Cellulose Blended Membranes for High-Salinity Water Pervaporation Desalination †

Abstract

:1. Introduction

2. Materials and Methods

Membrane Fabrication, Characterization, and Performance

3. Results and Discussion

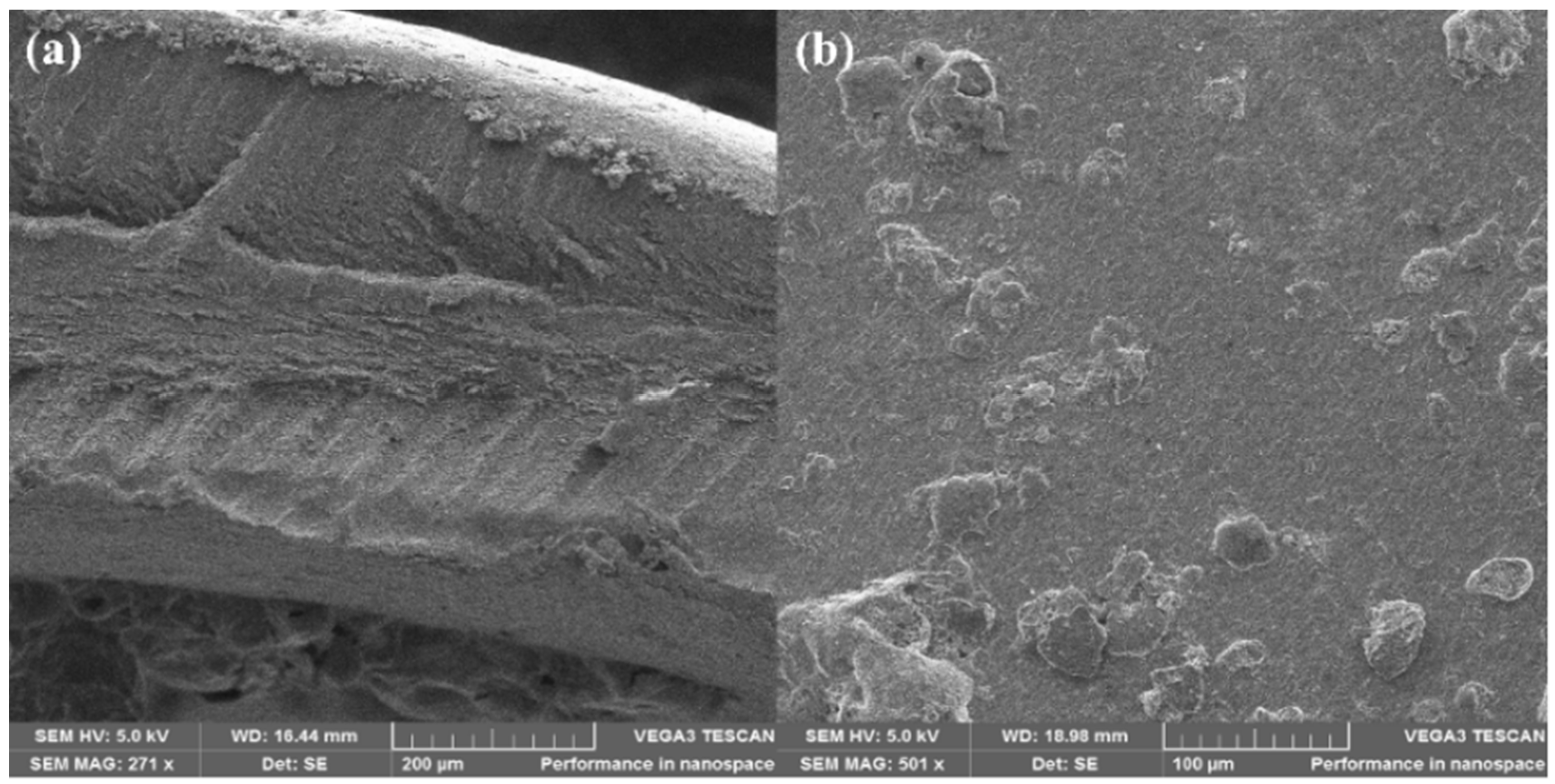

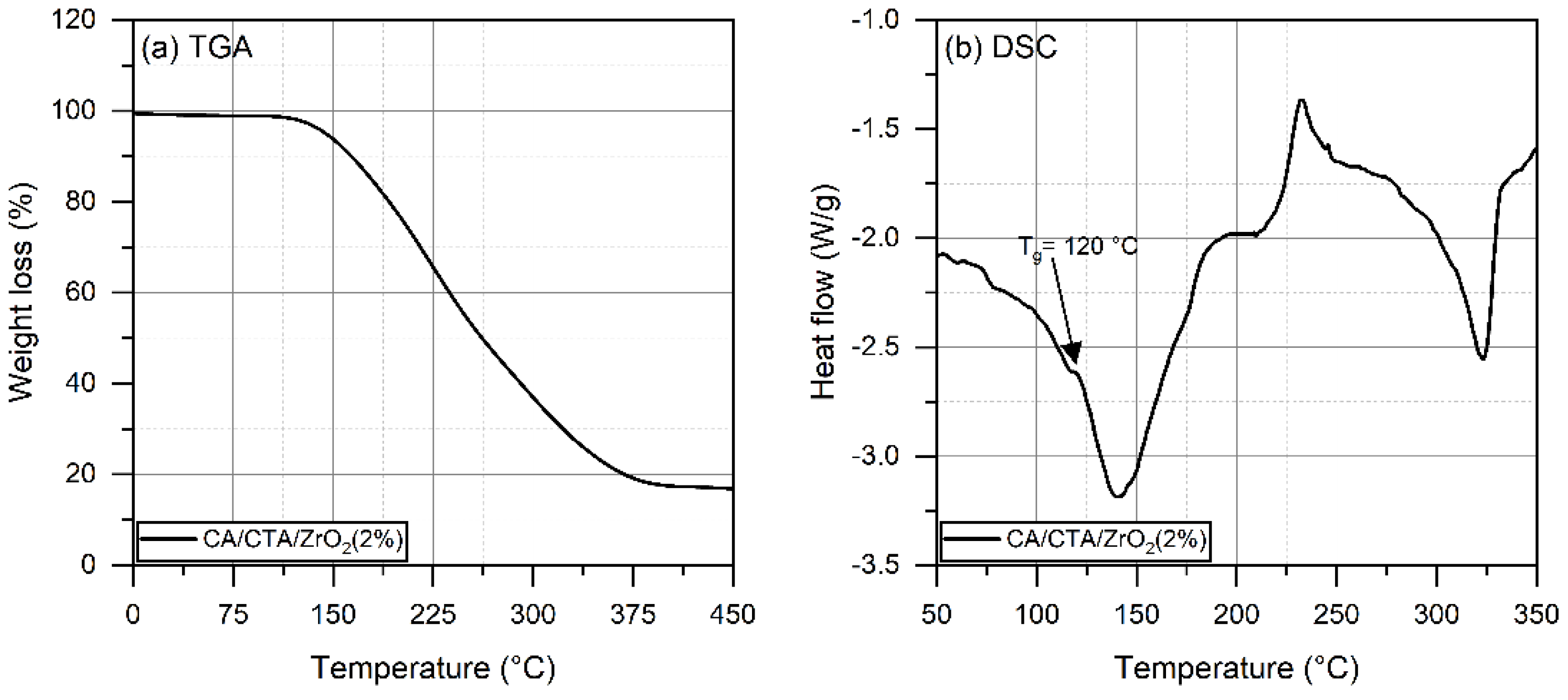

3.1. Membrane Characterization

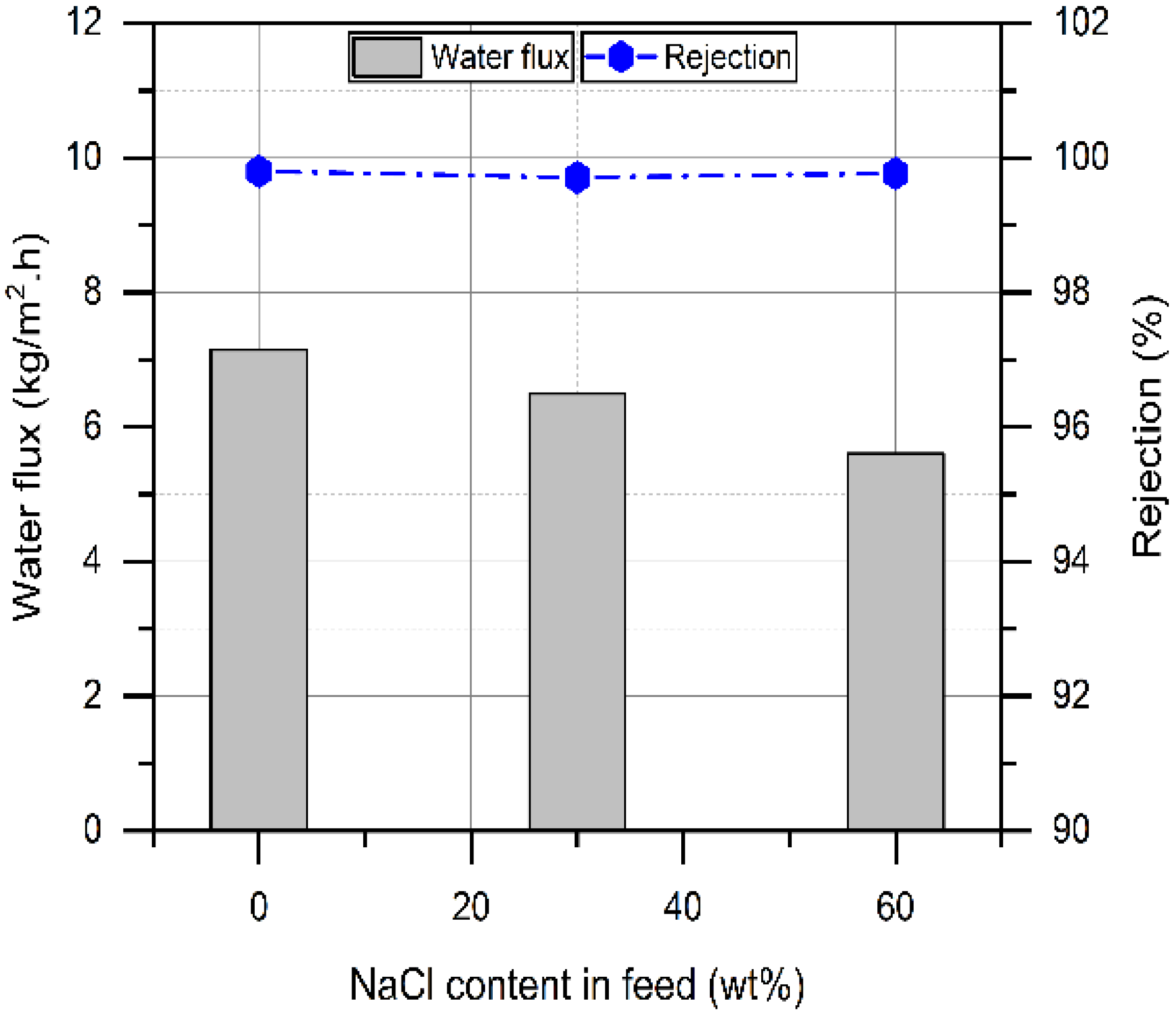

3.2. Pervaporation Performance

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Ahmed, F.E.; Khalil, A.; Hilal, N. Emerging desalination technologies: Current status, challenges and future trends. Desalination 2021, 517, 115183. [Google Scholar] [CrossRef]

- Dong, Y.D.; Zhang, H.; Zhong, G.J.; Yao, G.; Lai, B. Cellulose/carbon composites and their applications in water treatment—A review. Chem. Eng. J. 2021, 405, 126980. [Google Scholar] [CrossRef]

- Ahmed, D.; Isawi, H.; Badway, N.; Elbayaa, A.; Shawky, H. Highly porous cellulosic nanocomposite membranes with enhanced performance for forward osmosis desalination. Iran. Polym. J. 2021, 30, 423–444. [Google Scholar] [CrossRef]

- Teow, Y.H.; Mohammad, A.W. New generation nanomaterials for water desalination: A review. Desalination 2019, 451, 2–17. [Google Scholar] [CrossRef]

- Ali, M.; Zafar, M.; Jamil, T.; Butt, M.T.Z. Influence of glycol additives on the structure and performance of cellulose acetate/zinc oxide blend membranes. Desalination 2011, 270, 98–104. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fareed, J.; Zafar, M.; Saleem, M.; Malik, R.A.; Ali, M. Cellulose Blended Membranes for High-Salinity Water Pervaporation Desalination. Eng. Proc. 2021, 12, 57. https://doi.org/10.3390/engproc2021012057

Fareed J, Zafar M, Saleem M, Malik RA, Ali M. Cellulose Blended Membranes for High-Salinity Water Pervaporation Desalination. Engineering Proceedings. 2021; 12(1):57. https://doi.org/10.3390/engproc2021012057

Chicago/Turabian StyleFareed, Jawad, Muhammad Zafar, Mohsin Saleem, Rizwan Ahmed Malik, and Muddassir Ali. 2021. "Cellulose Blended Membranes for High-Salinity Water Pervaporation Desalination" Engineering Proceedings 12, no. 1: 57. https://doi.org/10.3390/engproc2021012057

APA StyleFareed, J., Zafar, M., Saleem, M., Malik, R. A., & Ali, M. (2021). Cellulose Blended Membranes for High-Salinity Water Pervaporation Desalination. Engineering Proceedings, 12(1), 57. https://doi.org/10.3390/engproc2021012057