Investigating Construction and Integration Techniques of Dry Silver-Based Textile Electrodes on Electromyography of Biceps Brachii Muscle †

Abstract

1. Introduction

2. Materials and Methods

2.1. Fabric Construction Types

2.2. Electrode Sizing and Placement

2.3. Integration Techniques

2.4. Experimental Design

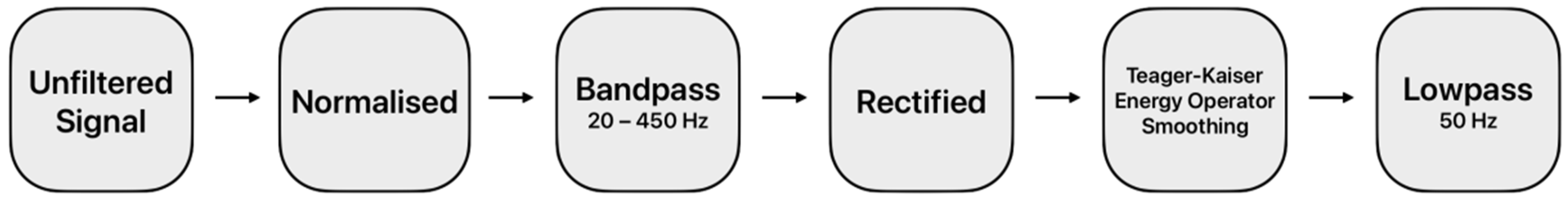

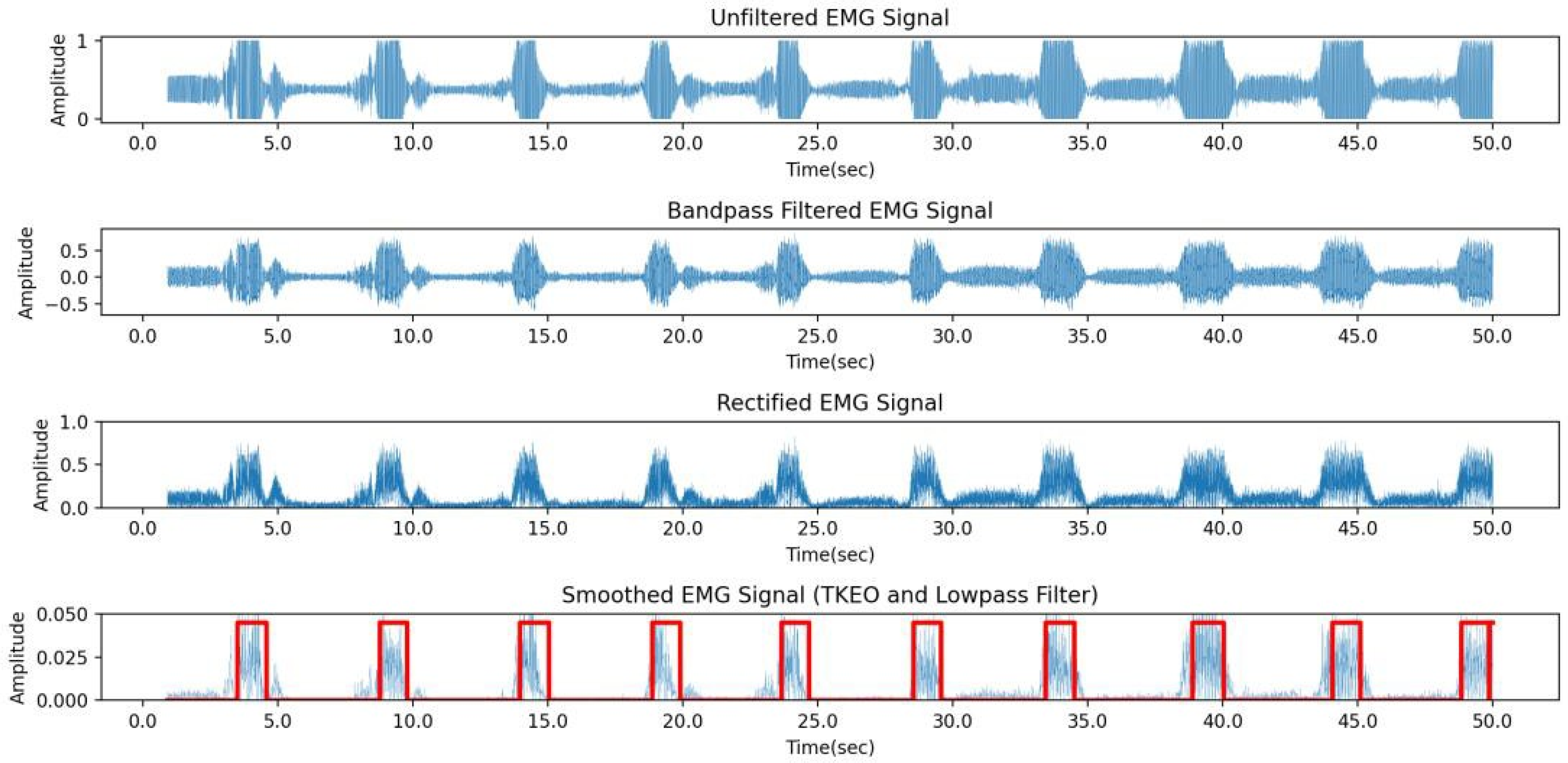

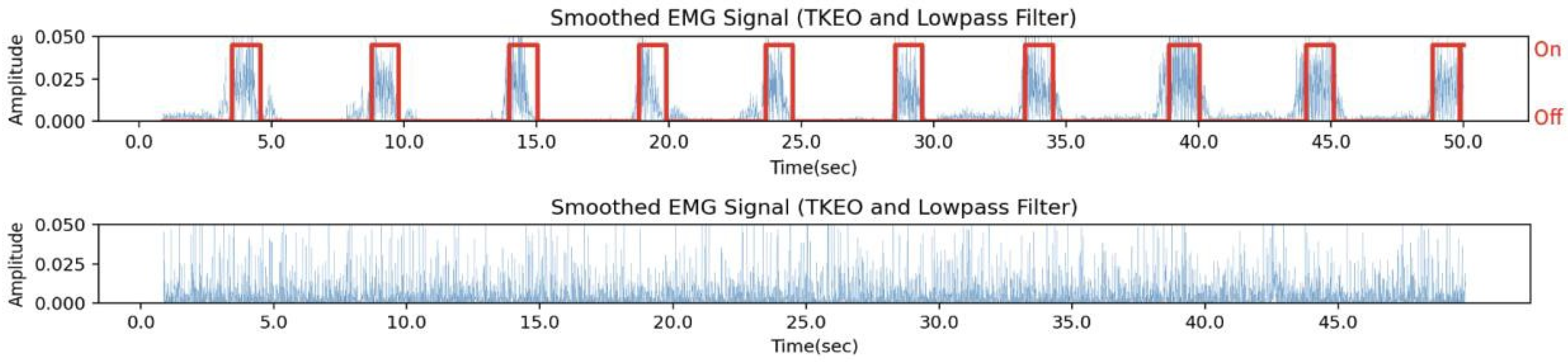

2.4.1. EMG Testing

2.4.2. Contact-Impedance Testing

3. Results

3.1. EMG

3.2. Contact-Impedance

4. Discussion

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yang, L.; Gan, L.; Zhang, Z.; Zhang, Z.; Yang, H.; Zhang, Y.; Wu, J. Insight into the Contact Impedance between the Electrode and the Skin Surface for Electrophysical Recordings. ACS Omega 2022, 7, 13906–13912. Available online: https://www.ncbi.nlm.nih.gov/pmc/articles/PMC9088920/ (accessed on 14 August 2023). [CrossRef] [PubMed]

- Searle, A.; Kirkup, L. A direct comparison of wet, dry and insulating bioelectric recording electrodes. Physiol. Meas. 2000, 21, 271–283. Available online: https://iopscience.iop.org/article/10.1088/0967-3334/21/2/307 (accessed on 14 August 2023). [CrossRef] [PubMed]

- Alizadeh-Meghrazi, M.; Ying, B.; Schlums, A.; Lam, E.; Eskandarian, L.; Abbas, F.; Sidhu, G.; Mahnam, A.; Moineau, B.; Popovic, M.R. Evaluation of dry textile electrodes for long-term electrocardiographic monitoring. Biomed. Eng. Online 2021, 20, 68. [Google Scholar] [CrossRef] [PubMed]

- Lam, E.; Alizadeh-Meghrazi, M.; Schlums, A.; Eskandarian, L.; Mahnam, A.; Moineau, B.; Popovic, M.R. Exploring textile-based electrode materials for electromyography smart garments. J. Rehabil. Assist. Technol. Eng. 2022, 9, 20556683211061995. Available online: https://www.ncbi.nlm.nih.gov/pmc/articles/PMC8811440/ (accessed on 14 August 2023). [CrossRef] [PubMed]

- SENIAM. Recommemdations for Sensor Locations in Arms or Hands. Available online: http://seniam.org/bicepsbrachii.html (accessed on 14 August 2023).

- Vervust, T.; Buyle, G.; Bossuyt, F.; Vanfleteren, J. Integration of stretchable and washable electronic modules for smart textile applications. J. Text. Inst. 2012, 103, 1127–1138. [Google Scholar] [CrossRef]

- McManus, L.; De Vito, G.; Lowery, M.M. Analysis and Biophysics of Surface EMG for Physiotherapists and Kinesiologists: Toward a Common Language with Rehabilitation Engineers. Front. Neurol. 2020, 11, 576729. Available online: https://www.frontiersin.org/article/10.3389/fneur.2020.576729/full (accessed on 14 August 2023). [CrossRef] [PubMed]

- Ravichandran, V.; Ciesielska-Wrobel, I.; Rumon, M.A.A.; Solanki, D.; Mankodiya, K. Characterizing the Impedance Properties of Dry E-Textile Electrodes Based on Contact Force and Perspiration. Biosensors 2023, 13, 728. Available online: https://www.mdpi.com/2079-6374/13/7/728 (accessed on 14 August 2023). [CrossRef] [PubMed]

- Gore, S.E.; Laing, R.M.; Wilson, C.A.; Carr, D.J.; Niven, B.E. Standardizing a Pre-Treatment Cleaning Procedure and Effects of Application on Apparel Fabrics. Text. Res. J. 2006, 76, 445–464. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dave, R.J.; Min, X.; Lou, Z.; Stewart, R. Investigating Construction and Integration Techniques of Dry Silver-Based Textile Electrodes on Electromyography of Biceps Brachii Muscle. Eng. Proc. 2023, 52, 21. https://doi.org/10.3390/engproc2023052021

Dave RJ, Min X, Lou Z, Stewart R. Investigating Construction and Integration Techniques of Dry Silver-Based Textile Electrodes on Electromyography of Biceps Brachii Muscle. Engineering Proceedings. 2023; 52(1):21. https://doi.org/10.3390/engproc2023052021

Chicago/Turabian StyleDave, Rohil J, Xue Min, Zhiyuan Lou, and Rebecca Stewart. 2023. "Investigating Construction and Integration Techniques of Dry Silver-Based Textile Electrodes on Electromyography of Biceps Brachii Muscle" Engineering Proceedings 52, no. 1: 21. https://doi.org/10.3390/engproc2023052021

APA StyleDave, R. J., Min, X., Lou, Z., & Stewart, R. (2023). Investigating Construction and Integration Techniques of Dry Silver-Based Textile Electrodes on Electromyography of Biceps Brachii Muscle. Engineering Proceedings, 52(1), 21. https://doi.org/10.3390/engproc2023052021