Damage Detection and Monitoring of a Concrete Structure Using 3D Laser Scanning †

Abstract

:1. Introduction

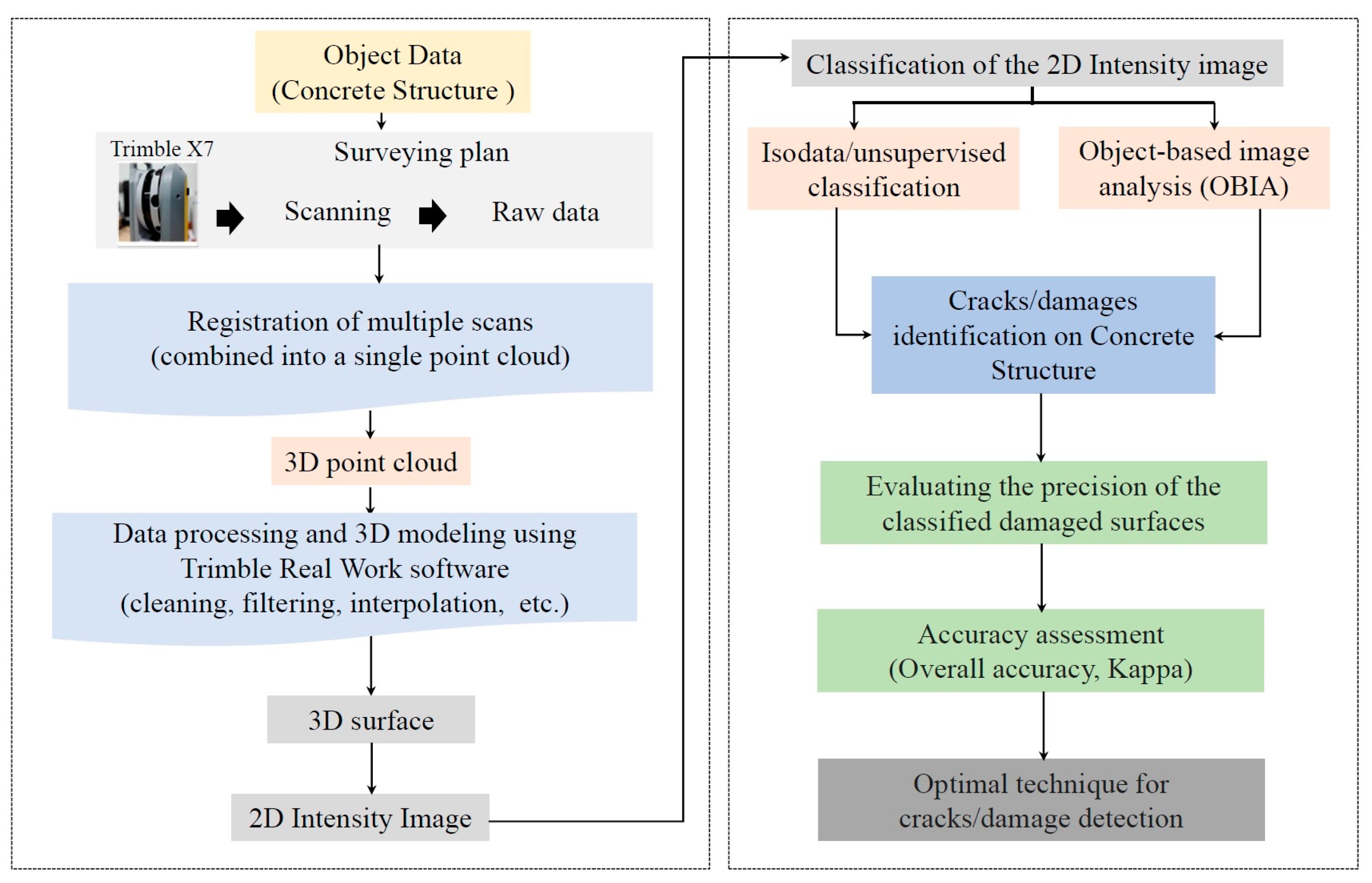

2. Materials and Methods

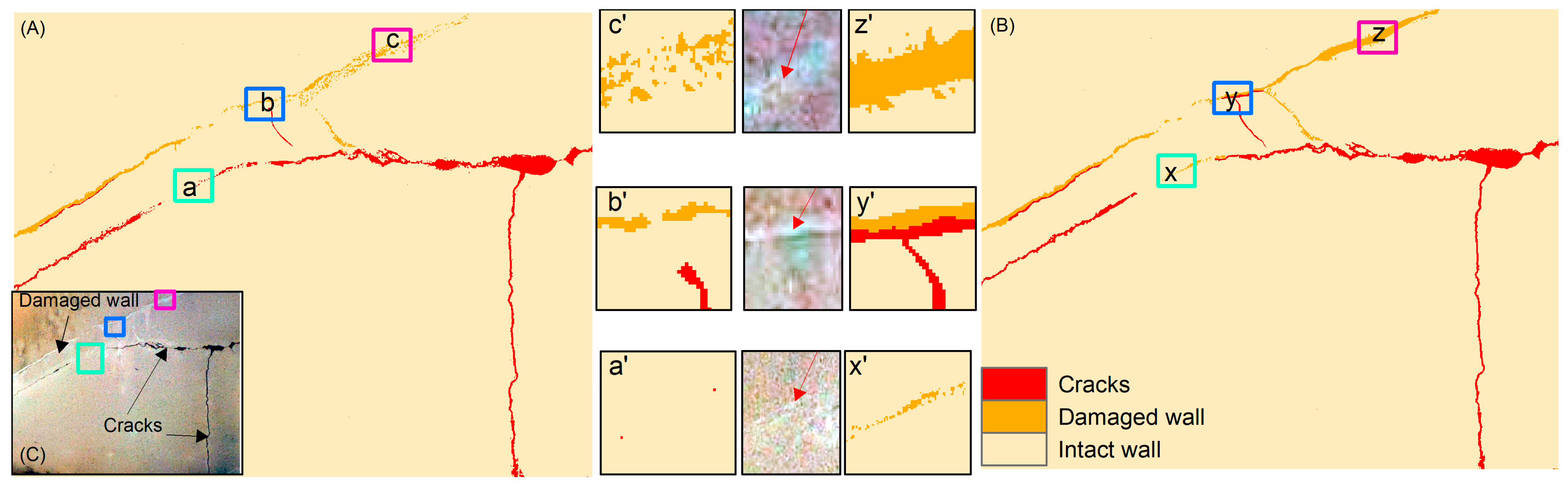

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Erkal, B.G.; Hajjar, J.F. Laser-based surface damage detection and quantification using predicted surface properties. Autom. Constr. 2017, 83, 285–302. [Google Scholar] [CrossRef]

- Cho, S.; Park, S.; Cha, G.; Oh, T. Development of image processing for crack detection on concrete structures through terrestrial laser scanning associated with the octree structure. Appl. Sci. 2018, 8, 2373. [Google Scholar] [CrossRef] [Green Version]

- Tzortzinis, G.; Ai, C.; Breña, S.F.; Gerasimidis, S. Using 3D laser scanning for estimating the capacity of corroded steel bridge girders: Experiments, computations and analytical solutions. Eng. Struct. 2022, 265, 114407. [Google Scholar] [CrossRef]

- Wu, C.; Yuan, Y.; Tang, Y.; Tian, B. Application of terrestrial laser scanning (TLS) in the architecture, engineering and construction (AEC) industry. Sensors 2021, 22, 265. [Google Scholar] [CrossRef]

- Mishra, M.; Lourenço, P.B.; Ramana, G.V. Structural health monitoring of civil engineering structures by using the internet of things: A review. J. Build. Eng. 2022, 48, 103954. [Google Scholar] [CrossRef]

- Yoon, J.S.; Sagong, M.; Lee, J.S.; Lee, K.S. Feature extraction of a concrete tunnel liner from 3D laser scanning data. NDT E Int. 2009, 42, 97–105. [Google Scholar] [CrossRef]

- Armesto-González, J.; Riveiro-Rodríguez, B.; González-Aguilera, D.; Rivas-Brea, M.T. Terrestrial laser scanning intensity data applied to damage detection for historical buildings. J. Archaeol. Sci. 2010, 37, 3037–3047. [Google Scholar] [CrossRef]

- Rabah, M.; Elhattab, A.; Fayad, A. Automatic concrete cracks detection and mapping of terrestrial laser scan data. NRIAG J. Astron. Geophys. 2013, 2, 250–255. [Google Scholar] [CrossRef] [Green Version]

- Valença, J.; Puente, I.; Júlio, E.N.B.S.; González-Jorge, H.; Arias-Sánchez, P. Assessment of cracks on concrete bridges using image processing supported by laser scanning survey. Constr. Build. Mater. 2017, 146, 668–678. [Google Scholar] [CrossRef]

- Ge, Y.; Liu, J.; Zhang, X.; Tang, H.; Xia, X. Automated Detection and Characterization of Cracks on Concrete Using Laser Scanning. J. Infrastruct. Syst. 2023, 29, 04023005. [Google Scholar] [CrossRef]

- Gui, R.; Xu, X.; Zhang, D.; Pu, F. Object-based crack detection and attribute extraction from laser-scanning 3D profile data. IEEE Access 2019, 7, 172728–172743. [Google Scholar] [CrossRef]

- Conrad, O.; Bechtel, B.; Bock, M.; Dietrich, H.; Fischer, E.; Gerlitz, L.; Wehberg, J.; Wichmann, V.; Böhner, J. System for Automated Geoscientific Analyses (SAGA) v. 2.1.4. Geosci. Model Dev. 2015, 8, 1991–2007. [Google Scholar] [CrossRef] [Green Version]

- Landis, J.R.; Koch, G.G. An application of hierarchical kappa-type statistics in the assessment of majority agreement among multiple observers. Biometrics 1977, 33, 363–374. [Google Scholar] [CrossRef] [PubMed]

- Story, M.; Congalton, R.G. Accuracy assessment: A user’s perspective. Photogramm. Eng. Remote Sens. 1986, 52, 397–399. [Google Scholar]

| Classification Techniques | Producer’s Accuracy | Cracks | Intact Wall | Damage Wall | User’s Accuracy | Cracks | Intact Wall | Damage Wall | Overall Accuracy | Kappa |

| isodata | 83.03 | 96.98 | 56.16 | 84.54 | 92.07 | 78.84 | 89.61 | 0.835 | ||

| OBIA | 90.69 | 97.63 | 45.31 | 87.31 | 92.60 | 80.55 | 90.74 | 0.858 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Adhikari, M.D.; Kim, T.-H.; Yum, S.-G.; Kim, J.-Y. Damage Detection and Monitoring of a Concrete Structure Using 3D Laser Scanning. Eng. Proc. 2023, 36, 1. https://doi.org/10.3390/engproc2023036001

Adhikari MD, Kim T-H, Yum S-G, Kim J-Y. Damage Detection and Monitoring of a Concrete Structure Using 3D Laser Scanning. Engineering Proceedings. 2023; 36(1):1. https://doi.org/10.3390/engproc2023036001

Chicago/Turabian StyleAdhikari, Manik Das, Tae-Hwan Kim, Sang-Guk Yum, and Joon-Yeong Kim. 2023. "Damage Detection and Monitoring of a Concrete Structure Using 3D Laser Scanning" Engineering Proceedings 36, no. 1: 1. https://doi.org/10.3390/engproc2023036001

APA StyleAdhikari, M. D., Kim, T.-H., Yum, S.-G., & Kim, J.-Y. (2023). Damage Detection and Monitoring of a Concrete Structure Using 3D Laser Scanning. Engineering Proceedings, 36(1), 1. https://doi.org/10.3390/engproc2023036001