Abstract

In order to ensure quality work, the main contractor chooses suppliers based upon various quality attributes. The key to quality work on mega projects is to select best-quality suppliers. This research shows the data analysis results of preference rating of quality factors for supplier selection in Pakistan’s construction industry as per the importance accorded to each factor by the contractors. After thorough literature review and qualitative content analysis, a total of 25 factors were finalized and, then, a survey was conducted targeting well-known contractors in Pakistan. The weighted sum model (WSM) technique was used to analyze the overall preference of quality attributes through literature and respondent scores. Correlation analysis was also performed to select the most reliable weight split. After significant analysis, ten crucial attributes were identified for supplier selection in the construction quality domain. Quality management system certification, Product reliability and Capability of handling abnormal quality problems were the top three selection criteria.

1. Introduction

In the vast and dynamic world of construction, whenever a firm wants to have a quality product, it needs a main contractor who can select the best quality supplier for any project. The selection of supplier plays a crucial part in overall performance [1]. If the supplier can provide consistent products, which conform to the standard requirements, ISO 9000 certification, for instance [2], then that supplier is likely to fulfill all the technical requirements and satisfy the domain of ‘conformance to the requirements’. Quality attributes, like product reliability and product durability [3], along with ability to handle problems [4], are of great importance. Much research shows that greater attention should be given to quality [5].

The literature contains information on many quality attributes that can enhance the overall performance of a quality project. For a supplier organization to be part of a quality project, it has to offer attributes which would result in its selection as supplier by the main contractor. It is usually perceived that a quality supplier increases the over-all cost of a project but much research has stressed the need to selecting the supplier by considering quality, delivery performance and other attributes and not just low cost [6]. This study evaluates the quality attributes which are crucial for supplier selection by the main contractor. The aim of this research was to study the perceptions of contractors regarding what constitutes quality attributes when selecting a supplier in the construction industry in Pakistan. The main objectives of this research are as follows:

- To identify, from existing literature, the quality attributes a supply organization or firm requires to be considered during the selection process.

- To highlight the most important attributes through statistical analysis, which serve as a guideline for suppliers to improve their quality standards in Pakistan’s construction industry.

2. Literature Review

In the modern era, supplier–customer relations have evolved a great deal. Parties prefer to have a more cooperative and durable relationship than just a short-term relationship.

In supply chain management, a long-term relationship is a very important factor of success for both buyers and suppliers. Therefore, supplier selection has become a matter of great attention for successful implementation of the supply chain [7]. In the supply chain, the founding attributes to form a relationship between the supplier and the buyer are quality, cost efficiency, delivery dependability, volume flexibility, information and customer service [8].

Dickson shed light on the top three indicators for performance evaluation of a supplier which are quality, delivery and performance history [9]. Raw materials, and components or services, are provided by the vendors to an organization which needs them. In the supply chain, the supplier is of a great importance for an organization. A suitable supplier should offer the company quality products in the right quantity at reasonable prices and at the right time [10]. Many consider raw material costs to be of highest priority, since raw material costs directly contribute to actual profits and an organization’s competitive advantage [11].

When a firm is selecting a supplier, it is making a decision to achieve multiple objectives which include minimizing procurement costs and maximizing quality and service performance at the same time [12]. As a rule of thumb, firms endeavor to increase competitiveness by reducing the cost of their products, as well as by following high quality standards. A survey by questionnaire of sixty people in a variety of industries in the United States of America, conducted by Freeland, regarding purchasing practices ranked quality as the most important criterion for supplier selection [13].

Chou and Chang stressed that the supplier should continuously strive to improve by reducing cost, increasing flexibility of operations and by increasing internal responsiveness, and, if it is a supply chain, then the supplier must be capable of providing low cost and high quality [14].

Many researchers have compared various quality criteria through different methods, like the fuzzy analytic hierarchy process (AHP) and the fuzzy geometric mean method. Kahraman compared supplier firms using fuzzy AHP, taking into account financial, managerial and quality systems as the criteria for supplier selection [15]. The relationship between supplier selection and business improvement is evident in research and business improvement is greatly affected by customer focus and improvement initiatives offered by the supplier [5].

Chan and Chan took quality as ‘conformance to specifications’ and rated it as the most important factor, followed by product reliability and product durability for supplier selection [3]. Kaur et al., using the fuzzy geometric mean method, concluded that quality is the most important factor for supplier selection, followed by cycle time and cost [16].

The criteria selection for the supplier selection process is a great challenge for both managers and policy-makers in industries [1]. Kannan et al. revealed that quality is the main criterion in selecting a green supplier for industry and is independent of other criteria. On the other hand, selection criteria like cost and service have higher dependencies on other criteria and are considered less important than quality [17].

The results of Verma and Pullman indicated that, although managers consider quality to be of utmost importance, when it comes to actual supplier selection, they prefer cost and delivery that is on time over quality [6]. Despite the fact that managers perceive quality to be more important than cost, in actual scenarios they do not select suppliers based on quality.

Kannan and Tan emphasized that suppliers should be viewed as an extension of the buying firm itself and not as independent entities to be dealt with at arm’s length [18]. In the case of single sourcing, the contractor needs to select the supplier who can satisfy the requirements of demand, quality, and delivery. In the case of multiple sourcing, the contractor needs more than one supplier, each supplier supplying different materials. Conventionally, in supply chain management, supplier selection is based on the supplier’s ability to meet quality requirements, delivery schedule, price, and service [19].

3. Methodology

To achieve the research objectives, in the first phase, a comprehensive literature review was carried out from 30 research articles belonging to different taxonomies i.e., construction, manufacturing, operational research, airline industry, production economics, and management sciences etc. From a thorough literature review of these works, 31 factors pertaining to quality assessment of supplier organizations were extracted. To avoid duplication and overlapping, the factors were briefly reviewed so as to subsequently short list them into 25 quality attributes of supplier organizations.

In the second phase, content analysis was performed to assess qualitative and quantitative significance so as to screen out less significant factors [20]. Quantitative score was based on frequency of appearance and qualitative score was based on the described level of importance/impact assessed subjectively by the authors. Analysis of significance involved a systematic literature review technique that also included experts from the local construction industry of Pakistan, so it was not limited to literature scores only [21].

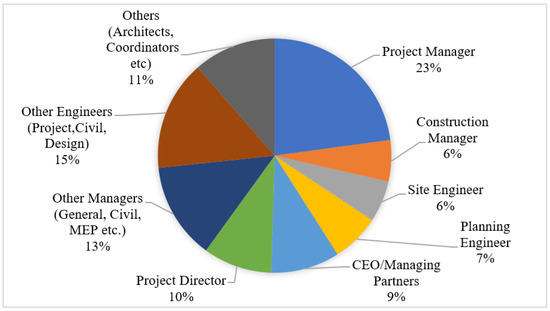

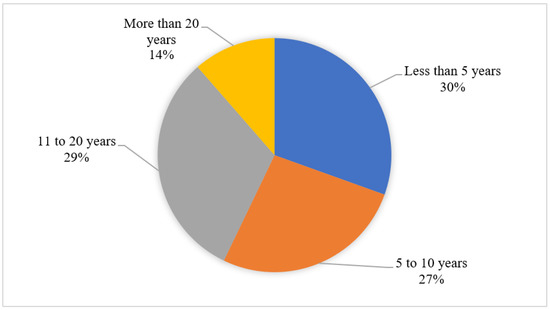

A questionnaire survey was carried out in which Pakistani contractors were asked to rate each factor according to their organization’s needs and practices in the supplier selection process on the Likert scale of 1–5, in which ‘1’ represented ‘very low’ and ‘5’ represented ‘very high’. A single response was taken from each contractor firm representing its quality practices and to avoid any mixing of opinions. A total of 105 responses were received which included responses from contractors carrying out different projects in various areas of Pakistan. Figure 1 and Figure 2 show the demographics of professionals as per their respective designation and experience. Their responses were aggregated in the form of a mean score. The total score consisted of both literature and respondent scores.

Figure 1.

Respondents’ distribution with respect to designation.

Figure 2.

Respondents’ distribution with respect to experience.

As the construction industry of Pakistan is in a developing state, international literature might not fully reflect the true nature of a developing industry [22]. Therefore, the literature and respondent score streams might require different treatments. Throughout the documented literature, there was no concrete usage of exact weighting range due to contextualized decision making [23]. Hence, the weight sum model (WSM) was used to analyze and propose decision weights.

In the third phase, a detailed statistical analysis was performed using the WSM technique in which different weight splits of 50/50, 40/60, 30/70, 20/80 were applied to the literature and respondent scores. Total, normalized and cumulative normalized scores were calculated for each weight split. Correlation analysis was also performed to statistically test the reliability of different weight splits.

4. Results and Discussion

The results of the qualitative content analysis and respondent score analysis in the form of literature and respondent scores, respectively, for each identified quality attribute are shown in Table 1.

Table 1.

Qualitative content analysis and respondent score analysis.

As discussed in the previous section, 50/50, 40/60, 30/70, 20/80 weight splits were utilized to analyze the literature and respondent scores. The results of each weight split showed variation in the rankings of quality attributes when sorted according to their respective normalized scores. Correlation values ranging between 0.7–0.9 suggest that there is statistically non-significant difference between various decision weight combinations [23]. The results of correlation analysis are shown in Table 2.

Table 2.

Correlation analysis.

Giving due significance to local experts, the 40/60 weight split was preferred because of its stronger correlation values in comparison with other weight splits. Here, 40 was the value in relation to the literature score and 60 the value in relation to the respondent score. The results of the 40/60 weight split are summarized in Table 3, highlighting the major 10 quality attributes, based on over 45% combined significance with a cumulative normalized score ranging from 0.052368256 to 0.45123597.

Table 3.

Top 10 quality attributes (40/60 WSM).

5. Conclusions and Recommendations

The results allowed us to achieve the objective of highlighting the most important quality attributes, which were ten in number. The three top ranked quality attributes were ‘Quality Management System Certification’, ‘Product Reliability’& ‘Capability of handling abnormal Quality Problems’. These were the attributes which contractors in Pakistan considered most prominent when evaluating supplier and vendor organizations for sub-contracting purposes in various construction projects. This research provides a guideline for Pakistani suppliers to improve the quality performance of their products and services in the above highlighted areas and to pursue these attributes in order to qualify for upcoming projects. This not only ensures healthy and mutually beneficial relationships between suppliers and contractors but also leads to project completion as per required specifications and with assured quality. This research captures an image of how contractors in Pakistan view ‘Quality’ while selecting the best supplier for their organizations. Future recommendations may include:

- Conducting similar surveys from the perspectives of clients and consultant organizations on how they perceive quality in the supplier selection process for quality-oriented projects.

- Preparing a decision-making model for supplier selection i.e., an analytic hierarchy process (AHP)/fuzzy-AHP model, in which certain weights would be assigned to each quality attribute via benchmarking/factor analysis and the performance of a supplier’s firm would be evaluated based on points scored in each of the attributive criteria. Such a model would lead to the appointment of key suppliers in Pakistan’s construction industry.

Author Contributions

Conceptualization, F.u.R.Q.; methodology, F.u.R.Q.; questionnaire survey, F.u.R.Q. and A.M.Y.; statistical data analysis, F.u.R.Q.; writing—original draft preparation, F.u.R.Q.; writing—review and editing, A.M.Y. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data supporting the findings of this study are available from the corresponding author on request. Data are not publicly available because it contains some confidential information.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Kannan, G.; Haq, A.N. Analysis of Interactions of Criteria and Sub-Criteria for the Selection of Supplier in the Built-in-Order Supply Chain Environment. Int. J. Prod. Res. 2007, 45, 3831–3852. [Google Scholar] [CrossRef]

- Akarte, M.M.; Surendra, N.V.; Ravi, B.; Rangaraj, N. Web Based Casting Supplier Evaluation Using Analytical Hierarchy Process. J. Oper. Res. Soc. 2001, 52, 511–522. [Google Scholar] [CrossRef]

- Chan, F.T.S.; Chan, H.K. Development of the Supplier Selection Model—a Case Study in the Advanced Technology Industry. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2004, 218, 1807–1824. [Google Scholar] [CrossRef]

- Lee, E.-K.; Ha, S.; Kim, S.-K. Supplier Selection and Management System Considering Relationships in Supply Chain Management. IEEE Trans. Eng. Manag. 2001, 48, 307–318. [Google Scholar] [CrossRef]

- Garfamy, R.M. Supplier Selection and Business Process Improvement. Int. J. Serv. Oper. Manag. 2009, 5, 233–250. [Google Scholar] [CrossRef]

- Verma, R.; Pullman, M.E. An Analysis of the Supplier Selection Process. Omega 1998, 26, 739–750. [Google Scholar] [CrossRef]

- Chen, C.-T.; Lin, C.-T.; Huang, S.-F. A Fuzzy Approach for Supplier Evaluation and Selection in Supply Chain Management. Int. J. Prod. Econ. 2006, 102, 289–301. [Google Scholar] [CrossRef]

- Bevilacqua, M.; Ciarapica, F.E.; Giacchetta, G. A Fuzzy-QFD Approach to Supplier Selection. J. Purch. Supply Manag. 2006, 12, 14–27. [Google Scholar] [CrossRef]

- Dickson, G.W. An Analysis of Vendor Selection Systems and Decisions. J. Purch. 1966, 2, 5–17. [Google Scholar] [CrossRef]

- Kuo, R.J.; Wang, Y.C.; Tien, F.C. Integration of Artificial Neural Network and MADA Methods for Green Supplier Selection. J. Clean. Prod. 2010, 18, 1161–1170. [Google Scholar] [CrossRef]

- Thongchattu, C.; Siripokapirom, S. Notice of Retraction: Green Supplier Selection Consensus by Neural Network. In Proceedings of the 2010 2nd International Conference on Mechanical and Electronics Engineering, Kyoto, Japan, 1–3 August 2010; Volume 2, pp. 313–316. [Google Scholar] [CrossRef]

- Xia, W.; Wu, Z. Supplier Selection with Multiple Criteria in Volume Discount Environments. Omega 2007, 35, 494–504. [Google Scholar] [CrossRef]

- Freeland, J.R. A Survey of Just-in-Time Purchasing Practices in the United. Prod. Inventory Manag. J. 1991, 32, 43. [Google Scholar]

- Chou, S.; Chang, Y. A Decision Support System for Supplier Selection Based on a Strategy-Aligned Fuzzy SMART Approach. Expert Syst. Appl. 2008, 34, 2241–2253. [Google Scholar] [CrossRef]

- Kahraman, C.; Cebeci, U.; Ulukan, Z. Multi-criteria Supplier Selection Using Fuzzy AHP. Logist. Inf. Manag. 2003, 16, 382–394. [Google Scholar] [CrossRef]

- Kaur, P.; Verma, R.; Mahanti, N.C. Selection of Vendor Using Analytical Hierarchy Process Based on Fuzzy Preference Programming. Opsearch 2010, 47, 16–34. [Google Scholar] [CrossRef]

- Kannan, G.; Haq, A.N.; Sasikumar, P.; Arunachalam, S. Analysis and Selection of Green Suppliers Using Interpretative Structural Modelling and Analytic Hierarchy Process. Int. J. Manag. Decis. Mak. 2008, 9, 163–182. [Google Scholar] [CrossRef]

- Kannan, V.R.; Tan, K.C. Supplier Selection and Assessment: Their Impact on Business Performance. J. Supply Chain Manag. 2002, 38, 11–21. [Google Scholar] [CrossRef]

- Hsu, C.-W.; Hu, A.H. Applying Hazardous Substance Management to Supplier Selection Using Analytic Network Process. J. Clean. Prod. 2009, 17, 255–264. [Google Scholar] [CrossRef]

- Hsieh, H.-F.; Shannon, S.E. Three Approaches to Qualitative Content Analysis. Qual. Health Res. 2005, 15, 1277–1288. [Google Scholar] [CrossRef] [PubMed]

- Ullah, F.; Ayub, B.; Siddiqui, S.Q.; Thaheem, M.J. A Review of Public-Private Partnership: Critical Factors of Concession Period. J. Financial Manag. Prop. Constr. 2016, 21, 269–300. [Google Scholar] [CrossRef]

- Naveed, M.H.; Thaheem, M.J.; Khurshid, M.B.; Farooqui, R.U.H. Performance Assessment of Construction Engineering and Management (CEM) Degree Program in Developing Countries: Case of Pakistan. Int. J. Constr. Educ. Res. 2017, 13, 3–23. [Google Scholar] [CrossRef]

- Ahmad, Z.; Thaheem, M.J.; Maqsoom, A. Building Information Modeling as a Risk Transformer: An Evolutionary Insight into the Project Uncertainty. Autom. Constr. 2018, 92, 103–119. [Google Scholar] [CrossRef]

- Birgün Barla, S. A Case Study of Supplier Selection for Lean Supply by Using a Mathematical Model. Logist. Inf. Manag. 2003, 16, 451–459. [Google Scholar] [CrossRef]

- Kannan, D.; Khodaverdi, R.; Olfat, L.; Jafarian, A.; Diabat, A. Integrated Fuzzy Multi Criteria Decision Making Method and Multi-Objective Programming Approach for Supplier Selection and Order Allocation in a Green Supply Chain. J. Clean. Prod. 2013, 47, 355–367. [Google Scholar] [CrossRef]

- Min, H. International Supplier Selection: A Multi-Attribute Utility Approach. Int. J. Phys. Distrib. Logist. Manag. 1994, 24, 24–33. [Google Scholar] [CrossRef]

- Chan, F.T.S.; Chan, H.K.; Ip, R.W.L.; Lau, H.C.W. A Decision Support System for Supplier Selection in the Airline Industry. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2007, 221, 741–758. [Google Scholar] [CrossRef]

- Chou, S.-Y.; Shen, C.-Y.; Chang, Y.-H. Vendor Selection in a Modified Re-Buy Situation Using a Strategy-Aligned Fuzzy Approach. Int. J. Prod. Res. 2007, 45, 3113–3133. [Google Scholar] [CrossRef]

- Shen, C.-Y.; Yu, K.-T. Enhancing the Efficacy of Supplier Selection Decision-Making on the Initial Stage of New Product Development: A Hybrid Fuzzy Approach Considering the Strategic and Operational Factors Simultaneously. Expert Syst. Appl. 2009, 36, 11271–11281. [Google Scholar] [CrossRef]

- Grisi, R.M.; Guerra, L.; Naviglio, G. Supplier Performance Evaluation for Green Supply Chain Management. In Business Performance Measurement and Management; Springer: Berlin/Heidelberg, Germany, 2010; pp. 149–163. [Google Scholar] [CrossRef]

- Lee, A.H.I.; Kang, H.-Y.; Hsu, C.-F.; Hung, H.-C. A Green Supplier Selection Model for High-Tech Industry. Expert Syst. Appl. 2009, 36, 7917–7927. [Google Scholar] [CrossRef]

- Braglia, M.; Petroni, A. A Quality Assurance-oriented Methodology for Handling Trade-offs in Supplier Selection. Int. J. Phys. Distrib. Logist. Manag. 2000, 30, 96–112. [Google Scholar] [CrossRef]

- Chan, F.T.S.; Kumar, N. Global Supplier Development Considering Risk Factors Using Fuzzy Extended AHP-Based Approach. Omega 2007, 35, 417–431. [Google Scholar] [CrossRef]

- Liu, F.-H.F.; Hai, H.L. The Voting Analytic Hierarchy Process Method for Selecting Supplier. Int. J. Prod. Econ. 2005, 97, 308–317. [Google Scholar] [CrossRef]

- Li, X.; Zhao, C. Selection of Suppliers of Vehicle Components Based on Green Supply Chain. In Proceedings of the 2009 16th International Conference on Industrial Engineering and Engineering Management, Beijing, China, 21–23 October 2009; pp. 1588–1591. [Google Scholar] [CrossRef]

- Kuo, R.J.; Lin, Y.J. Supplier Selection Using Analytic Network Process and Data Envelopment Analysis. Int. J. Prod. Res. 2012, 50, 2852–2863. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).