Unveiling the Benefits of Engineered Crumb Rubber for Asphalt Mixtures via Performance-Related Characterization: Rutting Behavior †

Abstract

:1. Introduction

2. Methodology

2.1. Conventional Characterization

2.2. Performance-Related Characterization—Basic Level

2.3. Performance-Related Characterization—Advanced Level

3. Results and Discussions

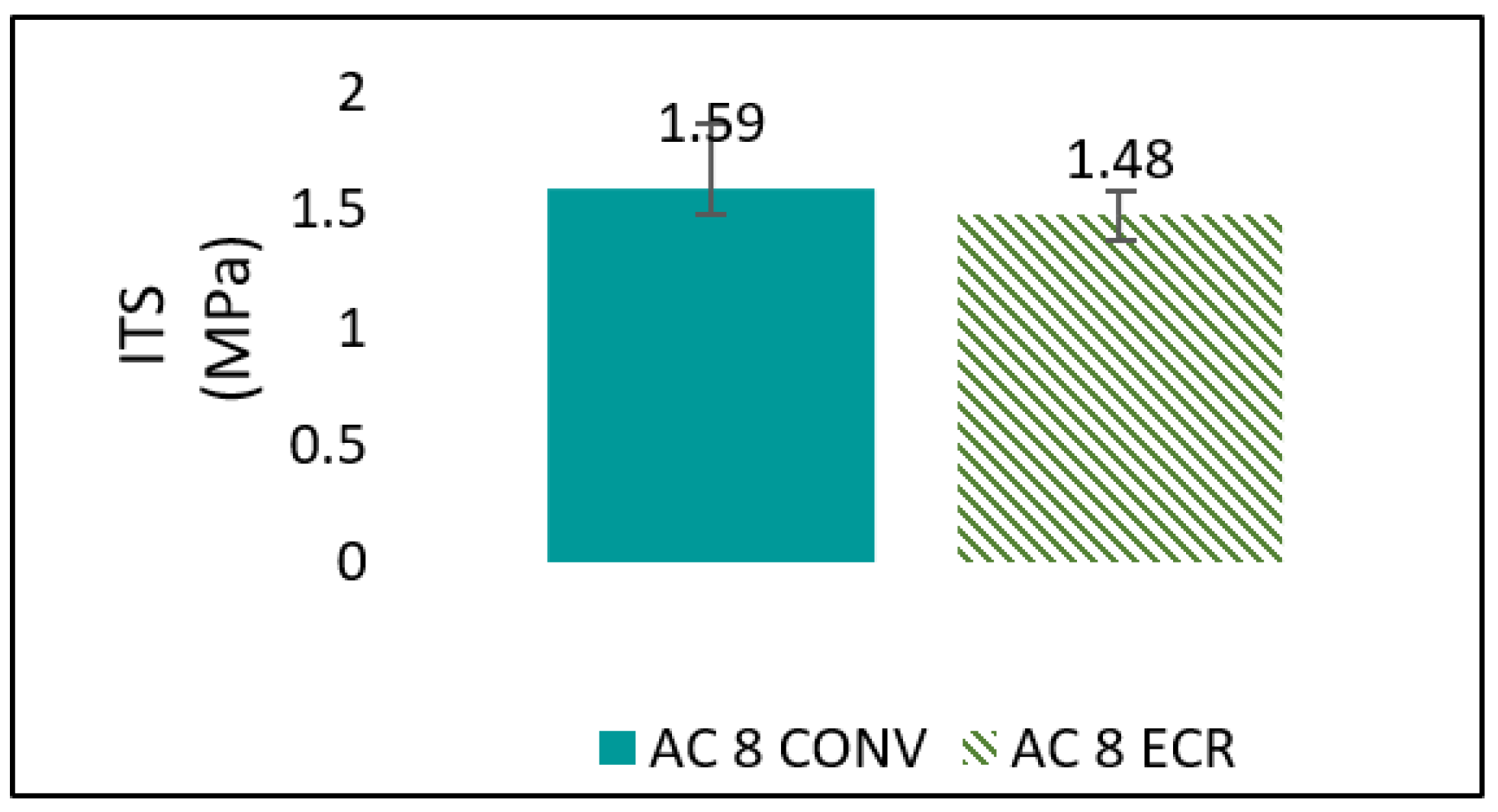

3.1. Conventional Characterization

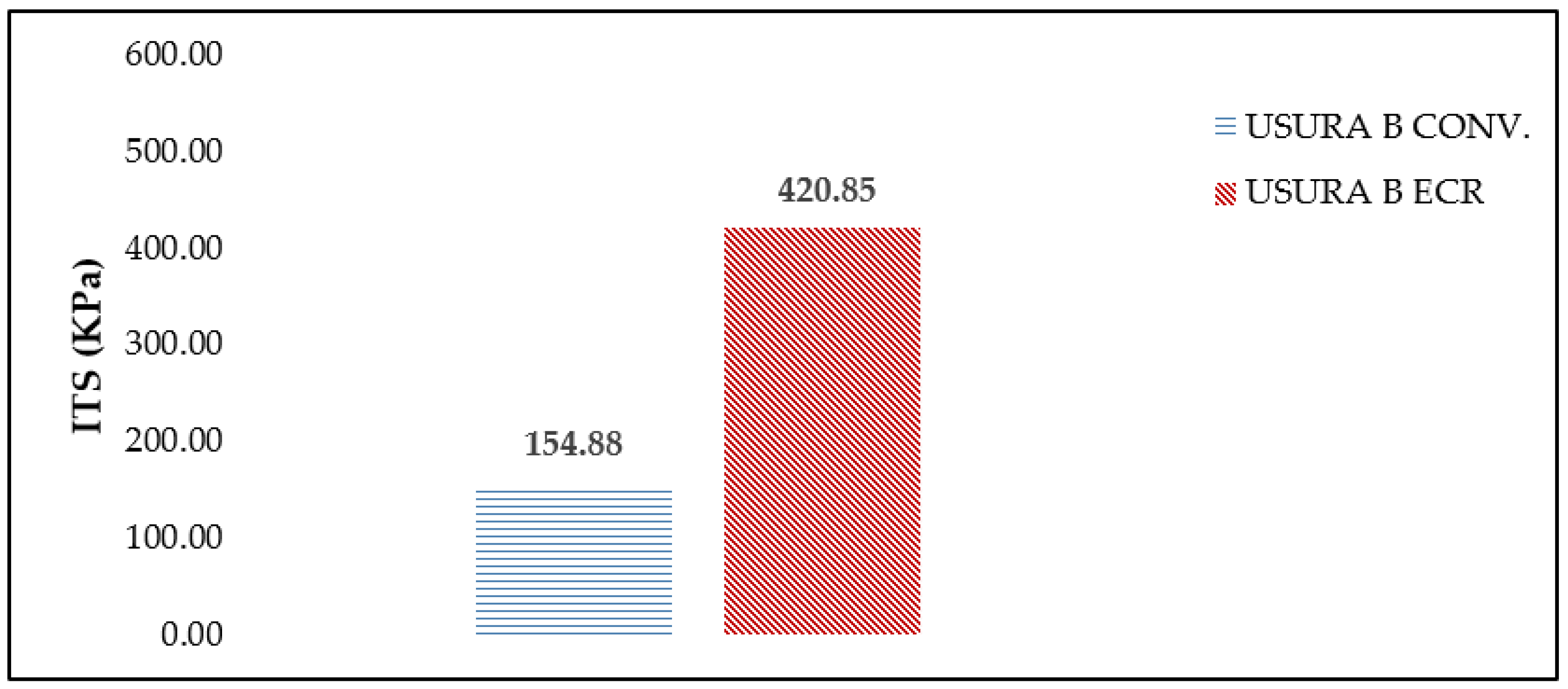

3.2. Performance-Related Characterization—Basic Level

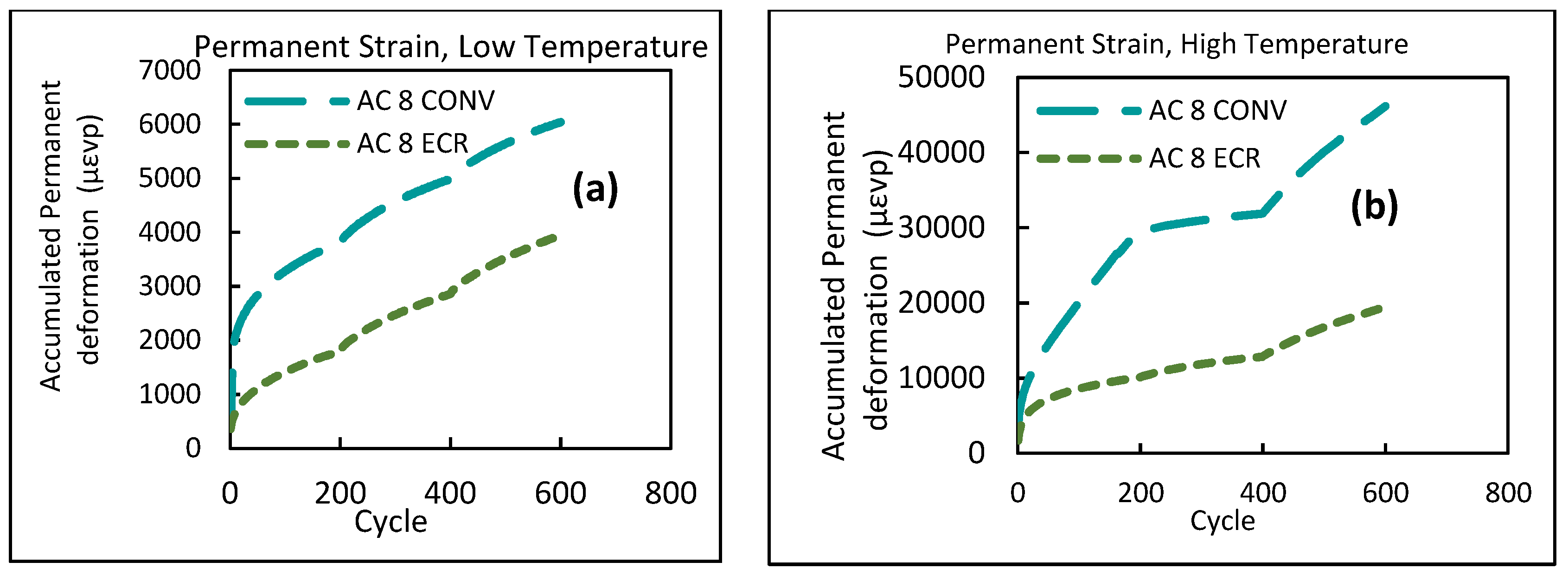

3.3. Performance-Related Characterization—Advanced Level

4. Summary and Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Meroni, F.; Flintsch, G.W.; Habbouche, J.; Diefenderfer, B.K.; Giustozzi, F. Three-level performance evaluation of high RAP asphalt surface mixes. Constr. Build. Mater. 2021, 309, 125164. [Google Scholar] [CrossRef]

- Anas S.p.A. Capitolato Speciale D’appalto-Norme Tecniche; Azienda Nazionale Autonoma delle Strade: Roma, Italy, 2016. [Google Scholar]

- Islam, M.R.; Hossain, M.I.; Tarefder, R.A. A study of asphalt aging using Indirect Tensile Strength test. Constr. Build. Mater. 2015, 95, 218–223. [Google Scholar] [CrossRef]

- Kim, D.; Kim, Y.R. Development of Stress Sweep Rutting (SSR) test for permanent deformation characterization of asphalt mixture. Constr. Build. Mater. 2017, 154, 373–383. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ghani, U.; Milazzo, S.; Giancontieri, G.; Mignini, C.; Buttitta, G.; Gu, F.; Lo Presti, D. Unveiling the Benefits of Engineered Crumb Rubber for Asphalt Mixtures via Performance-Related Characterization: Rutting Behavior. Eng. Proc. 2023, 36, 39. https://doi.org/10.3390/engproc2023036039

Ghani U, Milazzo S, Giancontieri G, Mignini C, Buttitta G, Gu F, Lo Presti D. Unveiling the Benefits of Engineered Crumb Rubber for Asphalt Mixtures via Performance-Related Characterization: Rutting Behavior. Engineering Proceedings. 2023; 36(1):39. https://doi.org/10.3390/engproc2023036039

Chicago/Turabian StyleGhani, Usman, Silvia Milazzo, Gaspare Giancontieri, Chiara Mignini, Gabriella Buttitta, Fan Gu, and Davide Lo Presti. 2023. "Unveiling the Benefits of Engineered Crumb Rubber for Asphalt Mixtures via Performance-Related Characterization: Rutting Behavior" Engineering Proceedings 36, no. 1: 39. https://doi.org/10.3390/engproc2023036039

APA StyleGhani, U., Milazzo, S., Giancontieri, G., Mignini, C., Buttitta, G., Gu, F., & Lo Presti, D. (2023). Unveiling the Benefits of Engineered Crumb Rubber for Asphalt Mixtures via Performance-Related Characterization: Rutting Behavior. Engineering Proceedings, 36(1), 39. https://doi.org/10.3390/engproc2023036039