Abstract

Fourteen-gauge solar PV mounting structure installations represent 60% of total solar PV installations in Pakistan. At least 34 (1.72%) structures were damaged on 13 June 2021 with an average 56 km/h wind speed on that day. Therefore, a need arose for a thorough analysis of the 14-gauge solar PV mounting structure. Computational analysis was carried out for 14-gauge solar PV mounting structures. The equivalent stress and total deformation in the structure were calculated computationally. Using computational analysis, it was found that 14-gauge solar PV mounting structures deformed at an 80 km/h wind velocity and broke at a 110 km/h wind velocity. Hence, 14-gauge solar PV mounting structures do not fulfil the building code of Pakistan.

1. Introduction

The damage percentage of solar PV structures has grown in various locations in Pakistan. On 13 June 2021, at least 34 (1.72%) solar mounting 14-gauge mild steel (MS) galvanized PV structures were damaged by wind in Islamabad and Rawalpindi alone. A total of 8417 Net-Metering Licenses for solar PV on-grid system installation were issued as per the 2020–2021 NEPRA annual report [1]. For the Islamabad and Rawalpindi district, 1976 licenses were issued and at least 34 (1.72%) solar PV mounting structures were damaged in one day [1]. Figure 1 shows a damaged solar PV mounting structure. According to the metrological office of Pakistan, strong wind speeds from 60 km/h to 100 km/h were recorded in past few years. Many solar PV mounting structures were damaged due to high wind speeds. Most damaged solar PV mounting structures were 14-gauge and 16-gauge galvanized steel rooftop structures that did not withstand the wind load and damaged below the safety requirement mentioned in the building code of Pakistan [2].

Figure 1.

Damages caused by wind to solar PV mounting structures at different locations. Red mark shows the damaged solar PV mounting structure.

2. Methodology

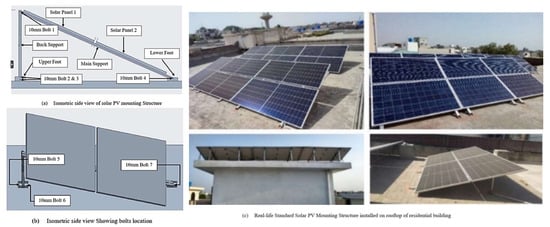

The 14-gauge solar PV mounting structure with two bolt-mounted solar panels was modelled using Creo Parametric 7.0 and imported into Ansys for FSI computational analysis. The LONGi 545W Solar Panel was modelled according to real-life dimensions [3]. Eight components, including main support with a 2500 mm length and 74 mm width, back support with a 1060 mm length and 79 mm width, upper foot with a 152 mm length and 83 mm width, and lower foot with a 150 mm length and 80 mm width, make up standard 14 gauge (2 mm thickness) solar PV mounting structure, which is extensively used in Pakistan, as shown in Figure 2. The angle of 24° was fixed throughout the study [4].

Figure 2.

The 14-gauge solar PV mounting structure with 2 solar PV modules.

2.1. Experimental Setup

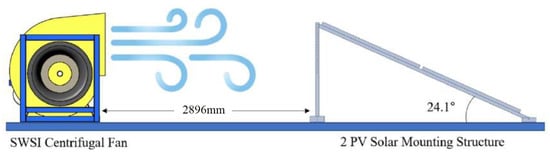

Single-Width Single-Inlet (SWSI) high-pressure centrifugal fan arrangement was employed for the validation of this study. Using a digital air velocity meter, the velocity at the fan outlet was measured at 31.67 km/h (1732 fpm). The fan and solar PV mounting structure arrangement is shown in Figure 3. The air velocity of 10.3 km/h was constant at the inlet of the solar PV mounting structure. The air velocity at different locations was measured. The height and width of planes perpendicular to the wind direction are 872 mm (2.86 ft) and 2256 mm (7.39 ft), respectively. The air velocity was compared with computational results for validation.

Figure 3.

Centrifugal fan setup with solar PV mounting structure.

2.2. Computational Setup

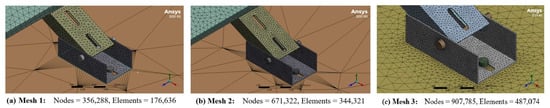

The Fluid Flow (Fluent) package of ANSYS Workbench 2021 R2 was employed in this work to investigate the equivalent stress and deformation in rooftop 14-gauge solar PV mounting structures at various wind speeds. Coarse (176,636 elements), medium (344,321 elements) and fine (487,074 elements) meshes were generated to validate mesh independence using the k−ω SST model, as shown in Figure 4.

Figure 4.

Nodes and elements of 3 tetrahedral meshes.

The difference in results between mesh with 671,322 nodes and one with 907,785 nodes is negligible compared to mesh with 356,288 nodes. The mesh with 907,785 nodes and 487,074 elements was considered sufficient to proceed with the computational analysis of a rooftop solar PV mounting structure subject to wind load. For experimental validation, a 10.3 km/h wind velocity was subjected from the inlet of the fluid domain. The results were validated with less than 10% error in experimental and computational results.

The boundary conditions for ANSYS computation were set up. At the inlet of fluid domain, a uniform wind velocity of 10.3 km/h, 25 km/h, 50 km/h, 75 km/h, 100 km/h, and 120 km/h were applied with a turbulence intensity of 5% and air density of 1.225 kg/m3.

2.3. Fluid–Structure Interaction (FSI)

After successful Fluent simulation, results from Fluid Flow (Fluent) were imported into a static structural setup. After connecting Fluid Flow (Fluent) with static structural qualities, material properties were initialized. Then, the pressure was imported for all bodies from Fluent to the static structural model. Figure 5 shows the imported pressure from Fluent at a 75 km/h wind velocity. The pressure on top of the solar panels was very low and near atmospheric pressure. The variation in contours is due to vortices of turbulent flow. The pressure at the back of the solar panel is highest because drag and lift forces both act on it [5].

Figure 5.

Imported pressure (MPa) from FSI simulation.

3. Results and Discussion

A centrifugal fan was placed and set up 2.896 m (9.5 feet) behind two PV panels fixed on the 14-gauge solar PV mounting structure. The air velocity at the intake plane at a distance of 9 feet varied from 9.9 km/h to 11.2 km/h at various positions. The average air velocity was 10.3 km/h since it was present at the majority of the sites. Throughout the experiment, the wind velocity was measured using a digital anemometer. To record the air velocity value, the digital anemometer was kept stable for five seconds at each location. With 25 points on each plane, a similar procedure was used for each plane. To determine the average air velocity at 25 points on each plane, the experiment was run three times.

Computational Results

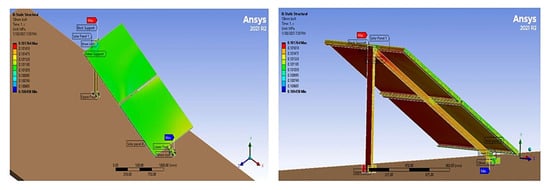

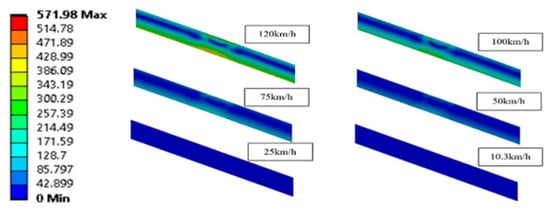

The 14-gauge solar mounting structure is stable when the wind velocity is at the start of the strong gale region on the Beaufort wind force scale, which is from 75 km/h to 88 km/h, as shown in Figure 6. In the strong gale region, which starts at a 75 km/h wind velocity, the equivalent stress on the main support of the structure is 221.62 MPa, which is less than the yield strength of steel (250 MPa). The structure failed at a 100 km/h wind velocity. However, structural stability is required up to 120 km/h according to the Building Code of Pakistan [2].

Figure 6.

Side view of main support showing equivalent stress (MPa) of 14-gauge solar PV mounting structure at different wind velocities.

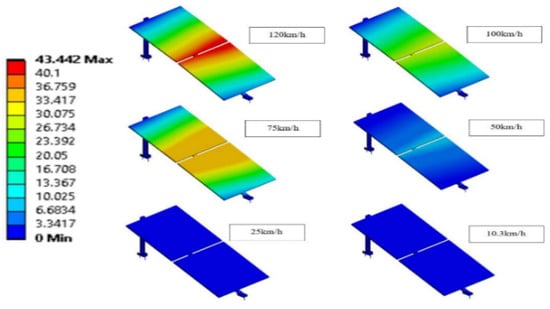

The total deformation of the solar PV mounting structure is shown in Figure 7. In this case, the main support plays an important role because the whole structure is in contact with the main support due to the preload on the solar panels. The deflection in the main support is 16.232 mm at a 75 km/h wind velocity. After a 75 km/h wind velocity, the deformation in the main support increased and the structure broke.

Figure 7.

Total deformation (mm) of symmetric 14-gauge structure in isometric view.

4. Conclusions

It was found that 14-gauge solar PV mounting structures installed in Pakistan do not meet the requirements of the Pakistani building code. The 14-gauge structure is being installed on a large scale in Pakistan and, using computational analysis, it was concluded that the structure is not safe at all and exceeds the yield strength at an 80 km/h wind velocity. The main support bears the whole load of the solar PV mounting structure because solar panels are bolted to the main support. It has been observed that most of the damaged solar PV mounting structures were installed with up to 550 W power ratings. The relevant authorities should allow PV modules with a lower area and more power that would bear recommended wind load. The solar PV mounting structure should be designed and built in accordance with the American Society of Civil Engineers (ASCE) worldwide standard.

Author Contributions

Conceptualization, review and supervision of project M.J.H.; Experimentation, investigation, and data processing A.M. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Informed consent was obtained from all subjects involved in the study.

Data Availability Statement

The data presented in this study are available on request.

Conflicts of Interest

The authors declare no conflict of interest.

References

- NEPRA. Annual Report 2020–21. 2021. Available online: https://nepra.org.pk/publications/Annual Reports/Annual Report 2020-21.pdf (accessed on 27 July 2023).

- Ministry of Housing & Works Experts Committee; PEC; NESPAK; International Code Council (ICC); American Concrete Institute (ACI). Building Code of Pakistan—Seismic Provisions—2007. 2007. Available online: https://www.pec.org.pk/wp-content/uploads/2021/05/Building-Code-of-Pakistan-Seismic-Provisions-2007.zip (accessed on 27 July 2023).

- LONGi Solar LR5-72HPH-535M-555M (545W) Solar Panel. 2021. Available online: https://static.longi.com/L_Gi_LE_T_TMD_059_107_LR_5_72_HPH_535_555_M_35_35_and_15_V14_895e6db05e.pdf (accessed on 8 September 2023).

- Shabbir, N.; Usman, M.; Jawad, M.; Zafar, M.H.; Iqbal, M.N.; Kütt, L. Economic analysis and impact on national grid by domestic photovoltaic system installations in Pakistan. Renew. Energy 2020, 153, 509–521. [Google Scholar] [CrossRef]

- Pantua, C.A.J.; Calautit, J.K.; Wu, Y. A fluid-structure interaction (FSI) and energy generation modelling for roof mounted renewable energy installations in buildings for extreme weather and typhoon resilience. Renew. Energy 2020, 160, 770–787. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).