An IOT-Enabled Generator for Power Monitoring and Load Management with Power Factor Improvement †

Abstract

1. Introduction

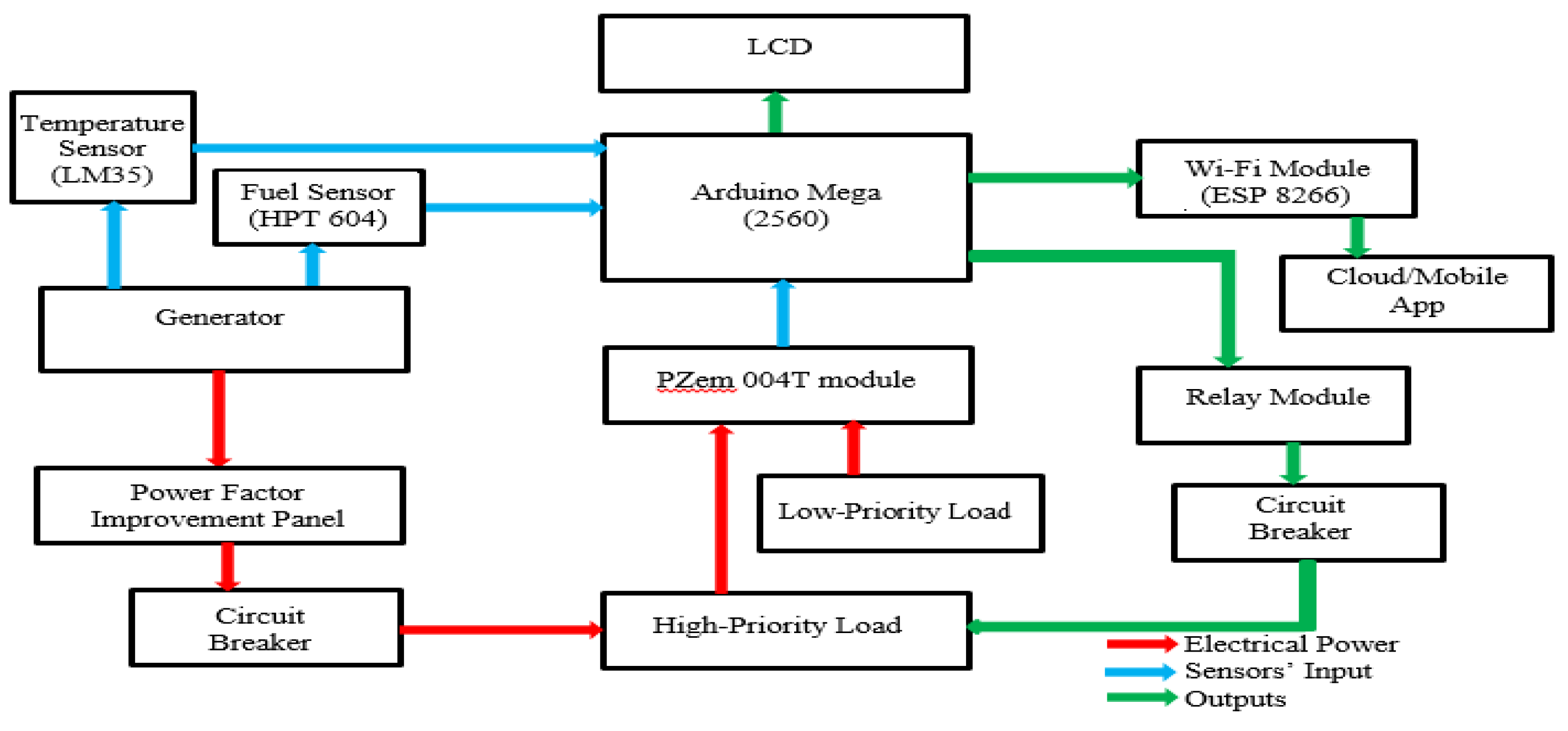

2. System Model and Description

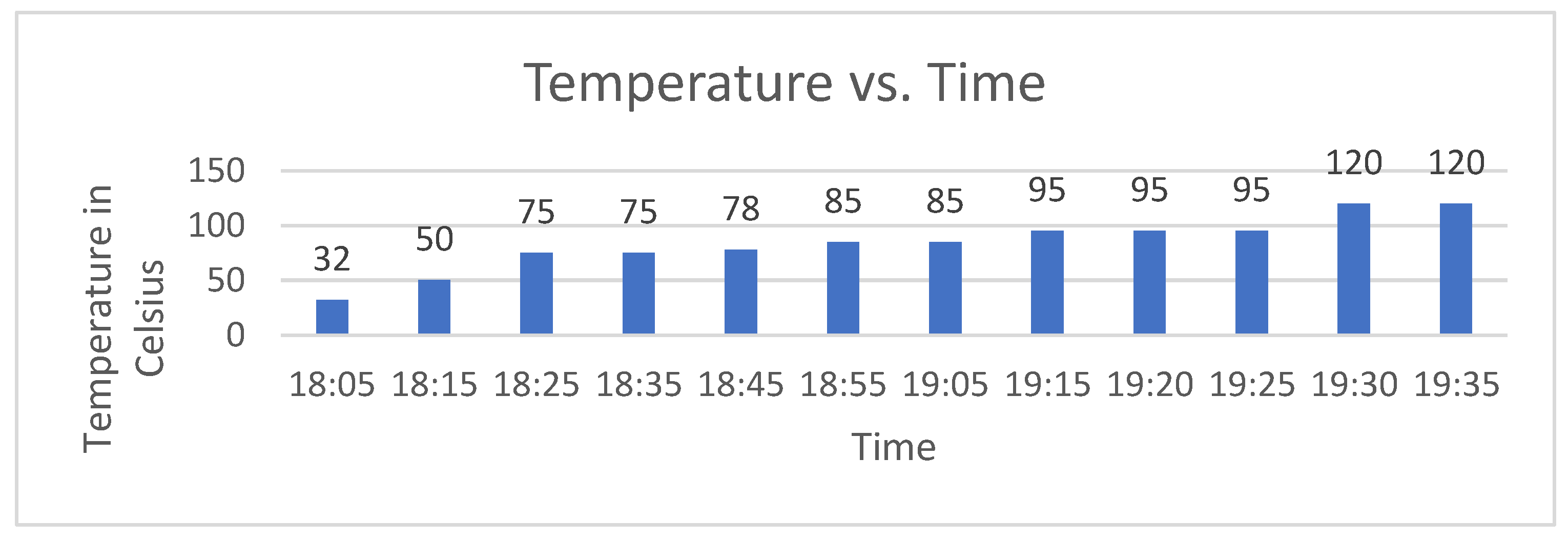

3. Results and Discussion

3.1. Thermal Analysis

3.2. Power Factor Analysis with and without Capacitive Bank

3.3. Analysis of Consumed Power in Terms of System Load

4. Conclusions

Author Contributions

Conflicts of Interest

References

- Khan, M.A.; Waqas, A.; Khand, Q.U.; Khan, S. Context Aware Fuel Monitoring System for Cellular Sites. Int. J. Adv. Comput. Sci. Appl. 2017, 8, 281–285. [Google Scholar]

- Obikoya, G.D. Design, construction, and implementation of remote fuellevel monitor system. EURASIP J. Wirel. Commun. Netw. 2014, 1, 76. [Google Scholar] [CrossRef]

- Khan, S.R.; Ferdousi, A.; Khan, S.R. Real Time Generator Fuel Level Measurement Meter Embedded with Ultrasound Sensor and Data Acquisition System. J. Autom. Control Eng. 2013, 1, 1–7. [Google Scholar] [CrossRef]

- Goundar, J.A.; Chand, A.A.; Tabua, N.; Prasad, R.; Chand, P.; Metha, U.; Mamun, K.A. Mechatronic design solution for fuel level monitoringusing pressure sensor. In Proceedings of the Asia-Pacific World Congress on Computer Science and Engineering, Nadi, Fiji, 4–5 November 2014. [Google Scholar]

- Ahmed, A.A.I.; Mohammed, S.A.E.; Satte, M.A.M.H. Fuel management system. In Proceedings of the 2017 International Conference on Communication, Control, Computing and Electronics Engineering (ICCCCEE), Khartoum, Sudan, 16–18 January 2017. [Google Scholar]

- Raja, P.S.; Geetha, B.G.; Raja, S. Detection of fuel theft in heavy vehicle. Int. J. Adv. Eng. Technol. 2016. E-ISSN 0976-3945. Available online: http://www.makeitortakeit.in/documents/147/9IOT_and_Arduino_based_Vechicle_and_fuel_Theft_Detection_System1 (accessed on 16 August 2020).

- Chandra, A.A.; Jannif, N.I.; Prakash, S.; Padiachy, V. Cloud Based Real-time Monitoring andControl of Diesel Generator using the IoT Technology. In Proceedings of the 2017 20th International Conference on Electrical Machines and Systems (ICEMS), Sydney, NSW, Australia, 11–14 August 2017. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Memon, G.S.; Jaffer, S.S.; Zaidi, S.; Sheikh, M.M.; Jabbar, M.U.; Ahad, A. An IOT-Enabled Generator for Power Monitoring and Load Management with Power Factor Improvement. Eng. Proc. 2021, 12, 33. https://doi.org/10.3390/engproc2021012033

Memon GS, Jaffer SS, Zaidi S, Sheikh MM, Jabbar MU, Ahad A. An IOT-Enabled Generator for Power Monitoring and Load Management with Power Factor Improvement. Engineering Proceedings. 2021; 12(1):33. https://doi.org/10.3390/engproc2021012033

Chicago/Turabian StyleMemon, Ghulam Shabir, Syed Saeed Jaffer, Shoaib Zaidi, Muhammad Mohsin Sheikh, Muhammad Umair Jabbar, and Abdul Ahad. 2021. "An IOT-Enabled Generator for Power Monitoring and Load Management with Power Factor Improvement" Engineering Proceedings 12, no. 1: 33. https://doi.org/10.3390/engproc2021012033

APA StyleMemon, G. S., Jaffer, S. S., Zaidi, S., Sheikh, M. M., Jabbar, M. U., & Ahad, A. (2021). An IOT-Enabled Generator for Power Monitoring and Load Management with Power Factor Improvement. Engineering Proceedings, 12(1), 33. https://doi.org/10.3390/engproc2021012033