Extra-Super-Fast Charger for Electric Vehicles (EVs) and Plug-In Hybrid Electric Vehicles (PHEVs) †

Abstract

:1. Introduction

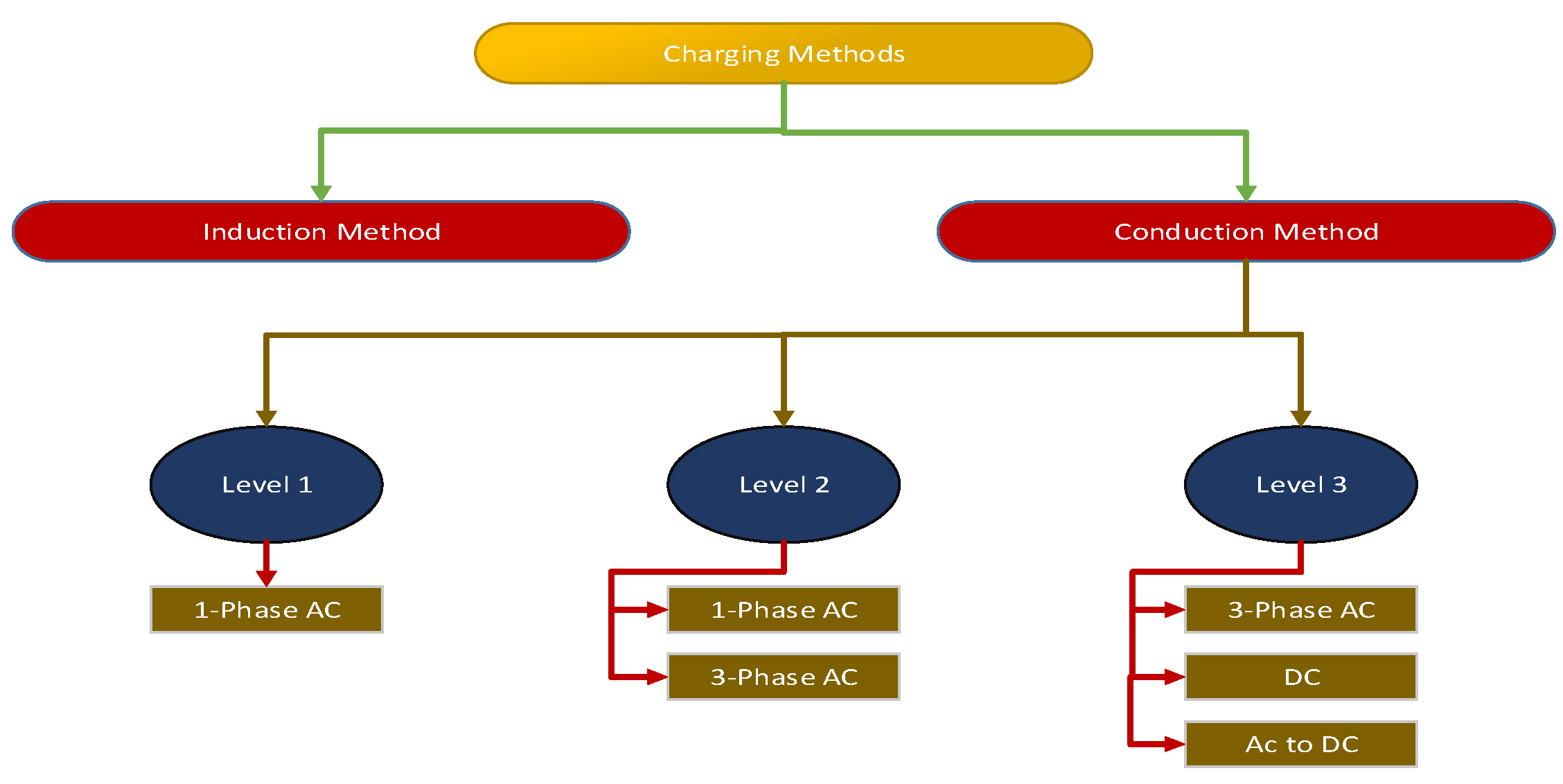

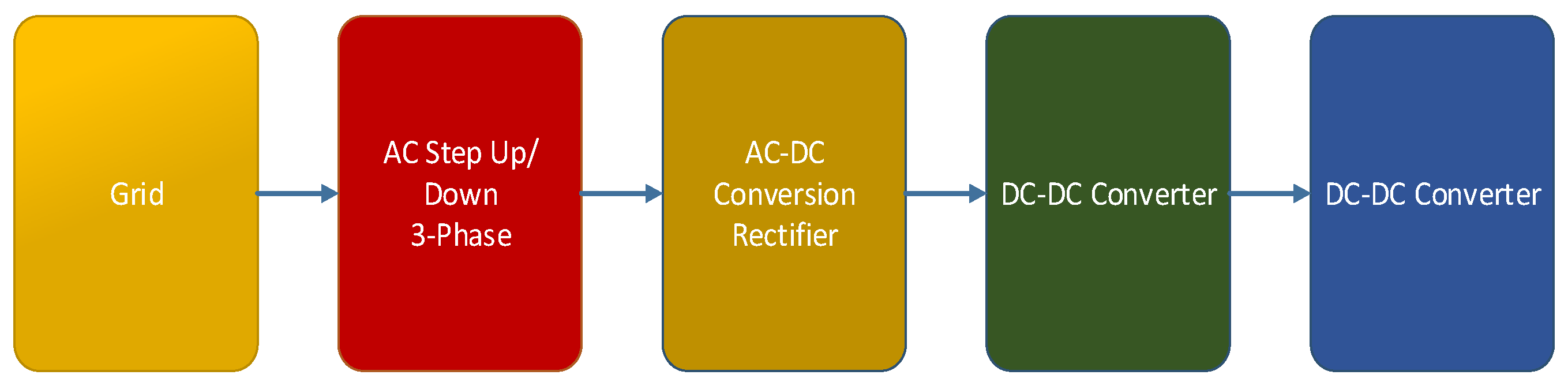

2. Proposed System

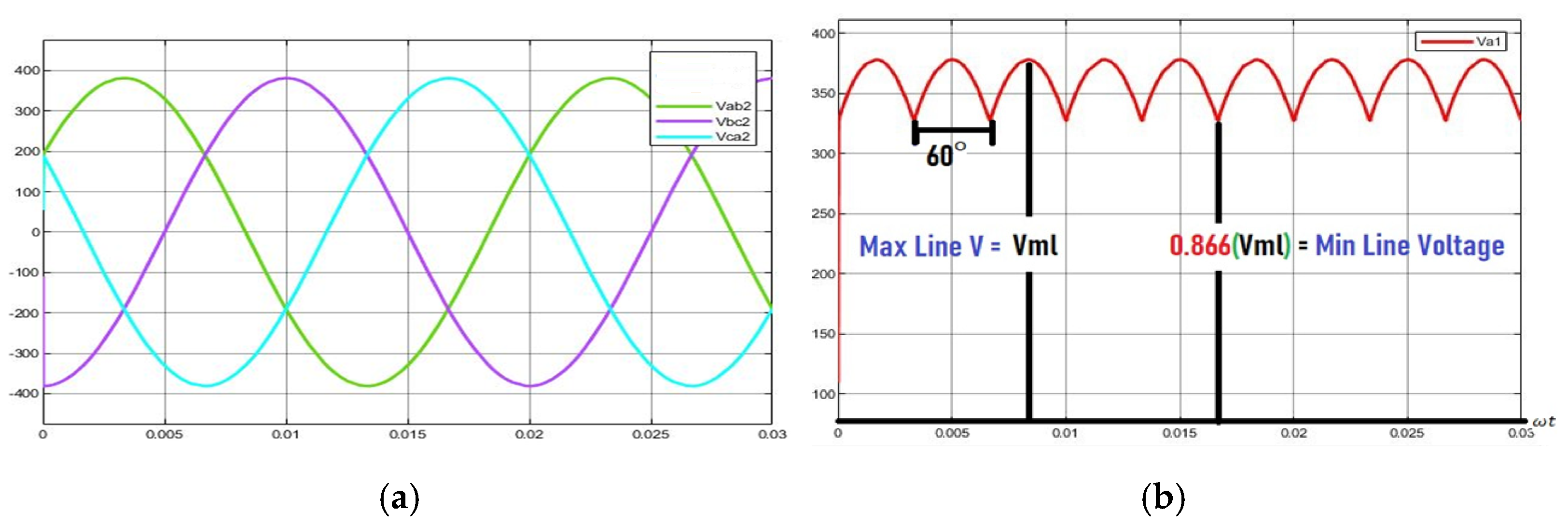

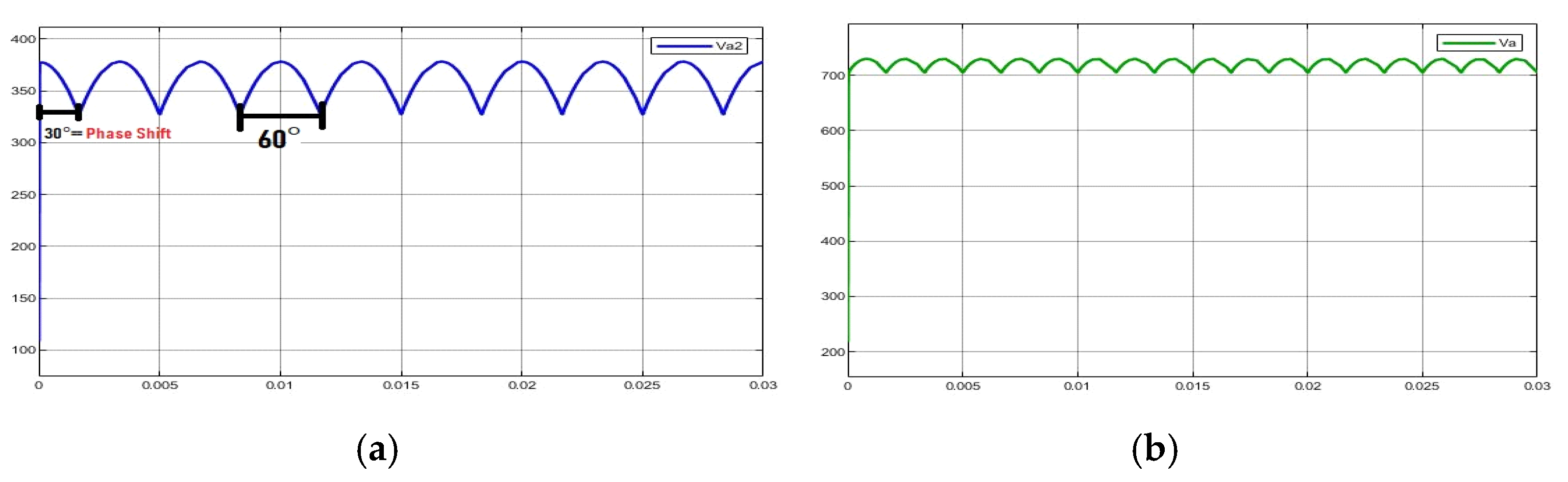

2.1. Six-Phase, Three-Winding Transformer

2.2. Pulse Diode Full Uncontrol Rectification

2.3. DC-to-DC Converter

2.4. Mathematical Formulae for Proposed Model

3. Simulation Results

4. Discussion and Comparative Analysis

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Genikomsakis, K.N.; Gutierrez, I.A.; Thomas, D.; Ioakimidis, C.S. Simulation and Design of Fast Charging Infractructure for a university based e-Carsharing system. IEEE Trans. Intell. Transp. Syst. 2017, 19, 1524–9050. [Google Scholar]

- Environment America Clean Air, Clean Water, and Open Source. Available online: https://environmentamerica.org/blogs/environment-america-blog/amc/what-difference-between-hybrid-cars-plug-hybrid-cars-and-electric (accessed on 21 January 2022).

- Farjah, A.; Bagheri, E.; Seifi, A.R.; Ghanbari, T. Main & Auxiliary Parts of Battery Storage, Aimed to fast charging of EV’s. In Proceedings of the 2018 9th annual power electronics drive system and technologies conference (PEDSTC), Tehran, Iran, 13–15 February 2018. [Google Scholar]

- Energy Efficiency and Renewable Energy. Available online: https://www.energy.gov/eere/vehicles/articles/fotw-1186-may-17-2021-national-average-cost-fuel-electric-vehicle-about-60 (accessed on 17 May 2021).

- Alsalemi, A.; Al-Zubiri, A.; Sadeghi, Y.; Massoud, A. The research is on Design of ultra-fast EVs battery charger. In Proceedings of the Symposium on Computer Applications and Industrial Electronics (ISCAIE), Penang, Malaysia, 3–4 April 2021. [Google Scholar]

- Yeale School of Environmnet. Available online: https://e360.yale.edu/digest/energy-department-report-finds-that-evs-cost-40-percent-less-to-maintain-than-conventional-cars (accessed on 23 June 2021).

- Nair, A.C.; Fernandes, B.G. A Solid State Transformer Base Fast Charging Station for all Category of Electric Vehicles. In Proceedings of the IECON 2018-44th Annual Conference of the IEEE Industrial Electronics Society, Washington, DC, USA, 21–23 October 2018. [Google Scholar]

- Vinoth, K.K.; Saravanakumar, R. Implementation of Five Level Battery Charging Scheme for Electric Vehicles. In Proceedings of the 2020 International Conference on Power, Instrumentation, Control and Computing (PICC), Thrissur, India, 17–19 December 2020. [Google Scholar] [CrossRef]

- Sharma, A.; Gupta, R. Bharat DC001 charging standard based electric vehicles EVs fast charger. In Proceedings of the IECON 2020 The 46th Annual Conference of the IEEE Industrial Electronics Society, Singapore, 18–21 October 2020. [Google Scholar]

- Chelladurai, B.; Sundarabalan, C.K.; Santhanam, S.N.; Guerrero, J.M. Interval Type-2 Fuzzy Logic Controlled Shunt Converter Coupled Novel High-Quality Charging Scheme for Electric Vehicles EVs. IEEE Trans. Ind. Inform. 2020, 17, 6084–6093. [Google Scholar] [CrossRef]

- Zan, X.; Xu, G.; Zhao, T.; Wang, R.; Dai, L. Multi Batteries Block Module Power Converter for EV’s Driven by Switched Reluctance Motors. IEEE Access 2021, 9, 140609–140618. [Google Scholar] [CrossRef]

- Guerriero, P.; Coppola, M.; Lauria, D.; Daliento, S. PWM Based Sliding Mode Control of a fast-charging charger for supercapacitors. In Proceedings of the 2020 International Symposium on Power Electronics, Electrical Drives, Automation and Motion (ISPEEDAM), Sorrento, Italy, 24–26 June 2020. [Google Scholar]

- Ahn, J.H.; Lee, B.K. High Efficiency Adaptive-Current Charging Strategy for Electric Vehicles EVs Considering Variations of Internal Resistance of Lithium-ion Battery. IEEE Trans. Power Electron. 2018, 34, 3041–3052. [Google Scholar] [CrossRef]

- Gaurav, A.; Gaur, A. The research title is on Modelling of Hybrid Electric Vehicle EVs Charger and Study the Simulation Results. In Proceedings of the 2020 International Conference on Emerging Frontiers in Electrical and Electronic Technologies (ICEFEET), Patna, India, 10–11 July 2020. [Google Scholar]

- Kravetz, F.I.; Gules, R. Soft-Switching High Static Gain Modified SEPIC Converter. Citation information. IEEE J. Emerg. Sel. Top. Power Electron. 2021, 9, 6739–6747. [Google Scholar] [CrossRef]

- Farooq, A.; He, C.; Chen, G. A Three Phase Interleaved Boost Converter with L & C Extension Mechanism. Tech. Gaz. 2018, 25, 52–59. [Google Scholar]

- Farooq, A.; Malik, Z.; Sun, Z.; Chen, G. A Review of Non-isolated High Step-down dc-dc Converters. Int. J. Smart Home 2015, 9, 133–150. [Google Scholar] [CrossRef]

| Name/Without Filter | Input Current THD | Rectifier O/P Voltage | Rectifier O/P Current |

|---|---|---|---|

| 3-Parallel SEPIC with 12 Pulse | 43.7% | 421.4 V | 63 A |

| 4-Series SEPIC with 12 Pulse | 43.46% | 365 V | 358 A |

| 4-Parallel SEPIC with 12 Pulse | 43.69% | 424 V | 62.51 A |

| 4-Parallel SEPIC with 3-Phase Full uncontrolled Rectifier | 158.62% | 366.7 V | 53.99 A |

| Name | Rectifier O/P Voltage Peak-to-Peak Ripples | Rectifier O/P Current Peak-to-Peak Ripples | O/P Voltage | O/P Current |

|---|---|---|---|---|

| 3-Parallel SEPIC with 12 Pulse | 430 − 400 = 30 Vp-p | 100 Ap-p | 643.7 V | 32.14 A |

| 4-Series SEPIC with 12 Pulse | 450 − 250 = 200 Vp-p | 1500 Ap-p | 1349 V | 67.42 A |

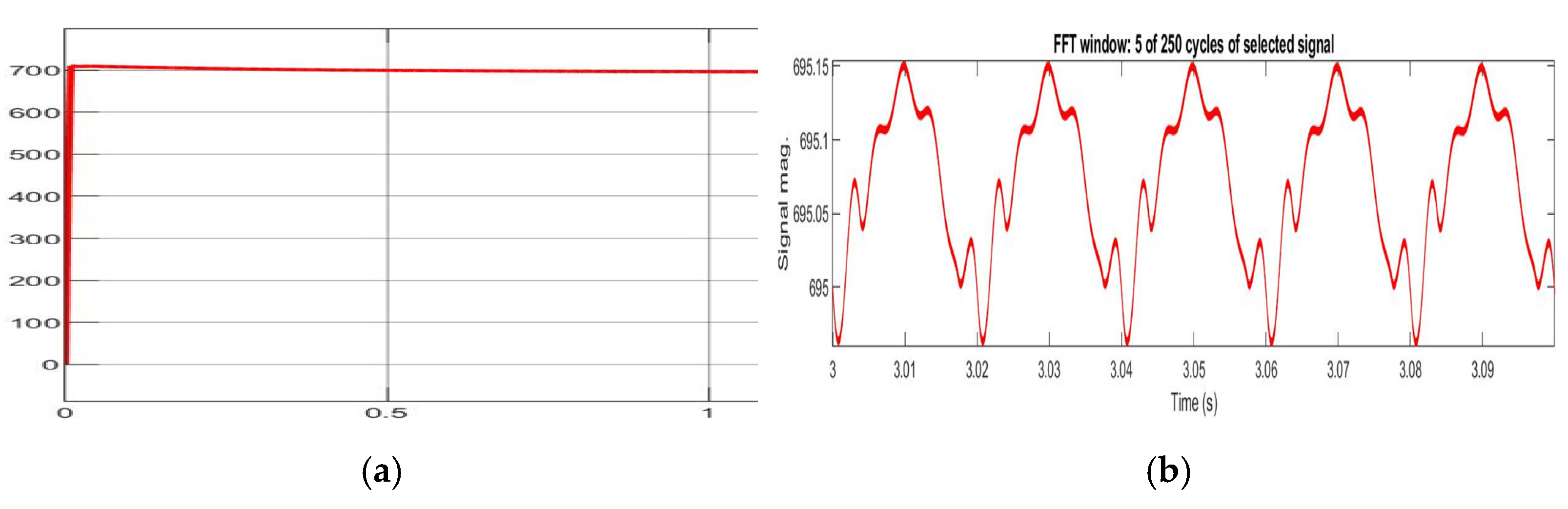

| 4-Parallel SEPIC with 12 Pulse | 450 − 500 = 50 Vp-p | 200 Ap-p | 695.1 V | 34.75 A |

| 4-Parallel SEPIC with 3-Phase Full uncontrolled Rectifier | 375 − 355 = 20 Vp-p | 300 Ap-p | 600 V | 30 A |

| Name | O/P Voltage Peak-Peak Ripples | O/P Current Peak-Peak Ripples | O/P V & I THD Bar Related DC |

|---|---|---|---|

| 3-Parallel SEPIC with 12 Pulse | 644.5 − 643 = 1.5 V | 32.22 − 32.16 = 0.006 A | 0.11% |

| 4-Series SEPIC with 12 Pulse | 1352 − 1346 = 6 V | 67.6 − 67.3 = 0.3 A | 0.29% |

| 4-Parallel SEPIC with 12 Pulse | 695.1 − 695 = 0.1 V | 34.756 − 34.74 = 0.008A | 0.01% |

| 4-Parallel SEPIC with 3-Phase Full uncontrolled Rectifier | 600.3 − 600.26 = 0.04 V | 30.015 − 30.013 = 0.002 A | 0% |

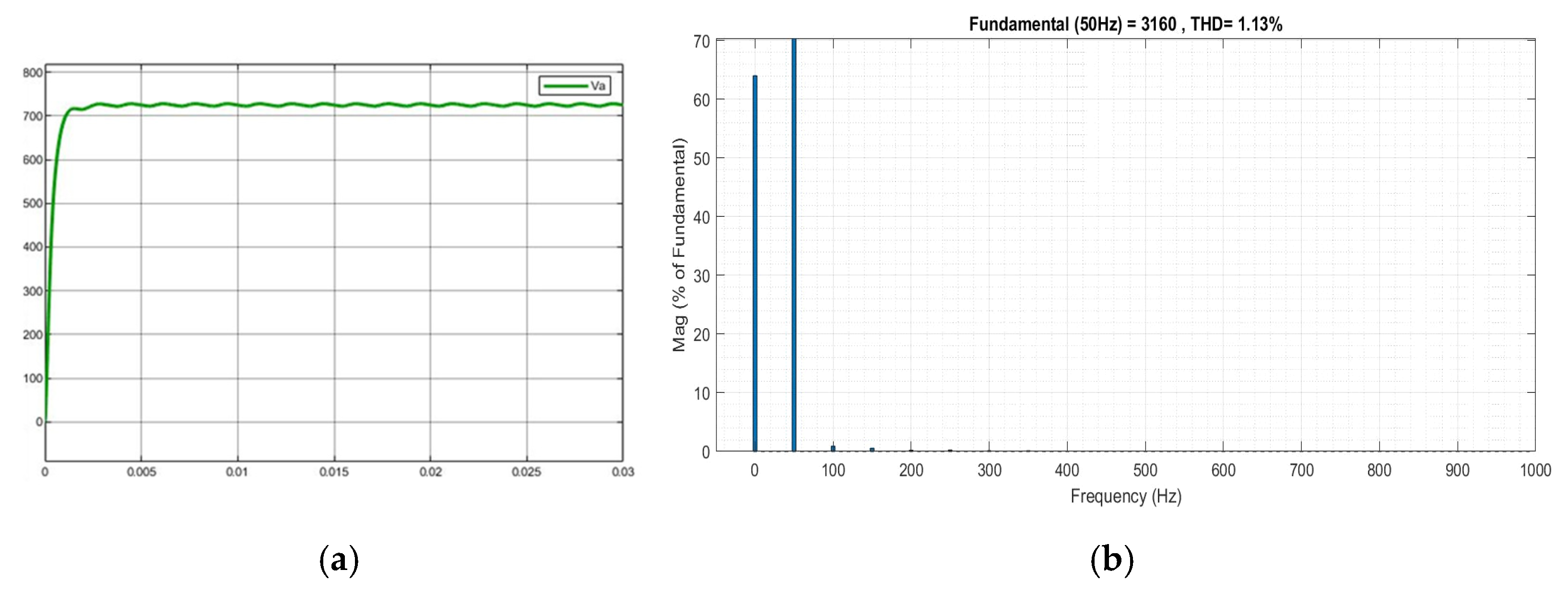

| THD of Input Current | 1.13% |

| Input Voltage | 220 V rms |

| Output Voltage Peak-to-Peak Ripples | 695.15 − 695 = 0.15 V |

| Output Current Peak-to-Peak Ripples | 34.756 − 34.748 = 0.008 A |

| Output Voltage to Load | Approximately 695 V = 700 V |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ayaz, M.M.A.; Farooq, A.; Haq, I. Extra-Super-Fast Charger for Electric Vehicles (EVs) and Plug-In Hybrid Electric Vehicles (PHEVs). Eng. Proc. 2023, 32, 24. https://doi.org/10.3390/engproc2023032024

Ayaz MMA, Farooq A, Haq I. Extra-Super-Fast Charger for Electric Vehicles (EVs) and Plug-In Hybrid Electric Vehicles (PHEVs). Engineering Proceedings. 2023; 32(1):24. https://doi.org/10.3390/engproc2023032024

Chicago/Turabian StyleAyaz, Mian Muhammad Amir, Ajmal Farooq, and Ihteshamul Haq. 2023. "Extra-Super-Fast Charger for Electric Vehicles (EVs) and Plug-In Hybrid Electric Vehicles (PHEVs)" Engineering Proceedings 32, no. 1: 24. https://doi.org/10.3390/engproc2023032024

APA StyleAyaz, M. M. A., Farooq, A., & Haq, I. (2023). Extra-Super-Fast Charger for Electric Vehicles (EVs) and Plug-In Hybrid Electric Vehicles (PHEVs). Engineering Proceedings, 32(1), 24. https://doi.org/10.3390/engproc2023032024