Comparative Investigation of the Thermal Conductivity of Water-Based Nanofluids with and without the Combination of Alumina and Carbon Nanotubes †

Abstract

:1. Introduction

2. Materials and Methods

2.1. Characterization of Nanofluids

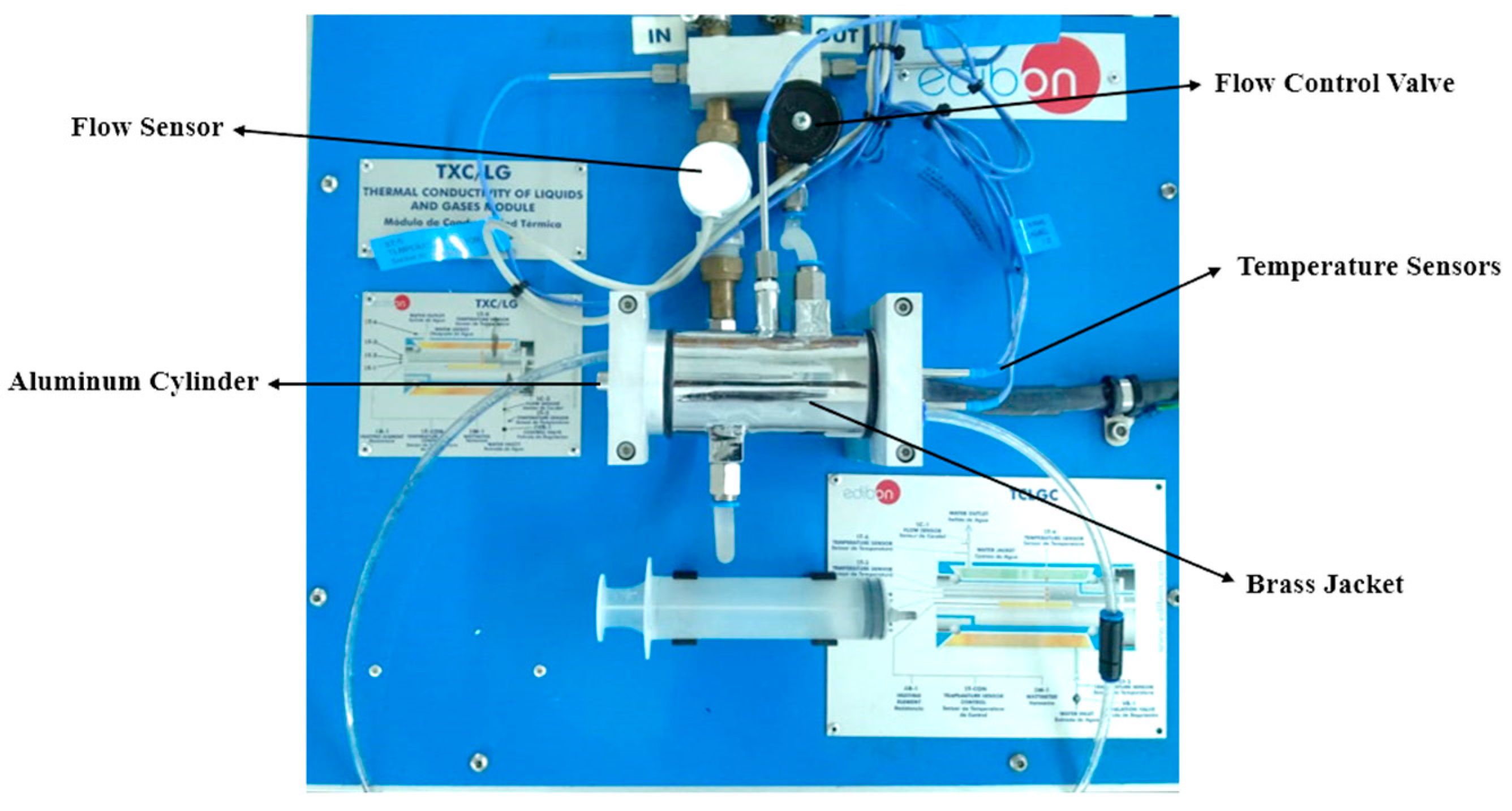

2.2. Experimental Analysis

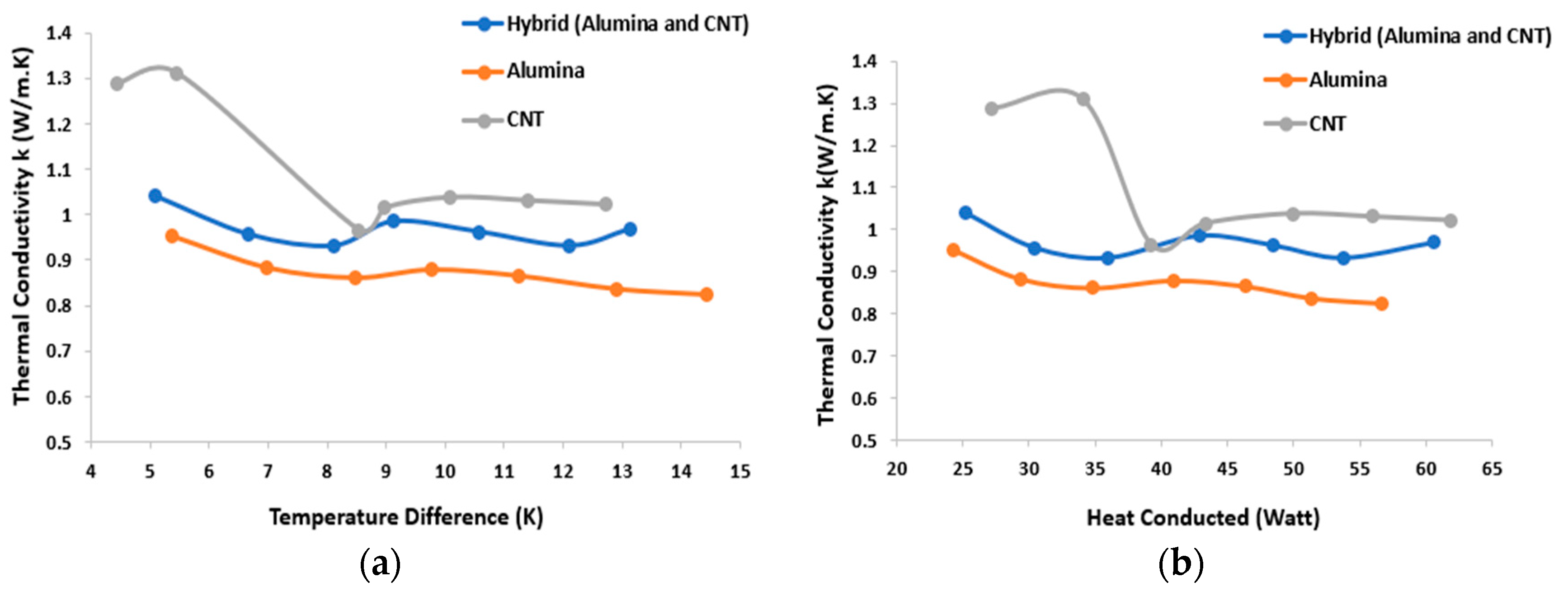

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Eastman, J.A.; Choi, U.S.; Li, S.; Thompson, L.J.; Lee, S. Enhanced Thermal Conductivity through the Development of Nanofluids. MRS Online Proc. Libr. OPL 1996, 457, 3. [Google Scholar] [CrossRef]

- Jang, S.P.; Choi, S.U.S. Effects of Various Parameters on Nanofluid Thermal Conductivity. J. Heat Transf. 2007, 129, 617–623. [Google Scholar] [CrossRef]

- Sajid, M.U.; Ali, H.M. Thermal conductivity of hybrid nanofluids: A critical review. Int. J. Heat Mass Transf. 2018, 126, 211–234. [Google Scholar] [CrossRef]

- Beck, M.P.; Yuan, Y.; Warrier, P.; Teja, A.S. The effect of particle size on the thermal conductivity of alumina nanofluids. J. Nanopart. Res. 2009, 11, 1129–1136. [Google Scholar] [CrossRef]

- Timofeeva, E.V.; Routbort, J.L.; Singh, D. Particle shape effects on thermophysical properties of alumina nanofluids. J. Appl. Phys. 2009, 106, 014304. [Google Scholar] [CrossRef]

- Kumanek, B.; Janas, D. Thermal conductivity of carbon nanotube networks: A review. J. Mater. Sci. 2019, 54, 7397–7427. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shoaib, M.T.B.; Rizwan, H.M.; Gull, M.N.; Khan, M.T.; Qureshi, M.T.; Malik, M.S.A.; Cheema, T.A. Comparative Investigation of the Thermal Conductivity of Water-Based Nanofluids with and without the Combination of Alumina and Carbon Nanotubes. Eng. Proc. 2023, 45, 21. https://doi.org/10.3390/engproc2023045021

Shoaib MTB, Rizwan HM, Gull MN, Khan MT, Qureshi MT, Malik MSA, Cheema TA. Comparative Investigation of the Thermal Conductivity of Water-Based Nanofluids with and without the Combination of Alumina and Carbon Nanotubes. Engineering Proceedings. 2023; 45(1):21. https://doi.org/10.3390/engproc2023045021

Chicago/Turabian StyleShoaib, Muhammad Talha Bin, Hafiz Muhammad Rizwan, Muhammad Naveed Gull, Muhammad Taha Khan, Muhammad Tahir Qureshi, Muhammad Shayan Ali Malik, and Taqi Ahmad Cheema. 2023. "Comparative Investigation of the Thermal Conductivity of Water-Based Nanofluids with and without the Combination of Alumina and Carbon Nanotubes" Engineering Proceedings 45, no. 1: 21. https://doi.org/10.3390/engproc2023045021

APA StyleShoaib, M. T. B., Rizwan, H. M., Gull, M. N., Khan, M. T., Qureshi, M. T., Malik, M. S. A., & Cheema, T. A. (2023). Comparative Investigation of the Thermal Conductivity of Water-Based Nanofluids with and without the Combination of Alumina and Carbon Nanotubes. Engineering Proceedings, 45(1), 21. https://doi.org/10.3390/engproc2023045021