An Effective Combination of PLC and Microcontrollers for Centralized Traffic Control and Monitoring System †

Abstract

:1. Introduction

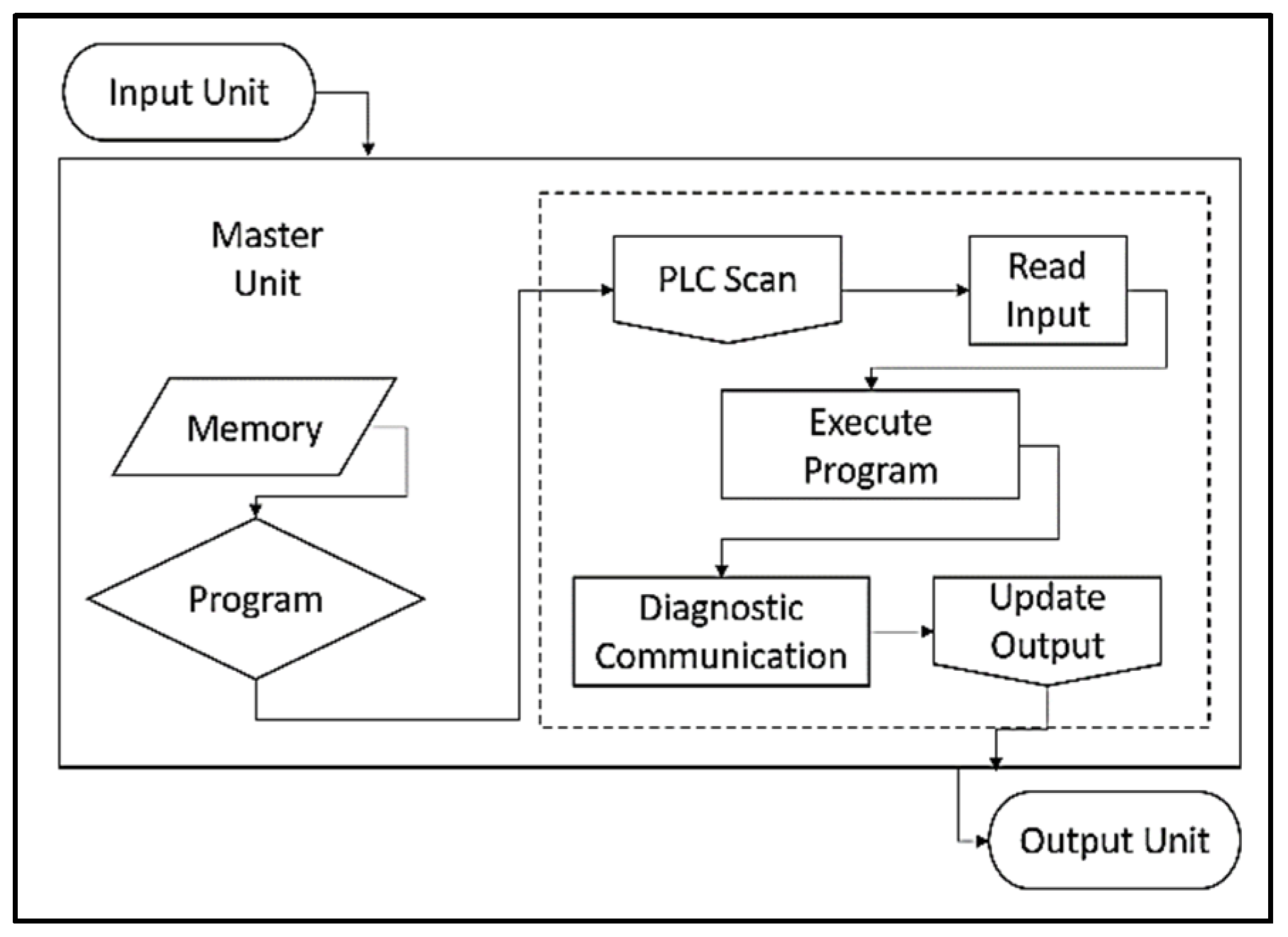

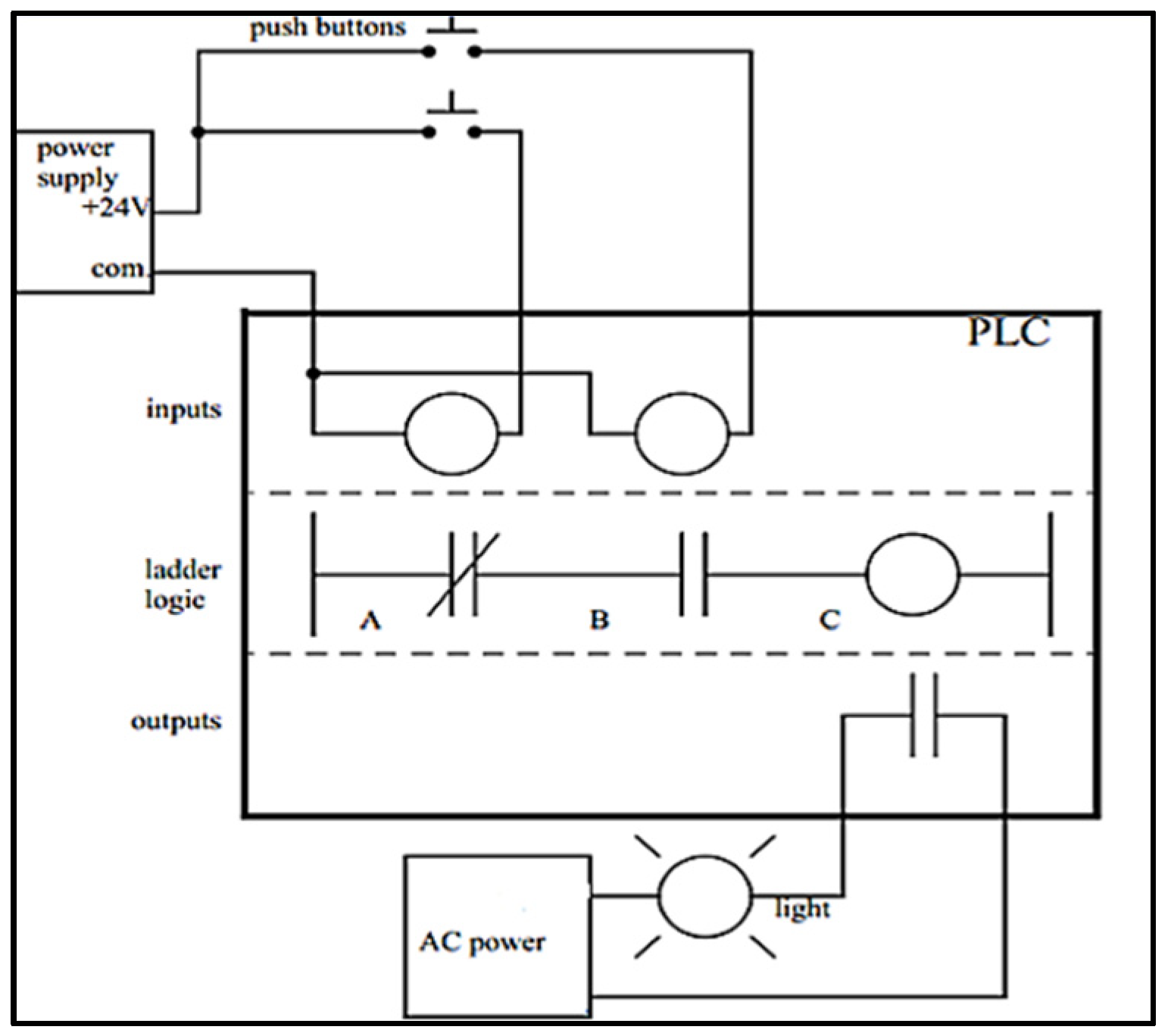

1.1. Internal Structure of PLC

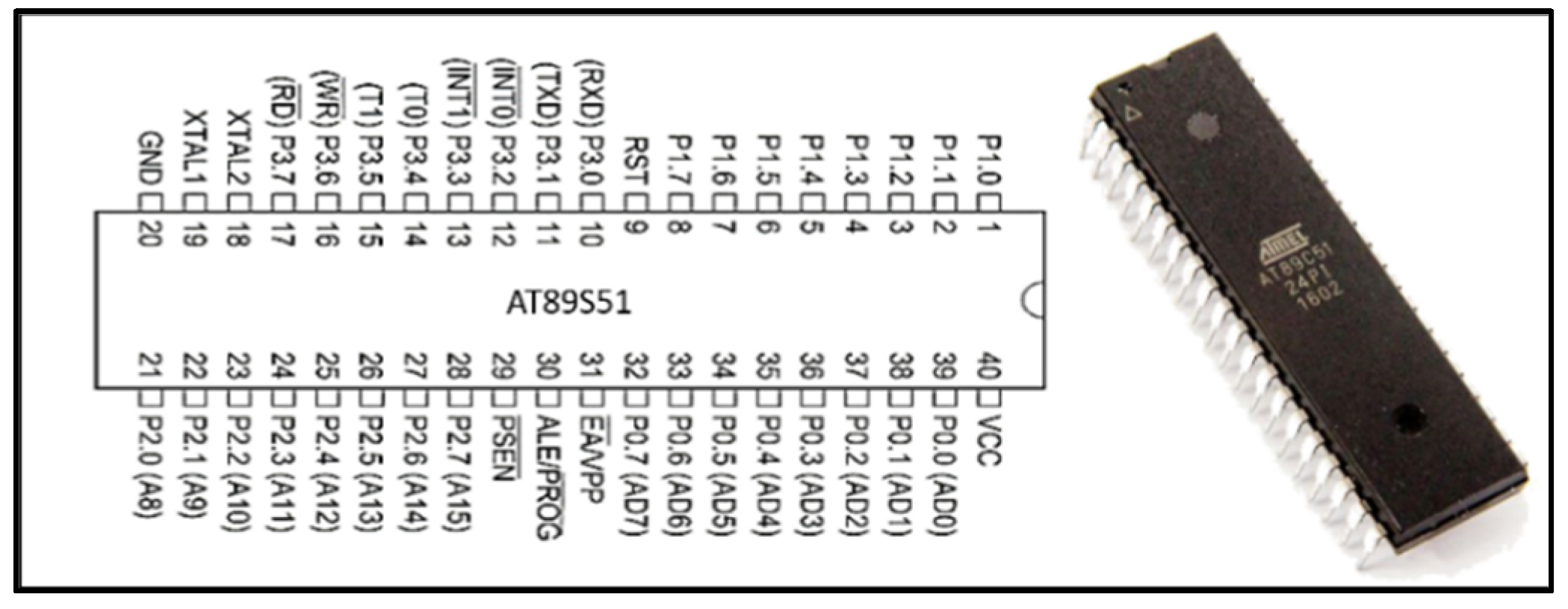

1.2. Internal Configuration of Microcontroller

2. Research Flow Diagram

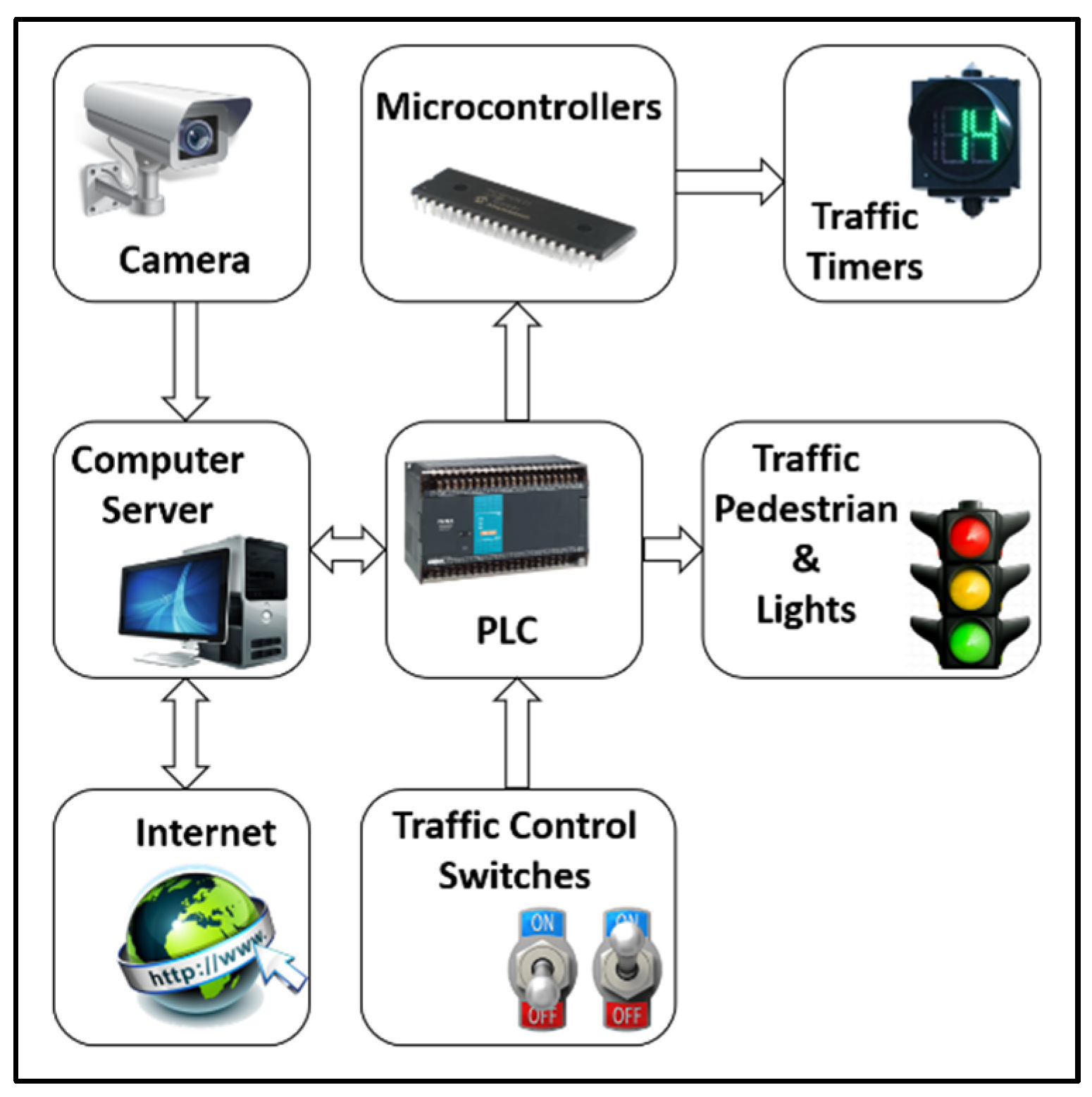

3. Methodology

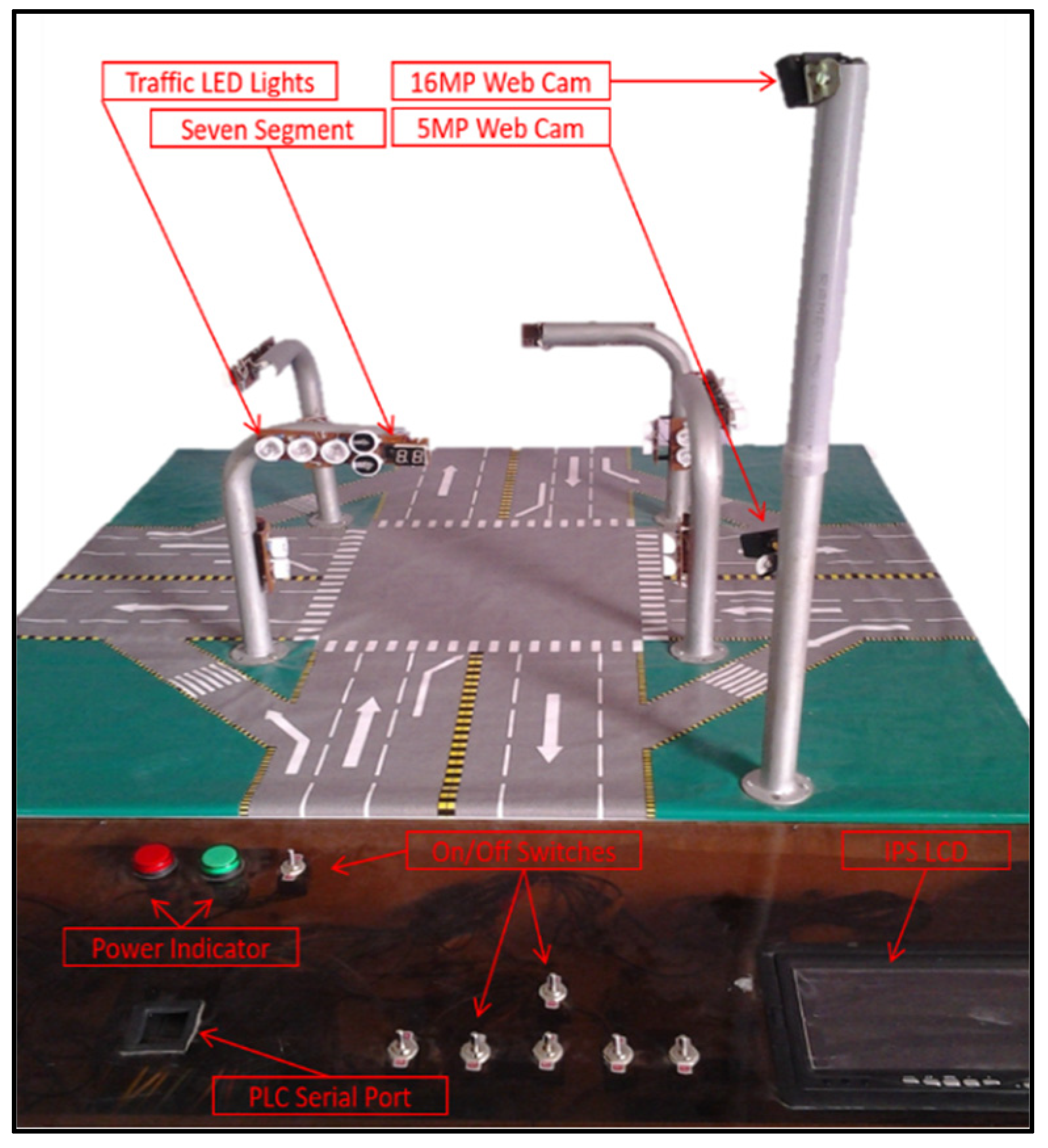

3.1. Implemented Model

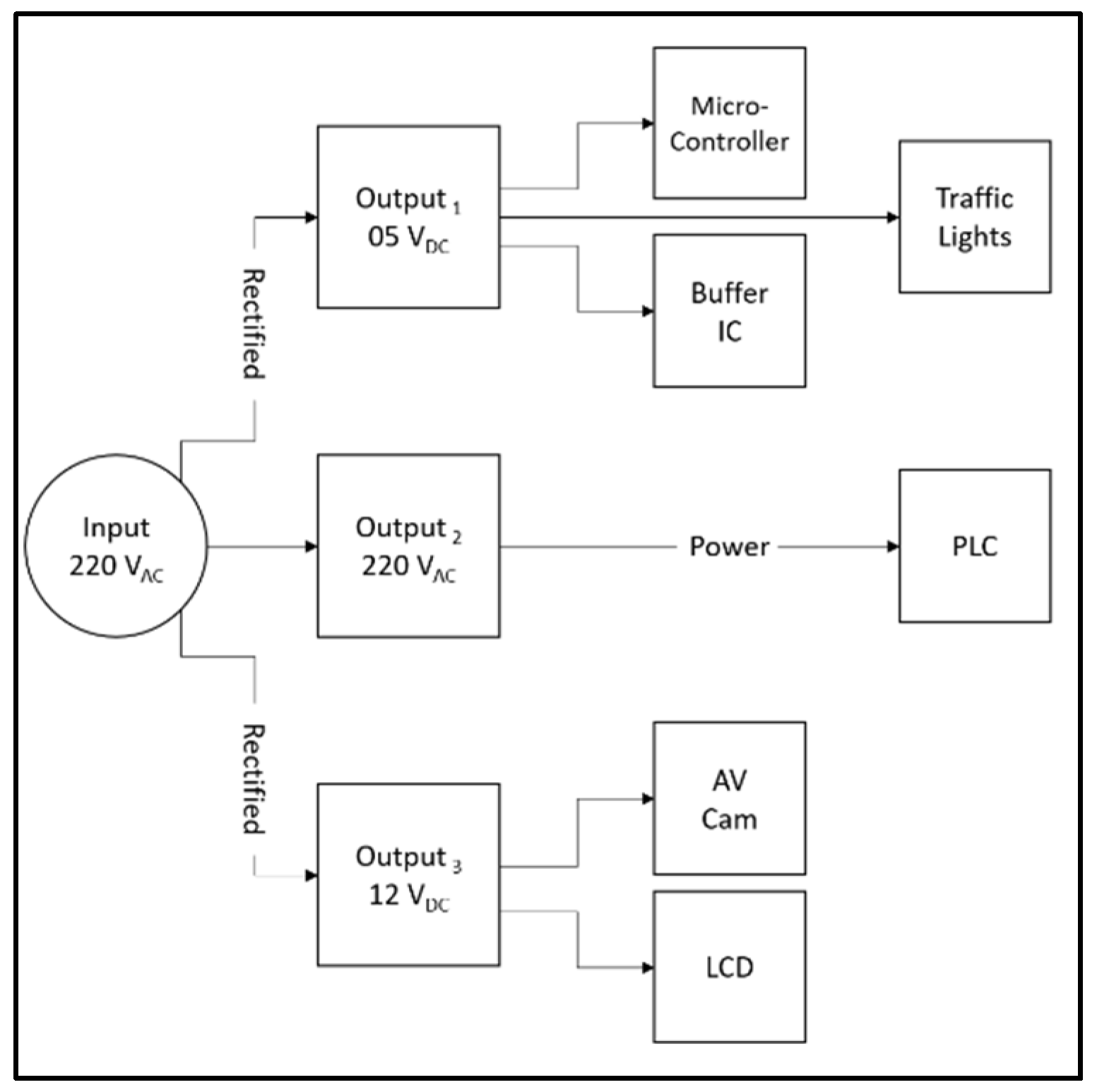

3.2. Power Division, Major Parts and Software

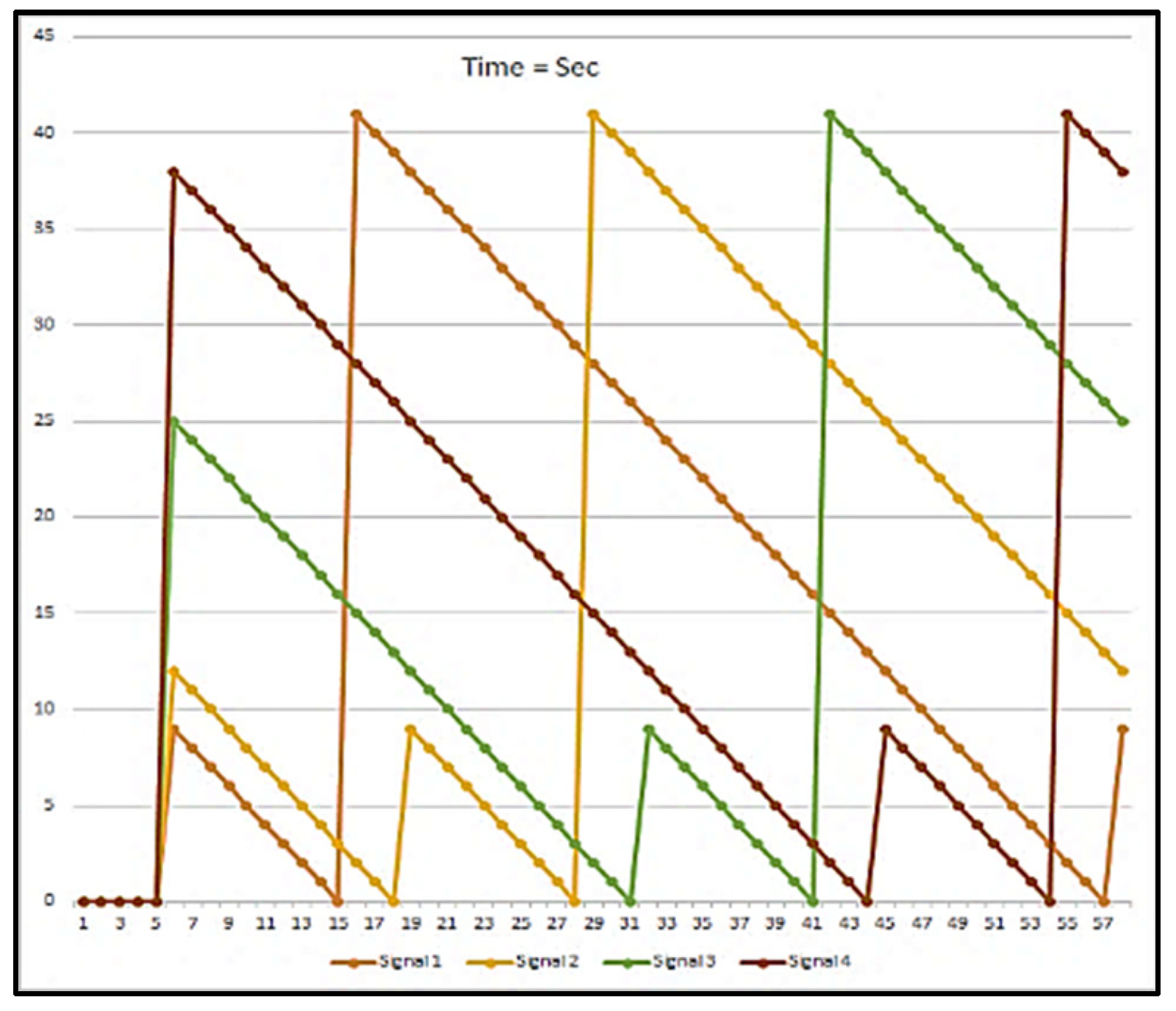

4. Results and Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Amir, S.; Kamal, M.S.; Khan, S.S.; Salam, K.M.A. PLC Based Traffic Control System with Emergency Vehicle Detection and Management. In Proceedings of the 2017 International Conference on Intelligent Computing, Instrumentation and Control Technologies ICICICT, Kannur, India, 6–7 July 2017; pp. 1467–1472. [Google Scholar] [CrossRef]

- Hanif, M.; Mohammad, N.; Harun, B. An Effective Combination of Microcontroller and PLC for Home Automation System. In Proceedings of the 2019 1st International Conference on Advances in Science, Engineering and Robotics Technology ICASERT, Dhaka, Bangladesh, 3–5 May 2019; pp. 1–6. [Google Scholar] [CrossRef]

- Technology Transfer. Available online: https://www.techtransfer.com/blog/programmable-logic-controller/ (accessed on 19 September 2021).

- Alzubaydy, A.I.J.; Aziz, A.B. Automatic Control of Electrical overhead Smart Trolley Crane AEOSTC Based Programmable Logic Controller (PLC). AJER 2017, 6, 54–62. Available online: http://www.ajer.org/papers/v6(12)/J06125462.pdf (accessed on 20 September 2021).

- Piyare, R.; Tazil, M. Bluetooth based home automation system using cell phone. In Proceedings of the 2011 IEEE 15th International Symposium on Consumer Electronics ISCE, Singapore, 13–16 June 2011; pp. 192–195. [Google Scholar] [CrossRef]

- Moser, K.; Harder, J.; Koo, S.G.M. Internet of things in home automation and energy efficient smart home technologies. In Proceedings of the 2014 IEEE International Conference on Systems, Man, and Cybernetics SMC, San Diego, CA, USA, 5–8 October 2014; pp. 1260–1265. [Google Scholar] [CrossRef]

- Ullah, I.; Ullah, F.; Ullah, Q.; Shin, S. Integrated Tracking and Accident Avoidance System for Mobile Robot. Int. J. Control Autom. Syst. 2013, 11, 1253–1265. [Google Scholar] [CrossRef]

- Ullah, I.; Ullah, F.; Ullah, Q. A sensor based robotic model for vehicle collision reduction. In Proceedings of the International Conference on Computer Networks and Information Technology, Abbottabad, Pakistan, 11–13 July 2011; pp. 251–255. [Google Scholar] [CrossRef]

- Ullah, I.; Ullah, Q.; Ullah, F.; Shin, S. Integrated collision avoidance and tracking system for mobile robot. In Proceedings of the 2012 International Conference of Robotics and Artificial Intelligence, Rawalpindi, Pakistan, 22–23 October 2012; pp. 68–74. [Google Scholar] [CrossRef]

| Major Parts | Minor Parts |

|---|---|

| PLC: FATEK FBs-40-MAR-AC, Master-Unit, Relay-Type, 40 I/O = 24 I/P-16 O/P, I/P Volts = 220 VAC, Built-in Power Supply Microcontroller: Atmel AT89S51 (40 Pins), ROM/RAM = 4 KB/128 bytes, I/P Pins = 32, Timer/Counter = 2(16 Bit), Interrupts = 6, Vcc = 5 V | Power Supply: I/P = 220 VAC, O/P = 5 & 12 VDC IPS LCD: 12 VDC AV Cameras: 5MP & 16MP Buffer IC: 74LS245-5VDC Clock Crystal: 12 MHz Capacitor: 10 µF Resistances: 120 Ω, 8.2 kΩ Power Indicator Light: 220 VAC Seven Segment: Common Cathode LED Lights: Red, Green & Yellow |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ahmed, B.; Shehzad, Q.; Ullah, I.; Zahoor, N.; Tayyab, H.M. An Effective Combination of PLC and Microcontrollers for Centralized Traffic Control and Monitoring System. Eng. Proc. 2021, 12, 71. https://doi.org/10.3390/engproc2021012071

Ahmed B, Shehzad Q, Ullah I, Zahoor N, Tayyab HM. An Effective Combination of PLC and Microcontrollers for Centralized Traffic Control and Monitoring System. Engineering Proceedings. 2021; 12(1):71. https://doi.org/10.3390/engproc2021012071

Chicago/Turabian StyleAhmed, Burhan, Qasim Shehzad, Irfan Ullah, Nabeel Zahoor, and Hafiz Muhammad Tayyab. 2021. "An Effective Combination of PLC and Microcontrollers for Centralized Traffic Control and Monitoring System" Engineering Proceedings 12, no. 1: 71. https://doi.org/10.3390/engproc2021012071

APA StyleAhmed, B., Shehzad, Q., Ullah, I., Zahoor, N., & Tayyab, H. M. (2021). An Effective Combination of PLC and Microcontrollers for Centralized Traffic Control and Monitoring System. Engineering Proceedings, 12(1), 71. https://doi.org/10.3390/engproc2021012071