1. Introduction

Automotive seat occupancy sensors have been used for many years by car companies to detect the presence of a seated person and activate the seatbelt sound alarm. Force-sensitive resistors (FSR) [

1] have been the most common sensors used by automotive companies to detect the presence of a person on the car seats. FSR are piezoresistive sensors that detect a change in the pressure on the seat surface provoking a modification in the resistance. A person is detected by setting a minimum threshold pressure that is set up on the sensors to avoid the seatbelt sound alarm from being activated by a light object. However, there are still false positives provoked by heavy objects that exceed that threshold.

In [

2], a flexible resistive sensor it is presented that is produced by a layer disposition of different materials, as an alternative option to FSR. The flexible sensor presented could be integrated into the seat fabric or just underneath it. However, as the working principle of the sensor is resistance variation by the change in the applied force, the possibility to have false positives caused by heavy objects still exists.

There have been attempts to change the nature of the FSR sensor for the capacitive sensor. The aim is to avoid false detection provoked by heavy objects. In [

3], a capacitive seat sensor for multiple occupancy detection is presented. The capacitive sensor presented varies its value depending on the person characteristics when it is sat on. The sensor consists of an aluminium foil integrated on the seat. Two capacitances are measured: one of them is measured between bottom part of the car chassis and the aluminium foil, and the other one is measured between the top part of the chassis and the aluminium foil. Both measurements take into account wide spaces, which could imply more possibilities to produce false detections.

In this paper, the automotive sensor presented is a step forward. The capacitive sensor is integrated into the seat fabric. As both of the sensor electrodes are in the textile, the capacitance is affected by closer environment and contact, avoiding the measurement of long areas which could imply new false positives.

The paper is organized as follows:

Section 2 covers the materials, methods and characterisation details. In

Section 3, the experimental results are presented and discussed. Finally, in

Section 4, the conclusions are summarized.

2. Materials and Methods

The proposed automotive seat occupancy sensor is based on an interdigital structure which is integrated into the woven fabric structure.

Figure 1 shows the integrated sensor structure. The textile capacitive sensor was built using a commercial Bekaert conductive yarn. The yarn was produced by the ring yarn method, where the conductive stainless steel fibbers were mixed with polyester fibbers in a proportion of 40/60%. The resultant yarn has a linear resistance of 50 Ω/cm.

To manufacture the textile capacitive sensor, the interdigital structure was built during the weave process of the fabric using a Dornier LWV8/J 71 weaving machine moved by a Jacquard Stäubli LX1600B. Some warp yarns were substituted by conductive yarns to prepare the vertical electrodes. The weft yarns were introduced normally by the weft system. The woven fabric was formed by cotton yarns in the warp and cotton–polyester mix yarns in the weft.

The textile capacitive sensor is incorporated over a car seat, as it can be seen in

Figure 2. One of the sensor sides has two snap connections where the sensor is connected to the microcontroller, which measures the sensor value. The microcontroller performs a common charge–discharge method to evaluate the capacitance value of the sensor; this method has been further explained and studied in previous works [

4].

To study the behaviour of the textile capacitive sensor over the car seat, three cases have been evaluated: a person, a heavy object and a bottle of water. The general procedure is similar for every case. The test starts with the seat unoccupied. Then, after a stabilization time, the studied person or object is placed over the sensor for 10 s. Later, it is retired, leaving the surface sensor free once more. The car seat then remained unoccupied for 10 s more. This cycle exposed was repeated 4 times for every case.

3. Results and Discussion

Three cases are being evaluated: people, a heavy object and a bottle of water.

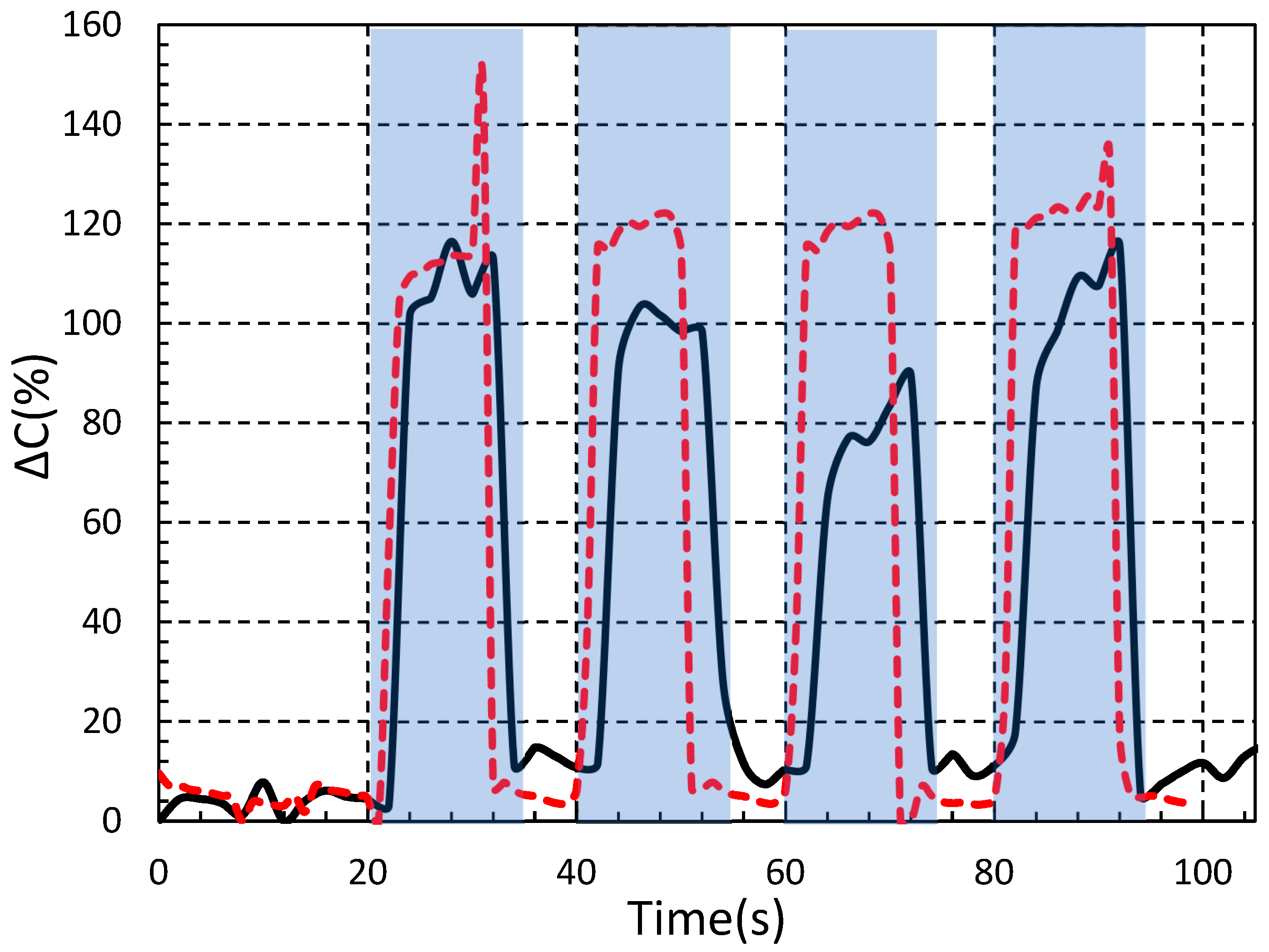

Figure 3 shows the experimental results for two people.

As can be seen, both cases clearly differentiate between the occupied (blue zones) and void states. The void state values are around 10% of the capacitance variation, which imply a slight increase from the start of the void state. This increase was due to the humidity or other substances retained by the fabric after each cycle was performed by the person.

Meanwhile, when a person was sat over the sensor, the capacitance variation experienced a significant increase, reaching values of around 100% of the capacitance variation. Some differences in the graph between both people exist. These changes could be related to physical characteristics of the human body which could affect the permittivity, but could also be related to the positioning of the buttock over the sensor. The last situation was observed on the third pulse of Person 1 (continuous line), where the capacitance variation was lower due to the misplacement of their body.

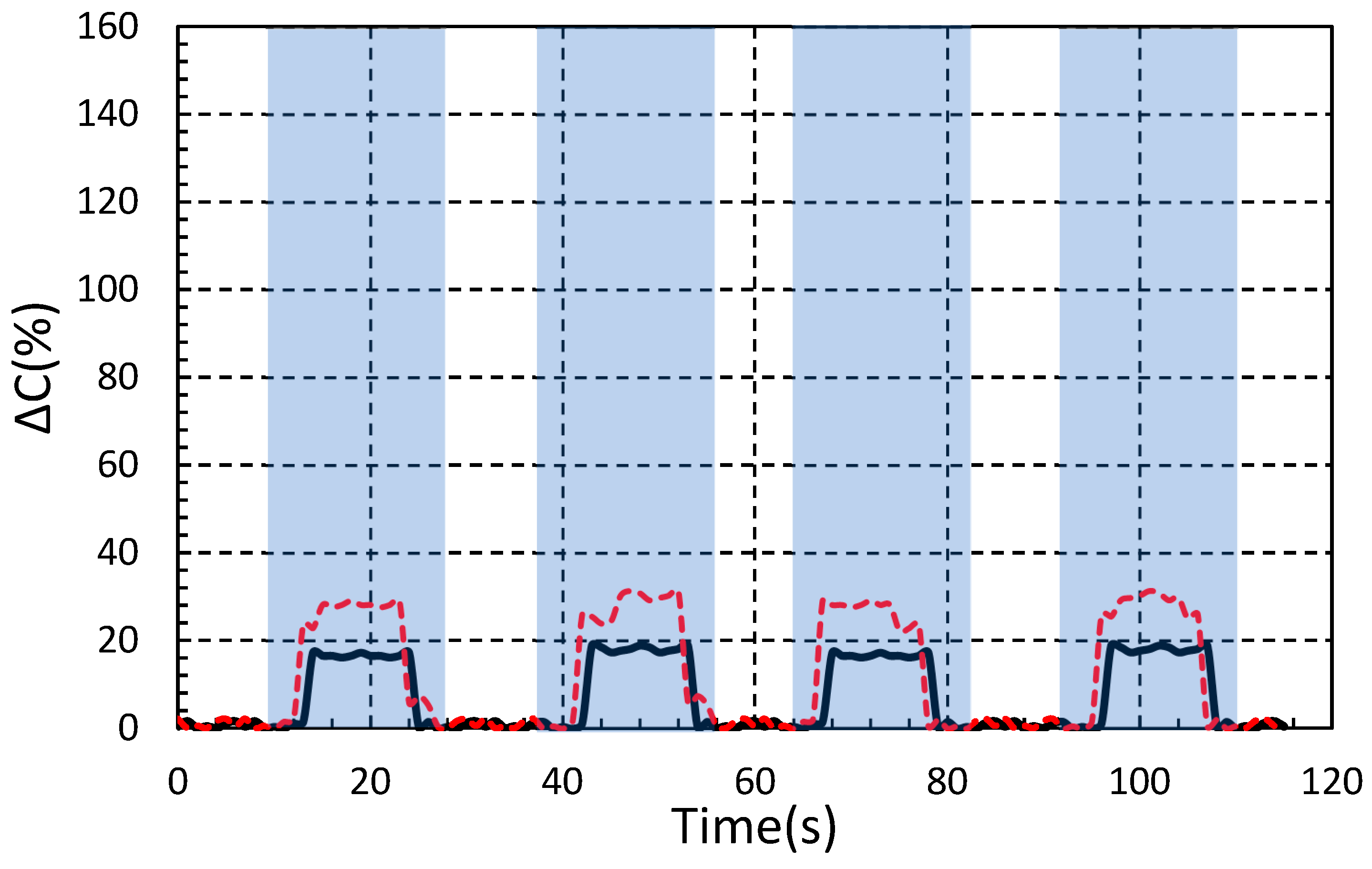

Finally, a test with object was performed. A bag with a weight of 20 kg and a 2 L bottle of water were prepared to be measured. The results are presented in

Figure 4. It is important to highlight that the maximum value obtained by the sensor when an object is detected is 32% of the full capacitance variation.

The cycle was performed for the 20 kg bag, as can be seen represented by a dashed line in the graph, but the sensor does not show any significant response compared with the person detection. The 20 kg bag was detected with a maximum value of 31% of capacitance variation. The change in capacitance was related with the permittivity difference between the sensor fabric and bag fabric. For the case of the bottle of water, depicted by a continuous line, the values observed demonstrate that the sensor was able to tell when the bottle was placed. The water inside the bottle provoked a change in the surrounding permittivity that resulted in 20% of the full capacitance variation being recorded. As seen in both cases, the weight of the object measured is not relevant for capacitance variation because the capacitance is only affected by permittivity.

In the case of sensing a person’s body, it can be observed how, during the void state, the sensor does not return to the initial value due to the remaining humidity from the person’s body; meanwhile, for the case of the object, this effect is not observed.

People measurement demonstrates the functionality of the presence capacitance sensor to distinguish between occupied and void situations. The response for a person is clearly differentiable from an object, even when a bottle of water is placed over the sensor. Therefore, this sensor could solve the false positives provoked by the FSR sensor in automotive applications, providing a new way of measurement directly integrated into the upholstery.

4. Conclusions

An automotive seat occupancy sensor based on e-textile technology is presented in this work. The sensor, based on a woven capacitive sensor, solves the problem suffered by FSR sensors. The sensor is capable of differentiating a person from an object due to the permittivity differences between them. The sensor could also be integrated directly into the upholstery of the car seat, saving space where the FSR sensors would otherwise be installed.

Author Contributions

Conceptualization, M.M.-E. and R.F.-G.; methodology, M.M.-E.; validation, M.M.-E., R.F.-G.; formal analysis, M.M.-E., I.G. and R.F.-G.; investigation M.M.-E.; data curation, M.M.-E.; writing—original draft preparation, M.M.-E.; writing—review and editing, M.M.-E., I.G. and R.F.-G.; supervision, I.G. and R.F.-G.; project administration, I.G. and R.F.-G.; funding acquisition, I.G. and R.F.-G. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Spanish Government “Ministerio de ciencia e innovacion” PID2021 124288OB I00 and AGAUR 2020FI-B 00028.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available within the article and there is presented in every graph. There is no more data apart from the presented.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Interlink Electronics Manufactures. Force Sensing Resistors An Overview of the Technology. p. 25. Available online: https://www.sparkfun.com/datasheets/Sensors/Pressure/fsrguide.pdf (accessed on 15 November 2022).

- Anwary, A.R.; Vassallo, M.; Bouchachia, H. Monitoring of Prolonged and Asymmetrical Posture to Improve Sitting Behavior. In Proceedings of the 2020 International Conference on Data Analytics for Business and Industry: Way Towards a Sustainable Economy (ICDABI), Sakheer, Bahrain, 26–27 October 2020. [Google Scholar] [CrossRef]

- Zeeman, A.S.; Booysen, M.J.; Ruggeri, G.; Lagana, B. Capacitive seat sensors for multiple occupancy detection using a low-cost setup. In Proceedings of the 2013 IEEE International Conference on Industrial Technology (ICIT), Cape Town, South Africa, 25–28 February 2013; pp. 1228–1233. [Google Scholar] [CrossRef]

- Marc, M.E.; Ignacio, G.; Raul, F.G. A Smart Textile System to Detect Urine Leakage. IEEE Sens. J. 2021, 21, 26234–26242. [Google Scholar] [CrossRef]

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).