Deterioration Detection of Heavy-Duty Anticorrosion Coating Using Near-Infrared Hyperspectral Imaging †

Abstract

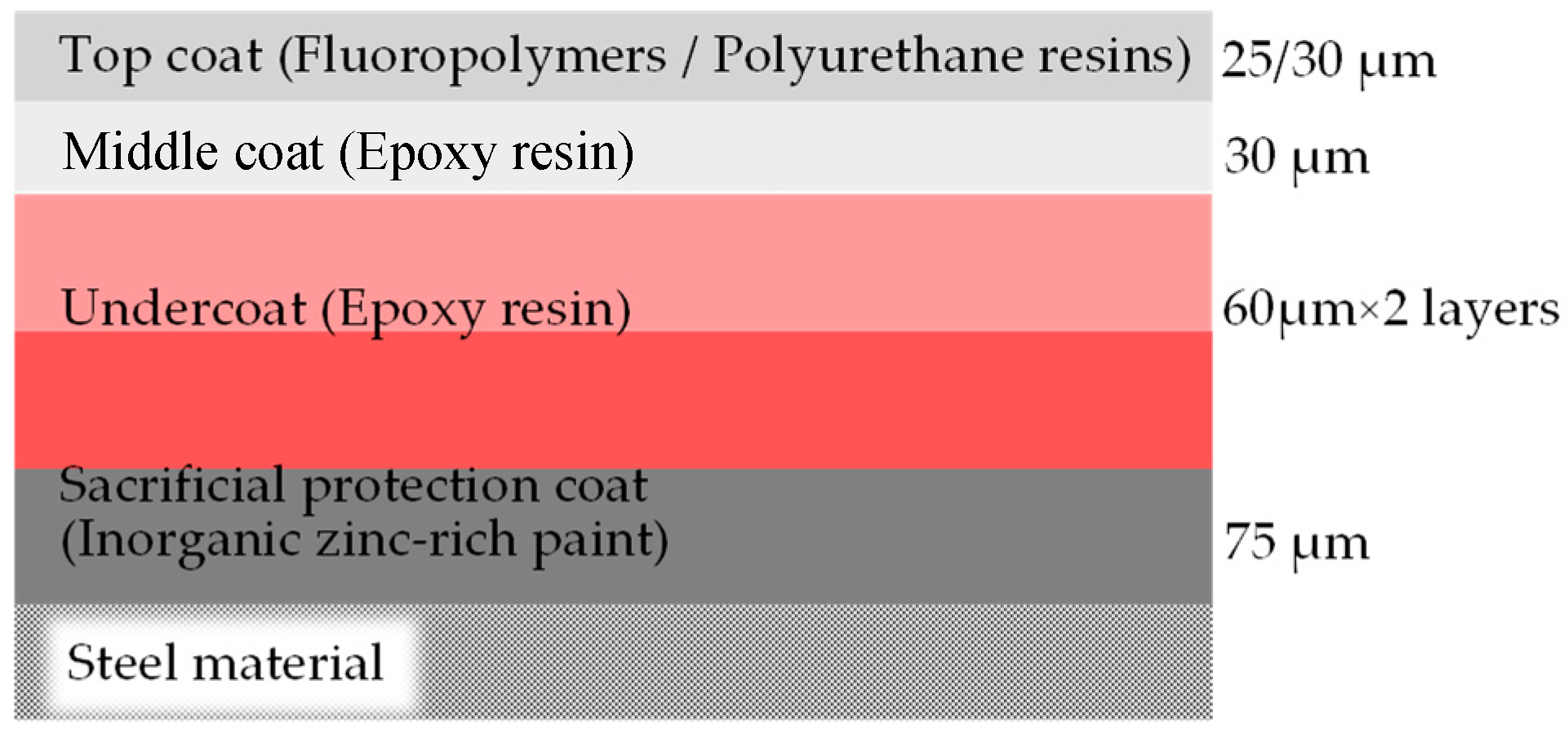

:1. Introduction

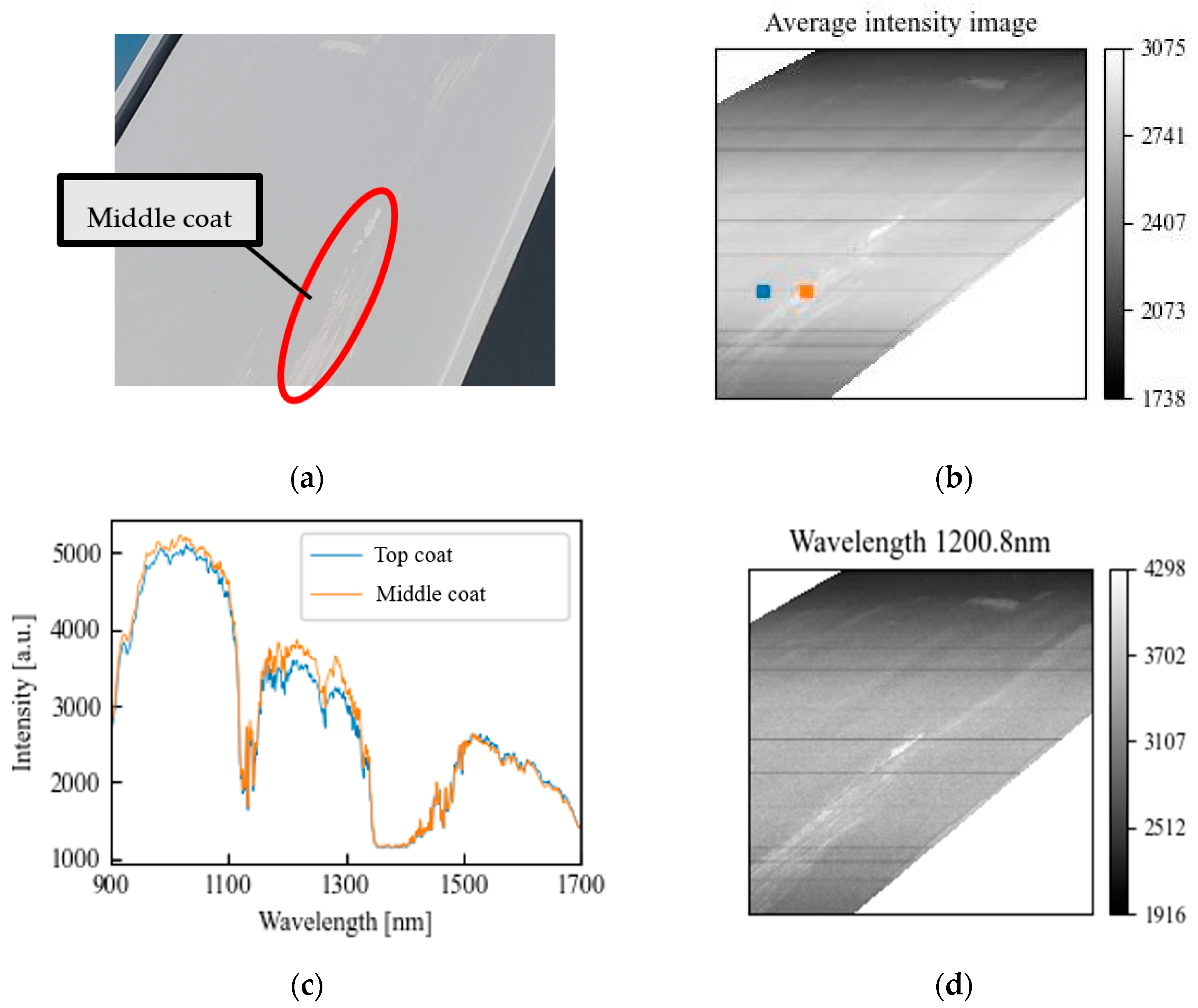

2. Principles of Hyperspectral Imaging

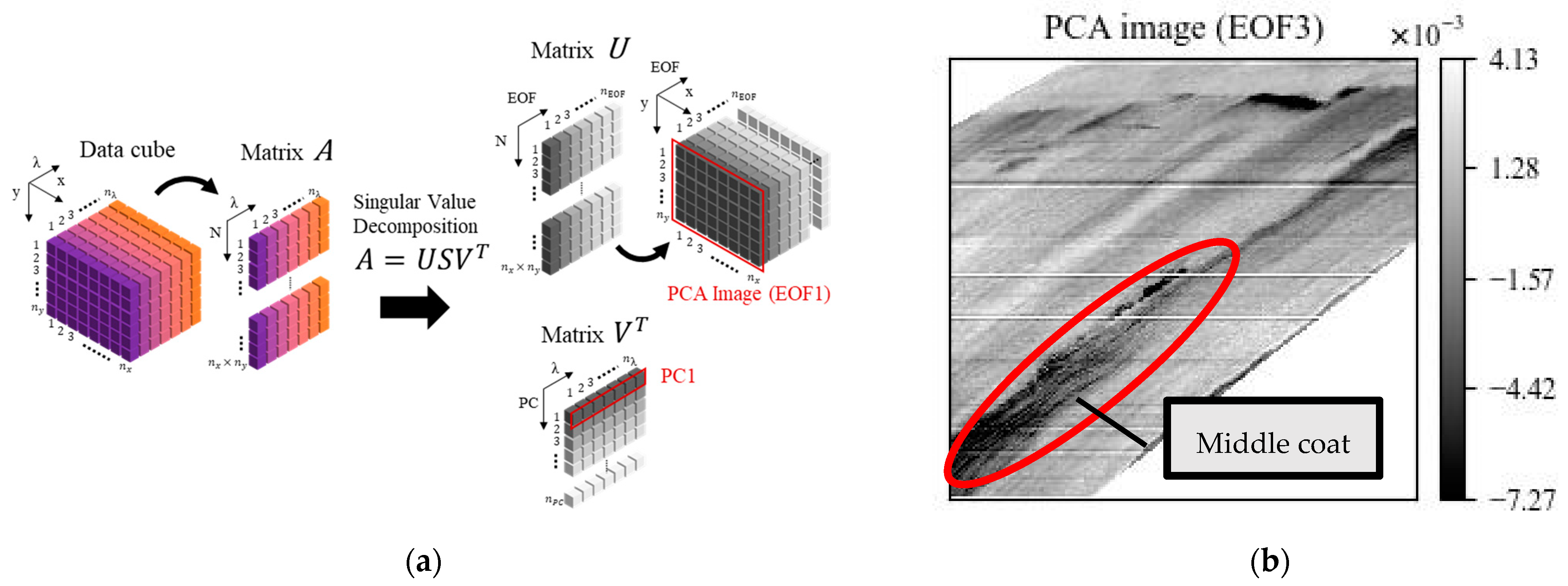

3. Measurement Results of Near-Infrared Hyperspectral Imaging

4. Improvements in Detection Accuracy for Coating Deterioration by Principal Component Analysis

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sakata, T.; Kishigami, S.; Ogawa, Y.; Arima, N.; Nishitani, M.; Shiozawa, D.; Sakagami, T. Quantitative assessment of heavy-duty anticorrosion coating thickness via near-infrared measurements. NDT E Int. 2023, 138, 102893. [Google Scholar] [CrossRef]

- Kishigami, S.; Mizokami, Y.; Sakata, T.; Ogawa, Y.; Shiozawa, D.; Sakagami, T. Detection of heavy-duty anticorrosion coating deterioration using near-infrared spectral characteristics. NDT E Int. 2022, 132, 102708. [Google Scholar] [CrossRef]

- Wang, Z.J.; Tian, G.Y.; Meo, M.; Ciampa, F. Image processing based quantitative damage evaluation in composites with long pulse thermography. NDT E Int. 2018, 99, 93–104. [Google Scholar] [CrossRef]

- Savitzky, A.; Golay, M.J.E. Smoothing + differentiation of data by simplified least squares procedures. Anal. Chem. 1964, 36, 1627–1639. [Google Scholar] [CrossRef]

- Geladi, P.; Macdougall, D.; Martens, H. Linearization and scatter-correction for near-infrared reflectance spectra of meat. Appl. Spectrosc. 1985, 39, 491–500. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Haruna, S.; Ogawa, Y.; Sakata, T.; Shiozawa, D.; Sakagami, T.; Yokoi, Y.; Sugiyama, T. Deterioration Detection of Heavy-Duty Anticorrosion Coating Using Near-Infrared Hyperspectral Imaging. Eng. Proc. 2023, 51, 13. https://doi.org/10.3390/engproc2023051013

Haruna S, Ogawa Y, Sakata T, Shiozawa D, Sakagami T, Yokoi Y, Sugiyama T. Deterioration Detection of Heavy-Duty Anticorrosion Coating Using Near-Infrared Hyperspectral Imaging. Engineering Proceedings. 2023; 51(1):13. https://doi.org/10.3390/engproc2023051013

Chicago/Turabian StyleHaruna, Shinsuke, Yuki Ogawa, Takumi Sakata, Daiki Shiozawa, Takahide Sakagami, Yoshiteru Yokoi, and Takeshi Sugiyama. 2023. "Deterioration Detection of Heavy-Duty Anticorrosion Coating Using Near-Infrared Hyperspectral Imaging" Engineering Proceedings 51, no. 1: 13. https://doi.org/10.3390/engproc2023051013

APA StyleHaruna, S., Ogawa, Y., Sakata, T., Shiozawa, D., Sakagami, T., Yokoi, Y., & Sugiyama, T. (2023). Deterioration Detection of Heavy-Duty Anticorrosion Coating Using Near-Infrared Hyperspectral Imaging. Engineering Proceedings, 51(1), 13. https://doi.org/10.3390/engproc2023051013