. Batteries and Supercapacitors for Energy Storage and Delivery Needs of India; Office of the Principal Scientific Adviser: New Delhi, India, 2014.

- Pershaanaa, M.; Bashir, S.; Ramesh, S.; Ramesh, K. Every bite of Supercap: A brief review on construction and enhancement of supercapacitor. J. Energy Storage 2022, 50, 104599. [Google Scholar] [CrossRef]

- Sharma, K.; Arora, A.; Tripathi, S.K. Review of supercapacitors: Materials and devices. J. Energy Storage 2019, 21, 801–825. [Google Scholar] [CrossRef]

- Şahin, M.E.; Blaabjerg, F.; Sangwongwanich, A. A Comprehensive Review on Supercapacitor Applications and Developments. Energies 2022, 15, 674. [Google Scholar] [CrossRef]

- Sajjad, M.; Lu, W. Covalent organic frameworks based nanomaterials: Design, synthesis, and current status for supercapacitor applications: A review. J. Energy Storage 2021, 39, 102618. [Google Scholar] [CrossRef]

- Zhang, L.; Yang, G.; Chen, Z.; Liu, D.; Wang, W. MXene coupled with molybdenum dioxide nanoparticles as 2D-0D pseudocapacitive electrode for high performance flexible asymmetric micro-supercapacitors. J. Mater. 2020, 6, 138–144. [Google Scholar] [CrossRef]

- Zhang, H.; Ma, Z.; Duan, S.; Liu, Y.; Jiang, X.; Jiang, G. Dawson-type polyoxometalate modified separator for anchoring/catalyzing polysulfides in high-performance lithium-sulfur batteries. Electrochim. Acta 2022, 428, 140868. [Google Scholar] [CrossRef]

- Kumar, S.; Saeed, G.; Zhu, L.; Hui, K.N.; Kim, N.H.; Lee, J.H. 0D to 3D carbon-based networks combined with pseudocapacitive electrode material for high energy density supercapacitor: A review. Chem. Eng. J. 2021, 403, 126352. [Google Scholar] [CrossRef]

- Alaghmandfard, A.; Ghandi, K. A Comprehensive Review of Graphitic Carbon Nitride (g-C3N4)–Metal Oxide-Based Nanocomposites: Potential for Photocatalysis and Sensing. Nanomaterials 2022, 12, 294. [Google Scholar] [CrossRef] [PubMed]

- Li, M.; Zheng, X.; Xie, L.; Yu, Y.; Jiang, J. The synergistic effect of carbon nanotubes and graphitic carbon nitride on the enhanced supercapacitor performance of cobalt diselenide-based composites. New J. Chem. 2021, 45, 14808–14814. [Google Scholar] [CrossRef]

- Li, Y.; Li, X.; Zhang, H.; Xiang, Q. Porous graphitic carbon nitride for solar photocatalytic applications. Nanoscale Horiz. 2020, 5, 765–786. [Google Scholar] [CrossRef]

- Hao, Q.; Jia, G.; Wei, W.; Vinu, A.; Wang, B.J. Graphitic carbon nitride with different dimensionalities for energy and environmental applications. Nano Res. 2020, 13, 18–37. [Google Scholar] [CrossRef]

- Mun, S.J.; Park, S.J. Graphitic carbon nitride materials for photocatalytic hydrogen production via water splitting: A short review. Catalysts 2019, 9, 805. [Google Scholar] [CrossRef]

- Filik, H.; Avan, A.A. Review on applications of carbon nanomaterials for simultaneous electrochemical sensing of environmental contaminant dihydroxybenzene isomers. Arab. J. Chem. 2020, 13, 6092–6105. [Google Scholar] [CrossRef]

- Muchuweni, E.; Mombeshora, E.T.; Martincigh, B.S.; Nyamori, V.O. Graphitic carbon nitride-based new-generation solar cells: Critical challenges, recent breakthroughs and future prospects. Sol. Energy 2022, 239, 74–87. [Google Scholar] [CrossRef]

- Gupta, N.; Todi, K.; Narayan, T.; Malhotra, B.D. Graphitic carbon nitride-based nanoplatforms for biosensors: Design strategies and applications. Mater. Today Chem. 2022, 24, 100770. [Google Scholar] [CrossRef]

- Babu, A.M.; Rajeev, R.; Thadathil, D.A.; Varghese, A.; Hegde, G. Surface Modulation and Structural Engineering of Graphitic Carbon Nitride for Electrochemical Sensing Applications; Springer: Berlin/Heidelberg, Germany, 2022; Volume 12, ISBN 0123456789. [Google Scholar]

- Gao, Y.; Li, T.; Zhu, Y.; Chen, Z.; Liang, J.; Hu, C. Highly nitrogen-doped porous carbon transformed from graphitic carbon nitride for efficient metal-free catalysis. J. Hazard. Mater. 2020, 393, 121280. [Google Scholar] [CrossRef]

- Ashritha, M.G.; Hareesh, K. A review on Graphitic Carbon Nitride based binary nanocomposites as supercapacitors. J. Energy Storage 2020, 32, 101840. [Google Scholar] [CrossRef]

- Jadoun, S.; Pal, N.; Chauhan, S.; Chinnam, S.; Aepuru, R.; Sathish, M. A Short Review on Conducting Polymer Nanocomposites. Biomed. Mater. Devices 2022, 1, 351–365. [Google Scholar] [CrossRef]

- Ahmed, S.; Ahmed, A.; Basha, D.B.; Hussain, S.; Uddin, I.; Gondal, M.A. Critical review on recent developments in conducting polymer nanocomposites for supercapacitors. Synth. Met. 2023, 295, 117326. [Google Scholar] [CrossRef]

- De La Fuente Salas, I.M.; Sudhakar, Y.N.; Selvakumar, M. High performance of symmetrical supercapacitor based on multilayer films of graphene oxide/polypyrrole electrodes. Appl. Surf. Sci. 2014, 296, 195–203. [Google Scholar] [CrossRef]

- Bashir, S.; Hasan, K.; Hina, M.; Ali Soomro, R.; Mujtaba, R. Conducting polymer/graphene hydrogel electrodes based aqueous smart Supercapacitors: A review and future prospects. J. Electroanal. Chem. 2021, 898, 115626. [Google Scholar] [CrossRef]

- Chauhan, N.P.S.; Jadoun, S.; Rathore, B.S.; Barani, M.; Zarrintaj, P. Redox polymers for capacitive energy storage applications. J. Energy Storage 2021, 43, 103218. [Google Scholar] [CrossRef]

- Ramachandran, S.; Basha, A.S.; Vadivel, S.; Rathinavel, S.; Engineering, T. Highly effective Pt-free counter electrode constructed by break bone-like CoTe @ graphite carbon thin films dye- synthesized solar cell. Sol. Energy 2023, 262, 111833. [Google Scholar] [CrossRef]

- Talukdar, M.; Deb, P. Recent progress in research on multifunctional graphitic carbon nitride: An emerging wonder material beyond catalyst. Carbon 2022, 192, 308–331. [Google Scholar] [CrossRef]

- Ghanem, L.G.; Hamza, M.A.; Taha, M.M.; Allam, N.K. Symmetric supercapacitor devices based on pristine g-C3N4 mesoporous nanosheets with exceptional stability and wide operating voltage window. J. Energy Storage 2022, 52, 104850. [Google Scholar] [CrossRef]

- Zhang, W.; Ling, Z.; Fang, X.; Zhang, Z. Anisotropically conductive Mg(NO3)2·6H2O/g-C3N4-graphite sheet phase change material for enhanced photo-thermal storage. Chem. Eng. J. 2022, 430, 132997. [Google Scholar] [CrossRef]

- Hoh, H.Y.; Zhang, Y.; Zhong, Y.L.; Bao, Q. Harnessing the Potential of Graphitic Carbon Nitride for Optoelectronic Applications. Adv. Opt. Mater. 2021, 9, 2100146. [Google Scholar] [CrossRef]

- Wang, Y.; Liu, L.; Ma, T.; Zhang, Y.; Huang, H. 2D Graphitic Carbon Nitride for Energy Conversion and Storage. Adv. Funct. Mater. 2021, 31, 2102540. [Google Scholar] [CrossRef]

- She, X.; Liu, L.; Ji, H.; Mo, Z.; Li, H. Template-free synthesis of 2D porous ultrathin nonmetal-doped g-C3N4 nanosheets with highly efficient photocatalytic H2 evolution from water under visible light. Appl. Catal. B Environ. 2016, 187, 144–153. [Google Scholar] [CrossRef]

- Wang, D.; Huang, S.; Li, H.; Chen, A.; Wang, P.; Yang, J. Ultrathin WO3 nanosheets modified by g-C3N4 for highly efficient acetone vapor detection. Sens. Actuators B Chem. 2019, 282, 961–971. [Google Scholar] [CrossRef]

- Zhou, L.; Wang, M.; Liu, Z.; Guan, J.; Li, T.; Zhang, D. High-performance humidity sensor based on graphitic carbon nitride/polyethylene oxide and construction of sensor array for non-contact humidity detection. Sens. Actuators B Chem. 2021, 344, 130219. [Google Scholar] [CrossRef]

- Meng, W.; Wu, S.; Wang, X.; Zhang, D. High-sensitivity resistive humidity sensor based on graphitic carbon nitride nanosheets and its application. Sens. Actuators B Chem. 2020, 315, 128058. [Google Scholar] [CrossRef]

- Vinoth, S.; Shalini Devi, K.S.; Pandikumar, A. A comprehensive review on graphitic carbon nitride based electrochemical and biosensors for environmental and healthcare applications. TrAC-Trends Anal. Chem. 2021, 140, 116274. [Google Scholar] [CrossRef]

- Bai, L.; Huang, H.; Yu, S.; Zhang, D.; Huang, H.; Zhang, Y. Role of transition metal oxides in g-C3N4-based heterojunctions for photocatalysis and supercapacitors. J. Energy Chem. 2022, 64, 214–235. [Google Scholar] [CrossRef]

- Qu, Y.; Zhang, X.; Lü, W.; Yang, N.; Jiang, X. All-solid-state flexible supercapacitor using graphene/g-C3N4 composite capacitor electrodes. J. Mater. Sci. 2020, 55, 16334–16346. [Google Scholar] [CrossRef]

- Jaiswal, A.; Pal, S.; Kumar, A.; Prakash, R. Metal free triad from red phosphorous, reduced graphene oxide and graphitic carbon nitride (red P-rGO-g-C3N4) as robust electro-catalysts for hydrogen evolution reaction. Electrochim. Acta 2020, 338, 135851. [Google Scholar] [CrossRef]

- Wang, X.; Li, G.; Li, M.; Liu, R.; Li, Z. Reinforced polysulfide barrier by g-C3N4/CNT composite towards superior lithium-sulfur batteries. J. Energy Chem. 2020, 53, 234–240. [Google Scholar] [CrossRef]

- Forouzandeh, P.; Ganguly, P.; Dahiya, R.; Pillai, S.C. Supercapacitor electrode fabrication through chemical and physical routes. J. Power Sources 2022, 519, 230744. [Google Scholar] [CrossRef]

- Mrinalini Kalyani, A.K.; Rajeev, R.; Benny, L.; Cherian, A.R.; Varghese, A. Surface tuning of nanostructured graphitic carbon nitrides for enhanced electrocatalytic applications: A review. Mater. Today Chem. 2023, 30, 101523. [Google Scholar] [CrossRef]

- Liang, S.; Yan, W.; Wu, X.; Zhang, Y.; Zhu, Y. Gel polymer electrolytes for lithium ion batteries: Fabrication, characterization and performance. Solid State Ion. 2018, 318, 2–18. [Google Scholar] [CrossRef]

- Xu, Y.; Zhou, Y.; Guo, J.; Zhang, S.; Lu, Y. Preparation of the poly (3,4-ethylenedioxythiophene):poly(styrenesulfonate)@g-C3N4 composite by a simple direct mixing method for supercapacitor. Electrochim. Acta 2018, 283, 1468–1474. [Google Scholar] [CrossRef]

- Baruah, K.; Sarmah, D.; Kumar, A. Ternary hybrid nanocomposites of polypyrrole nanotubes with 2D self-assembled heterostructures of protonated g-C3N4-rGO as supercapacitor electrodes. Ionics 2021, 27, 3153–3168. [Google Scholar] [CrossRef]

- Verma, C.J.; Keshari, A.S.; Dubey, P.; Prakash, R. Polyindole modified g-C3N4 nanohybrids via in-situ chemical polymerization for its improved electrochemical performance. Vacuum 2020, 177, 109363. [Google Scholar] [CrossRef]

- Chen, J.; Wang, Y.; Cao, J.; Liao, L.; Liu, Z. Pulsed electrochemical fabrication of graphene / polypyrrole composite gel films for high performance and flexible supercapacitors. Electrochim. Acta 2020, 361, 137036. [Google Scholar] [CrossRef]

- Vinothkumar, V.; Kesavan, G.; Chen, S.M. Graphitic carbon nitride nanosheets incorporated with polypyrrole nanocomposite: A sensitive metal-free electrocatalyst for determination of antibiotic drug nitrofurantoin. Colloids Surf. A Physicochem. Eng. Asp. 2021, 629, 127433. [Google Scholar] [CrossRef]

- Kumar, S.; Weng, P.; Fu, Y. NiO/g-C3N4/PANI/Ni-metal-organic framework composite for high-energy supercapacitor electrodes. Mater. Chem. 2023, 28, 101385. [Google Scholar] [CrossRef]

- Zhang, H.; Usman Tahir, M.; Yan, X.; Liu, X.; Su, X.; Zhang, L. Ni-Al layered double hydroxide with regulated interlayer spacing as electrode for aqueous asymmetric supercapacitor. Chem. Eng. J. 2019, 368, 905–913. [Google Scholar] [CrossRef]

- Pakzad, P.; Mehrpooya, M.; Pourfayaz, F.; Ganjali, M.R. Electrochemical aspects of Co3O4 nanorods supported on the cerium doped porous graphitic carbon nitride nanosheets as an efficient supercapacitor electrode and oxygen reduction reaction electrocatalyst. Int. J. Hydrogen Energy 2023, 48, 16294–16319. [Google Scholar] [CrossRef]

- Chen, X.; Zhu, X.; Xiao, Y. and X. Yang, “PEDOT/g-C 3 N 4 binary electrode material for supercapacitors. J. Electroanal. Chem. 2015, 743, 99–104. [Google Scholar] [CrossRef]

- Zhou, S.; Tao, X.; Ma, J.; Guo, L.; Zhu, Y.; Wei, X. Synthesis of flower-like PANI/g-C3N4 nanocomposite as supercapacitor electrode. Vacuum 2018, 149, 175–179. [Google Scholar] [CrossRef]

- Dong, G.; Fan, H.; Fu, K.; Ma, L.; Zhang, W. The evaluation of super-capacitive performance of novel g-C3N4/PPy nanocomposite electrode material with sandwich-like structure. Compos. Part B Eng. 2019, 162, 369–377. [Google Scholar] [CrossRef]

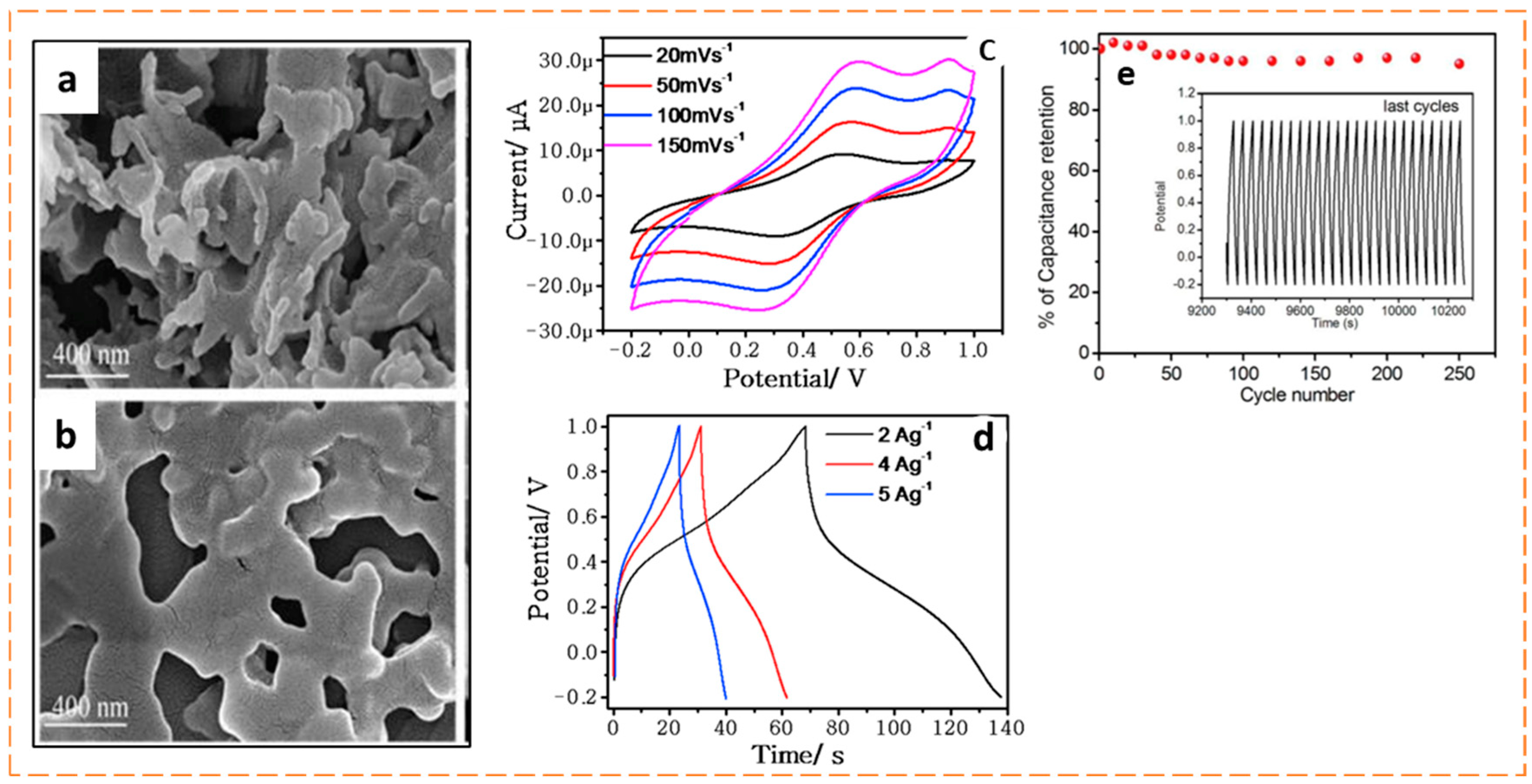

- Dhandapani, E.; Prabhu, S.; Duraisamy, N.; Ramesh, R. Polyindole intercalated graphitic carbon nitride (PIn/g-C3N4) composites for high-performance supercapacitor application. J. Energy Storage 2021, 44, 103360. [Google Scholar] [CrossRef]

- Li, F.; Dong, Y.; Dai, Q.; Nguyen, T.T.; Guo, M. Novel freestanding core-shell nanofibrillated cellulose/ polypyrrole/tubular graphitic carbon nitride composite film for supercapacitors electrodes. Vacuum 2018, 161, 283–290. [Google Scholar] [CrossRef]

- Ma, J.; Tao, X.Y.; Zhou, S.X.; Song, X.Z.; Zhu, Y.B.; Guo, L.T.; Liu, Z.S.; Fan, H.L.; Wei, X.Y. Facile fabrication of Ag/PANI/g-C 3 N 4 composite with enhanced electrochemical performance as supercapacitor electrode. J. Electroanal. Chem. 2019, 835, 346–353. [Google Scholar] [CrossRef]

- Arora, R.; Nehra, S.P.; Lata, S. Trio obtainment through polypyrrole insertions in argentum/graphitic carbon nitride for accelerating super-capacitive energy parameters. J. Energy Storage 2022, 56, 105879. [Google Scholar] [CrossRef]

- Xie, H.; Guo, Z.; Wang, M.; Ma, S.; Kong, Z.; He, Z. Facile fabrication of PANI/g-C3N4/MXene composites as electrode materials for supercapacitors. New J. Chem. 2023, 47, 8670–8678. [Google Scholar] [CrossRef]

- Pourfarzad, H.; Badrnezhad, R.; Ghaemmaghami, M.; Saremi, M. In situ synthesis of C3N4/PPy/MnO2 nanocomposite as a high performance active material for asymmetric supercapacitor. Ionics 2021, 27, 4057–4067. [Google Scholar] [CrossRef]

- Rehim, M.H.A.; Badawy, A.A.; Turky, G. Electrical properties and heavy ions removal ability of graphitic carbon nitride/polypyrrole composite. J. Phys. Chem. Solids 2022, 167, 11074. [Google Scholar] [CrossRef]

- Chahal, P.; Madaswamy, S.L.; Lee, S.C.; Wabaidur, S.M.; Dhayalan, R. Novel manganese oxide decorated polyaniline/graphitic carbon nitride nanohybrid material for efficient supercapacitor application. Fuel 2022, 330, 125531. [Google Scholar] [CrossRef]

- Kumar, A.; Khanuja, M. Template-free graphitic carbon nitride nanosheets coated with polyaniline nanofibers as an electrode material for supercapacitor applications. Renew. Energy 2021, 171, 1246–1256. [Google Scholar] [CrossRef]

- Qin, X.; Wan, J.; Zhang, Q.; Zhang, Y.; Yu, H.; Shi, S. Polyaniline-modified graphitic carbon nitride as electrode materials for high-performance supercapacitors. Carbon Lett. 2023, 33, 781–790. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chaluvachar, P.; Mahesha, G.T.; Sudhakar, Y.N.; Nair, V.; Pai, D. A Review on Graphitic Carbon Nitride and Conducting Polymer Nanocomposite Electrodes for Supercapacitors. Eng. Proc. 2023, 59, 154. https://doi.org/10.3390/engproc2023059154

Chaluvachar P, Mahesha GT, Sudhakar YN, Nair V, Pai D. A Review on Graphitic Carbon Nitride and Conducting Polymer Nanocomposite Electrodes for Supercapacitors. Engineering Proceedings. 2023; 59(1):154. https://doi.org/10.3390/engproc2023059154

Chicago/Turabian StyleChaluvachar, Priyanka, Gonuru Thammanaiah Mahesha, Yethadka Narahari Sudhakar, Vishnu Nair, and Dayananda Pai. 2023. "A Review on Graphitic Carbon Nitride and Conducting Polymer Nanocomposite Electrodes for Supercapacitors" Engineering Proceedings 59, no. 1: 154. https://doi.org/10.3390/engproc2023059154

APA StyleChaluvachar, P., Mahesha, G. T., Sudhakar, Y. N., Nair, V., & Pai, D. (2023). A Review on Graphitic Carbon Nitride and Conducting Polymer Nanocomposite Electrodes for Supercapacitors. Engineering Proceedings, 59(1), 154. https://doi.org/10.3390/engproc2023059154