Abstract

Bitumen rejuvenators are used to improve or restore the physical and mechanical performance of aged bitumen. Traditional bitumen rejuvenators are a product of crude oil. As crude oil production declines and the environmental and financial costs of crude oil increase, there is an urgent need to identify more environmentally sustainable bitumen rejuvenator alternatives. Bitumen rejuvenators generated from biological sources offer an environmentally friendly and economically viable alternative to the crude oil-based bitumen rejuvenators. This paper describes a study wherein microalgae oil was used as an aged bitumen rejuvenator. The chemical, physical, and mechanical effects of microalgae oil on 70/100pen aged bitumen were investigated. The results indicate that microalgae oil has the potential to be used as an aged bitumen rejuvenator.

1. Introduction

The current drive to improve the sustainability of the asphalt industry is driving research in bio-based materials, specifically about whether they are suitable for use in road construction. Traditionally, crude oil products have been used as bitumen modifiers (softeners and strengtheners) in asphalt production. Recent studies [1,2] have shown that oils extracted from microalgae biomass can also be used to modify bitumen. Audo et al. [1] demonstrated that microalgae biomass can be converted into a water-insoluble material made of a mixture of an oily component and solid residues, which is ideal for the production of bio-binder [3]. Maximum bio-oil yields in the range of 40–50% have been reported [1], though they are in the initial stages of development. The BioRePavation project [4] demonstrated that microalgae oil can be used as an asphalt binder in the construction of new asphalt mixtures and in the asphalt recycling process.

This paper presents the results of a study conducted to assess the performance of microalgae oil as a rejuvenator for aged asphalt bitumen. Microalgae oil and biomass were tested for their chemical, physical, and mechanical compatibility and effects on the 70/100pen aged asphalt binder. Two plant-based oils (soy bean and palm oil) were used as comparative bio-oils, and a commercially available bio-based rejuvenator was used as a control material. The blends were prepared by adding rejuvenating oil (3% by weight) to aged bitumen. Fourier-Transform Infrared Spectroscopy (FTIR) was used to investigate the prevalence of chemical functional groups and possible differences between the pure and blended bitumen samples. Dynamic Shear Rheometer (DSR) was used to investigate the mechanical performance. Optical microscopy was used to investigate the physical appearance of the bitumen blends due to ageing and also as rejuvenating oils were added.

2. Materials and Methods

2.1. Materials

Microalgae biomass (Nannochloropsis Oceanica paste) and oil extracted from Nannochloropsis Oceanica paste biomass were supplied by Wageningen University. Two additional bio-based oils were selected for the study: soy bean oil (purchased from Ademia Cosmetiques) and palm oil (purchased from Cosmetica Natural Oils Ltd., Ipswich, UK). A standard, commercially available bio-based rejuvenator, Neomex® Hr, was supplied by Latexfalt B.V., and bitumen 70/100pen was supplied by Breedongroup PLC.

2.2. Methods

2.2.1. Bitumen Ageing Process

Fresh 70/100pen bitumen was aged in accordance with the protocol outlined by Kliewer [5]. The goal was to simulate 15 years of bitumen ageing. One kilogram of bitumen was poured into a stainless steel tray lined with greaseproof paper. The thickness of the bitumen layer in the tray was 10 mm. The tray was then placed in a forced air draft oven and subjected to a two-step ageing process as follows: step 1—4 h at 135 °C; step 2—4 days at 85 °C. Because the bitumen ageing was insufficient following steps 1 and 2, we extended step 2 by 16 days.

2.2.2. Blending Process

Five different blends containing 70/100pen of aged bitumen, four different rejuvenating oils, and a blend containing microalgae biomass were made. The blends were prepared by adding rejuvenating oil (3% by weight) to aged bitumen. The microalgae biomass blend was designed according to the lipid content in the microalgae biomass. The microalgae biomass lipid analysis was tested according to the Folch method [6]. Our analysis demonstrated that the dry weight biomass lipid content was 20%, and the moisture content was 70%. Table 1 summarizes the blend constituent weights.

Table 1.

Bitumen blends, weight 200g.

Low shear blending was adopted for the blends preparations. The blend sample preparation process began by heating blend constituents, aged 70/100pen bitumen, and rejuvenating oil separately at 160 °C for 30 min before blending. Once the bitumen and oil reached 160 °C, the bitumen was placed on a temperature-controlled hot plate, and the oil was added to the bitumen. The blending temperature was held constant at 160 °C and mixed for 30 min at 600 RPM. In order to prevent foaming of the bitumen blend, the moisture was removed from the microalgae biomass by placing it in the oven at 100 °C for 60 min prior the blending.

2.2.3. Fourier-Transform Infrared Spectroscopy (FTIR)

The FTIR test method was employed to study the prevalence of chemical functional groups and possible differences between the pure and blended bitumen samples. The investigation was undertaken according to the protocol described by Hofko et al. [7].

2.2.4. Dynamic Shear Rheometer (DSR)

The DSR approach was employed to investigate bitumen stiffness change. The Dynamic Share Rheometer (DSR) test was conducted in accordance with EN 14770:2012.

2.2.5. Microscopic Analysis

To investigate the microstructure characteristics of the blends, a Zeiss Axioplan digital microscope with a Zeiss Plan-Neofluar lens was used at 200 times magnification. The goal was to map the dispersion of the rejuvenating oils throughout the blends and link the possible changes in physical properties to changes in the microstructure (occurring due to chemical interactions within the blends).

3. Results

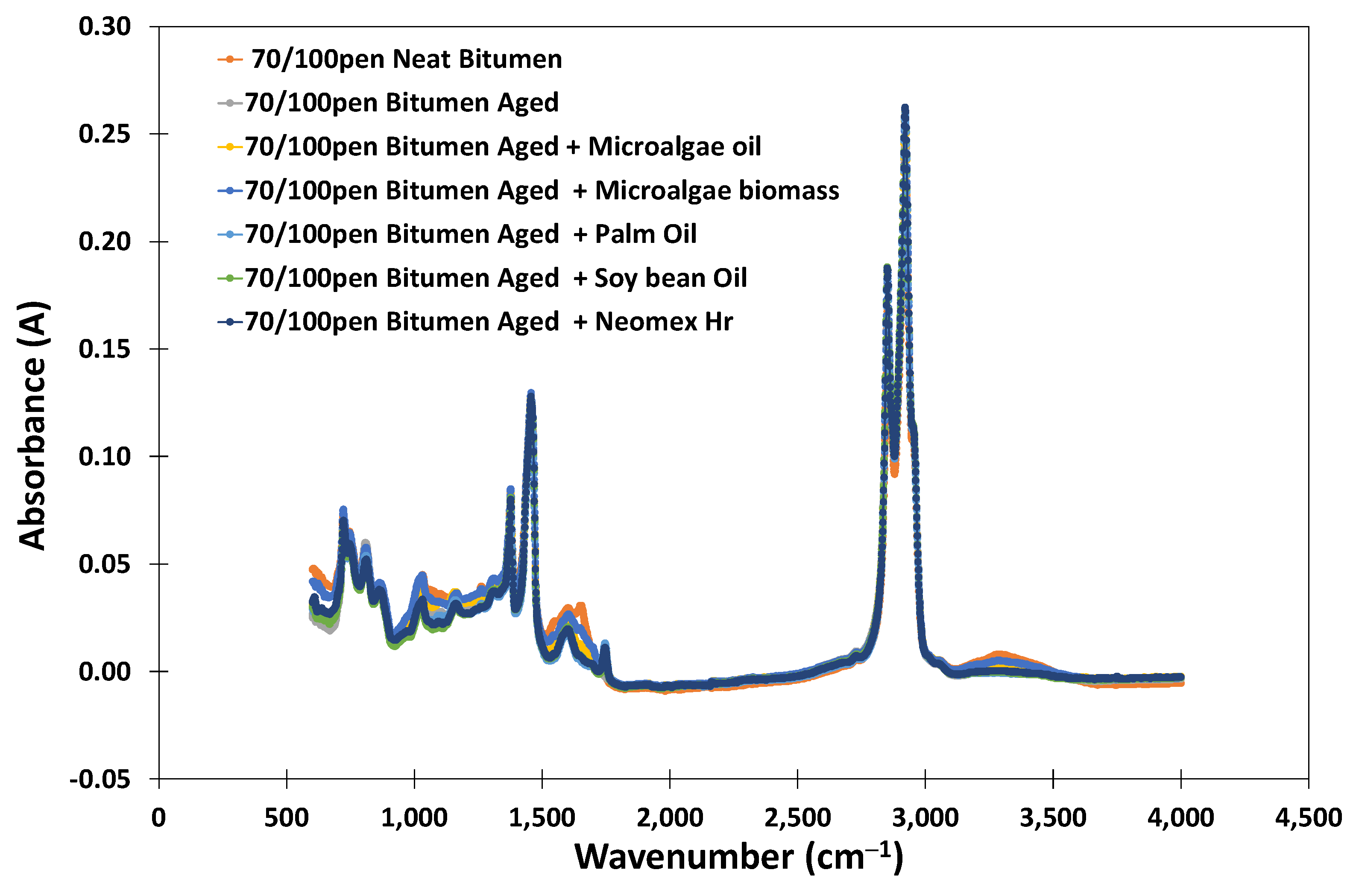

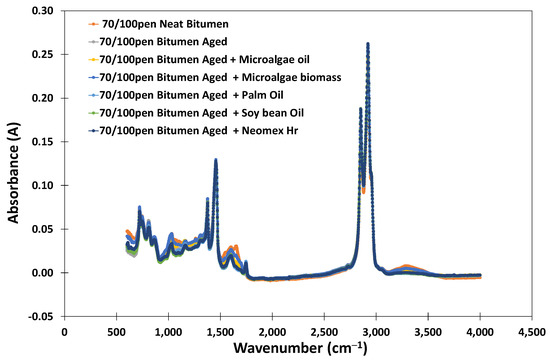

3.1. Fourier-Transform Infrared Spectroscopy (FTIR)

Figure 1 shows the chemical composition with respect to functional groups in comparison to neat bitumen, aged bitumen, and rejuvenated aged bitumen blends (detected via FTIR). All seven blends demonstrate a very similar spectrum. At the lower end of the wavenumber, the blend with microalgae biomass shows a closer response to the neat bitumen, whereas all of the blends containing rejuvenating oils show the same response. This indicates that microalgae oil blends have a very similar chemical composition to blends containing Neomex Hr (a standard bio-based rejuvenator) and plant-based oils.

Figure 1.

IR-spectra of 70/100pen aged bitumen and neat, aged, and rejuvenated aged bitumen.

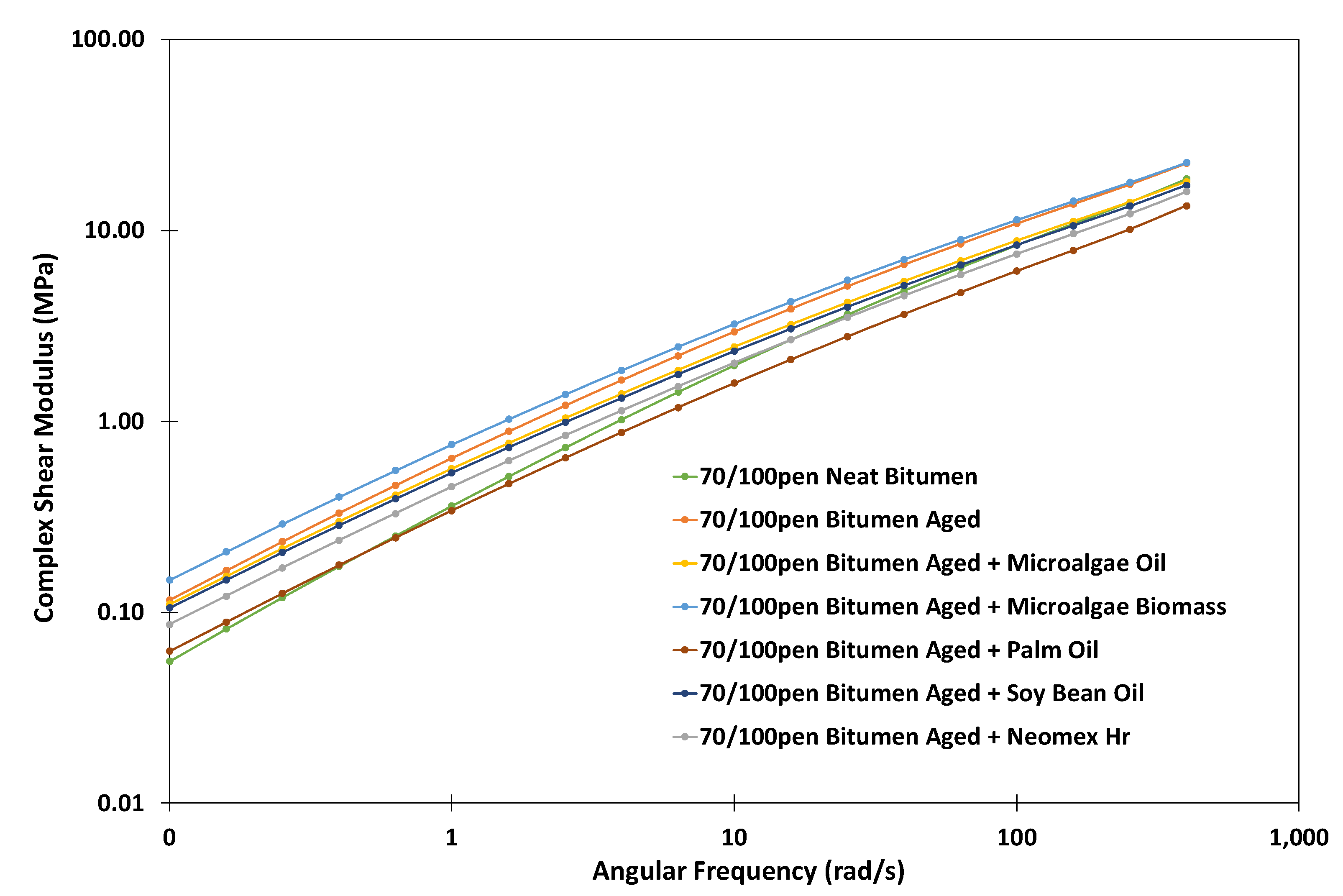

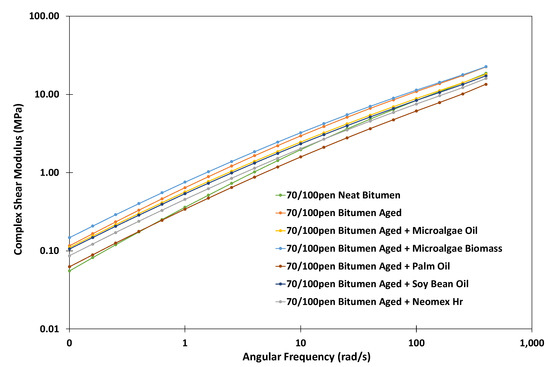

3.2. Dynamic Shear Rheometer (DSR)

Figure 2 shows the results from the DSR test. The results show that the rejuvenating oils in aged bitumen blends reduce the complex shear modulus and stiffness of aged bitumen. The blends containing the microalgae oil and soy bean oil have very similar responses, whereas palm oil showed the strongest softening effect on the aged binder, exhibiting an even better softening effect than Neomex Hr (a standard bio-based rejuvenator). The blend containing microalgae biomass resulted in a higher stiffness than the aged bitumen.

Figure 2.

DSR data for 70/100pen aged bitumen and rejuvenated aged bitumen.

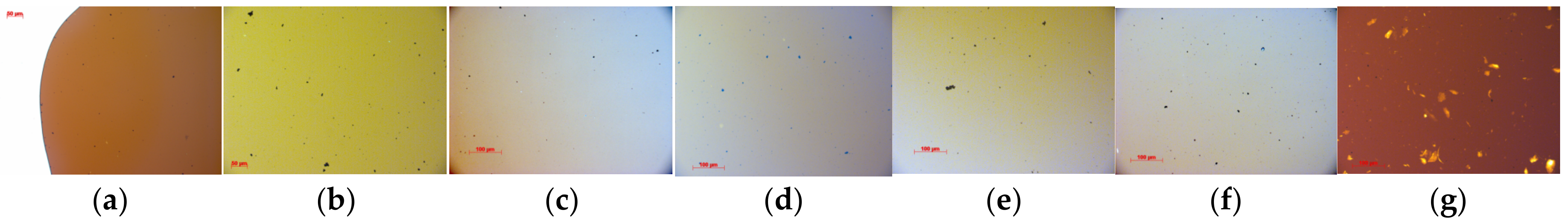

3.3. Microscopic Analysis

Figure 3 illustrates the optical microscope images of 70/100pen bitumen (neat, aged, and blends containing rejuvenating oils and microalgae biomass). The images show that the ageing and rejuvenating oils cause the bitumen to become pale and much lighter in appearance (Figure 3c–f). However, the blend containing microalgae biomass shows a darker appearance with light specs throughout the test sample. These specs are the organic material particles in the blend. Nevertheless, the images show the full homogenous structure of the material, indicating a good blending process and a lack of separation of rejuvenating oils and aged bitumen.

Figure 3.

Microscopic images of 70/100pen bitumen: (a) neat, (b) aged, (c) aged with Neomex Hr, (d) aged with microalgae oil, (e) aged with palm oil, (f) soy bean oil and (g) aged bitumen with microalgae biomass.

4. Conclusions

The results reported in this study demonstrate that microalgae oil performs well as an aged bitumen rejuvenator in comparison to Neomex Hr (a standard bio-based rejuvenator) and plant-based (soy and palm) oils. The results illustrate that microalgae oil matches the chemical and mechanical performance of plant-based oils and Neomex Hr (a standard bio-based rejuvenator), indicating that microalgae oil can be used as an aged bitumen rejuvenator.

Upon request from the microalgae biomass and oil suppliers (Wageningen University), the microalgae biomass was also investigated, and the results were surprising. The biomass showed good chemical compatibility with the bitumen. Regarding mechanical performance, the complex shear modulus of the blend did increase but not to a significant level. This finding is promising because if microalgae biomass could be inserted directly into the bitumen mix, it would reduce the financial cost of implementing bio-based rejuvenators into asphalt mix production by eliminating the need for biomass processing, i.e., biomass oil extraction.

A future research direction is to investigate the performance of these oils and microalgae biomass as rejuvenators within a full asphalt mix.

Author Contributions

Conceptualization, A.T.; methodology, A.T.; formal analysis, A.T., D.v.V. and K.R.-S.; investigation, A.T.; resources, D.v.V., K.R.-S. and G.L.; data curation, A.T.; writing—original draft preparation, A.T.; writing—review and editing, A.T., D.v.V., K.R.-S. and G.L.; visualization, A. T.; supervision, G.L.; project administration, G.L.; funding acquisition, A.T. and G.L. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by European Commission H2020 Marie Skłodowska Curie Individual Fellowship (IF) research funding programme, project: Advanced Solutions for Asphalt Pavements (ASAP), grant number 886828.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data generated in the study are fully presented within this article.

Acknowledgments

The authors would like to thank Declan O’Pray from Breedongrouop PLC for supplying the bitumen material, Hans Hendrikse from Latexfalt BV for supplying Neomex Hr rejuvenator, and Rene Wiffels, Iago Dominguez Teles and Rafael Cubero, from Wageningen University for supplying microalgae biomass and microalgae oil.

Conflicts of Interest

The authors declare no conflict of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript; or in the decision to publish the results.

References

- Audo, M.; Paraschiv, M.; Queffélec, C.; Louvet, I.; Hémez, J.; Fayon, F.; Lépine, O.; Legrand, J.; Tazerout, M.; Chailleux, E.; et al. Subcritical Hydrothermal Liquefaction of Microalgae Residues as a Green Route to Alternative Road Binders. ACS Sustain. Chem. Eng. 2015, 3, 8. [Google Scholar] [CrossRef]

- Penki, R.; Rout, S.K. Next-generation bitumen: A review on challenges and recent developments in bio-bitumen preparation and usage. Biomass Conv. Bioref. 2021. [Google Scholar] [CrossRef]

- Tabaković, A. Bio-Binder—Innovative Asphalt Technology. Appl. Sci. 2020, 10, 8655. [Google Scholar] [CrossRef]

- French Institute of Science and Technology Devoted to Transport Planning and Networks (IFSTTAR). BioRePavation. 2020. Available online: http://biorepavation.ifsttar.fr/ (accessed on 17 February 2022).

- Kliewer, J.E.; Bell, C.A.; Sosnovske, D.A. Investigation of the relationship between field performance and laboratory ageing properties of asphalt mixtures. In Engineering Properties of Asphalt Mixtures and the Relationship to Their Performance; Huber, G.A., Decker, D.S., Eds.; ASTM International: West Conshohocken, PA, USA, 1995. [Google Scholar]

- Axelsson, M.; Gentili, F. A Single-Step Method for Rapid Extraction of Total Lipids from Green Microalgae. PLoS ONE 2014, 9, e89643. [Google Scholar] [CrossRef] [PubMed]

- Hofko, B.; Alavi, M.Z.; Grothe, H.; Jones, D.; Harvey, J. Repeatability and sensitivity of FTIR ATR spectral analysis methods for bituminous binders. Mater. Struct. 2017, 50, 187. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).