1. Introduction

Lithium-ion batteries have been replacing non-renewable energy sources over the past decade in order to have a clean and green environment with fewer carbon emissions. The internal combustion engines used in vehicles play a major role in the carbon emissions causing global warming [

1]. A uniform temperature within the safe limits for lithium-ion batteries should be maintained for optimal operation during the charging and discharging cycle of the cell. There are a number of methods to control these temperatures, some of which are liquid cooling [

2], air cooling [

3], and phase change materials passive cooling. The phase change material-based BTMS was first proposed by Al-Hallaj and Selman [

4]. Their study conducted a performance evaluation of the thermal management system for lithium-ion batteries using both air and PCM. The findings showed that the battery’s discharge rate and ambient temperature have a significant impact on the air-cooling management system’s performance, with high ambient temperatures and moderate discharge rates making it impossible to maintain a safe battery temperature [

2]. Wang et al. conducted an experimental investigation into the impact of utilizing fins on enhancing battery TMS performance. In their technique, paraffin with a melting temperature of 44 °C was used. The average battery temperature was reduced by 8 °C [

5].

PCMs with high latent heat storage are a very effective passive cooling method for lithium-ion cells. Battery thermal management systems (TMSs) have been rigorously tested numerically by previous research; however, the numerical analysis of battery TMSs has many simplifications to obtain favorable results. Real-time ambient environment effects with an increase and decrease in ambient temperature cannot be studied numerically. This leads us to the development of an experimental model to simulate the batteries for analysis and investigation of cell temperatures in natural convection, as well as when placed in PCM at a high discharge rate.

2. Methodology

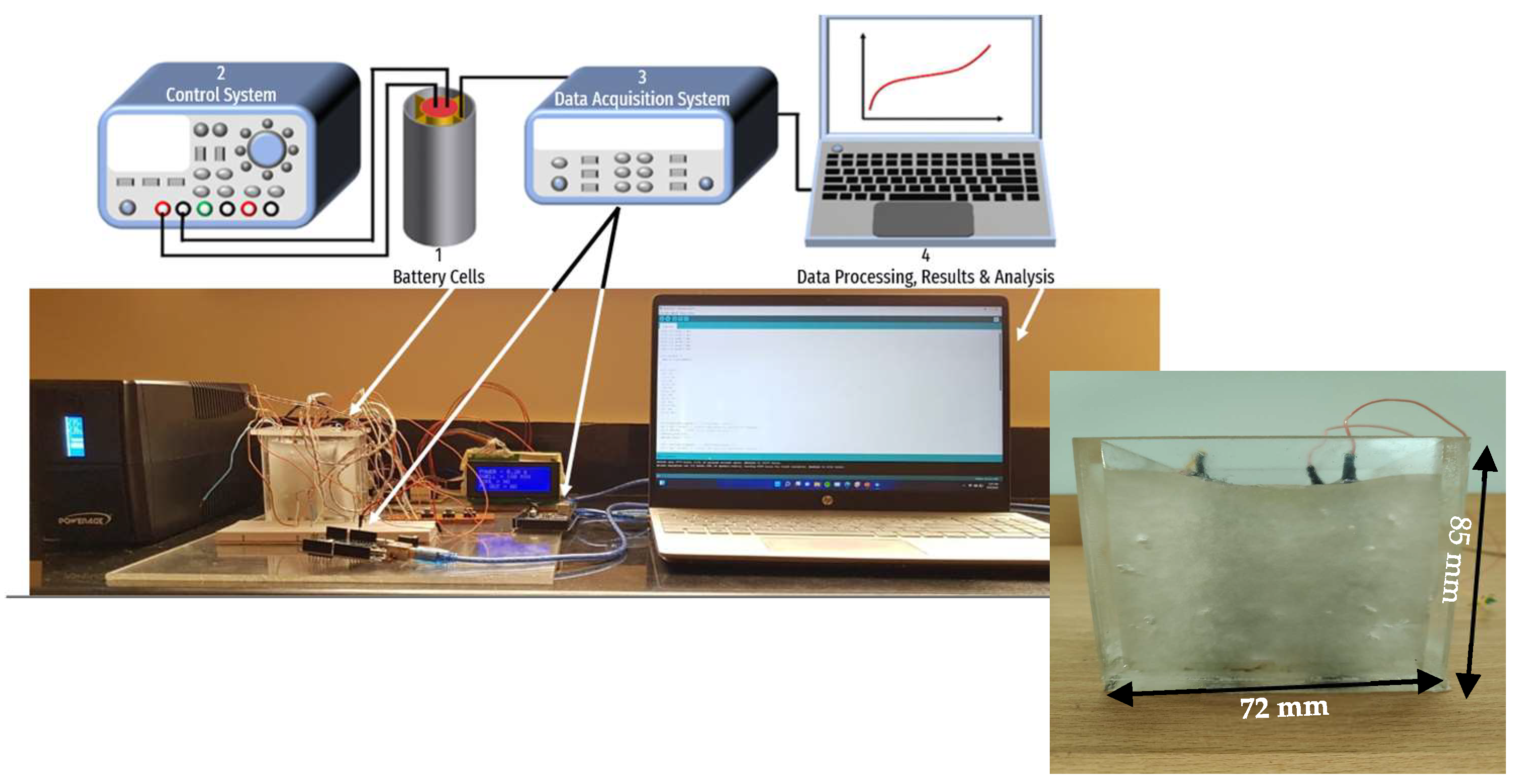

The experimental setup is designed to simulate the heat generation rates of an 18,650 lithium-ion cell using ceramic heaters placed inside an aluminum housing. The aluminum housing and the heater combined have the same dimensions as the 18,650 lithium-ion cell, which is 18 mm in diameter and 65 mm in height. A circuit using a combination of microcontrollers and ICs was designed for pulse wave modulation (PWM), producing similar discharging/charging waves as conducted by the lithium-ion cell controlled by the amount of power supplied in Watts to the ceramic heaters. The circuit has the capability of producing 0.05 W to 6 W with increments of 0.05 W. The circuit, with its current capability, has the ability to simulate 1C, 2C, and 3C discharge rates in a 2 × 2 square configuration of cells. The circuit connected to the cells is shown in

Figure 1. The acrylic housing containing the whole system is 72 mm × 72 mm in length and width and has a height of 85 mm.

The data acquisition system includes thermocouples paired with Arduinos for temperature measurement both for the cell and PCM.

The C rating is a crucial performance parameter that describes the discharge and charge capabilities of the battery. It indicates the rate at which a battery can be discharged or charged in relation to its capacity. The C rating is expressed as a multiple of the battery’s capacity, typically in units of “C”. The general formula to calculate the maximum discharge or charge current (I) based on the C rating [

6] is as follows:

The heat generation rates or the wattage ratings for different discharge rates are taken from Choudhari et al. [

7]. The heat generation rates are shown in

Table 1.

The cells are placed with 250 g of RT-42 fully submersed into the PCM. The system is given the heat generation rates of 3C to study the change in the heating curve for the cell. The PCM temperature is measured using 6 K type thermocouples placed at different heights and spacing uniformly, which will average out the PCM temperature, giving the melt fraction. The K-type thermocouple has an accuracy of ±2.2 °C. The experiment time is set to be 6000 s; however, the experiment would be truncated if the cell temperature increases the threshold of 50 °C.

3. Results

In the case of cells placed in natural convection, the rate of change of cell temperature was very high, and it crossed the benchmark temperature of 45 °C at 306 s. The naturally cooled experiment was truncated at 411 s when the temperature exceeded 50 °C. In the case of cells placed in RT-42, the comparison in

Figure 2a shows that the benchmark temperature of 45 °C was achieved in 1495 s and the maximum temperature achieved in 6000 s was 56.365 °C; however, the cell in an actual scenario would discharge much sooner, and the temperatures would remain under 50 °C.

The comparison of PCM and cell temperature is shown in

Figure 2b which illustrates that although the PCM prolongs the time to reach the upper limit of the optimal temperature 45 °C, it does not throttle the cell temperature very effectively. The rate of change of cell temperature is more than the rate of change of PCM temperature, which results in a rise in overall cell temperature.

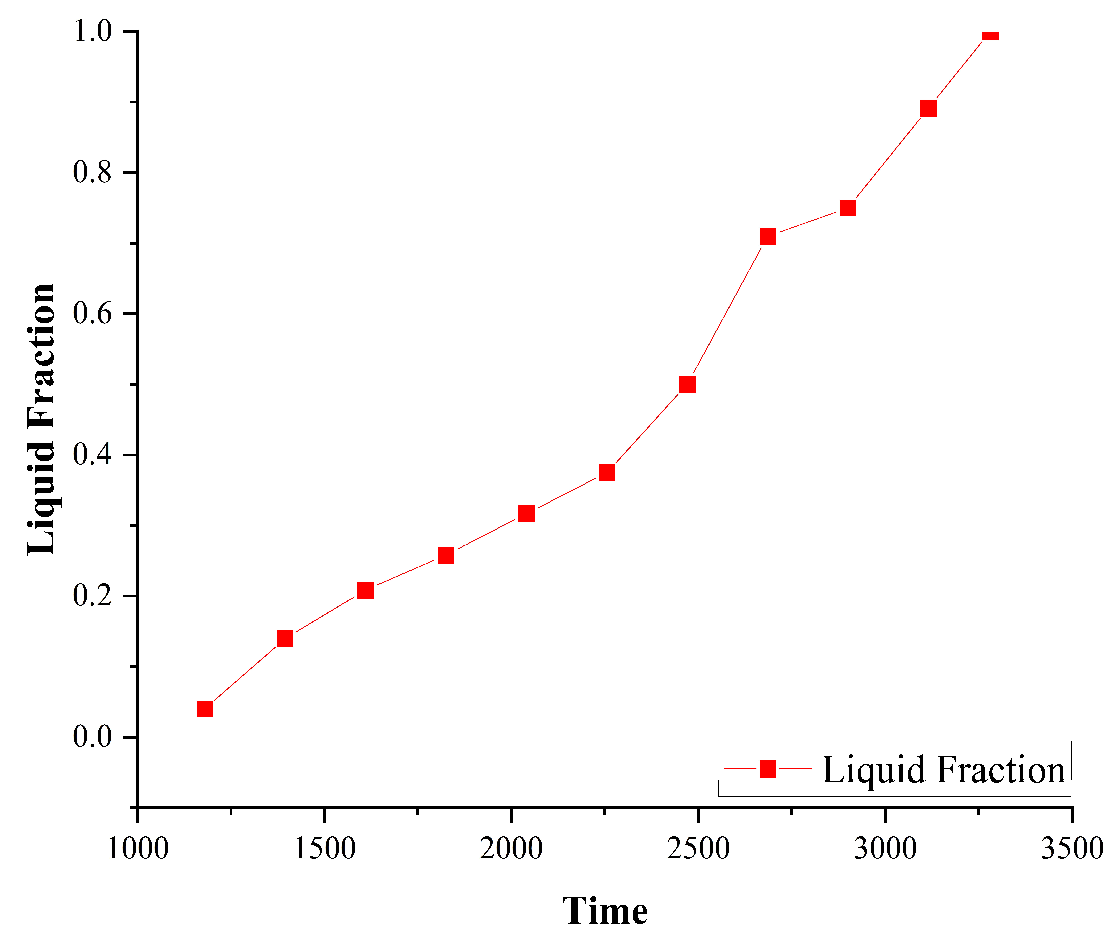

Figure 3 shows the melting fraction between the solidus temperature of 38 °C and the liquidus temperature of 43 °C, as provided by the datasheet from OEM for RT-42. The trends show that the melting slowed down due to the low thermal conductivity of PCM, and the heat started to accumulate. The corresponding cell temperature when melting starts at 1180 s is 43.43 °C, and the melt fraction is 4%. At 2500 s, when the melt fraction is 49.167%, the cell temperature is 47.095 °C, which is above the maximum optimal temperature of 45 °C. This means that due to heat accumulation, although the PCM is melting due to a weak thermal network and no external enhancement for heat transfer from cell to PCM, the cell temperature keeps rising, and the effectiveness of the systems reduces. Finally, a melting fraction of 100% is achieved at 3280 s, where the cell temperature is 48.07 °C.

4. Discussion

The analysis performed showed that a 79.53% increase in the operating time was observed staying under the maximum optimal temperature for the cells, which was 45 °C. The time range from 1490 s to 6000 s in the case of cells placed in PCM showed that the temperature rise slowed down but crossed 50 °C at 4270 s. The effectiveness of the cooling through PCM dropped when the melting region moved away from the surface of the cell, and the heat started to accumulate around the cell. This is due to the 0.2 W/m-K thermal conductivity value of the PCM. So, beyond a certain point, the rate of change in temperature increased. The solution to this problem is the addition of fins and their optimization while keeping the mass of PCM constant. Another way the thermal conductivity of the PCM can be enhanced is through ongoing research for experimentation.

Author Contributions

Methodology, Experimental Analysis, and Writing—Original Draft: S.A. Editing, Review, and Investigation: M.M.K. All authors have read and agreed to the published version of the manuscript.

Funding

The research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Abas, N.; Kalair, A.; Khan, N. Review of fossil fuels and future energy technologies. Futures 2015, 69, 31–49. [Google Scholar] [CrossRef]

- Sabbah, R.; Kizilel, R.; Selman, J.R.; Al-Hallaj, S. Active (air-cooled) vs. passive (phase change material) thermal management of high power lithium-ion packs: Limitation of temperature rise and uniformity of temperature distribution. J. Power Sources 2008, 182, 630–638. [Google Scholar] [CrossRef]

- Wei, Y.; Agelin-Chaab, M. Development and experimental analysis of a hybrid cooling concept for electric vehicle battery packs. J. Energy Storage 2019, 25, 100906. [Google Scholar] [CrossRef]

- Al Hallaj, S.; Selman, J.R. A Novel Thermal Management System for Electric Vehicle Batteries Using Phase-Change Material. J. Electrochem. Soc. 2000, 147, 3231. [Google Scholar] [CrossRef]

- Wang, Z.; Zhang, H.; Xia, X. Experimental investigation on the thermal behavior of cylindrical battery with composite paraffin and fin structure. Int. J. Heat Mass Transf. 2017, 109, 958–970. [Google Scholar] [CrossRef]

- Available online: https://www.power-sonic.com/blog/what-is-a-battery-c-rating/ (accessed on 7 August 2023).

- Choudhari, V.G.; Dhoble, A.S.; Panchal, S. Numerical analysis of different fin structures in phase change material module for battery thermal management system and its optimization. Int. J. Heat Mass Transf. 2020, 163, 120434. [Google Scholar] [CrossRef]

| Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).