Design of Textile Antenna for Moisture Sensing †

Abstract

:1. Introduction

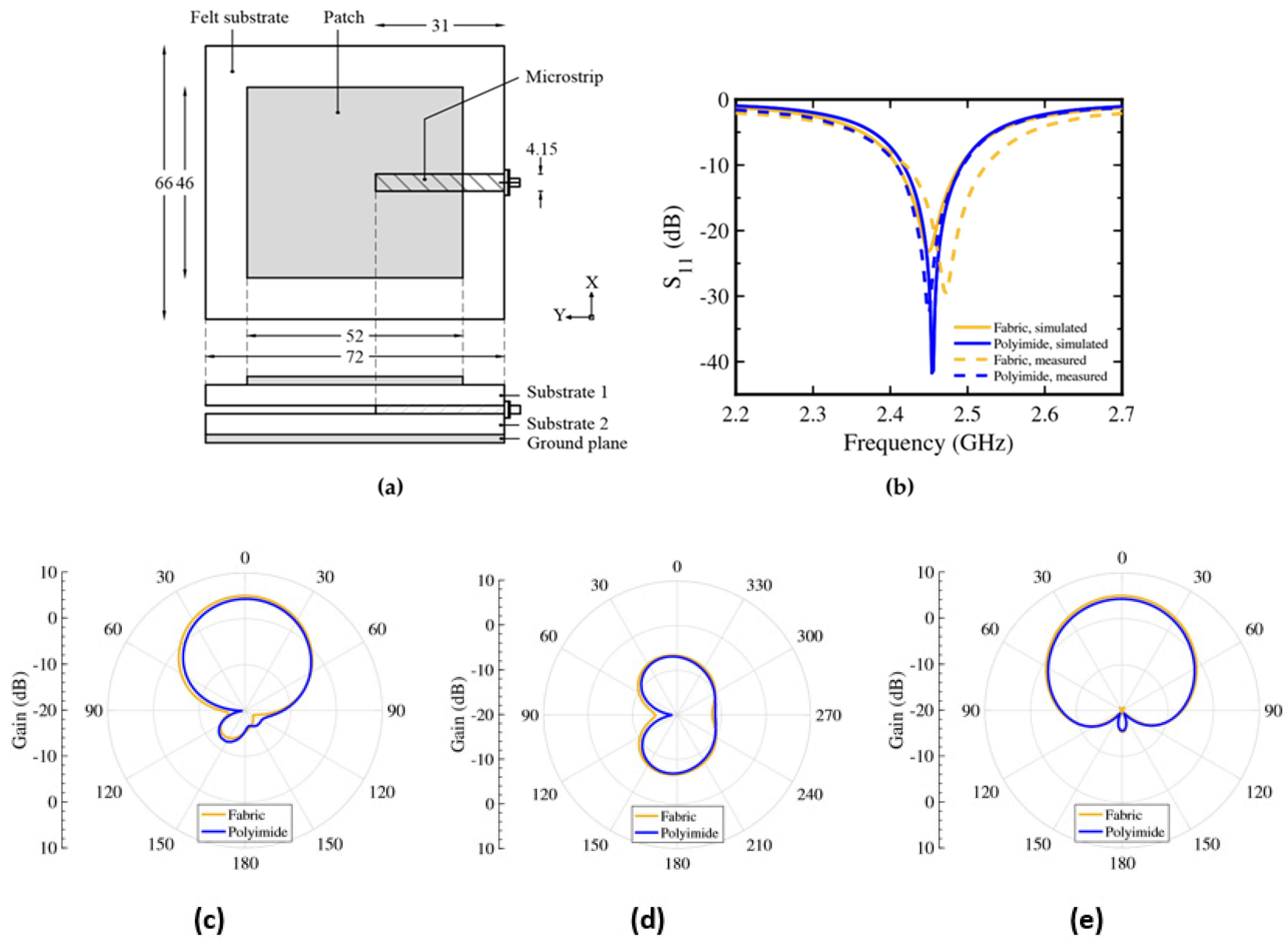

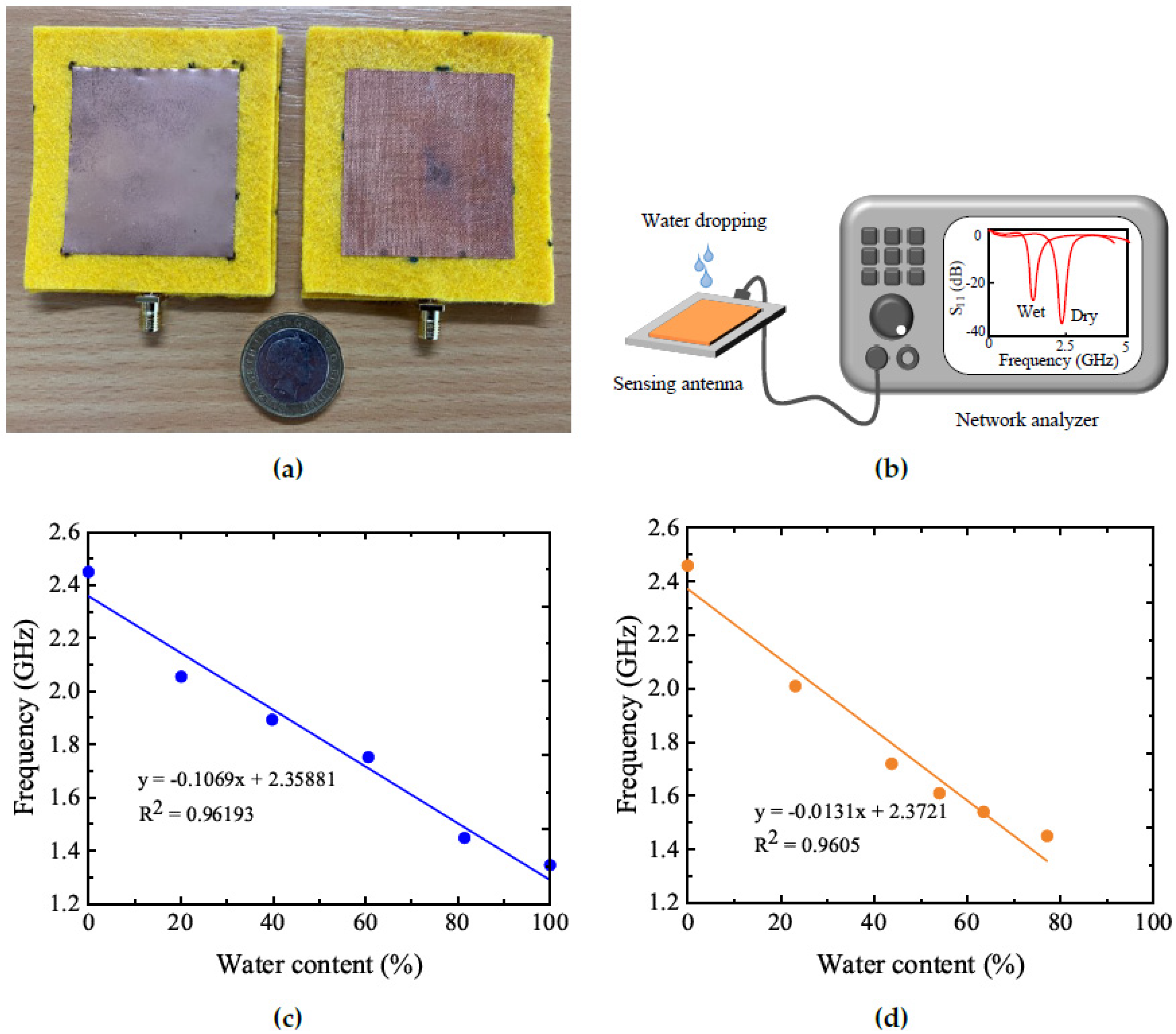

2. Antenna Design

3. Measurements and Results

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- El Gharbi, M.; Fernández-García, R.; Ahyoud, S.; Gil, I. A review of flexible wearable antenna sensors: design, fabrication methods, and applications. Materials 2020, 13, 3781. [Google Scholar] [CrossRef] [PubMed]

- Bonefačić, D.; Bartolic, J. Embroidered textile antennas: influence of moisture in communication and sensor applications. Sensors 2021, 21, 3988. [Google Scholar] [CrossRef] [PubMed]

- Bonefačić, D. Textile antenna as moisture sensor. In Proceedings of the 14th European Conference on Antennas and Propagation (EuCAP), Copenhagen, Denmark, 15–20 March 2020; pp. 1–3. [Google Scholar]

- CST. Microwave Suite 2017. Available online: https://www.cst.com (accessed on 22 November 2021).

- GTS. GTS 7800–Copper Polyimide Laminates. Available online: https://www.gtsflexible.com/ (accessed on 22 November 2021).

- Meftex. Meftex 30. Available online: https://www.meftex.cz (accessed on 22 November 2021).

- 3M. 3M Spray Mount. Available online: https://www.3m.co.uk/3M/en_GB/p/d/v000143885/ (accessed on 23 November 2021).

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ullah, I.; Wagih, M.; Beeby, S.P. Design of Textile Antenna for Moisture Sensing. Eng. Proc. 2022, 15, 11. https://doi.org/10.3390/engproc2022015011

Ullah I, Wagih M, Beeby SP. Design of Textile Antenna for Moisture Sensing. Engineering Proceedings. 2022; 15(1):11. https://doi.org/10.3390/engproc2022015011

Chicago/Turabian StyleUllah, Irfan, Mahmoud Wagih, and Steve P. Beeby. 2022. "Design of Textile Antenna for Moisture Sensing" Engineering Proceedings 15, no. 1: 11. https://doi.org/10.3390/engproc2022015011

APA StyleUllah, I., Wagih, M., & Beeby, S. P. (2022). Design of Textile Antenna for Moisture Sensing. Engineering Proceedings, 15(1), 11. https://doi.org/10.3390/engproc2022015011