Experimental Study on Bond Strength of Locally Manufactured GFRP Bar †

Abstract

:1. Introduction

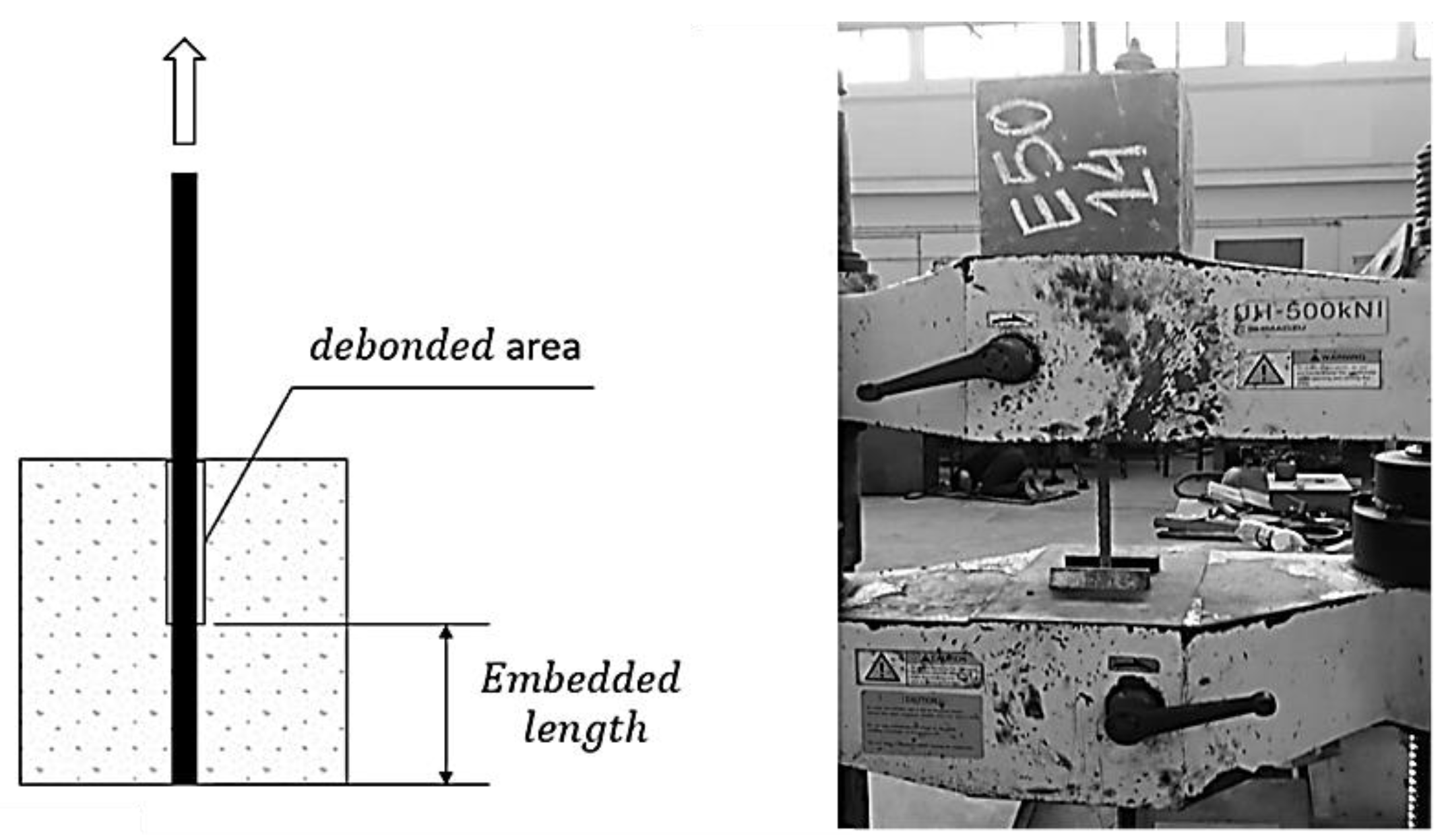

2. Experimental Programme

2.1. Materials

2.2. Test Results

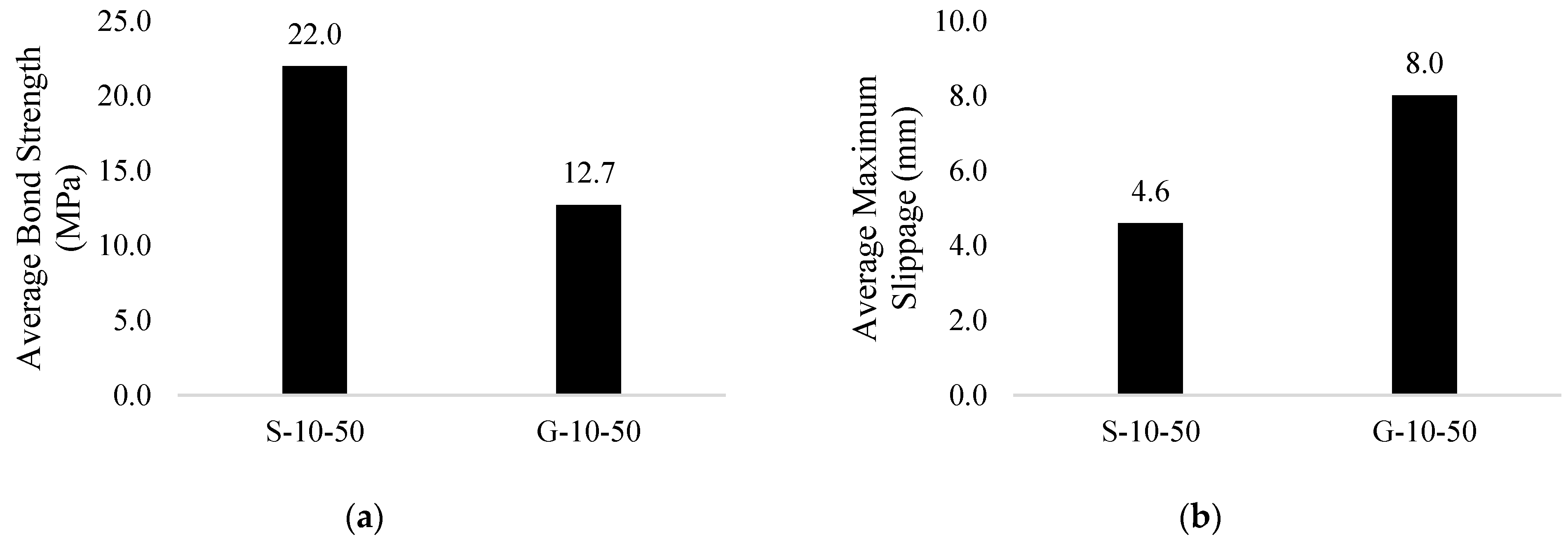

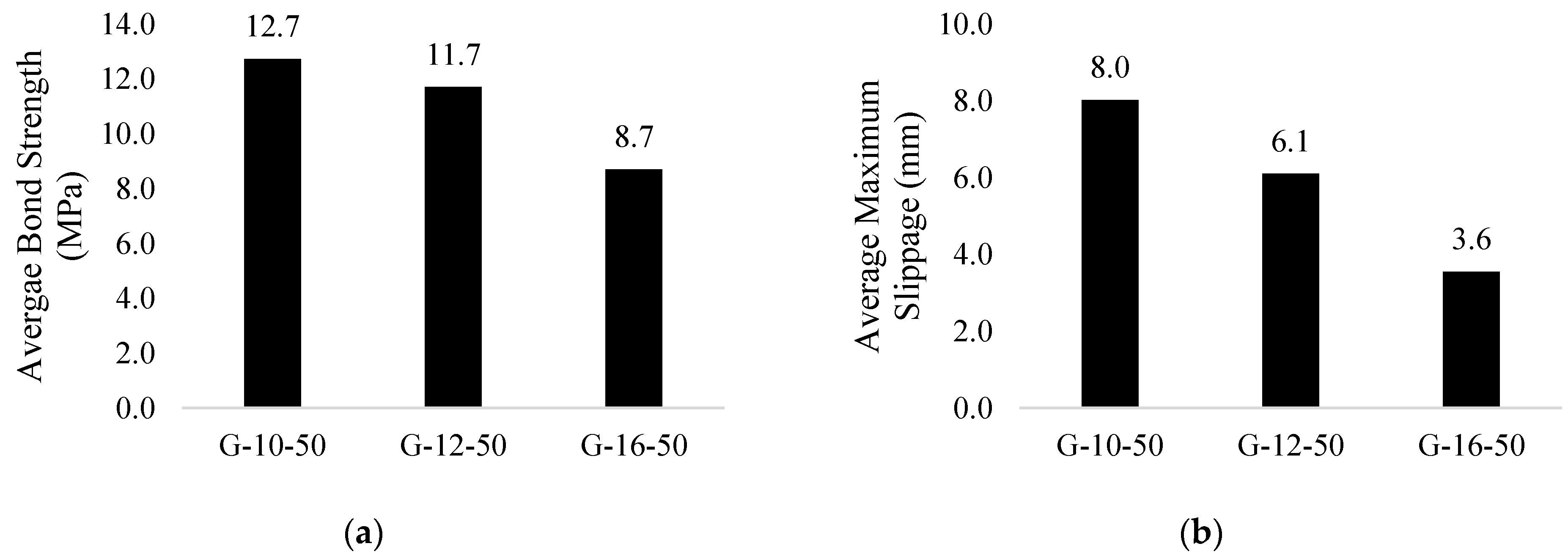

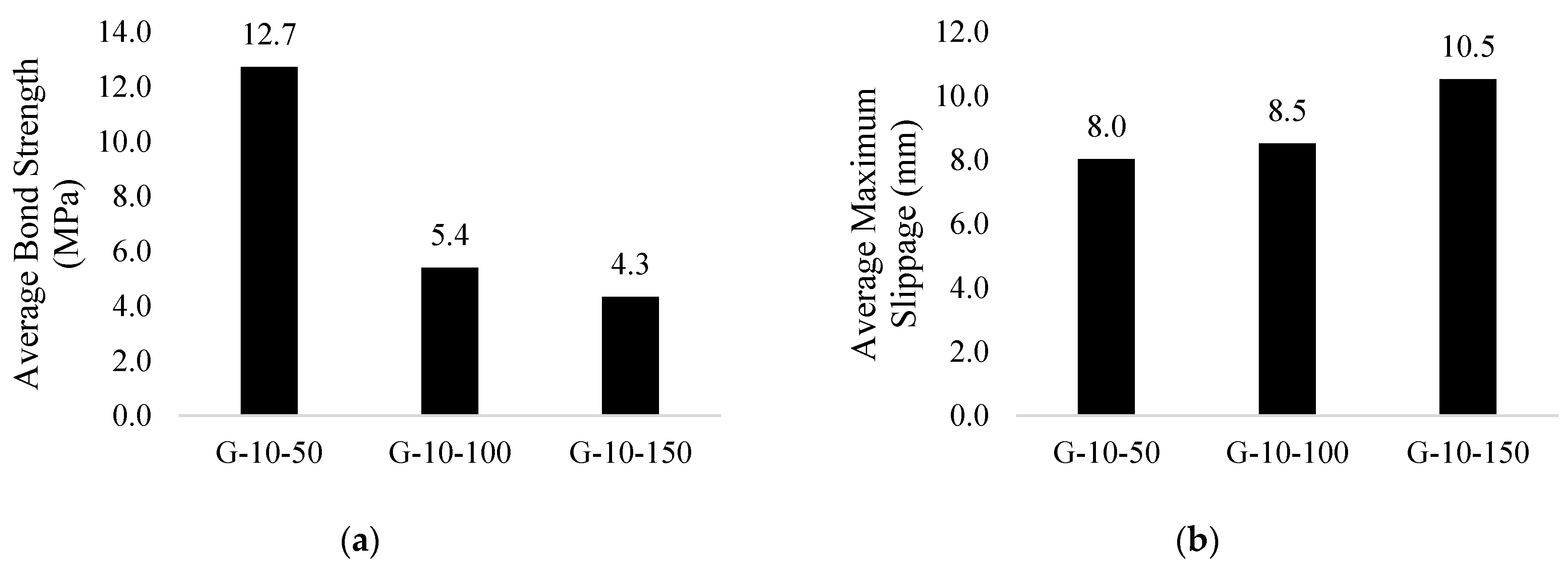

3. Results and Discussion

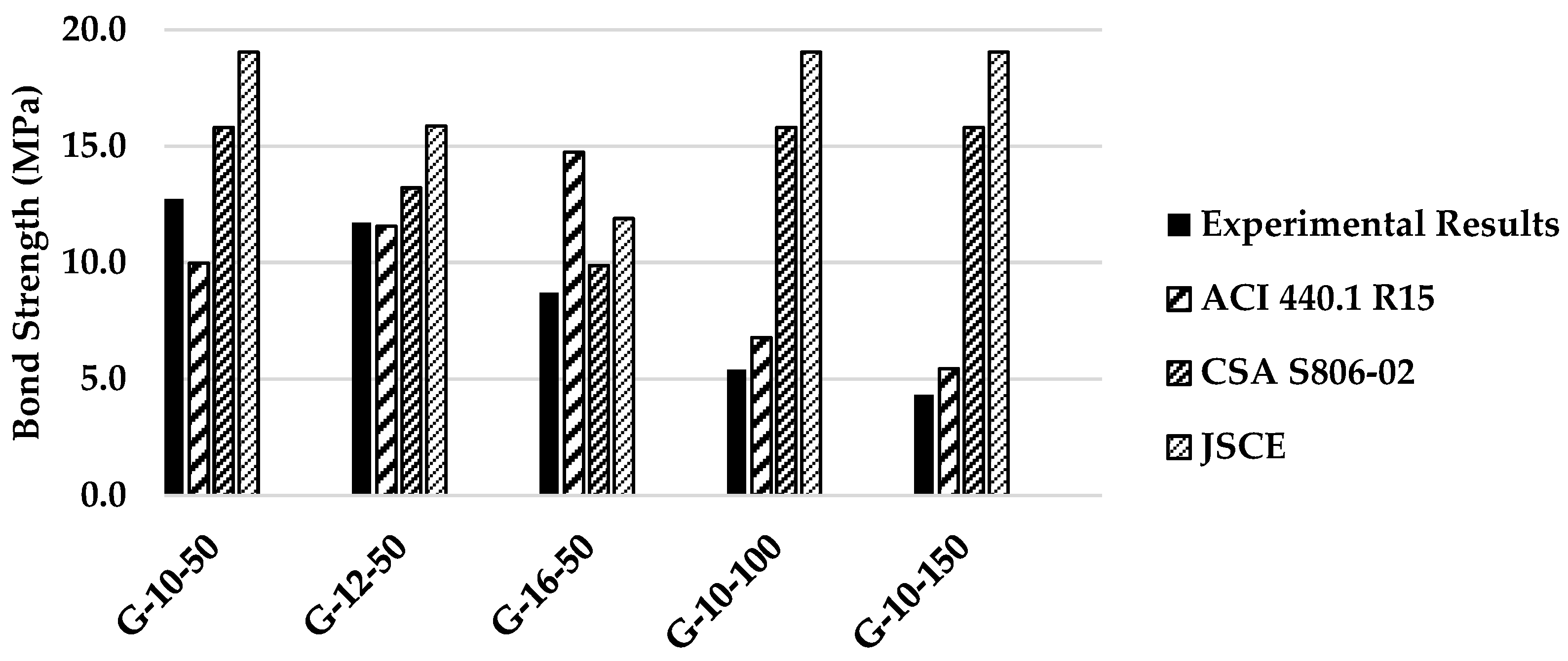

Analytical Results

4. Conclusions

- It is found there is pull-out failure in all the tested specimens.

- The bond strength of the locally manufactured GFRP bar is found 42% less than steel rebar, therefore, it is suggested to improve the mechanical interlock of GFRP bar.

- The bond strength and maximum slippage of GFRP bar is found to be decreased with increase in diameter.

- The bond strength decreased while maximum slippage increased with increase in embedded length of GFRP bar.

- The experimental results are found to be in good accord with ACI 440.1 R15 predictions.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Nanni, A.; de Luca, A.; Zadeh, H.J. Reinforced Concrete with FRP Bars Mechanics and Design; CRC Press: Boca Raton, FL, USA, 2014. [Google Scholar]

- Brown, V.L.; Bartholomew, C.L. FRP reinforcing bars in reinforced concrete members. Mater. J. 1993, 90, 34–39. [Google Scholar]

- Pecce, M.; Manfredi, G.; Realfonzo, R.; Cosenza, E. Experimental and analytical evaluation of bond properties of GFRP bars. J. Mater. Civ. Eng. 2001, 13, 282–290. [Google Scholar] [CrossRef]

- Achillides, Z.; Pilakoutas, K. Bond behavior of fiber reinforced polymer bars under direct pullout conditions. J. Compos. Constr. 2004, 8, 173–181. [Google Scholar] [CrossRef]

- Patil, S.B.; Manjunatha, G.S. Experimental study on bond strength of GFRP bars. Mater. Today Proc. 2020, 21, 1044–1049. [Google Scholar] [CrossRef]

- Yan, F.; Lin, Z.; Yang, M. Bond mechanism and bond strength of GFRP bars to concrete: A review. Compos. Part B Eng. 2016, 98, 56–69. [Google Scholar] [CrossRef]

- Harajli, M.; Abouniaj, M. Bond performance of GFRP bars in tension: Experimental evaluation and assessment of ACI 440 guidelines. J. Compos. Constr. 2010, 14, 659–668. [Google Scholar] [CrossRef]

- Tastani, S.P.; Pantazopoulou, S.J. Bond of GFRP bars in concrete: Experimental study and analytical interpretation. J. Compos. Constr. 2006, 10, 381–391. [Google Scholar] [CrossRef]

- Emparanza, A.R.; Kampmann, R.; Basalo, F.D.Y. State-of-the-Practice of Global Manufacturing of FRP Rebar and Specifications. In Proceedings of the 13th International Symposium on Fiber-Reinforced Polymer Reinforcement for Concrete Structures, Anaheim, CA, USA, 15–19 October 2017. [Google Scholar]

- ACI 440.1R15; Guide for the Design and Construction of Structural Concrete Reinforced with FRP Bars. American Concrete Institute: Farmington Hills, MI, USA, 2015.

- Canadian Standards Association. Design and Construction of Building Components with Fibre-Reinforced Polymers, No. 2; Canadian Standards Association: Toronto, ON, Canada, 2002. [Google Scholar]

- Machida, A.; Uomoto, T. Recommendation for Design and Construction of Concrete Structures Using Continuous Fiber Reinforcing Materials; Japan Soc. of Civil Engineers: Tokyo, Japan, 1997. [Google Scholar]

| Material | Amount (kg/m3) | Proportion by wt. |

|---|---|---|

| Cement | 450 | 1.00 |

| Coarse Aggregate | 982 | 2.18 |

| Fine Aggregate | 662 | 1.47 |

| Water | 222 | 0.49 |

| Specimen ID | Concrete Strength (MPa) | Max Pull out Force (Pmax) (KN) | Bond Stress (τ) (MPa) | Average Bond Stress (τavg) (MPa) | Maximum Slippage (mm) | Average Max Slippage (mm) | Failure Mode |

|---|---|---|---|---|---|---|---|

| S-10-50 | 23.0 | 34.7 | 22.1 | 22.0 | 4.4 | 4.6 | PO |

| 23.0 | 34.3 | 21.8 | 4.8 | PO | |||

| G-10-50 | 23.0 | 19.4 | 12.3 | 12.7 | 7.7 | 8.0 | PO |

| 23.0 | 20.6 | 13.1 | 8.3 | PO | |||

| G-12-50 | 23.0 | 23.3 | 12.4 | 11.7 | 6.5 | 6.1 | PO |

| 23.0 | 20.8 | 11.0 | 5.7 | PO | |||

| G-16-50 | 23.0 | 24.1 | 9.6 | 8.7 | 3.7 | 3.6 | PO |

| 23.0 | 19.6 | 7.8 | 3.4 | PO | |||

| G-10-100 | 23.0 | 17.6 | 5.6 | 5.4 | 8.7 | 8.5 | PO |

| 23.0 | 16.3 | 5.2 | 8.3 | PO | |||

| G-10-150 | 23.0 | 19.8 | 4.2 | 4.3 | 10.8 | 10.5 | PO |

| 23.0 | 21.0 | 4.5 | 10.2 | PO |

| Reference | Equations for Bond Strength |

|---|---|

| ACI 440.1 R15 [10] | |

| CSA S806-02 [11] | |

| JSCE [12] |

| Specimen ID | Average Bond Stress (MPa) | Analytical Results | ||

|---|---|---|---|---|

| ACI 440.1 R15 | CSA S806-02 | JSCE | ||

| G-10-50 | 12.7 | 9.97 | 15.8 | 19.03 |

| G-12-50 | 11.7 | 11.56 | 13.2 | 15.86 |

| G-16-50 | 8.7 | 14.74 | 9.87 | 11.89 |

| G-10-100 | 5.4 | 6.77 | 15.8 | 19.03 |

| G-10-150 | 4.3 | 5.44 | 15.8 | 19.03 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ifrahim, M.S.; Sangi, A.J.; Hamza, S.M. Experimental Study on Bond Strength of Locally Manufactured GFRP Bar. Eng. Proc. 2022, 22, 4. https://doi.org/10.3390/engproc2022022004

Ifrahim MS, Sangi AJ, Hamza SM. Experimental Study on Bond Strength of Locally Manufactured GFRP Bar. Engineering Proceedings. 2022; 22(1):4. https://doi.org/10.3390/engproc2022022004

Chicago/Turabian StyleIfrahim, Muhammad Saad, Abdul Jabbar Sangi, and Syed Muhammad Hamza. 2022. "Experimental Study on Bond Strength of Locally Manufactured GFRP Bar" Engineering Proceedings 22, no. 1: 4. https://doi.org/10.3390/engproc2022022004

APA StyleIfrahim, M. S., Sangi, A. J., & Hamza, S. M. (2022). Experimental Study on Bond Strength of Locally Manufactured GFRP Bar. Engineering Proceedings, 22(1), 4. https://doi.org/10.3390/engproc2022022004