Abstract

Shot peening is a widely used surface treatment method for improving fatigue life by inducing surface compressive residual stresses. In critical automotive components such as parabolic leaf springs, shot peening under pre-tension (stress shot peening) can further enhance durability. This study presents a finite element model simulating stress peening in high-strength spring steels, incorporating realistic boundary conditions, material degradation due to decarburization, and stochastic shot properties, offering a high-accuracy yet computationally efficient alternative to extensive experimental testing. Results show that both below- and above-yield pre-stressing produce beneficial residual stresses, while the consideration on decarburization effects significantly alters surface stress fields. The model offers a reliable, time-efficient alternative to experiments for process and fatigue life optimization.

1. Introduction

Shot peening (SP) is a mechanical surface treatment process aiming at extending the fatigue life of metallic components by introducing compressive residual stresses at and beneath the surface. This compressive field impedes the initiation and growth of surface cracks under cyclic loading [1,2]. Key SP process parameters include shot size and type, impact velocity, angle of incidence, and peening exposure time. While the SP process is widely used in various applications, such as aerospace industry [3] or welds [4], as well as on various materials [5], the present study focuses on the automotive sector for heavy truck applications, specifically, on a modified version of the conventional SP, the so-called stress shot peening (SSP).

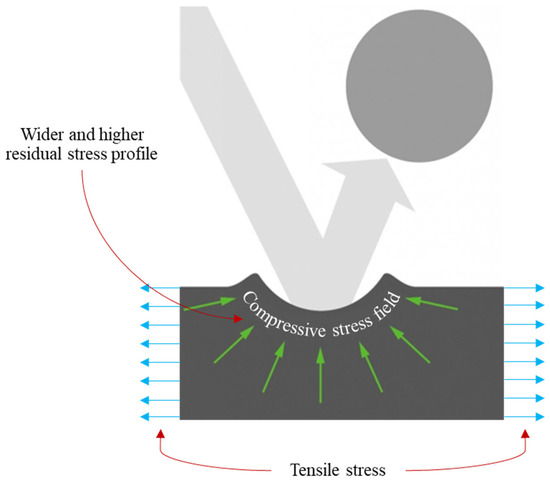

In SSP, these impacts are applied while the component is under pre-tension (illustrated with blue arrows in Figure 1), typically in bending. A visual description of the process is presented in Figure 1. This pre-stressed condition amplifies the depth and magnitude of induced compressive stresses, offering superior fatigue resistance—a vital advantage for applications in safety components, such as automotive leaf springs [6,7,8].

Figure 1.

Operational principle of stress shot peening.

2. Motivation

In the transition toward lightweight designs for vehicles, especially battery-powered trucks, ultralight leaf springs require optimized mechanical performance and resistance to stress relaxation. This is the main objective of the e-TRUCKS project [9].

Conventional SP simulation models typically rely on simplifying assumptions, such as uniform shot sizes [10], rigid shot behavior [11], and uniform material properties. While the existing literature has contributed significantly to the understanding of the process, developed models may have a limited accuracy on the calculated parameters. The implementation of stochastic parameters of the process is a more recent advancement in the existing literature [12,13].

This study addresses these shortcomings by implementing an enhanced, modular, finite element (FE) workflow, based on recent literature findings [14] capable of simulating the peening process including material surface degradation and pre-stress conditions.

3. FE Simulation Model

3.1. Description

Considering a leaf spring component as an example here, the FE model was developed to simulate a local region of a leaf spring subjected to SSP. This examined small region of interest’s dimensions are 5 mm width and 15 mm thickness, with a 2 × 2 mm peened area. The model is implemented using an explicit dynamic mechanical approach for impact simulations and a static step for pre-stressing, using ANSYS/LS-Dyna version 2021 R1 explicit and implicit solver [15], respectively, mainly focused on the accuracy.

3.2. Mesh and Boundary Conditions

Boundary conditions constrain the bottom and lateral surfaces in all space directions (X, Y, Z), alongside semi-infinite elements in specimen boundaries. A refined mesh with a length of 40 μm is applied towards the peened surface to accurately capture stress gradients and stress fields, transitioning smoothly to a coarser mesh outside this region for an optimal computational efficiency, resulting in a total of 67,000 hexahedral volume elements, for the corresponding thickness of 15 mm.

3.3. Application of Pre-Stress

A linearly distributed displacement is applied to the longitudinal (X) direction on boundary surfaces, to simulate bending-induced pre-tension, following the suggestion of Gakias et al. [14]. The pre-stress due to the applied bending is introduced prior to peening and is maintained during the SSP process. Pre-stress levels examined here include 20% and 50% of the material’s yield strength (1450 MPa), as well as a reference scenario exceeding yield stress of 1750 MPa.

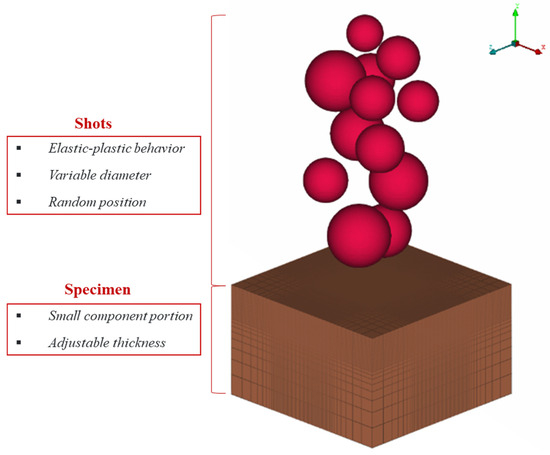

The details of the described model are visually presented in Figure 2 below.

Figure 2.

Key features of the SSP model.

4. Material Modeling

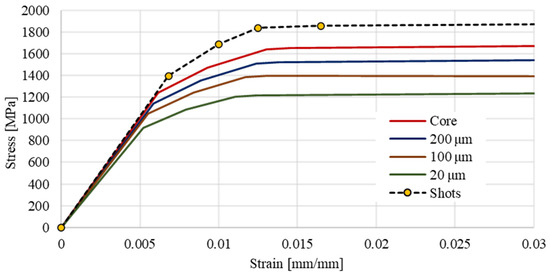

Surface Mechanical Properties

Compared to the core, the surface layers exhibit degraded mechanical properties due to decarburization caused by the applied heat treatment [16]. Nanoindentation was employed on real leaf springs made of 51CrV4 spring steel after their heat treatment and before any surface treatment process, to obtain accurate material stress–strain responses at various depths from surface [16], using the SSCUBONI algorithm [17]. Such σ-ε curves of various layers and the core are presented in Figure 3 below. These data enable the application of elastoplastic material models with depth-dependent properties.

Figure 3.

Fundamental material σ-ε curves for specimen surface and shots.

Shot material properties were also derived from cast steel nanoindentation curves and validated against the manufacturer’s and standard specifications [18,19]. Moreover, the model incorporates a mixed hardening law, combining isotropic and kinematic components. For improved mechanical behavior under dynamic loading, strain rate effects are considered via Cowper–Symonds parameters, with material data obtained from the study of Zabel et al. [20]. Temperature effects are not considered, since the SSP process under investigation here occurs at room temperature.

5. Case Study and Results

5.1. Experimental Setup

The experimental investigation of the influence of the pre-stress level included material samples of 51CrV4 of 15 mm of thickness, without any decarburized surface, using a 4-point bending rig to apply a proper bending pre-stress, similar to the leaf spring production process. While pre-stressed, the samples were peened under an impact angle of ~10°, with an average velocity of 75 m/s. After the process, the specimens were released from the rig. X-Ray Diffraction (XRD) was used to obtain residual stress profiles.

5.2. Shot Modeling

A dedicated tool (“sFEre”) [21] was developed to stochastically generate an FE mesh for shots, based on sieve analysis data for standard industrial shot mixes containing various sizes [22]. This allowed for simulation and reproduction of a realistic shot mix of S390 shot type as presented in Table 1 below. The impact velocity was set at 75 m/s with a 10° impact angle relative to the vertical (Y) axis, reproducing the experimental setup.

Table 1.

Sieve analysis data of brand-new S390 shots and modeled shots (cumulative percentage mass for each sieve level).

5.3. Residual Stress Profiles

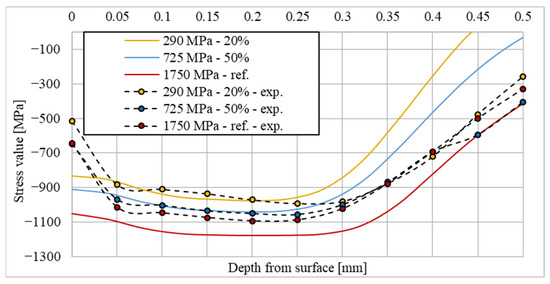

At first, simulation results have been compared with experimentally obtained data from stress shot-peened thin samples of 51CrV4. Here, simulations with three different pre-stress levels of 290 MPa, 725 MPa and 1750 MPa have been investigated. The results are summarized in Figure 4.

Figure 4.

Residual stress profiles for various pre-stress levels and comparison with experimental results.

Above-yield pre-stress of 1750 MPa results in a wider and deeper compressive residual stress field (green curve in Figure 4). However, even sub-yield pre-stressing (725 MPa and 290 MPa) produces sufficient compressive regions near the surface; see yellow and blue curves in Figure 4, closely aligning with corresponding experimental data (dashed lines with marker symbols in Figure 4). Overall, the agreement between experimental and simulation results, especially in the 0–0.3 mm depth range, is satisfactory. The deviations of the residual stress profiles for 1750 MPa amount to less than 100 MPa.

5.4. Decarburization Effects

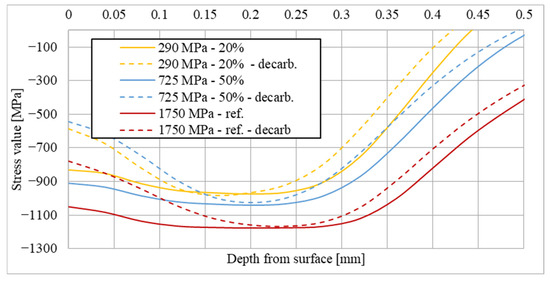

Considering the results shown in the previous subsection as satisfactory for a basic SSP model verification, though surely limited, the further step is to apply the SSP to real, decarburized components. This is relevant when moving from laboratory specimens to real, full-scale leaf springs. Figure 5 compares calculated residual stress profiles for stress shot-peened non-decarburized and decarburized surfaces of leaf spring samples made of 51CrV4. The stress–strain curves presented in Figure 3 account for the degraded material properties.

Figure 5.

Calculated residual stress profiles, assuming decarburized and non-decarburized surface.

The solid and dashed curves in Figure 5 represent the non-decarburized and decarburized condition, respectively. Different colors stand for the different pre-stresses. A notable reduction in residual stress close to the surface reveals the effect of decarburization. This is due to the lower strength properties of the decarburized, near-surface layers compared to the core.

6. Discussion

The developed FE-based SSP simulation model offers multiple benefits over existing approaches. It introduces realistic, stochastic shot distributions, material degradation, e.g., due to decarburization, and accurate boundary and pre-stress modeling, resulting in better alignment with experimental outcomes. The model can easily be adapted for different geometries, materials, and loading conditions.

One of the major result outcomes is the marginal difference between below-yield and above-yield stress peening in terms of compressive stress efficacy, suggesting that under specific design constraints, sub-yield pre-stressing may be sufficient. Moreover, the role of decarburization—often neglected—proves to be critical in stress field prediction and fatigue life modeling. Fatigue life estimation models might account for decarburization on surface layers, especially in the early failure-critical depth range.

7. Conclusions

An advanced 3D finite element model for SSP simulation was developed. Its major highlight includes the incorporation of real material surface properties, pre-stress conditions, and stochastic shot mixes. Though validated here by a quite narrow experimental database, the SSP simulation model predicts qualitatively and quantitatively the experimental residual stress profiles sufficiently. Undoubtfully, further experimental results are required to continue the model’s validation and verification process.

The findings demonstrate the following:

- Sufficient residual stress can be achieved even under sub-yield pre-stress levels.

- Decarburized surfaces significantly reduce near-surface residual stress magnitudes.

- The model correlates well with first experimental data, enabling predictive applications in lightweight design.

Therefore, the presented SSP approach may significantly reduce the experimental effort to develop optimal SSP (or SP) processes, especially for components made of high-strength materials with varying or degraded mechanical properties. It may limit the reliance on physical trials of the most promising SSP scenarios. Furthermore, it provides engineers with a robust tool to derive fatigue life-influencing parameters like residual stress and roughness profiles (though the latter are not further discussed here), that can be directly incorporated into the fatigue design of components, in very early stages of development, when prototypes are not available.

Author Contributions

Conceptualization, C.G. and S.D.; methodology, C.G., S.D. and V.S.; software, C.G.; validation, P.A., E.G. and S.D.; investigation, C.G. and S.D.; resources, G.S. and V.S.; writing—original draft preparation, C.G.; writing—review and editing, S.D. and G.S.; visualization, C.G.; supervision, G.S. and S.D.; project administration, G.S.; funding acquisition, G.S. and V.S. All authors have read and agreed to the published version of the manuscript.

Funding

Part of this research was funded by European Research Executive Agency (REA) with the project number 101156140 (Steels for ultralight asymmetric leaf springs for battery electric trucks with resistance to relaxation of residual stresses—e-TRUCKS).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The raw data supporting the conclusions of this article will be made available by the authors on request.

Acknowledgments

The Center for Interdisciplinary Research and Innovation (CIRI AUTH—ΚΕDΕΚ), and the DRAM Group are gratefully acknowledged. The authors would like to acknowledge the Research Fund Coal & Steel. BETA CAE is gratefully acknowledged for the provision of ANSA and META software.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Almer, J.D.; Cohen, J.B.; Moran, B. The Effects of Residual Macrostresses and Microstresses on Fatigue Crack Initiation. Mater. Sci. Eng. A 2000, 284, 268–279. [Google Scholar] [CrossRef]

- De los Rios, E.; Walley, A.; Milan, M.; Hammersley, G. Fatigue Crack Initiation and Propagation on Shot-Peened Surfaces in A316 Stainless Steel. Int. J. Fatigue 1995, 17, 493–499. [Google Scholar] [CrossRef]

- James, M.N.; Newby, M.; Hattingh, D.G.; Steuwer, A. Shot-Peening of Steam Turbine Blades: Residual Stresses and Their Modification by Fatigue Cycling. Procedia Eng. 2010, 2, 441–451. [Google Scholar] [CrossRef]

- Khajeian, A.; Mahmoudi, A.H.; Mehmanparast, A. Shot Peening Effects on Residual Stresses Redistribution of Offshore Wind Monopile Multi-Pass Weldments. Mar. Struct. 2019, 66, 106–120. [Google Scholar] [CrossRef]

- Jambor, M.; Trško, L.; Šulák, I.; Šiška, F.; Bagherifard, S.; Guagliano, M.; Florková, Z. Application of Shot Peening to Improve Fatigue Properties via Enhancement of Precipitation Response in High-Strength Al–Cu–Li Alloys. J. Mater. Res. Technol. 2024, 33, 9595–9602. [Google Scholar] [CrossRef]

- Mueller, E. Stress Peening—A Sophisticated Way of Normal Shot Peening. J. Mater. Sci. Eng. A 2019, 9, 56–63. [Google Scholar] [CrossRef]

- Klumpp, A.; Grau, C.; Rößler, R.; Dapprich, S.; Dietrich, S.; Schulze, V. Experimental Assessment of the Effects of Modified Stress Peening Treatments on Surface Layer States and Fatigue Behavior in Leaf Spring Steel 52CrV4Mo. In Proceedings of the 14th International Conference On Shot Peening, Milan, Italy, 4–9 September 2022; Curran Associates, Inc.: New York, NY, USA, 2022. [Google Scholar]

- Aggarwal, M.L. Modeling of Shot Peening Parameters for Weight Reduction of EN45A Spring Steel Leaf Springs. Conf. Model. Identif. Control 2012, 3, 642–645. [Google Scholar] [CrossRef]

- E-TRUCKS—Steels for Ultralight Asymmetric Leaf Springs for Battery Electric Trucks with Resistance to Relaxation of Residual Stresses, GA 101156140, Research Project, Funded by the Research Fund for Coal and Steel. 2024. Available online: https://www.e-trucks-project.eu (accessed on 7 August 2024).

- Ghasemi, A.; Hassani-Gangaraj, S.M.; Mahmoudi, A.H.; Farrahi, G.H.; Guagliano, M. Shot Peening Coverage Effect on Residual Stress Profile by FE Random Impact Analysis. Surf. Eng. 2016, 32, 861–870. [Google Scholar] [CrossRef]

- Mylonas, G.I.; Labeas, G. Numerical Modelling of Shot Peening Process and Corresponding Products: Residual Stress, Surface Roughness and Cold Work Prediction. Surf. Coat. Technol. 2011, 205, 4480–4494. [Google Scholar] [CrossRef]

- Gariépy, A.; Miao, H.Y.; Lévesque, M. Simulation of the Shot Peening Process with Variable Shot Diameters and Impacting Velocities. Adv. Eng. Softw. 2017, 114, 121–133. [Google Scholar] [CrossRef]

- Hu, D.; Gao, Y.; Meng, F.; Song, J.; Wang, Y.; Ren, M.; Wang, R. A Unifying Approach in Simulating the Shot Peening Process Using a 3D Random Representative Volume Finite Element Model. Chin. J. Aeronaut. 2017, 30, 1592–1602. [Google Scholar] [CrossRef]

- Gakias, C.; Maliaris, G.; Savaidis, G. An Investigation of Stress Shot Peening Using a 2D FEM-Based Simulation Approach. Int. J. Fatigue 2024, 181, 108130. [Google Scholar] [CrossRef]

- ANSYS/LS-DYNA Version 2021 R1. Available online: https://www.dynasupport.com/manuals/ls-dyna-manuals/ls-dyna_manual_volume_i_r13.pdf (accessed on 21 November 2024).

- Pappa, M.; Savaidis, G.; Michailidis, N. Stress-Shot-Peened Leaf Springs Material Analysis Through Nano- and Micro-Indentations. Materials 2021, 14, 4795. [Google Scholar] [CrossRef] [PubMed]

- Bouzakis, K.-D.; Michailidis, N.; Erkens, G. Thin Hard Coatings Stress–Strain Curve Determination through a FEM Supported Evaluation of Nanoindentation Test Results. Surf. Coat. Technol. 2001, 142–144, 102–109. [Google Scholar] [CrossRef]

- Kholee Blast. Available online: https://www.kholeeblastpaint.com/product/S330-Steel-Shots.html (accessed on 22 March 2024).

- SAE J827_201310; High-Carbon Cast-Steel Shot. SAE International: Warrendale, PA, USA, 2013. [CrossRef]

- Zabel, A.; Rödder, T.; Tiffe, M. Material Testing and Chip Formation Simulation for Different Heat Treated Workpieces of 51CrV4 Steel. Procedia CIRP 2017, 58, 181–186. [Google Scholar] [CrossRef]

- Gakias, C.; Lamprou, A. sFEre. Available online: https://github.com/lmemd/sFEre (accessed on 2 February 2024).

- Surface Enhancement Committee SAE International. SAE J444: Cast Shot and Grit Size Specifications for Cleaning and Peening; 400 Commonwealth Drive: Warrendale, PA, USA, 2023. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).