Abstract

Due to its advantages—energy efficiency, heating speed, non-contact, controllability, etc.—induction heating has been widely used in many industries. The purpose of this article is to review the basics of induction heating in the food industry and analyze a pilot experiment on the concentration of a food solution. The developed laboratory induction evaporator showed good results. The research needs and future prospects of this technology in other food industries are also presented.

1. Introduction

Most food liquid products of plant origin are aqueous solutions or suspensions containing dry solutes. In order to reduce the amount of liquid and transportation and storage costs, negative chemical and biochemical reactions, and microbiological processes, it is recommended to remove part of the water from the products.

In order to reduce the volume of transportation and storage of liquid semi-finished products, as well as produce the finished product, drying and concentration processes are used on farms.

Existing industrial methods for obtaining liquid products with a high solids content are characterized by elevated process temperatures, leading to significant losses of volatile aromatic components and intense corrosion of the equipment. Currently, all liquid products are concentrated by evaporation.

In practice, as a rule, water vapor is used to heat solutions to the boiling point. Compared with other coolants, steam has the following advantages: high heat transfer coefficient, low consumption, easy transportation, and low cost.

However, with the emerging global trend of increasing prices for hydrocarbon fuels (oil, gas), by which the boiler plants of most food industry enterprises operate, the cost of steam produced has increased and, ultimately, the profitability of production has decreased. In this regard, enterprises began to search for alternative sources of thermal energy.

We believe that induction heaters are more efficient and economical; they generate heat by using electromagnetic field energy in magnetic materials [1]. Today, the increasing use of induction heating can be explained by its main advantage—non-contact and practical inertia when transferring energy from an inductor and converting it into thermal energy. It is known that induction heating is traditionally widely used in the metallurgical industry as a fast-heating method that does not require direct contact with the product for heat transfer [2]. Modern advances in technology, i.e., in power electronics, control methods, and the design of induction heating components, have allowed the development of highly reliable and economical systems, making this technology available and ubiquitous [3].

However, the application of this technology in the food industry is still in an early stage. In particular, the optimal designs have not yet been determined, and various design and operational parameters of induction heating apparatuses for use in the processes of drying, pasteurization, sterilization, and frying of food products have not been sufficiently studied [4].

Induction heating, unlike other methods, provides volumetric and practical inertia of heat release, i.e., the possibility of a quick stop and start of the thermal effect on the material being processed is created, as well as high accuracy of adjustment of the heating process and its reproducibility. Traditional heating methods provide heating of the surface, and the induction method contributes to a faster increase in temperature with a more intense uniformity of heat release since when the field interacts with the heated object, thermal energy is released in its volume. As is known, due to the wave structure of the electromagnetic field, heat is released unevenly and evens out over time by heat transfer. Due to the fact that the rate of heat transfer is dependent on the properties of the material, then, accordingly, this process takes a different time. Temperature equalization for solid dielectrics with low thermal conductivity can take a long time. With a faster wave energy supply, this can cause local overheating and the effect of a thermal explosion. For liquids that have high thermal conductivity, the rate of temperature equalization is faster, but localized overheating zones can also form, which can have a negative impact on the quality of the finished product.

2. Methods

The research used the model of an induction evaporator developed by the author. The developed apparatus has been tested and evaluated for the reliability of heat generation from its induction coils and evaporation of moisture from products. At the same time, the ambient temperature in the test room, the influence of lighting, the stability of the power supply (220 volts—1 phase), and the temperature of the product during the entire process depending on time were determined.

The temperature generated by each induction coil and induced on the support materials was recorded and measured with a thermometer capable of displaying temperatures from 0 °C to 160 °C. To document the time, a conventional stopwatch was used with the ability to record with an accuracy of tenths of a second. This provides a proven and academically acceptable means of measuring all related performance parameters.

The induction heater has been tested under maximum loads. All data were recorded in accordance with the work cycle. This should be sufficient to establish the integrity and durability of the device, as well as the durability of the supporting elements. In particular, the first of the evaluations was carried out on the ability of the induction coil to consistently create an induction process without errors or failures. The heat generated in the process was recorded at identical time points measured with a stopwatch.

The study used a descriptive analysis for each of the physical quantities. Basic measurements were carried out for each characteristic of the system. A logical statistical analysis of all obtained data was also carried out in order to summarize the predicted durability of the induction heating apparatus. Threats to the validity of this study were (1) power fluctuations for the induction coil, (2) instrument calibration failure and inaccurate readings, and (3) incorrect data recording and storage. [5]

3. Results and Discussion

The most economical method of heating solutions in metal containers, which is based on the use of induction heating, has been developed and confirmed in practice. Such heating is carried out with the help of electric currents induced directly in the walls of the apparatus, and the body itself is a heat carrier with high efficiency.

Induction heating compared to other electric heating methods has a higher efficiency (over 90%) [6] and a longer service life.

The search for the design and control algorithm determined that the most rational is the design of a single-layer cylindrical inductor. Based on the foregoing, in the technology of concentrated products, it is proposed to use an induction steam generator instead of a steam boiler. The evaporator is replaced by a cylindrical device. Hollow rods are placed inside the cylinder, through which the food liquid mass passes. The cylinder, when the winding is turned on and under the influence of an electromagnetic field, is heated to a predetermined temperature. The rod heats up, and the mass also heats up.

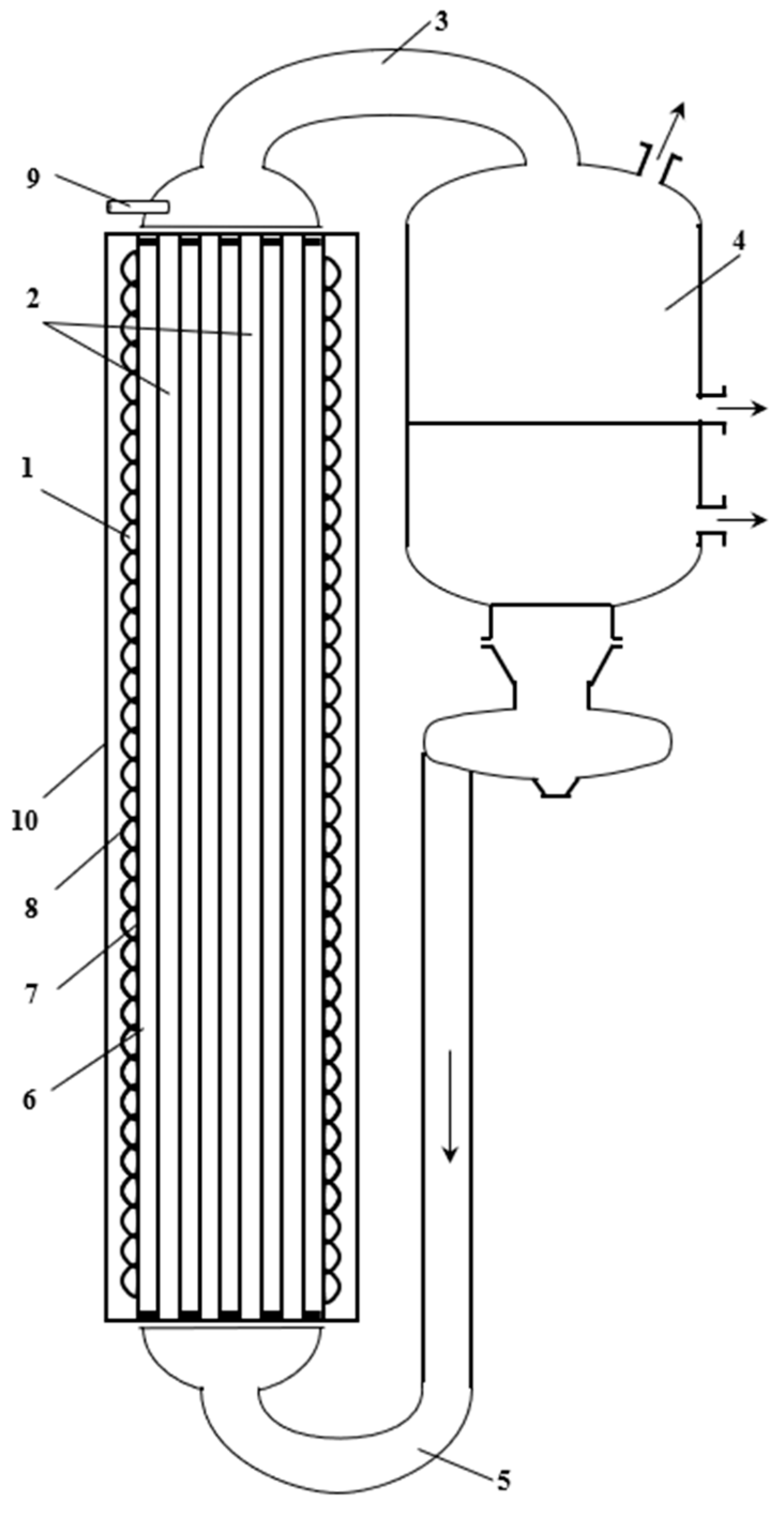

The induction-type evaporator (Figure 1) consists of an inductor, 1, heating plates, 2, an upper outlet pipe, 3, a lower discharge pipe, 5, and a pumping unit, 4. The inductor, 1, includes a metal frame, 6, heat insulators, 7, electrical winding, 8, housing 10, and a thermostat, 9. The number of turns of the inductor is 360, the total power of the inductor is 3.6 kW, and the voltage is 220 V. The outer diameter of the cylinder is 0.062 m [7].

Figure 1.

Induction evaporator.

It works by pumping the product from bottom to top through thin-walled nozzles, and the steam–product mixture enters the upper part of the housing through the outlet pipe. Steam is removed from the side, and the product under the pressure of a continuously incoming mass comes out. When connected to the network, the inductor winding creates an electromagnetic field that heats all metal parts and the product. The temperature is regulated by a thermostat by turning the inductor on and off.

An analysis of the results of laboratory studies shows that the specific energy consumption for the evaporation of 1 kg of water is 0.63 kW, and the evaporation rate is 4.5 L/h.

The effectiveness of the developed induction evaporator has been confirmed by laboratory tests and is recommended for implementation in the production of concentrated food products (tomato paste, condensed milk) and other thermal technological processes.

Based on the results of this research, the author obtained national patents for the use of induction heating in the food industry, in particular for the pasteurization of milk, the evaporation of liquid products, and the drying of fruits, vegetables, and dairy products [8].

4. Conclusions

The use of induction heating in the food industry is a green innovation that saves resources and improves productivity and efficiency. Its main advantages are ensuring the required product quality, fast heating, easy control, and non-contact heat generation.

The introduction of the technical solutions proposed above into production practice will reduce the duration of the production process, lower the capital costs, and save the energy resources of the enterprise. Induction heating technology will achieve the goals of sustainable development in the food industry.

Supplementary Materials

The following are available online at https://www.mdpi.com/article/10.3390/ECP2023-14687/s1.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

All data is provided in the results section of this paper.

Conflicts of Interest

The author declares no conflict of interest.

References

- Shields, J.P. ABC’s of Radio-Frequency Heating, 1st ed.; H.W. Sams & Co.: Indianapolis, IN, USA, 1969. [Google Scholar]

- Rudnev, V.; Loveless, D.; Cook, R.; Black, M. Handbook of Induction Heating; Marcel Dekker Inc.: Monticello, NY, USA, 2003. [Google Scholar]

- Lucia, O.; Maussion, P.; Dede, E.; Burdio, J. Induction heating technology and its applications: Past developments, current technology, and future challenges. IEEE Trans. Ind. Electron. 2013, 61, 2509–2520. [Google Scholar] [CrossRef]

- El-Mashad, H.M.; Pan, Z. Application of Induction Heating in Food Processing and Cooking. Food Eng. Rev. 2017, 9, 82–90. [Google Scholar] [CrossRef]

- Hampton, B.A. An Evaluation of Induction Heating in Healthcare Food Industry. Master’s Thesis, Western Kentucky University, Bowling Green, KY, USA, 2018. [Google Scholar]

- Başaran, A.; Yilmaz, T.; Civi, C. Application of inductive forced heating as a new approach to food industry heat exchangers: A case study—Tomato paste pasteurization. J. Therm. Anal. Calorim. 2018, 134, 2265–2274. [Google Scholar] [CrossRef]

- Habibov, A.H. To reduce the energy consumption of the concentrated food production process. Bull. Technol. Univ. Tajikistan 2009, 1, 100–103. [Google Scholar]

- Sultanov, Z.S.; Habibov, A.H. Efficiency of Innovative and Technological Development of the Regional Food Subcomplex; Publishing House RTSU: Dushanbe, Tajikistan, 2019; Volune 174. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).