Abstract

Composite fibers are an essential component of modern concrete structures, providing enhanced mechanical properties and durability. There are different types of fibers commonly used in concrete such as steel, glass, carbon, polypropylene fibers, etc. Composite fibers include a combination of two or more of these fibers. Composite fibers are discussed in detail, along with their properties and benefits. This paper also highlights the effects of composite fibers on the various properties of concrete, such as compressive strength, tensile strength, toughness, and durability. Furthermore, this paper discusses some of the challenges and limitations associated with the use of composite fibers in concrete, including issues related to fiber dispersion, fiber–matrix interactions, and cost-effectiveness. Finally, this paper concludes with a discussion of the future directions of research on composite fibers in concrete, focusing on potential advancements in fiber technology, improved manufacturing techniques, and the development of new fiber–matrix systems. Overall, this paper provides a comprehensive overview of the current state of the art in composite fibers in concrete and serves as a valuable resource for researchers and practitioners in the field.

1. Introduction

Due to its adaptability, toughness, and strength, concrete is the most widely used building material worldwide. However, it is prone to cracking and failure under tensile stress, which can result in structural damage and a shorter service life despite its many benefits [1]. Different kinds of fibers are added into concrete to improve its mechanical properties, such as its strength, hardness, and durability, in order to address this problem and increase its tensile strength. Modern concrete constructions require the use of these composite fibers, which are created from materials like steel, glass, carbon, and polypropylene and enable the structures to resist significant stress and strain. The development of fibers dates back to the Neolithic period when people used wheat straw in mud to increase its tensile strength and employed it for various purposes. Over the past few decades, the usage of fibers in concrete has become more widespread. For instance, steel fibers have been utilized to reinforce concrete and lessen cracking since the 1960s [2,3]. Additionally, the use of glass and carbon fibers has become more popular in concrete construction, which offers good corrosion resistance and a high strength-to-weight ratio [4].

This paper provides a thorough analysis of the most recent, cutting-edge research on composite fibers in concrete. The paper begins by outlining the many kinds of fibers that are frequently used in concrete, along with their characteristics and advantages. The impacts of composite fibers on different concrete parameters, including compressive strength, tensile strength, toughness, and durability, are then examined [5]. This research also outlines a number of difficulties and restrictions related to the usage of composite fibers in concrete, including issues related to fiber distribution, fiber–matrix interactions, and cost-effectiveness [6,7]. The use of composite fibers in concrete is then illustrated with examples from both structural and non-structural situations. Finally, the paper concludes with a discussion of future directions in concrete composite fiber research, with a focus on potential advances in fiber technology, improvements in manufacturing techniques, and the development of new fiber matrix systems. Overall, the purpose of this study is to introduce the readers to the field of fibers and their applications while also presenting a thorough grasp of composite fibers in concrete.

2. Types of Composite Fibers in Concrete

Composite fibers are typically made by combining two or more types of fibers to create a material that exhibits the desired properties. The utilization of fibers to enhance the mechanical properties of concrete is quite common today [8]. By using different types of fibers in concrete, its properties can be altered to the desired strength and durability [9]. Table 1 presents a tabular comparison between different types of composite fibers along with their properties and composition.

Table 1.

Different types of composite fibers, their properties, and their composition.

3. Mechanical Properties of Concrete

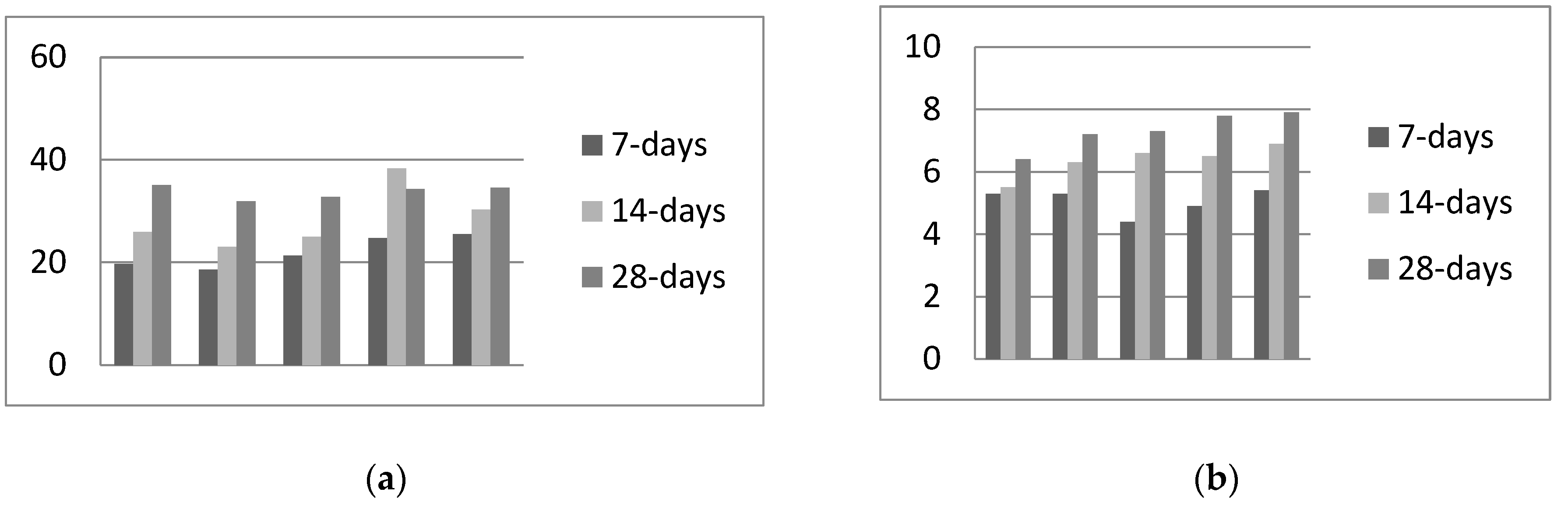

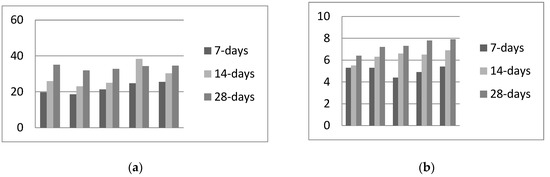

Concrete’s mechanical properties, including compressive strength, tensile strength, toughness, and durability, can be greatly improved by the addition of composite fibers. We present a general overview of how composite fibers affect certain characteristics. The inclusion of fibers in the concrete matrix affects the mechanical characteristics of fiber-reinforced concrete (FRC) [10]. Figure 1a,b presents values of compressive strength and tensile strength for different percentages of steel polymer matrix (0–1.25%). The first batch contains no fiber reinforcement and subsequent batches contain fibers in % increments of 0.25%.

Figure 1.

Mechanical properties of fiber-reinforced concrete. (a) Compressive strength. (b) Flexural strength of composite fiber concrete.

3.1. Compressive Strength

By improving its ability to withstand external loads, the addition of composite fibers can increase the compressive strength of concrete. For instance, it was discovered that steel fibers can boost concrete’s compressive strength by up to 15%, depending on the fiber volume fraction and aspect ratio, as illustrated in Figure 1a. The bridging effect of fibers, which slows the spread of cracks and improves material ductility, is thought to be responsible for the increase in compressive strength [7].

3.2. Tensile Strength

One of the issues with concrete is its low tensile strength, and to address this issue, fiber-reinforced concrete, a new type of concrete composite, was designed [8]. Concrete’s tensile strength can be considerably increased by the inclusion of composite fibers, making it less likely to crack or break under tensile stress. As seen in Figure 1b, polymer steel composites, for instance, have been proven to increase the tensile strength of concrete by up to 50%.

3.3. Ductility

The splitting tensile strength of fiber-reinforced concrete (FRC) is a measure of its resistance to tensile forces applied perpendicular to the direction of the applied load. It is a crucial factor in determining how well FRC performs overall in terms of crack resistance across a range of applications.

3.4. Modulus of Elasticity

The modulus of elasticity, which gauges a material’s stiffness or rigidity, can be significantly impacted by the addition of fibers to concrete. The mechanical properties of concrete change as a result of the fibers, which act as a reinforcement within the concrete matrix [3]. When fibers are added to concrete, the material becomes more composite by bridging fissures and has a higher load-bearing capability.

3.5. Toughness

The ability of a material to withstand energy absorption and prevent fracture or crack propagation is referred to as toughness. By bridging and stopping cracks that may occur while the concrete is under load, composite fibers help to increase the concrete’s durability [8]. Composite fibers serve as reinforcement when cracks first appear in the concrete matrix, dispersing stress and stopping the cracks from spreading.

3.6. Durability

The ability of a substance to resist deterioration and degradation over time, particularly when subjected to extreme environmental conditions, is referred to as durability. Concrete’s durability is increased by composite fibers in a number of ways.

4. Challenges and Limitations of Using FRC

Composite fibers offer many advantages when used as reinforcement in concrete, but there are also some challenges and limitations to consider. Cost is one of the main drawbacks of employing composite fibers in concrete [5]. The compatibility of composite fibers with the concrete matrix is another drawback. To ensure effective fiber adhesion to the matrix, the characteristics of the fibers and the concrete mix must be precisely matched. Composite reinforcements may be less effective and less durable due to incompatibility [5,6,7]. The use of composite fibers can also provide some difficulties. Composite fibers can present additional difficulties during the mixing procedure.

5. Future Directions in Research on Composite Fibers in Concrete

Recent years have seen a lot of interest in the use of composite fibers in concrete, and research is still being performed to examine potential new applications and difficulties. The use of short fibers or whiskers is both the simplest and most efficient method. It was discovered that this technique considerably increases concrete’s tensile strength and decreases tensile cracking. To create new varieties of composite fibers with enhanced characteristics and performance compared to existing materials, research is currently being conducted. Advanced manufacturing techniques such as 3D printing and automated fiber placement enable composite fibers to be more accurately and efficiently incorporated into concrete [2,3,4]. These techniques can also be used to tailor the orientation and distribution of fibers within concrete, which can improve the overall performance of composite reinforcements.

6. Conclusions

Finally, this conference paper on composite fibers will offer insightful information about the wide variety of composite fibers and their uses. This article presents a comparative analysis of the various fiber types, including carbon fiber, glass fiber, steel fiber, natural fiber, basalt fiber, and ceramic fiber. A high strength-to-weight ratio, stiffness, fatigue resistance, impact resistance, heat resistance, affordability, a renewable nature, and biodegradability are just a few of the special advantages that each type of fiber provides. This paper’s objective is to present a thorough overview of the various aspects of CFRPs, including their structural and durability properties, ongoing research into their use as reinforcing materials for concrete structures, and the application of FRP sheets in the rehabilitation of deteriorated concrete structures. Though they have not been thoroughly examined, topics pertaining to the production of FRP composites and design processes have been included for informational and comprehensive purposes.

Author Contributions

Conceptualization, S.K. (Samiullah Khan) and S.K. (Safeer Khattak); methodology, S.K. (Samiullah Khan); software, S.K. (Samiullah Khan); validation, S.K. (Samiullah Khan), H.K. and S.K. (Safeer Khattak); formal analysis, S.K. (Samiullah Khan); investigation, S.K. (Samiullah Khan); resources, S.K. (Safeer Khattak); data curation, H.K.; writing—original draft preparation, S.K. (Samiullah Khan). All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

All data is obtained from open source articles and journals.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Monfared, V.; Ramakrishna, S.; Alizadeh, A.; Hekmatifar, M. A systematic study on composite materials in civil engineering. Ain Shams Eng. J. 2023, 6, 102251. [Google Scholar] [CrossRef]

- Yoo, D.-Y.; Banthia, N. Mechanical properties of ultra-high-performance fiber-reinforced concrete: A review. Cem. Concr. Compos. 2016, 73, 267–280. [Google Scholar] [CrossRef]

- Fediuk, R.; Smoliakov, A.; Muraviov, A. Mechanical Properties of Fiber-Reinforced Concrete Using Composite Binders. Adv. Mater. Sci. Eng. 2017, 2017, 2316347. [Google Scholar] [CrossRef]

- Mahmood, A.; Noman, M.T.; Pechočiaková, M.; Amor, N.; Petrů, M.; Abdelkader, M.; Militký, J.; Sozcu, S.; Hassan, S.Z.U. Geopolymers and Fiber-Reinforced Concrete Composites in Civil Engineering. Polymers 2021, 13, 2099. [Google Scholar] [CrossRef] [PubMed]

- Mobini, M.H.; Khaloo, A.; Hosseini, P.; Esrafili, A. Mechanical properties of fiber-reinforced high-performance concrete incorporating pyrogenic nanosilica with different surface areas. Constr. Build. Mater. 2015, 101, 130–140. [Google Scholar] [CrossRef]

- Bheel, N.; Awoyera, P.; Aluko, O.; Mahro, S.; Viloria, A.; Sierra, C.A.S. Sustainable composite development: Novel use of human hair as fiber in concrete. Case Stud. Constr. Mater. 2020, 13, e00412. [Google Scholar] [CrossRef]

- Klyuev, S.V.; Khezhev, T.; Pukharenko, Y.; Klyuev, A. Fiber Concrete for Industrial and Civil Construction. Mater. Sci. Forum 2019, 945, 120–124. [Google Scholar] [CrossRef]

- Lee, H.; Choi, M.K.; Kim, B.-J. Structural and functional properties of fiber reinforced concrete composites for construction applications. J. Ind. Eng. Chem. 2023, 125, 38–49. [Google Scholar] [CrossRef]

- You, X.; Lin, L.; Fu, B.; Xiang, Y. Ultra-high performance concrete reinforced with macro fibres recycled from waste GFRP composites. Case Stud. Constr. Mater. 2023, 18, e02120. [Google Scholar] [CrossRef]

- Marcalikova, Z.; Cajka, R.; Bilek, V.; Bujdos, D.; Sucharda, O. Determination of Mechanical Characteristics for Fiber-Reinforced Concrete with Straight and Hooked Fibers. Crystals 2020, 10, 545. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).