Computational Feasibility Study for Time-Frequency Analysis of Non-Stationary Vibration Signals Based on Wigner-Ville Distribution †

Abstract

:1. Introduction

2. Material and Methods

2.1. Dataset

2.2. Methodology of the Resulting Average Spectrum

2.3. Methodology of Reducing the Sampling Frequency

2.4. Joint Analysis

3. Results and Dicussion

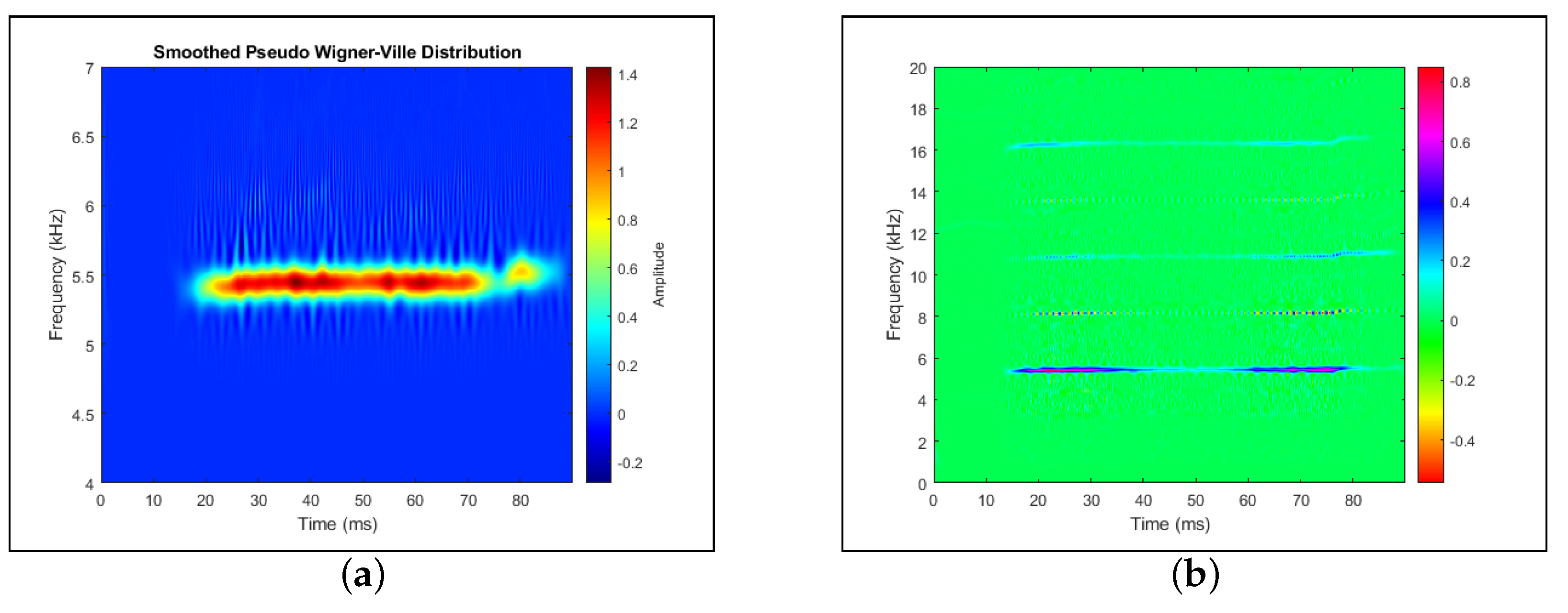

3.1. Methodology of the Resulting Average Spectrum

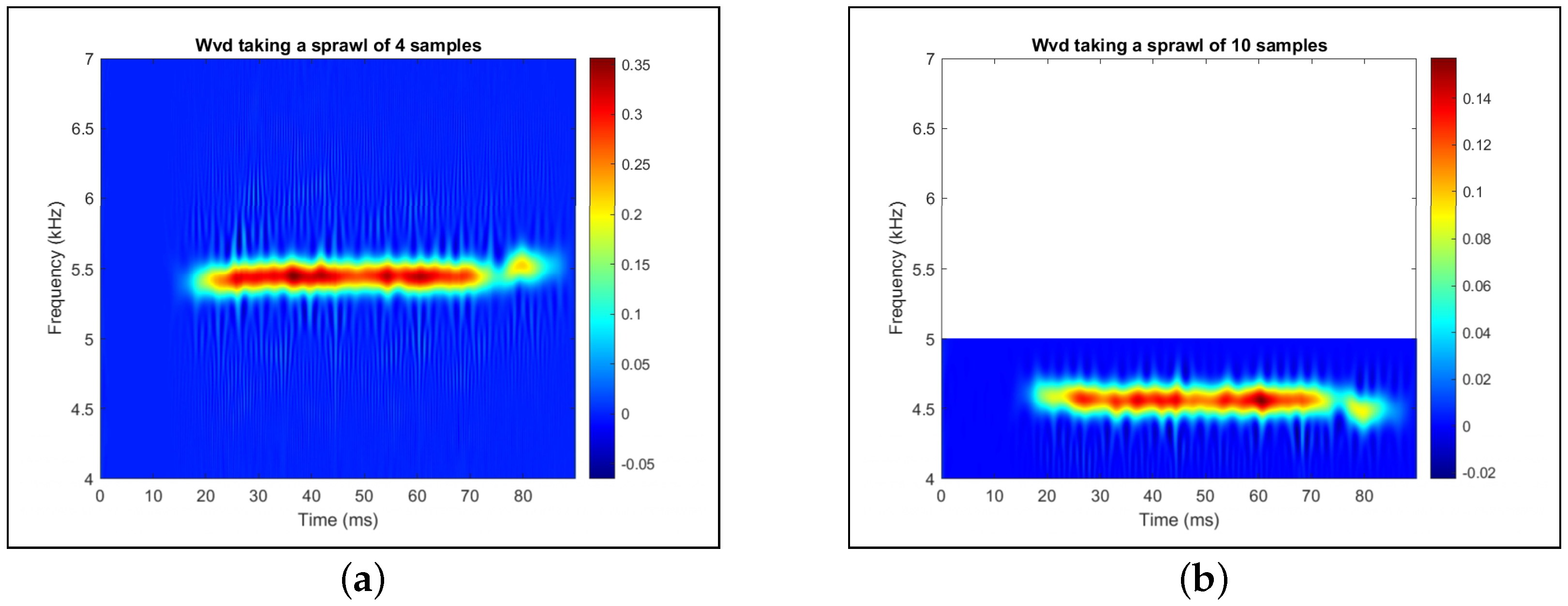

3.2. Methodology of the Resulting Average Spectrum

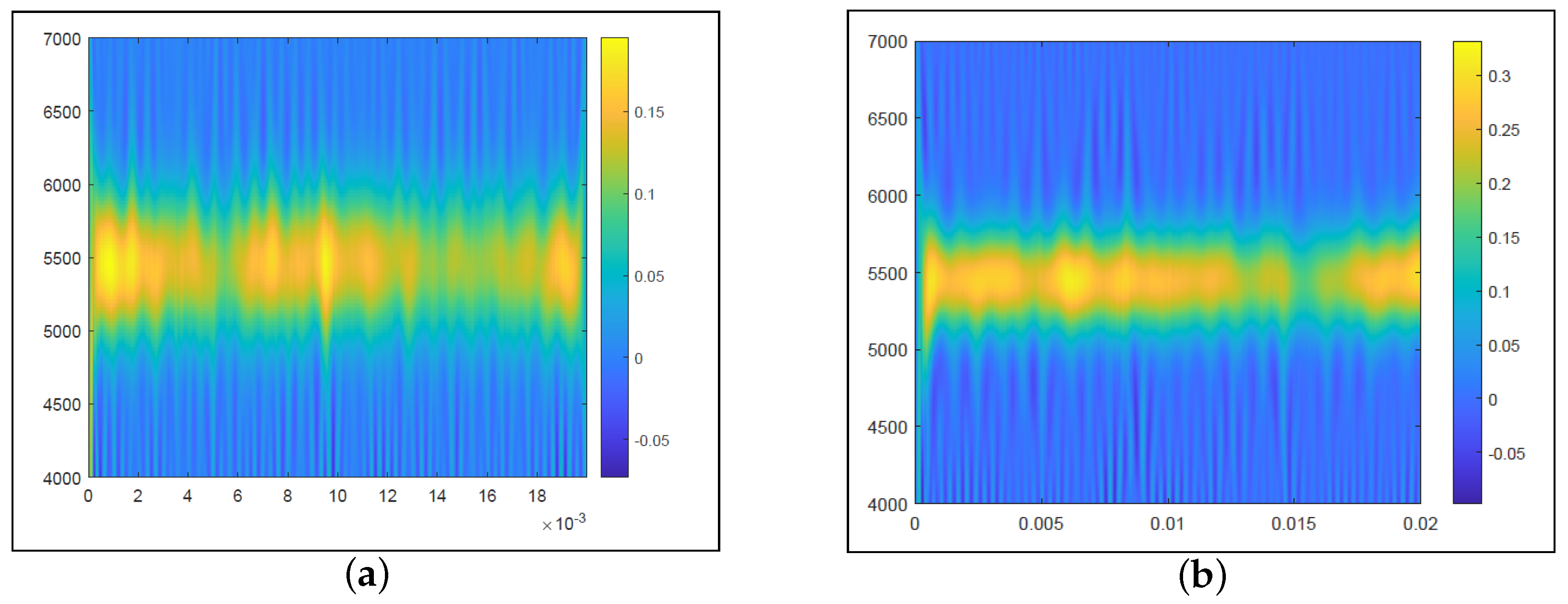

3.3. Methodology of Reducing the Sampling Frequency

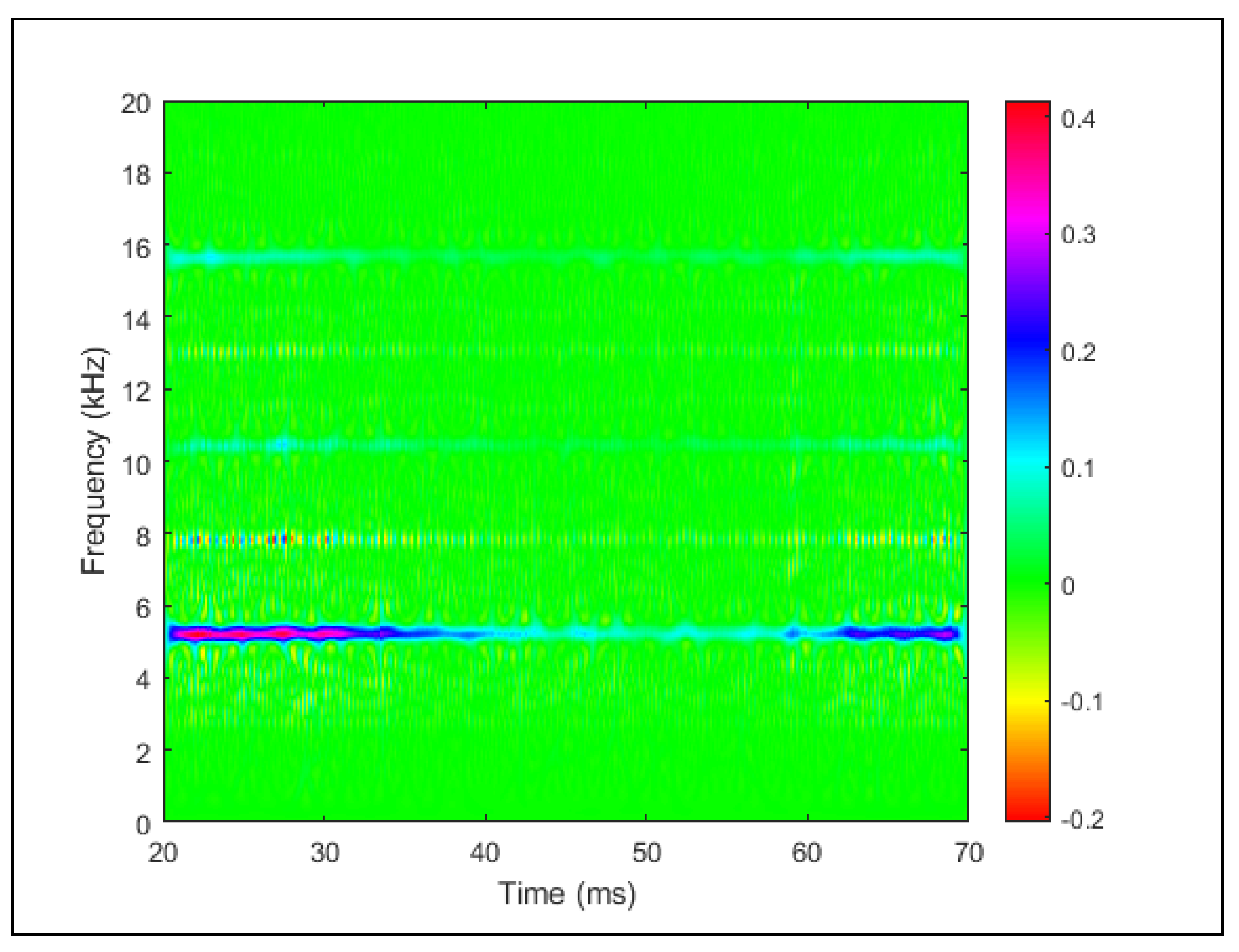

3.4. Joint Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| WVD | Wigner−Ville Distribution |

| CNN | Convolutional Neural Networks |

References

- Çınar, Z.M.; Abdussalam Nuhu, A.; Zeeshan, Q.; Korhan, O.; Asmael, M.; Safaei, B. Machine Learning in Predictive Maintenance towards Sustainable Smart Manufacturing in Industry 4.0. Sustainability 2020, 12, 8211. [Google Scholar] [CrossRef]

- Ding, H.; Gao, R.X.; Isaksson, A.J.; Landers, R.G.; Parisini, T.; Yuan, Y. State of AI-Based Monitoring in Smart Manufacturing and Introduction to Focused Section. IEEE/ASME Trans. Mechatron. 2020, 25, 2143–2154. [Google Scholar] [CrossRef]

- Serin, G.; Sener, B.; Ozbayoglu, A.M.; Unver, H.O. Review of tool condition monitoring in machining and opportunities for deep learning. Int. J. Adv. Manuf. Technol. 2020, 109, 953–974. [Google Scholar] [CrossRef]

- Wang, Z.; Oates, T. Imaging Time-Series to Improve Classification and Imputation. arXiv 2015, arXiv:1506.00327. [Google Scholar]

- Scholl, S. Fourier, Gabor, Morlet or Wigner: Comparison of Time-Frequency Transforms. arXiv 2021, arXiv:2101.06707. [Google Scholar]

- Huang, Z.; Zhu, J.; Lei, J.; Li, X.; Tian, F. Tool Wear Monitoring with Vibration Signals Based on Short-Time Fourier Transform and Deep Convolutional Neural Network in Milling. Math. Probl. Eng. 2021, 2021, 9976939. [Google Scholar] [CrossRef]

- Aghazadeh, F.; Tahan, A.; Thomas, M. Tool condition monitoring using spectral subtraction and convolutional neural networks in milling process. Int. J. Adv. Manuf. Technol. 2018, 98, 3217–3227. [Google Scholar] [CrossRef]

- Kai Goebel, A.A. Documentation for Mill Data Set; NASA AMES Research Center: Mountain View, CA, USA, 2007. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

de Angeles Dias, L.O.; Conceição Junior, P.O.; Monson, P.M.d.C. Computational Feasibility Study for Time-Frequency Analysis of Non-Stationary Vibration Signals Based on Wigner-Ville Distribution. Eng. Proc. 2023, 58, 126. https://doi.org/10.3390/ecsa-10-16193

de Angeles Dias LO, Conceição Junior PO, Monson PMdC. Computational Feasibility Study for Time-Frequency Analysis of Non-Stationary Vibration Signals Based on Wigner-Ville Distribution. Engineering Proceedings. 2023; 58(1):126. https://doi.org/10.3390/ecsa-10-16193

Chicago/Turabian Stylede Angeles Dias, Luis Otávio, Pedro Oliveira Conceição Junior, and Paulo Monteiro de Carvalho Monson. 2023. "Computational Feasibility Study for Time-Frequency Analysis of Non-Stationary Vibration Signals Based on Wigner-Ville Distribution" Engineering Proceedings 58, no. 1: 126. https://doi.org/10.3390/ecsa-10-16193

APA Stylede Angeles Dias, L. O., Conceição Junior, P. O., & Monson, P. M. d. C. (2023). Computational Feasibility Study for Time-Frequency Analysis of Non-Stationary Vibration Signals Based on Wigner-Ville Distribution. Engineering Proceedings, 58(1), 126. https://doi.org/10.3390/ecsa-10-16193