2. Methodology

Biomedical model effluent—Stock aqueous solutions of phenol (500 mg/L) were created for the creation of synthetic biomedical solutions by weighing and dissolving the appropriate quantity of the respective component in distilled water. These solutions were then stored and subjected to spectrophotometric analyses to determine their quality. When used, a stock solution was diluted to a lower concentration than its original concentration. Subsequently, 0.467 mL of phenol was dissolved in 1000 mL of distilled water to create a phenol stock solution with a 500-ppm concentration, and the stock solution was then diluted to create other concentrations.

Synthesis of modified activated carbons from potato peels—A potato peel is an advanced green adsorbent since it is rich in high-value elements, particularly polysaccharides, and lignin, which may be burned to produce carbonaceous material. The potato skins used in the experiment were sourced from either Greek cultivars or leftovers from restaurants. The potato peels were thoroughly cleaned with distilled water before being baked in an oven for 24 h at 393 K to eliminate dust and other inorganic contaminants [

8]. The dry material was crushed, and then a uniform particle size of 0.45–0.15 mm was obtained using sieving.

Estimation of Sample—A UV–visible spectrophotometer was used to analyze the estimate of phenol. At 270 nm, phenol’s maximum wavelength was discovered [

9]. To determine different optical densities at various concentrations, the sample was calibrated. The calibrated findings, which display a graphical depiction of the calibration of phenol, are highly useful for determining the specific phenol removal capabilities of various adsorbents. To calculate the amount of phenol absorbed (

qe, mg/g), the following relationship was used [

10]:

where

V is the volume of the solution (L),

M is the weight of the adsorbent utilized (g), and

C0 is the initial concentration of phenol (mg/L).

Ce is the equilibrium liquid phase concentration of phenol [

11]. The following equation was used to express the percentage of phenol elimination:

where

Ce denotes the final concentration and

C0 denotes the initial concentration of phenol.

3. Results and Discussion

The phenol sample was calibrated to determine different optical densities at different concentrations. The calibrated results are highly useful for determining each adsorbent’s phenol elimination capabilities. The standard stock solution was made in various concentrations, and a spectrophotometer was used to measure the absorbance of each concentration.

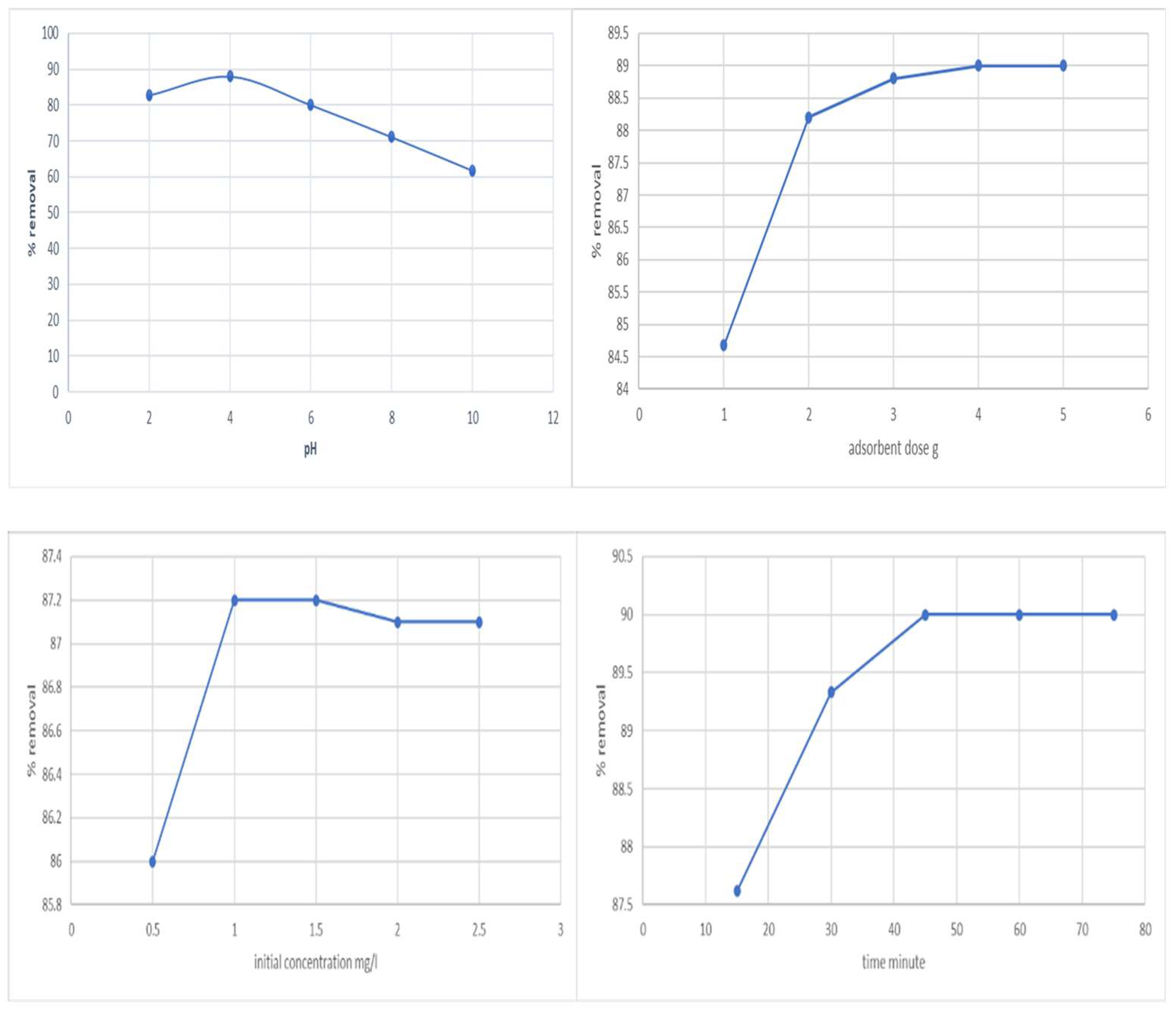

Effect of pH—The degree of ionization of the adsorbate during the reaction is influenced by pH, which also affects the solubility of phenol ions in the solution and replaces some of the positive ions present at the active sites. Within a pH range of 2 to 10, pH’s initial impact on phenol’s adsorption was determined (

Figure 1). At pH 4, the maximum adsorption was found to be 88.07%. The difference in the concentrations of H+ and OH- in the solutions may be the cause of this.

Effect of adsorbent dosage—The dosage of the adsorbent is a crucial parameter since it controls the system’s sorbent–sorbate equilibrium as well as the adsorbent’s capacity for a particular phenol concentration. Within the adsorbent dosage range of 1–5 g/L, the adsorbent dose’s impact on phenol’s adsorption was evaluated (

Figure 1). Adsorption effectiveness was shown to rise with increasing adsorbent dosage; however, adsorption volume was found to decrease. The adsorption efficiency did not considerably increase after a particular dosage. Therefore, 2 g/L was chosen as the ideal concentration for the subsequent adsorption trials.

Effect of initial concentration—The initial concentration acts as a crucial driving factor to go around all of phenol’s mass transfer resistance between the aqueous and solid phases. The initial phenol concentration is controlled between 0.5 and 2.5 mg/L (

Figure 1). The starting phenol content was increased up to 1 mg/L, and this modestly improved the equilibrium adsorption efficiency of the activated carbon.

Effect of time—The properties of activated carbon and the number of sorption sites it offered influenced how long it took to reach equilibrium. Time was restricted to 15 to 75 min for this experiment (

Figure 1). In the first 30 min, significant amounts of phenol were eliminated, and equilibrium was established in 45 min.

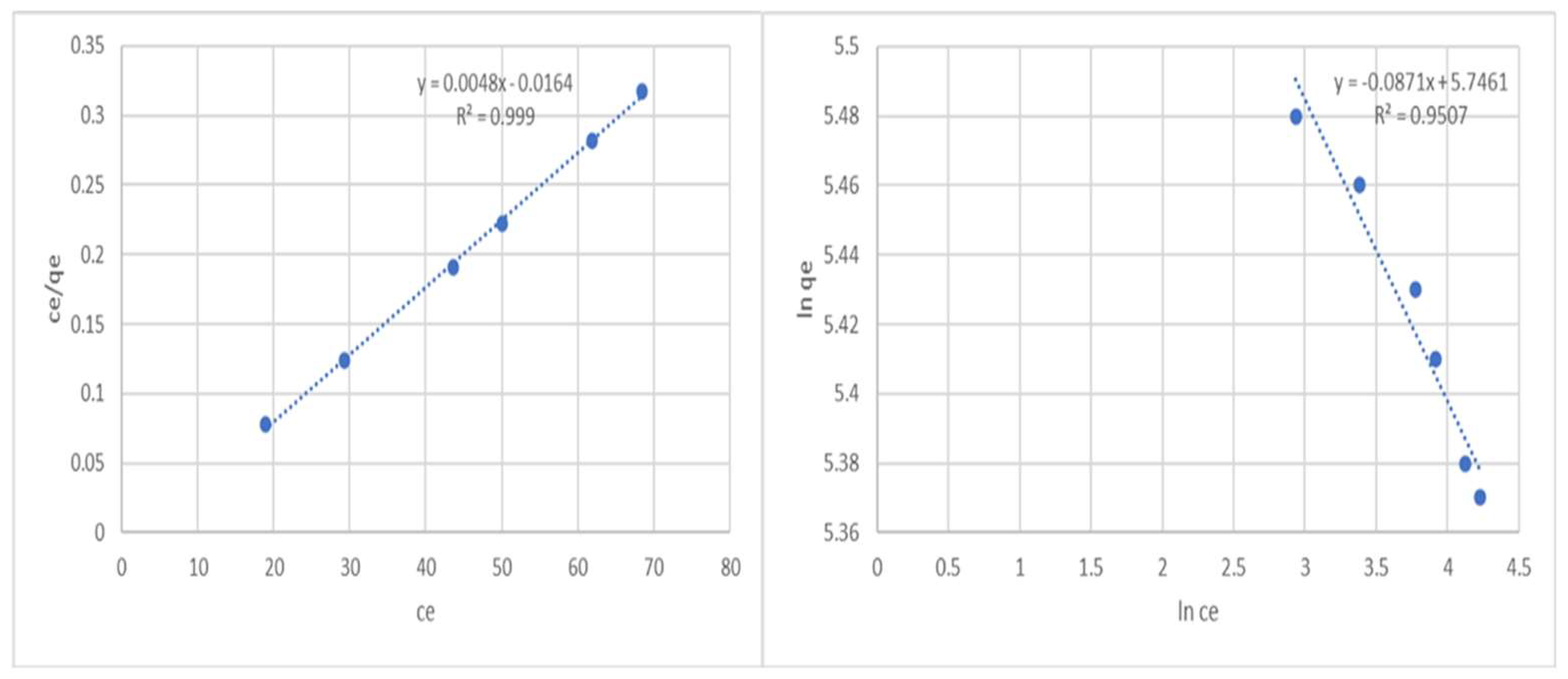

Isotherm—To best utilize adsorbents, it is essential to understand how solutes interact with them by using the term “adsorption isotherm.” The link between the volume of phenol adsorbed and its equilibrium concentration in solutions was modeled by the Langmuir and Freundlich isotherms. The Langmuir isotherm is given by the following equation:

where

Ce (mg/L) denotes the equilibrium concentration of the adsorbate,

qe (mg/g) is the quantity of adsorbate adsorbed per unit mass of adsorbent,

qo denotes the Langmuir constants linked to adsorption capacity, and

kL denotes the constant relating to the free energy of adsorption. The following equation can be used to express the Langmuir isotherm in its linearized version:

To determine the Langmuir constants, a graph between

Ce/

qe and

Ce is drawn (

Figure 2). The dimensionless separation factor (

RL) can be used to express the key features of the Langmuir isotherm.

RL is represented in the following equation:

where the concentration of phenol is highest in

Co. The value of R

L indicates whether the isotherm is unfavorable (

RL > 1), irreversible (

RL = 0), linear (

RL = 1), or favorable (0 <

RL < 1). The graph illustrates a linear relationship between

Ce/

qe and

Ce based on experimental data, demonstrating the Langmuir model’s applicability (

R2 = 0.999). The Langmuir isotherm is favorable for the adsorption of phenol onto the activated carbon, as demonstrated by the value of

RL, which was discovered to be 0.00678.

The Freundlich isotherm is given by the following equation:

where (1/

n) is a measure of the adsorption intensity, and

Kf generally represents the adsorption capacity. The Freundlich isotherm model’s linearized form is as follows:

A straight line with a slope of 1/

n and an intercept of

lnKf is produced by plotting

lnqe versus

lnCe (

Figure 2). The size of the exponent n determines how favorable adsorption is. According to conventional wisdom, n numbers between 2 and 10 indicate favorable adsorption quality, 1–2 indicate highly challenging adsorption quality, and n numbers less than 1 indicate undesirable adsorption quality. Our n value of 11.48 indicates good adsorption properties. The

R2 value, 0.9507, is lower than the Langmuir isotherm model’s value. Therefore, the Freundlich isotherm is not the ideal isotherm model to describe the phenol adsorption mechanism.

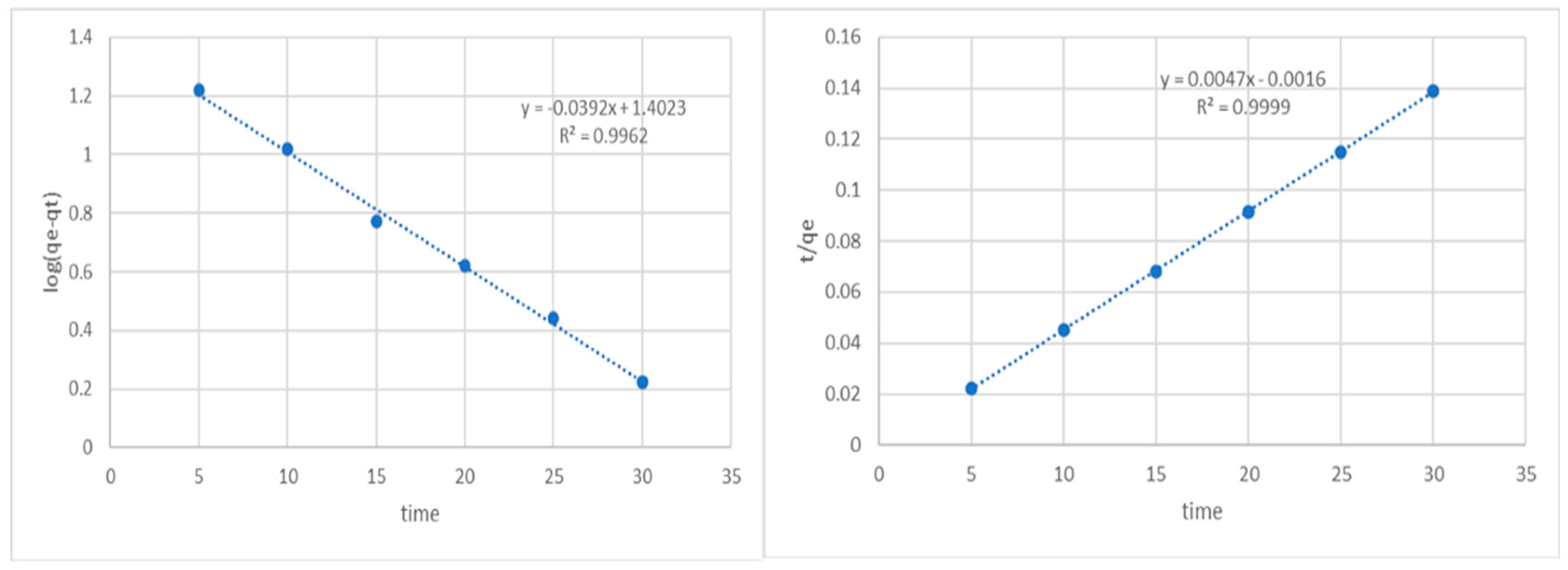

Kinetics studies—The rate of the adsorption process and potential rate-controlling phase were examined using kinetics models. These investigations provided information on the rate of change in the reaction. Pseudo-first-order and pseudo-second-order models were used to analyze the kinetic data gathered from studies. The conformance between the kinetic models and the experimental data was expressed using the correlation coefficient (R2).

The Lagergren pseudo-first-order model has been widely used to predict the phenol kinetics, and its formula is given as follows:

where

K1 is the equilibrium rate constant of pseudo first order adsorption (1/h),

qe denotes the quantity of phenol adsorbed (mg/g) at equilibrium, and

qt is the amount of phenol adsorbed (mg/g) at any time. The linearized form of the equation is given as follows:

The slope and intercept can be calculated from the plot of log (

qe −

qt) over time, which is typically used to calculate the equilibrium adsorption density

qe and first-order rate constants

K1 and

R2 (

Figure 3). We discovered that there was a significant disparity between the calculated (

qe, cal) and experimental (

qe, exp) adsorption capacity values and that the

R2 value derived for the pseudo-first-order kinetic model exhibits a consistent trend. The computed

qe is substantially lower than the experimental

qe (225 mg/g) at 25.45 mg/g.

The behavior is predicted by the pseudo-second-order model for the whole adsorption range. It is consistent with the rate-controlling step being an adsorption mechanism.

The equation is as follows:

K2 is the equilibrium rate constant of pseudo-second-order adsorption. The linearized form of the equation is given as follows:

The values of

qe and the second-order rate constant

K2 were determined using the slope and intercept of the plot of

t/

qt vs.

t, respectively (

Figure 3). The linear relationship between the plot of

t/

qt versus

t indicates that second-order kinetics is appropriate in this situation. As the initial phenol concentration rose, the rate constant generally dropped. The second-order kinetic model’s correlation coefficient was higher than 0.99. The experimental findings (225 mg/g) and the value computed by the

qe (212.76 mg/g) correspond extremely well.