Machine-Vision-Based Plastic Bottle Inspection for Quality Assurance †

Abstract

:1. Introduction

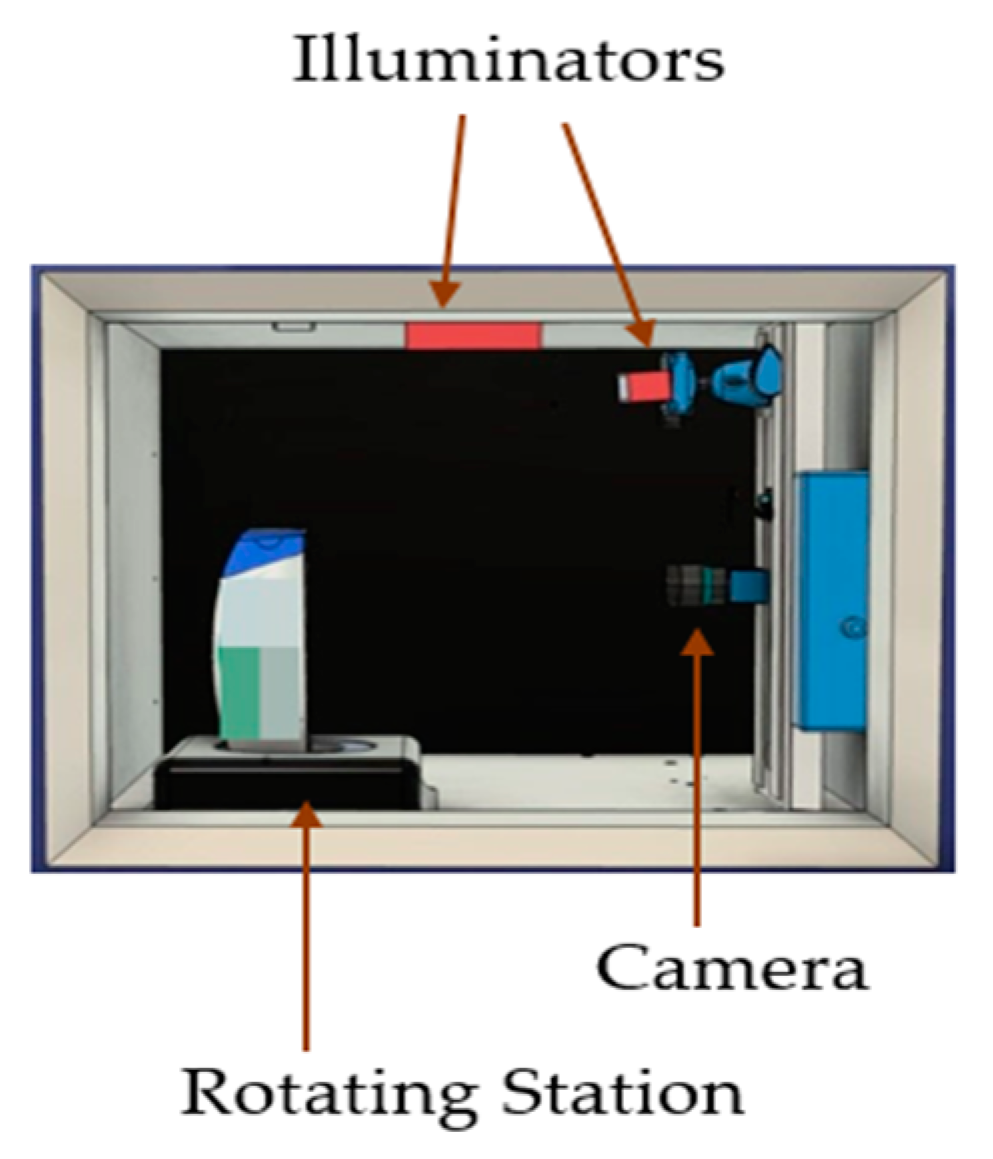

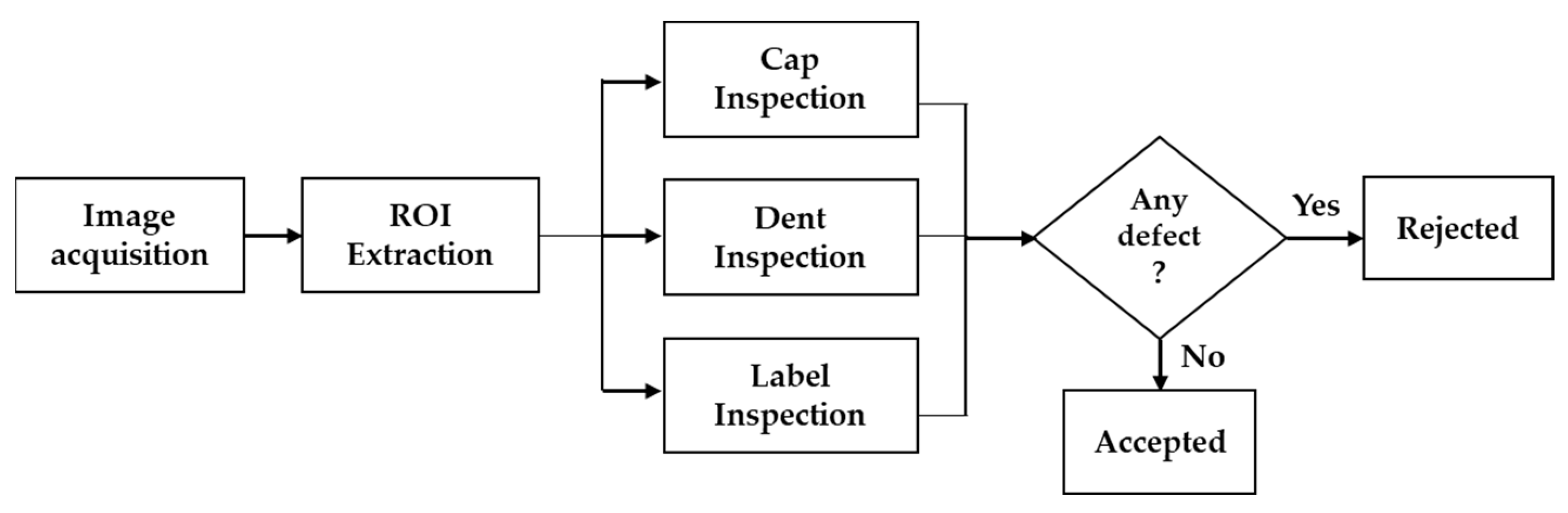

2. Proposed Methodology

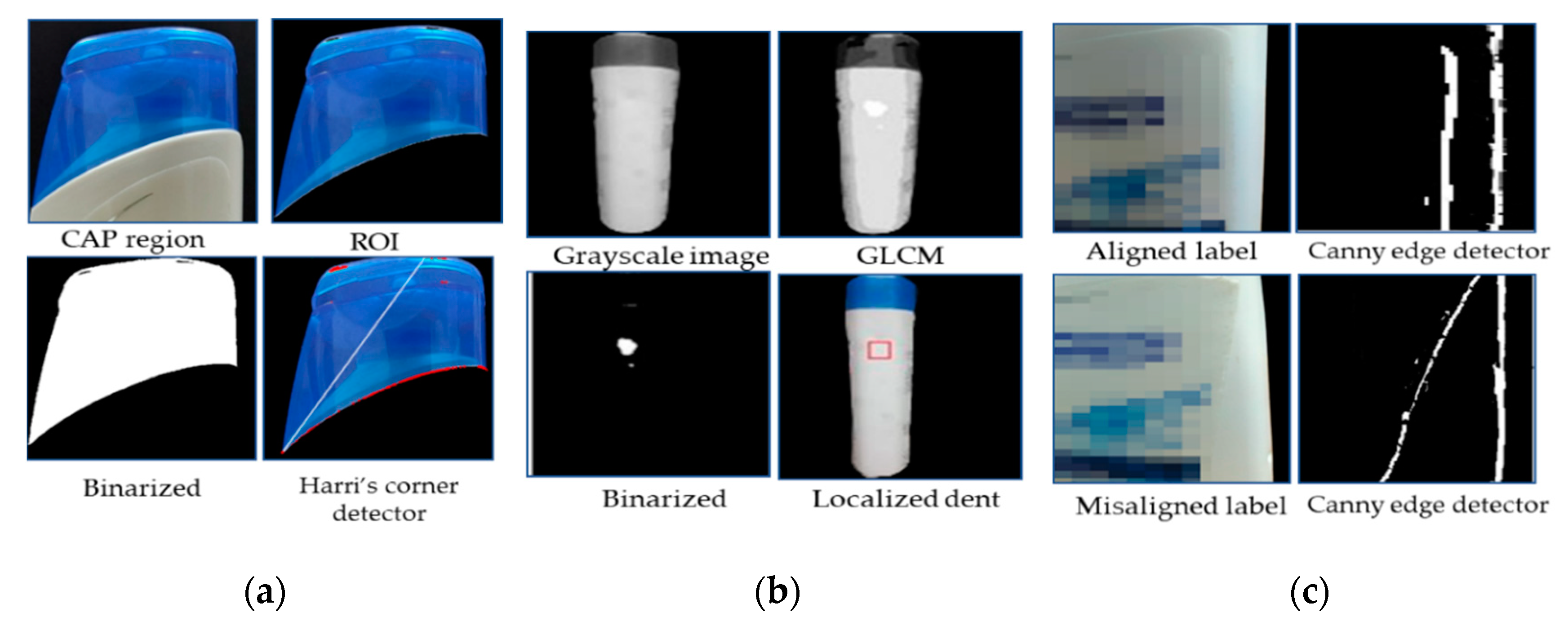

2.1. Cap Inspection

2.2. Dent Inspection

2.3. Label Inspection

3. Results

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Galindo-Salcedo, M.; Pertúz-Moreno, A.; Guzmán-Castillo, S.; Gómez-Charris, Y.; Romero-Conrado, A.R. Smart manufacturing applications for inspection and quality assurance processes. Procedia Comput. Sci. 2022, 198, 536–541. [Google Scholar] [CrossRef]

- Teng, S.-A.; Chao, C.-J.; Teng, M.-N. A Human Factors Engineering Analysis of Waste Disposal Industry. In Proceedings of the 2019 IEEE 6th International Conference on Industrial Engineering and Applications (ICIEA), Tokyo, Japan, 12–15 April 2019; pp. 577–582. [Google Scholar] [CrossRef]

- Zhang, T.; Ding, B.; Zhao, X.; Liu, G.; Pang, Z. LearningADD: Machine learning based acoustic defect detection in factory automation. J. Manuf. Syst. 2021, 60, 48–58. [Google Scholar] [CrossRef]

- Abhijit, M.; Priya, S.S. Detecting faulty bottle caps using CNN model. In Proceedings of the 2021 2nd International Conference on Smart Electronics and Communication (ICOSEC), Trichy, India, 7–9 October 2021; pp. 1446–1452. [Google Scholar] [CrossRef]

- Bahaghighat, M.; Mirfattahi, M.; Akbari, L.; Babaie, M. Designing quality control system based on vision inspection in pharmaceutical product lines. In Proceedings of the 2018 International Conference on Computing, Mathematics and Engineering Technologies (iCoMET), Sukkur, Pakistan, 3–4 March 2018; pp. 1–4. [Google Scholar] [CrossRef]

- Arun, J.S.; George, J.; Jaya, J.; Janardhana, S.; Sabareesaan, K.J. Visual quality analysis of using computer aided inspection technique. In Proceedings of the 2013 International Conference on Current Trends in Engineering and Technology (ICCTET), Coimbatore, India, 3 July 2013; pp. 134–137. [Google Scholar] [CrossRef]

- Horputra, P.; Phrajonthong, R.; Kaewprapha, P. Deep Learning-Based Bottle Caps Inspection in Beverage Manufacturing and Packaging Process. In Proceedings of the 2021 9th International Electrical Engineering Congress (iEECON), Pattaya, Thailand, 10–12 March 2021; pp. 499–502. [Google Scholar] [CrossRef]

- Zhang, X.; Yan, L.; Yan, H. Defect detection of bottled liquor based on deep learning. In Proceedings of the CSAA/IET International Conference on Aircraft Utility Systems (AUS 2020), Online Conference, 18–21 September 2020; Volume 2020, pp. 1259–1264. [Google Scholar] [CrossRef]

- Koodtalang, W.; Sangsuwan, T.; Sukanna, S. Glass Bottle Bottom Inspection Based on Image Processing and Deep Learning. In Proceedings of the 2019 Research, Invention, and Innovation Congress (RI2C), Bangkok, Thailand, 11–13 December 2019; pp. 1–5. [Google Scholar] [CrossRef]

- Bahaghighat, M.; Abedini, F.; S’hoyan, M.; Molnar, A.-J. Vision Inspection of Bottle Caps in Drink Factories Using Convolutional Neural Networks. In Proceedings of the 2019 IEEE 15th International Conference on Intelligent Computer Communication and Processing (ICCP), Cluj-Napoca, Romania, 5–7 September 2019; pp. 381–385. [Google Scholar] [CrossRef]

- Wang, J.; Fu, P.; Gao, R.X. Machine vision intelligence for product defect inspection based on deep learning and Hough transform. J. Manuf. Syst. 2019, 51, 52–60. [Google Scholar] [CrossRef]

- Li, F.; Hang, Z.; Yu, G.; Wei, G.; Xinyu, C. The method for glass bottle defects detecting based on machine vision. In Proceedings of the 2017 29th Chinese Control Additionally, Decision Conference (CCDC), Chongqing, China, 28–30 May 2017; pp. 7618–7621. [Google Scholar] [CrossRef]

- Fu, L.; Zhang, S.; Gong, Y.; Huang, Q. Medicine Glass Bottle Defect Detection Based on Machine Vision. In Proceedings of the 2019 Chinese Control Additionally, Decision Conference (CCDC), Nanchang, China, 3–5 June 2019; pp. 5681–5685. [Google Scholar] [CrossRef]

- Kumchoo, W.; Chiracharit, W. Detection of loose cap and safety ring for pharmaceutical glass bottles. In Proceedings of the 2018 International ECTI Northern Section Conference on Electrical, Electronics, Computer and Telecommunications Engineering (ECTI-NCON), Chiang Rai, Thailand, 25–28 February 2018; pp. 125–130. [Google Scholar] [CrossRef]

- Xie, H.; Lu, F.; Ouyang, G.; Shang, X.; Zhao, Z. A rapid inspection method for encapsulating quality of PET bottles based on machine vision. In Proceedings of the 2017 3rd IEEE International Conference on Computer and Communications (ICCC), Chengdu, China, 13–16 December 2017; pp. 2025–2028. [Google Scholar] [CrossRef]

- Saad, N.M.; Rahman, N.N.S.A.; Abdullah, A.R.; Wahab, F.A. Shape defect detection for product quality inspection and monitoring system. In Proceedings of the 2017 4th International Conference on Electrical Engineering, Computer Science and Informatics (EECSI), Yogyakarta, Indonesia, 19–21 September 2017; pp. 1–6. [Google Scholar] [CrossRef]

| List of Defects | No. of Defected Bottles | Correct Detection | False Detection | Accuracy |

|---|---|---|---|---|

| Cap Defect | 30 | 30 | 0 | 100% |

| Dent Defect | 20 | 18 | 2 | 90% |

| Label Defect | 15 | 14 | 1 | 93% |

| Work | Product | Defect | Results % | Limitations |

|---|---|---|---|---|

| [11] | Glass bottle | Crack | 97.3% | For glass bottle, bottom surface only |

| [12] | Glass bottle | Crack | 96% | For glass bottle, mouth surface only |

| Missing edge | ||||

| Dirt | ||||

| [13] | Glass bottle | Loose Cap | 87% | For glass bottle, loose cap only |

| [14] | Plastic bottles | Loose Cap | 99% | For loose cap only |

| [15] | Plastic bottles | Shape of bottle | 100% | For bottle shape only |

| Proposed Work | Plastic bottles | Cap | 95% | Inspects the complete bottle for multiple defects |

| Dent | ||||

| Label |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kazmi, M.; Hafeez, B.; Khan, H.R.; Qazi, S.A. Machine-Vision-Based Plastic Bottle Inspection for Quality Assurance. Eng. Proc. 2022, 20, 9. https://doi.org/10.3390/engproc2022020009

Kazmi M, Hafeez B, Khan HR, Qazi SA. Machine-Vision-Based Plastic Bottle Inspection for Quality Assurance. Engineering Proceedings. 2022; 20(1):9. https://doi.org/10.3390/engproc2022020009

Chicago/Turabian StyleKazmi, Majida, Basra Hafeez, Hashim Raza Khan, and Saad Ahmed Qazi. 2022. "Machine-Vision-Based Plastic Bottle Inspection for Quality Assurance" Engineering Proceedings 20, no. 1: 9. https://doi.org/10.3390/engproc2022020009

APA StyleKazmi, M., Hafeez, B., Khan, H. R., & Qazi, S. A. (2022). Machine-Vision-Based Plastic Bottle Inspection for Quality Assurance. Engineering Proceedings, 20(1), 9. https://doi.org/10.3390/engproc2022020009