Behaviour of Concrete Column Reinforced with Steel Bars Exhibiting Uncertain Yield Strength †

Abstract

:1. Introduction

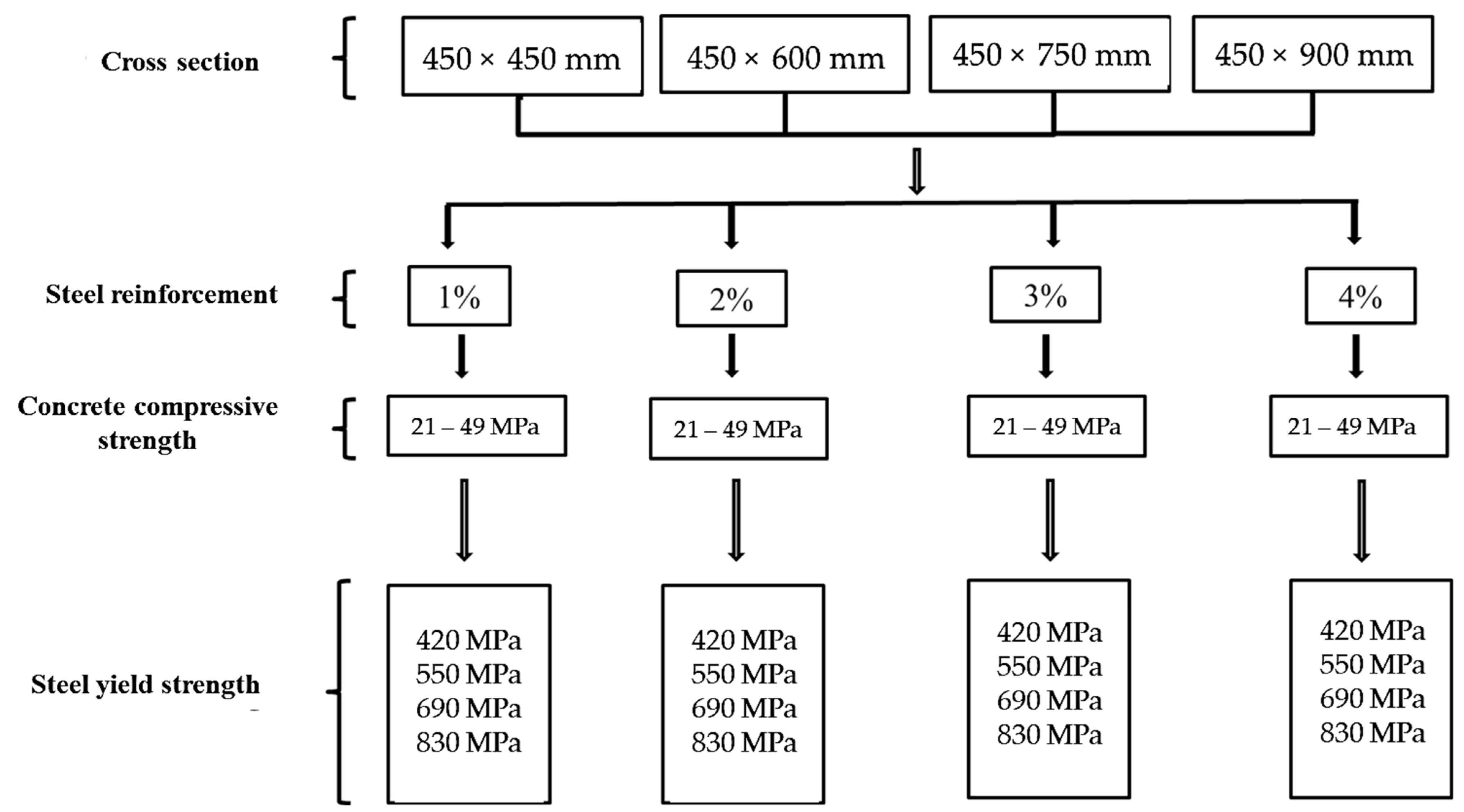

2. Methodology

3. Results and Discussion

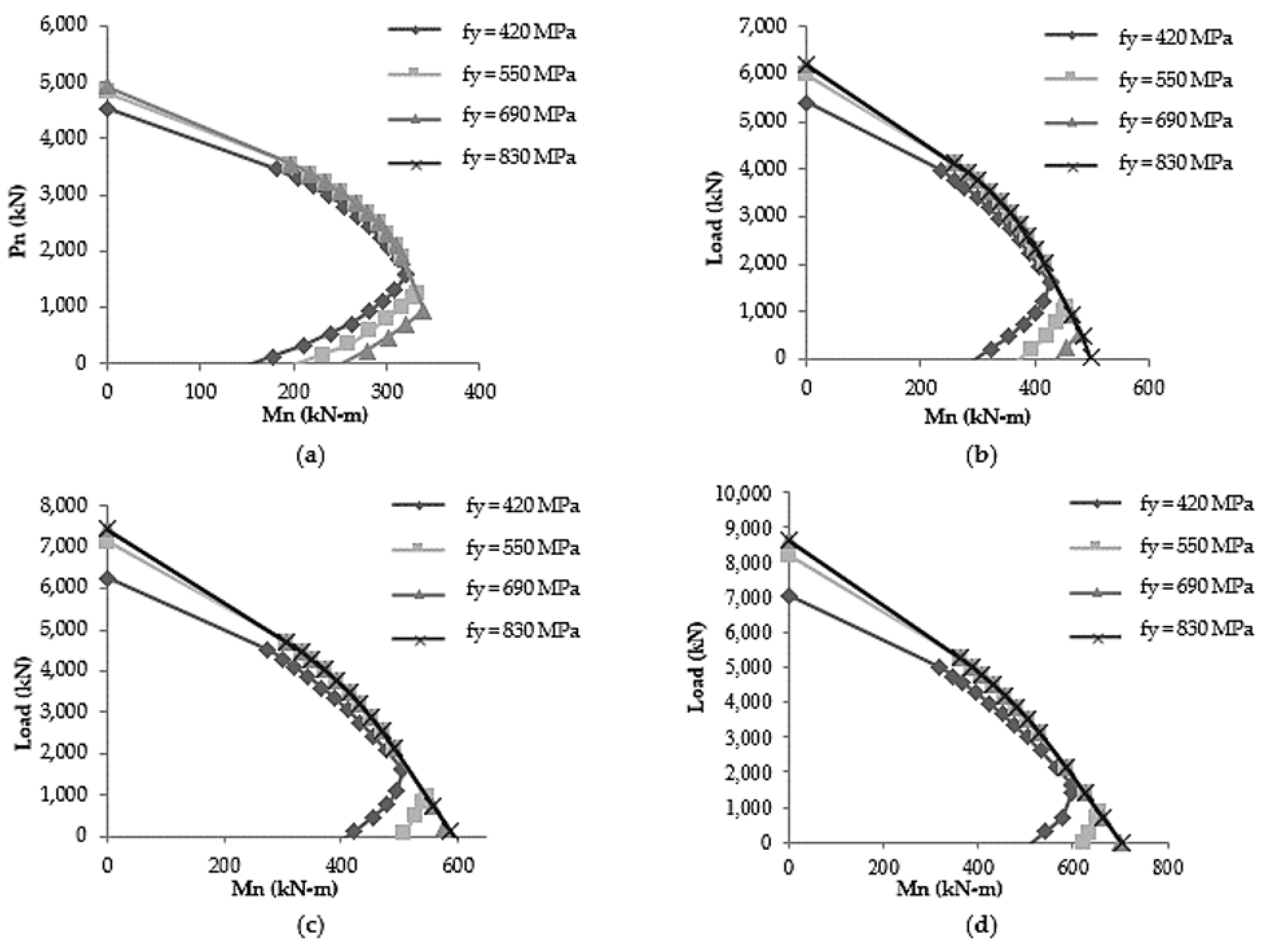

3.1. Comprehensive Parametric Study

3.2. Reduction Factor

- A balance load is selected at yield strength values of 420 MPa (ideal case) and 830 MPa (worst case) from the load–moment interaction diagrams at all concrete compressive strength values (20–60 MPa) for a reinforcement ratio ranging from 1% to 4%.

- A factor Z is calculated by dividing a balance load at a yield strength of 830 MPa (worst case) by a balance load value at a yield strength of 420 MPa (ideal case).

- Based on the comprehensive parametric study, concrete compressive strength and reinforcement ratio are two variables selected for the analysis, where reinforcement ratio is limited until the positive balance load values at a maximum yield strength of 830 MPa (worst case). Please note that yield strength is not considered an input variable since it is unknown and uncertain, and a column cross section is also not considered an input variable in order to keep the equation independent of column dimensions.

- A multivariable regression, as shown in Figure 6, is performed on the Z factor, concrete compressive strength, and reinforcement ratio to obtain Equation (1):where is the concrete compressive strength (MPa), while is the reinforcement ratio (%).

4. Conclusions

- The comprehensive parametric study reveals that a load corresponding to a balance condition drops with an increase in rebar yield strength; consequently, a tension-controlled region is reduced. This is a drastic effect of an unintentional higher yield strength on the behaviour of an RC column, as the failure mode changes from ductile to brittle.

- A reduction factor (Z) is introduced using multivariable regression analysis to compensate for the effect of an unintentional higher yield strength on the behaviour of an RC column. This Z factor should be multiplied with the balance load of a 420 MPa rebar yield strength (ideal case) to generate the same tension-controlled region on an interactor diagram as that of an 830 MPa rebar yield strength (worst case).

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Rafi, M.M.; Siddiqui, S.H. Study of variations of execution methods from standard specifications—A local perspective. In Proceedings of the Second International Conference on Construction in Developing Countries (ICCIDC-II), Cairo, Egypt, 3–5 August 2010; pp. 326–336. [Google Scholar]

- Kankam, C.K.; Adom-Asamoah, M. Strength and ductility characteristics of reinforcing steel bars milled from scrap metals. Mater. Des. 2002, 23, 537–545. [Google Scholar] [CrossRef]

- Lodi, S.H.; Masroor, S.A. Comparative evaluation of reinforcing bars produced in Pakistan. NED Univ. J. Res. 1994, 1, 35–47. [Google Scholar]

- Rafi, M.M.; Lodi, S.H.; Nizam, A. Chemical and mechanical properties of steel rebars manufactured in Pakistan and their design implications. J. Mater. Civ. Eng. 2014, 26, 338–348. [Google Scholar] [CrossRef]

- ASTM A615. Standard Specification for Deformed and Plain Carbon-Steel Bars for Concrete Reinforcement. ASTM International: West Conshohocken, PA, USA, 2016.

- Manzoor, S.; Ahmad, S.H. Characteristics of Grade 60 and Grade 72.5 Re-bars in Pakistan. Int. J. Mod. Eng. Res. 2013, 3, 667–673. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khan, G.; Khan, M.S.; Rafi, M.M. Behaviour of Concrete Column Reinforced with Steel Bars Exhibiting Uncertain Yield Strength. Eng. Proc. 2022, 22, 7. https://doi.org/10.3390/engproc2022022007

Khan G, Khan MS, Rafi MM. Behaviour of Concrete Column Reinforced with Steel Bars Exhibiting Uncertain Yield Strength. Engineering Proceedings. 2022; 22(1):7. https://doi.org/10.3390/engproc2022022007

Chicago/Turabian StyleKhan, Gul, Muhammad Saad Khan, and Muhammad Masood Rafi. 2022. "Behaviour of Concrete Column Reinforced with Steel Bars Exhibiting Uncertain Yield Strength" Engineering Proceedings 22, no. 1: 7. https://doi.org/10.3390/engproc2022022007

APA StyleKhan, G., Khan, M. S., & Rafi, M. M. (2022). Behaviour of Concrete Column Reinforced with Steel Bars Exhibiting Uncertain Yield Strength. Engineering Proceedings, 22(1), 7. https://doi.org/10.3390/engproc2022022007