Abstract

Cool roof coatings are being applied on rooftops to reflect solar irradiance back into the atmosphere. Bifacial photovoltaic modules can receive solar irradiance from the front and rear side. The purpose of this study is to investigate the impact of reflected irradiance caused by cool roof coating (CRC) on the performance of bifacial photovoltaic (bPV) modules and monofacial photovoltaic (mPV) modules. According to the experiments, cool roof coating is an efficient way to increase the output and efficiency of solar modules. Experimental results show that for cool roof coating based on TiO2 and FC resin with an average albedo of 0.63, the peak power output of the bifacial photovoltaic module is increased by 3.29% and its highest peak power efficiency is 18.1%. A peak power bifacial gain of 15.6% is seen. Due to a 1.3 °C decrease in temperature, the monofacial photovoltaic module power output also increased by 0.24%.

1. Introduction

Solar energy is considered as the most significant and highly developing source of renewable energy due to its global availability. Bifacial photovoltaic (bPV) modules are quickly gaining a market share due to their increased power production [1]. The amount of light absorbed on the bifacial solar cell’s rear side determines the rise in bifacial photovoltaic module production [2]. The solar irradiance reflected from the surrounding surfaces enhances the bifacial photovoltaic module efficiency, as well as the power output [3]. Researchers ran numerous trials with various configurations to increase the bifacial photovoltaic module’s yield. A 26% increase in bifacial gain is observed when flat mirrors are used behind the bifacial photovoltaic module [3]. The results of the experiment, which involved a bifacial solar module installed on a green roof with plant leaves, showed that for silver leaves, the increase in the photovoltaic module’s bifacial gain is up to 13%. In contrast, white sand’s irradiance reflection (albedo) of 0.47 results in an output gain of 4% [4]. A PV system with an aluminum sheet reflector was built, increasing the system’s annual output by 15% [5]. The albedo of fresh snow typically ranges from 0.4 to 0.8, and due to snow’s high reflectivity of up to 80%, a bifacial photovoltaic system’s total energy output increased by up to 20% [6]. Cool roof coatings, with high solar reflectance values, primarily aim to reflect solar radiation back into the atmosphere, reducing the energy requirements for cooling [7]. By adding reflectors, the bifacial gain was raised to an optimum value. According to the simulation results, using a standard ground cover with soil and vegetation, an albedo of 0.25 provides a bifacial gain of less than 10%. In addition, bifacial gain was increased to 20% when a white concrete surface with an albedo of 0.5 was used as the test condition [8].

2. Methodology

2.1. Preparation of Cool Roof Coating

Titanium dioxide (TiO2) was chosen as a covering pigment for a cool roof coating due to its high reflection in the near infrared region (NIR), ranging from 750 to 2500 nm. TiO2 powder was purchased from Vinkimya Private Limited, based in Lahore. The coating was prepared by utilizing a low-cost and straightforward procedure. Water was used as the solvent, with small amounts of antifoaming, dispersing, and wetting agents added to it. To achieve even mixing, the solution was swirled for 10 min. Then, while still swirling, FC resin was added as a filler and adhesive to prevent the coating from peeling after application. TiO2 was added after a period of stirring at an amount of 50% by weight (after drying), and the stirring speed was raised. To get rid of the bubbles created by stirring, the mixture was allowed to stand for a while [9]. After that, the coating was applied on a glass substrate as a test specimen and on the installation site of photovoltaic modules with a paint spryer machine up to a thickness of 0.5 mm (dried) and was allowed to air dry.

2.2. Experimental Setup

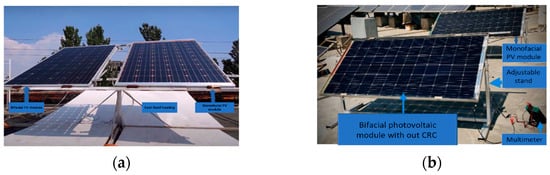

Figure 1 shows the experimental setup with CRC (a) and without CRC (b). The experimental setup consisted of a TiO2 cool roof coating covering the ground, mPV, bPV, and an adjustable stand. Photovoltaic modules were installed on the roof of MED UET Taxila, Pakistan (33.7° N, 72.8° E latitude angle). The tilt angle of the PV module was kept at almost 34°. Solar irradiance, temperature, and photovoltaic module output were measured by using a pyrometer, laser thermometer and digital multimeter, respectively.

Figure 1.

Bifacial and monofacial photovoltaic modules with CRC (a) and bifacial and monofacial photovoltaic modules without CRC (b).

3. Results and Discussion

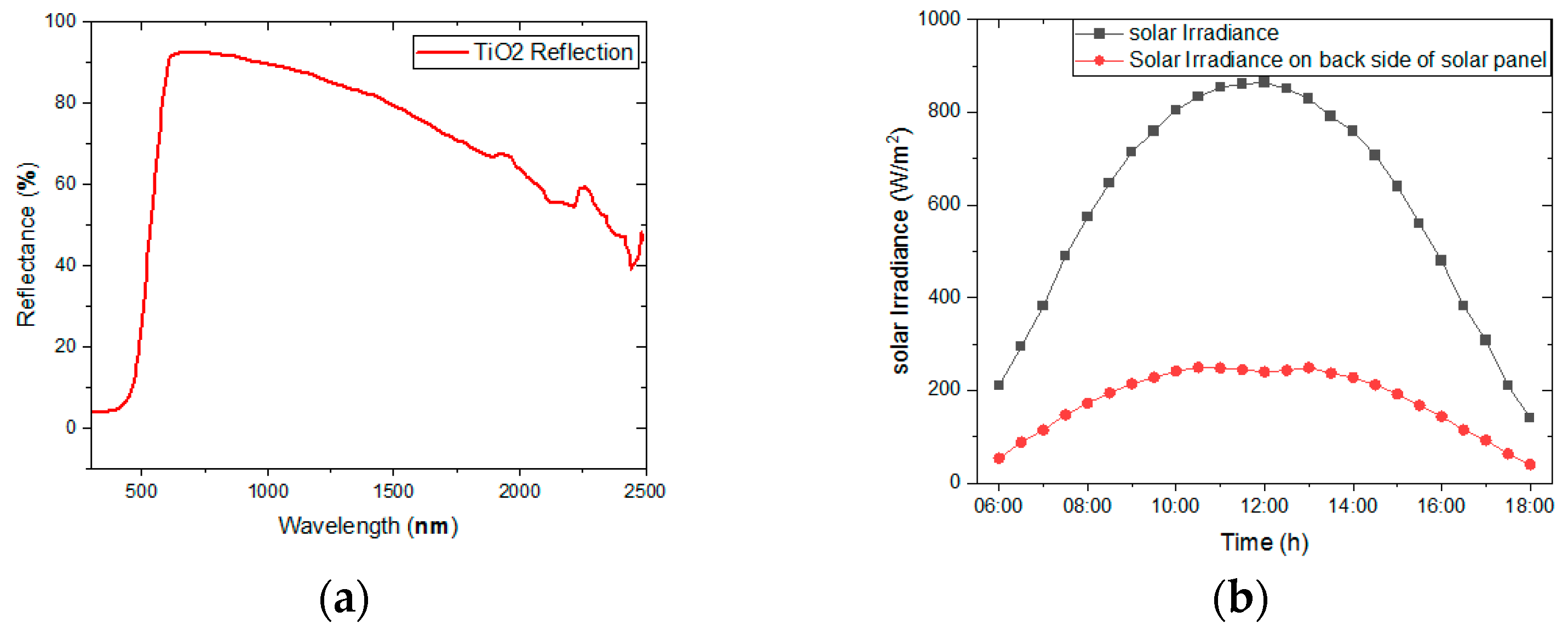

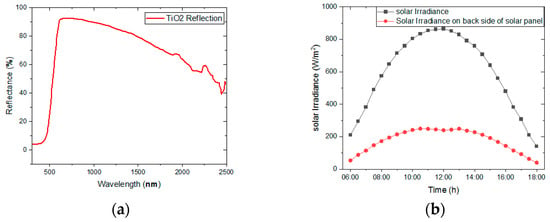

The reflectance spectrum of a single-layer TiO2 resin-based cool roof coating with 0.5 mm thickness was obtained by using a spectrophotometer (DR 6000) and a glass substrate test specimen, and the results are shown Figure 2a.

Figure 2.

Spectral reflection of the TiO2 coating (a) and solar irradiance on the front and back surface of the PV module (b).

The TiO2 cool roof coating exhibits 0.61 spectrum reflectance for ultraviolet region, 0.64 in the visible spectrum, and 0.723 for the near infrared region, and the total reflection observed for the cool roof coating is 0.63. Figure 2b illustrates the amount of solar irradiance incident on the front side and irradiance on the rear side of the bifacial photovoltaic module due to reflection. The irradiance on the front side varied from 141.3 W/m2 to 863.6 W/m2. The reflected irradiance on the rear side of the bifacial photovoltaic module ranged from 40.2 W/m2 to 248 W/m2 due to the cool roof coating.

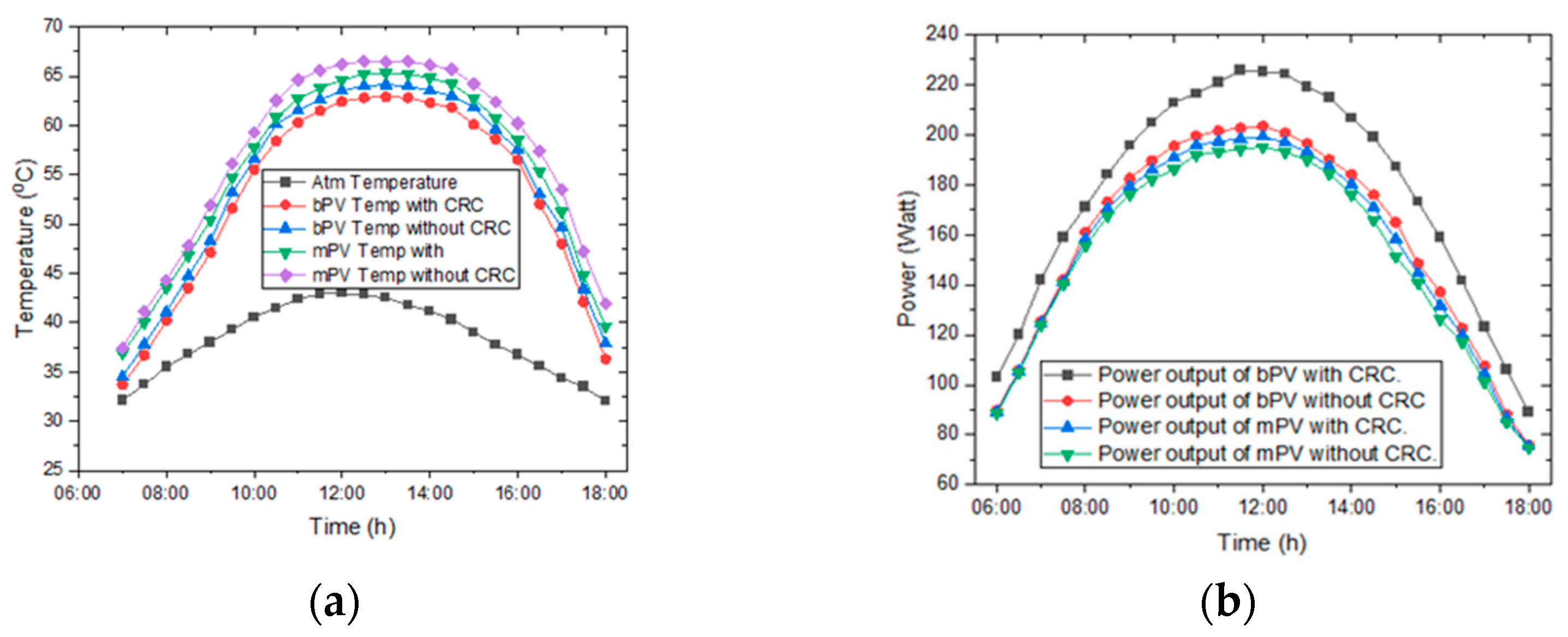

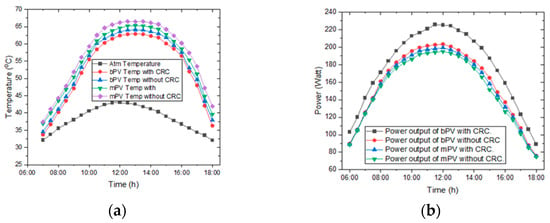

The temperature of photovoltaic modules with and without the cool roof coating is illustrated in Figure 3a. It is observed that the temperatures of the photovoltaic modules with the cool roof coating are lower those of the photovoltaic modules without the cool roof coating. The maximum temperature for the monofacial photovoltaic module without CRC is 66.5 °C at 13:30. The monofacial photovoltaic module with CRC, the bifacial photovoltaic module without CRC, and the bifacial photovoltaic module have temperatures of 65.2 °C, 63.9 °C, and 62.7 °C, respectively. The temperature of bifacial photovoltaic module is lower than that of the monofacial photovoltaic module, due to the transparency of bifacial photovoltaic module. The highest peak power is produced by the bifacial photovoltaic module with the cool roof coating, with an efficiency of 18.09%, as shown in Figure 3b.

Figure 3.

Comparison of PV module temperature (a) and power output (b).

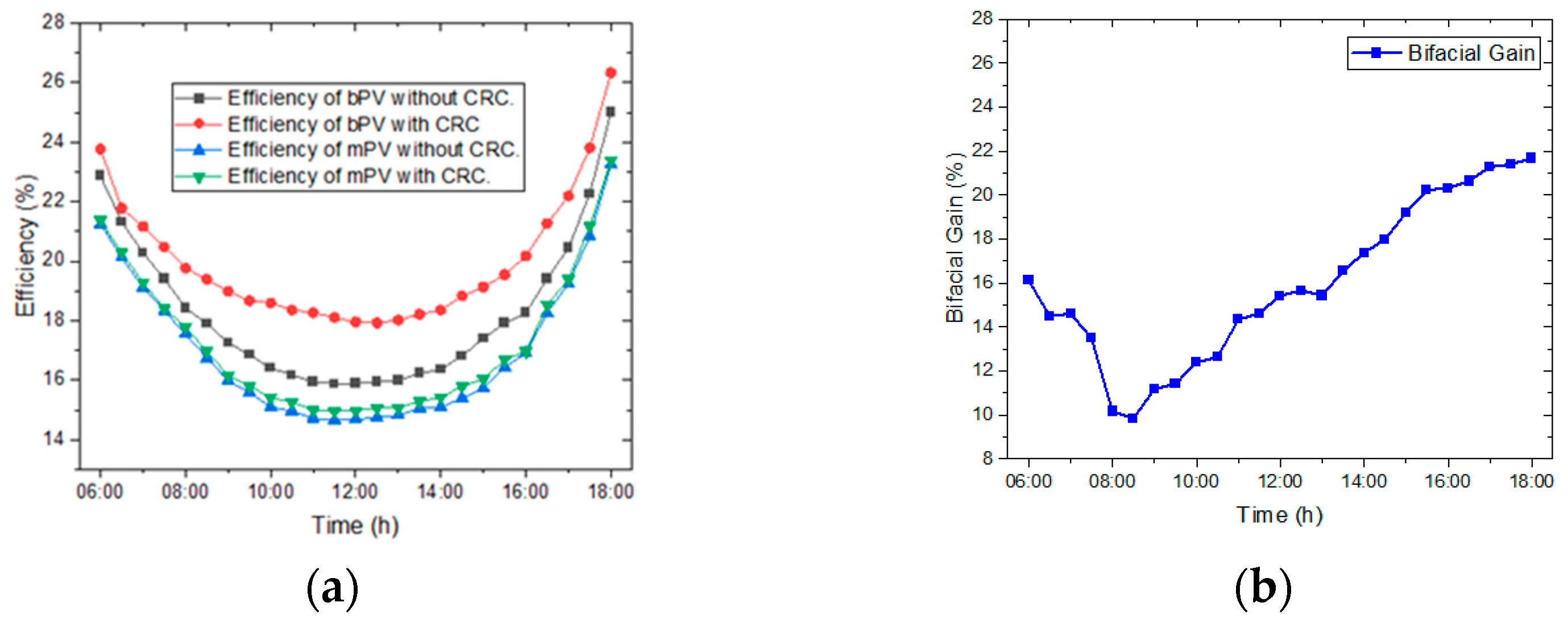

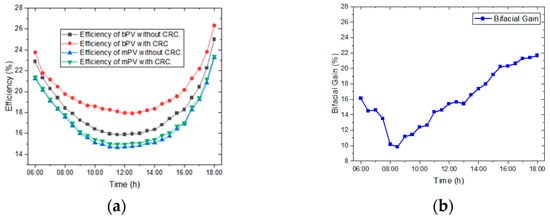

The peak power of the bifacial photovoltaic module is enhanced by 3.29% with the usage of the cool roof coating, as shown in Figure 4a. The bifacial photovoltaic module also outperforms the monofacial photovoltaic module with and without the cool roof coating, by 5.28% and 5.52%, respectively. The efficiency of the bifacial photovoltaic module is more than that of the monofacial photovoltaic module because of the rear irradiance and the lower module temperature due to the transparency of the bifacial photovoltaic module. The bifacial gain of the bifacial photovoltaic module is shown in Figure 4b. The bifacial gain measured at peak power is 15.6%. The highest bifacial increase was 21.68% in the evening.

Figure 4.

Efficiency of PV modules (a) and the bifacial gain of the bifacial photovoltaic module (b).

4. Conclusions

The purpose of this study was to investigate the impact of a cool roof coating on the performance of bPV and mPV modules which was developed by using TiO2 and FC resin.

A considerable increase in power and efficiency has been observed for the bifacial PV module. According to the experimental findings, cool roof coatings provide enough reflection (albedo) to improve the efficiency of bifacial PV modules. It is observed that the peak power efficiency of the bifacial PV module increased by 3.29% and ranges up to 18.1%, with the average reflection (albedo) of the cool roof coating being 0.63. A peak power bifacial gain of up to 15.6% is observed, while the highest bifacial gain is 21.68%. The performance of the monofacial PV module is also increased by 0.24% due to the 1.3 °C decrease in the temperature caused by using the cool roof coating.

Author Contributions

K.M.: Conceptualization, methodology, formal analysis, investigation, resources, data curation, B.T. and M.A.: data curation, writing—original draft preparation, A.H.: writing—review and editing, supervision. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Shoukry, I.; Libal, J.; Kopecek, R.; Wefringhaus, E.; Werner, J. Modelling of Bifacial Gain for Stand-alone and in-field Installed Bifacial PV Modules. Energy Procedia 2016, 92, 600–608. [Google Scholar] [CrossRef]

- Cuevas, A.; Luque, A.; Eguren, J.; del Alamo, J. 50 Per cent more output power from an albedo-collecting flat panel using bifacial solar cells. Sol. Energy 1982, 29, 419–420. [Google Scholar] [CrossRef]

- Lo, C.K.; Lim, Y.S.; Rahman, F.A. New integrated simulation tool for the optimum design of bifacial solar panel with reflectors on a specific site. Renew. Energy 2015, 81, 293–307. [Google Scholar] [CrossRef]

- Rodriguez-Pastor, D.A.; Ildefonso-Sanchez, A.F.; Soltero, V.M.; Peralta, M.E.; Chacartegui, R. A new predictive model for the design and evaluation of bifacial photovoltaic plants under the influence of vegetation soils. J. Clean. Prod. 2023, 385, 135701. [Google Scholar] [CrossRef]

- Ganesan, K.; Winston, D.P.; Sugumar, S.; Jegan, S. Performance analysis of n-type PERT bifacial solar PV module under diverse albedo conditions. Sol. Energy 2023, 252, 81–90. [Google Scholar] [CrossRef]

- Taomoto, Y.; Hosokawa, K.; Yagami, M.; Hanzawa, H.; Ohkawa, T.; Iwamoto, K. Bifacial tracking system in snowy region. In Proceedings of the BiFiPV 2016 Workshop, Miyazaki, Japan, 29–30 September 2016. [Google Scholar]

- Santamouris, M.; Synnefa, A.; Karlessi, T. Using advanced cool materials in the urban built environment to mitigate heat islands and improve thermal comfort conditions. Sol. Energy 2011, 85, 3085–3102. [Google Scholar] [CrossRef]

- Sun, X.; Khan, M.R.; Deline, C.; Alam, M.A. Optimization and performance of bifacial solar modules: A global perspective. Appl. Energy 2018, 212, 1601–1610. [Google Scholar] [CrossRef]

- He, Y.; Xia, Z.; Wang, R.; Yan, Y.; Hu, K.; Sun, H.; Liu, X. An easily prepared and long-term effective cooling coating that can be cooled to sub-ambient temperature without polyethylene film. Sol. Energy 2022, 246, 1–13. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).